Professional Documents

Culture Documents

72 Thinline: Click Here To Go To TDPRI Where File Was Posted

72 Thinline: Click Here To Go To TDPRI Where File Was Posted

Uploaded by

Javier Martin0 ratings0% found this document useful (0 votes)

3 views6 pagesOriginal Title

Telecaster-Thinlines.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views6 pages72 Thinline: Click Here To Go To TDPRI Where File Was Posted

72 Thinline: Click Here To Go To TDPRI Where File Was Posted

Uploaded by

Javier MartinCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Click here to go to TDPRI

where file was posted

72 Thinline

the area around the f hole

on the inside of the cap is

routed to a thickness of 1/8

so that the edges of the cutout

arent the full thickness of the cap

the control route has solid walls

- no chamber in this area unless you design it otherwise.

for balance, weight here might be a good thing.

because of the way the jack hole hits the control route,

you may want to consider drilling the jack hole before routing.

with a 7/8 bit and a hand drill, its a potential wrist twister

when the bit hits the open area on one side.

with a drill press, it will put your clamping to the test.

it scaled showing .3 and .6 radii being used.

redrawn here to show that either 1.125 or 1.25

and .625 drill bits work just as well.

Classic Player Thinline

switch

wire channel

in back only

otherwise, its back access with cover

69 & 90s Thinline

69 button

90s button

binding

drawn as .08

the control hole in the cap is an approximation

pup wiring channels on body only - not top/cap.

when gluing on the top, having it face down will

keep excess glue from running down the sides

of the chambers and channels

Gone Fishing

if putting a switch here,

cut a channel

word has it that you can fish mini pots in after the cap in glued on and the body finished.

place pots and switch for looks or to fit your hands

chamber worksheet

You might also like

- AR 15 Lower Receiver Step by StepDocument81 pagesAR 15 Lower Receiver Step by StepNorm96% (27)

- 72 Custom - Deluxe Telecaster PlanDocument7 pages72 Custom - Deluxe Telecaster PlanPhilip Gregory Sougles50% (2)

- SLIM DVDrom JAE Conector Pin OutDocument11 pagesSLIM DVDrom JAE Conector Pin OutLuisa Antonia Valladares EyzaguirreNo ratings yet

- 4E845 Machining The AR 15 Lower Reciever Forging PDFDocument62 pages4E845 Machining The AR 15 Lower Reciever Forging PDFpalaciosro100% (2)

- PCB ChecklistDocument5 pagesPCB Checklistizzati_2607100% (1)

- 1911 Frame TutorialDocument22 pages1911 Frame Tutorialblackta6100% (6)

- Plastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1From EverandPlastic Injection Mold Design for Toolmakers - Volume I: Plastic Injection Mold Design for Toolmakers, #1Rating: 5 out of 5 stars5/5 (2)

- Vistabule 2014 Feb Brochure LRDocument10 pagesVistabule 2014 Feb Brochure LRAlexandre S. CorrêaNo ratings yet

- Fender Telecaster Thinlines PDFDocument6 pagesFender Telecaster Thinlines PDFFernando CasaseusNo ratings yet

- Flexible Voltage Regulator LayoutDocument9 pagesFlexible Voltage Regulator LayoutMahesh PhapaleNo ratings yet

- BHManual Fuselage46 79rev1Document34 pagesBHManual Fuselage46 79rev1viorelu99No ratings yet

- The Big Troubleshooting GuideDocument50 pagesThe Big Troubleshooting GuidePablo PerezNo ratings yet

- 3481 Quorn 02Document4 pages3481 Quorn 02Andy LNo ratings yet

- Quorn: Tool and Cutter GrinderDocument4 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- Exhaust and CombustionDocument1 pageExhaust and CombustionKhoinguyen NguyenNo ratings yet

- EngineStartButton PDFDocument6 pagesEngineStartButton PDFkiki ValleryNo ratings yet

- 3D Printed CETME/HK Bending Jig and MandrelDocument13 pages3D Printed CETME/HK Bending Jig and Mandrelrand0100% (1)

- 001 Tevo Tarantula Build First StepsDocument3 pages001 Tevo Tarantula Build First StepsAhmad Wildan IlhamiNo ratings yet

- Engine Start Button E46 MANUALDocument6 pagesEngine Start Button E46 MANUALBilly Georgiou100% (1)

- R1900 Clue Book Ver 2 PDFDocument32 pagesR1900 Clue Book Ver 2 PDFOldCotton Wear100% (1)

- Frosty T Burner Build: All The Ratios Are Derived From The Pipe IameterDocument4 pagesFrosty T Burner Build: All The Ratios Are Derived From The Pipe IameterKain402No ratings yet

- Toyota KZJ95 Coolant Temperature Gauge Modification - Forum IH8-1Document17 pagesToyota KZJ95 Coolant Temperature Gauge Modification - Forum IH8-1Mouhamed FofanaNo ratings yet

- AWCY? Apple PieDocument8 pagesAWCY? Apple PieCWONo ratings yet

- Quorn: Tool and Cutter GrinderDocument5 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- Answers For Apm 214 EssayDocument2 pagesAnswers For Apm 214 EssaymichealNo ratings yet

- Pinewood Derby TipsDocument15 pagesPinewood Derby TipsrjzepfelNo ratings yet

- Quorn: Tool and Cutter GrinderDocument5 pagesQuorn: Tool and Cutter GrinderDan HendersonNo ratings yet

