Professional Documents

Culture Documents

ASI Simple Connection Capacity Tables PDF

ASI Simple Connection Capacity Tables PDF

Uploaded by

icehorizon880 ratings0% found this document useful (0 votes)

164 views37 pagesOriginal Title

ASI Simple Connection Capacity Tables.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

164 views37 pagesASI Simple Connection Capacity Tables PDF

ASI Simple Connection Capacity Tables PDF

Uploaded by

icehorizon88Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 37

aman gen mete contents

Sa eS a one

ust v2 Romeo

ieee Se Ect Sie

ern re nsenve Moet tor ao Suerte. a

‘Copyright© 2007 iy A ‘About the contributing author and editor vill 5.5 Configuration B—Sections

smucooe 1 * Sonn “

1 OEE OF CODES ast 6 AMOLECEA COMEETEN

ogre 1 OAM Samseteenty

pate oc AUEOAIA STEEL ETETE 1b See oate Le Reine an

hed by: AUSTRAL 1.3 Included connections 3 Double angle cleats a7

sr st aya eet mt pro a ay fn tat to em aa

Sumas Ins sao 2 cxouernoa eras . Searegace

vse emt om nace Mnon oti i itn se Serra i Serer “

Le BS sions 2 oa Sanit tate

ce er te i al at oon ae hte rer 2 Biosines ; Scere eae

ie Seon 5 Sets

thereon noses) i Gees 2

ee coeeeeete | 2 cm Bas ERE Ra age

ie snare once stern meee | oesoverss Seat

et | Sees a Design capacity tables +

‘orsty. ‘Ths pba orgie spr of Minimum design actons on. _Typla eating of conection —

cetera Repeats oe Soe a |

1. Stool, Strctual-Standards - Aust Fi eon 1978 Sees 22 6.7 Recommended design model—

2. Stoo. stuctural—Specieatons - Australia. Second etn 1581 enero Single ange coat

; Sei. saliche MEnSDER ATE COMIN ng STI Sacco

a Etat we se Sopa Sigg

‘Mr ypieal dealing of connection 26 Goniuration © Sing a

stolen St wan, | 143 Rooonmanded Design Mage — ea sg i

i rere | S Sewanee

Seige Stans ga Seincr St ae

‘Also inthis sores: 4S Configuration B-Single line ‘cleat double line of bolts to

A et cee Sree Sens 3) Soto o

rt en se Semeee Set "| sernencee :

Soe att ese Swe ceeee

Saocan terrace 5 mpamesrorurecomecon. 7 SM grcu Pat

Denign Gui 6 Seated connections 5.1 Descrintion of connection ar Commentionm 6

2 Seueuhedtmcan

sci Te wren sae nn tt a pny un

cro cate at ee hn Sn Se

reece sete te tn, Ta mee nats abe

Se spent ae a eae he

Bema ete tice amin cig ny sone ey

ics Sie ean ete i cae a

Sree Satis Bt a ry Sela Sao

SEN caste ener conan Steyn rcay nao

ona sete Sentai aa tmet as aaa Se

Seeins encsarstendebegoct stem es

econ ene pum angus tease

2 ee na

Seaimeiiaa

space ane men . ser sew pe "

¢ SOIR a etn ® ¢ 2S en *

LIST OF FIGURES

Page

Figure 1 Selected connections 3

Figure2 90% 8 010 at bar or late

‘component

Figure 3 180° 10 fat bar o pate

component 5

Fiqure4 200 or 150 10 al bar o pate

‘component

Figure § 100. 100 x8 EA ange

‘component 6

Figure 8 180 x 100. 10 UA angle

component. 6

Figure 7 Supporied member ena

proparatons 8

Figure 8. Single web cops ‘a

Figute 9. Double web cope 8

Figite 10 Hole al e-enant comer 8

Figure 11 Flange cope 15

Figure 12 Bol eesrance for fange cope... 15

Figure 13 Single wob coped (SivC)

Figure 14 Doutle wob copes (OW)