- LANCNC Display Mount Plate Installation v5Document10 pagesLANCNC Display Mount Plate Installation v5Maquina EspecialNo ratings yet

- Stompbox WorkshopDocument18 pagesStompbox Workshopchris_holden249580% (10)

- Anthem: Tru - Mic TechnologyDocument5 pagesAnthem: Tru - Mic TechnologyMitsuo CovinosNo ratings yet

- A Grinding SpindleDocument4 pagesA Grinding Spindlewillows300No ratings yet

- A Arm Crossmember IsntalationDocument6 pagesA Arm Crossmember IsntalationgndaltoeNo ratings yet

- Filament Motion SensorsDocument8 pagesFilament Motion Sensorsksolomon75No ratings yet

- Homemade RF Step AttenuatorDocument8 pagesHomemade RF Step Attenuatorngt881No ratings yet

- Tranny Instructions Rev.-5!20!16Document7 pagesTranny Instructions Rev.-5!20!16Carlos OrtegaNo ratings yet

- Assembly Instructions For Strat and Tele Style PickupsDocument10 pagesAssembly Instructions For Strat and Tele Style PickupsLazyfingers61100% (2)

- Casio DM100 Sample ExpansionDocument17 pagesCasio DM100 Sample ExpansionSesan del futuroNo ratings yet

- Airguns and Airgun DIYDocument6 pagesAirguns and Airgun DIYgorlanNo ratings yet

- Ez Engine Build InstructionsDocument24 pagesEz Engine Build InstructionsAnonymous T7zEN6iLHNo ratings yet

- Lower Guide Drill JigDocument5 pagesLower Guide Drill Jigwiccanways100% (1)

- Buttress Run-Out - API ConnectionDocument2 pagesButtress Run-Out - API ConnectionEDWIN M.PNo ratings yet

- CW Hotline Assembly Manual v0.51-2 PDFDocument5 pagesCW Hotline Assembly Manual v0.51-2 PDFMattNo ratings yet

- Simple Choke Calculator TutorialDocument4 pagesSimple Choke Calculator TutorialAnonymous zuM28o8IyNNo ratings yet

- Ad 9850 ControllerDocument10 pagesAd 9850 ControllerMario Plinio CrivelliNo ratings yet

- TURN 992 GT3R GuideDocument18 pagesTURN 992 GT3R Guidemarqueslaurent64No ratings yet

- Pressure Vessel Dimension InspectionDocument12 pagesPressure Vessel Dimension Inspectionalokbdas100% (3)

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsFrom EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsRating: 5 out of 5 stars5/5 (1)

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3From EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3No ratings yet

- Family Handyman Ultimate Organizing SolutionsFrom EverandFamily Handyman Ultimate Organizing SolutionsRating: 5 out of 5 stars5/5 (2)

- Steam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversFrom EverandSteam Turbines A Book of Instruction for the Adjustment and Operation of the Principal Types of this Class of Prime MoversRating: 5 out of 5 stars5/5 (2)

- Metalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsFrom EverandMetalwork and Machining Hints and Tips for Home Machinists: 101 Plans and DrawingsNo ratings yet

- Manual 2016 Nitro g5Document2 pagesManual 2016 Nitro g5Alexandre S. CorrêaNo ratings yet

- F e A T U R e SDocument2 pagesF e A T U R e SAlexandre S. CorrêaNo ratings yet

- Modular CNC Router 2009v1 FREE PLANSDocument10 pagesModular CNC Router 2009v1 FREE PLANSModularCNC57% (7)

- The UltralightDocument20 pagesThe UltralightAlexandre S. Corrêa100% (2)

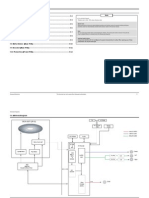

- Schematic Diagrams: Special NoteDocument12 pagesSchematic Diagrams: Special NoteAlexandre S. Corrêa100% (1)

- Schematic Diagram DVD-P370Document8 pagesSchematic Diagram DVD-P370Alexandre S. Corrêa0% (1)

- 74LVX32 Low Voltage Quad 2-Input OR Gate: General Description FeaturesDocument5 pages74LVX32 Low Voltage Quad 2-Input OR Gate: General Description FeaturesAlexandre S. CorrêaNo ratings yet

- XR-A550 XR-A330: Stereo CD Cassette Deck ReceiverDocument82 pagesXR-A550 XR-A330: Stereo CD Cassette Deck ReceiverAlexandre S. CorrêaNo ratings yet

- 74688Document4 pages74688Alexandre S. CorrêaNo ratings yet

- 74574Document6 pages74574Alexandre S. CorrêaNo ratings yet

- TL 074Document10 pagesTL 074Alexandre S. CorrêaNo ratings yet

- 74LVX157 Low Voltage Quad 2-Input Multiplexer: General Description FeaturesDocument6 pages74LVX157 Low Voltage Quad 2-Input Multiplexer: General Description FeaturesAlexandre S. CorrêaNo ratings yet

- TDA2002 10wDocument21 pagesTDA2002 10wAlexandre S. CorrêaNo ratings yet

- 74AC00 - 74ACT00 Quad 2-Input NAND Gate: General Description FeaturesDocument8 pages74AC00 - 74ACT00 Quad 2-Input NAND Gate: General Description FeaturesAini NierisNo ratings yet