Seaton

Figure 15 Typical web side pate

connections 25

Figure 18 Single ine of tos to beam web

boamto-coumn or bear to beam

onnectons uncoped, single and

‘ube (oot shown) wob coped

Page

Figur 21 Typical fexble ond plate

connections ar

Figure 22. Uneaped and single web coped

boam fend pat located omards

top et boar 38

Figure 28, Uncoped and single web coped

bam (end pat oeatod owas

botom af beam) a

Figure 24 Double web coped team

{endplate dopth matches

‘erating depth of web). 28

Figure 25 Goometry configuration A—

sectone > 500 mm deo 40

Figure 26 Geometry configuration B—

member 500 mm deep 42

Figure 27 Typical single ans doutle ange

Cent connections “6

Figure 28 Altematve 'A—Single ine of

bots to beam web ar

Figure 29 ARematve Doub line of

bots ta beam wad ar

Figure 30 double ne of bos to

‘supporing member. ar

Figure 31 Geometry configuration A

Double angi cleat single ine

ef bots supported mambor 48

Figue 92 Geometry configuration B—

Dowslo angi leat double ine of

Dols to supperted member. ...54

oe, 26 Powe ateotva CSinfe tne

Fro 17 Dou na feo bea wt, voteioneam we 2

caer ieemovctn Fgue’ atematve D~Dodie ne ot

‘Shsclone tees rig st ey

Sho Sub we igure 36 Saline oe supstng

Se ea

fects fa Sense Sian

Figs 19 Cooney cotien 8S Ste ast aro 8t

Sora! 31 gue 37 Gaon cotatin D~

Fe 20 Grontecniaion Bote Seana deat eo

eee Sei epstes mamta 64

eng cpt sr sl 5

e me ete gen con oan g

ee

LIST OF TABLES

aoe ove

{ete cameron moans alyed..8 Tae 18 eb sate des aay

{tbe 2 Aaa ote af Cnponens. 8 wide

Tate vais 7 Sarena

Te ri nn eee

at 3¢ lines for welded section Table 19 Web side plate design capacity

flanges. 0 table—Configuration |

ett & Gee te wad econ ee a

see sora ie

Ta? Gaele opal ge Feet tp 38

some 11 Tato 20 ie ee aes coe

Tite 8 en npesBeam bam ieee ater:

can a as IE ORES

Seca “ Smoreiaen

taied Wevcoper Sounba Fe tr tp 88

hee deme Tete 21 eb pls ey coe

Sreadnanbee “ wae ema

Tale 10 Dae ange eps Seam at NS on

Se Pesce 6 Steenets enews

‘Table 11 Universal beams—Grade 300 ‘Member < 250 mm deep. 36

oot ct Tate22 ese np Sn pact

cote, » Ceectgenton xan

‘Table 12, Welded beams—Grade 300 > 500 mm deep a

pee eereorea a Tote 28 eno ent og opecty

eck a catenins toe”

Table 13. Parallel flange channels — > 350 mm but < 500 mm deep.....43

octet our Toto 2 Fete pt eo eapaciy

oedema apes 2 ceetaganee” heer

Table 14 Single web coped universal beams— » 250 men but < 350 mm deep.....44

de wooed tae 25 mtn eaten pel

Se cr Rh er Heaters

or 2 rene 4s

Tbe 18 Sou cope tel ange Ta6 28 Rg cl dog apecy

Se Ses Een (Ske Cenagratash

Teli Setpareact Pont Pee ete

Sacer s bots rpors men

Tat taDvute nb tne ever Konda elem a

Sa tan Tala. Ange ce! og eps

Somuaithasioee (ae Sores

Sete elt ot

‘abl 8 Deue wo cop sal ene

chamelsCrade 90 Dec bate supped me

‘section moment and shear “Member > 350 mm but < $00 mm

‘capacili 24 deep. St

‘able 18 ‘Web side plate design capacty Canoe

ue ate ei Caco

SM nen Ere on gle ot

Senden ee Sok sages nia”

Fer 20 deb 28 Nontr™ 2mm 380 mm 5

tae 17 wep nd cassty ane te et deg apa

peace fg a i

single line of bolls! mm eee an figuration A

samt Sais aos ce ene

Mae S90 eee

e eee i tc Pa

Page

: “Table 30. Angle oat desi capacty

Page

: sorcnneaance 12) het sin agcy

/ Sate Sanne gotnganet

es eae see Sa te

: es ae

: reas age ces aoe

| seer wee tegen

| Saber See somnconce

| rea et Sg geet

. Sense Te i wm etetenee

gl seep. ‘Member > 300 mm deep «2

| Table 22. Ange cleat design capacity Table 25, Angle cleat design capacily

| sce ee soengunee

. Sabet pore ae

. eee See tae Semen ae

oe Member > 250 mm but = 350 mm Member <300 mm deep 63

ee 00p | or

e soem meet ee

PREFACE

This now series of connection publications by the Australian institute of Stee! (AS!) covering

capacity tables, theory and design of incvigyal simple connections wil be known as. tt

Strucutl Steel Connections Seves, Part." ed. 2007 ("Connection Saree, Part 1). This

Connection Series, Pari detals the method ot design ‘and provides capacity tables and

‘etaing parameters for a range of simple connects commonly used fo sfctual steel in

‘Ausra. Connections have a major ongineerng and econome imporiance sec! svete

Influencing design, detaiing, fabrication ang erection costa. Standardestion of design approach

integrated with industry dealing isthe kay to minimum costs at each siage. Ths Connections

Series, Part 1 in conjunction withthe future Connection Series. Part 2 Yor raid connections

(collecively the Svuctural Stool Connections Serles ot “Connecdon Series) replaces. and

enhances an ASI fagship publcauon fst released in 1978 al which time connecion design

Iheories wore developed for tho purpose of generating and releasing connection capacty

‘ables, The fist thee eons were released in permissible sess lormat. The fourth tion

‘Design of Structural Connections (often rfered lo asthe Groen Book) was released in 1994 in

limit state formal but there was no subsequent reloase of alm state companion document

containing connection design capacity ables,

This now Connections Series, Par 1 in lit state format to the Australian Standard for Stee!

Structures AS 4100-1998 (Ret 1) separates Ihe Design Capacity Tables from the Connection

‘Theory Handbook 1 and Design Guides for connection paris and each Indvidval simple

connoction type. Connection model elemental Ieory i reterenced Back to Hanabook * in each

‘ype of connection formulated. Revision of the AS! connection theory and models ncliged

Surveys of best practice Is tne Australian steal nousty

‘The now Connections Series format with separate design guides for indvidual connection type

's intended to facitiate adcion to oF revision of connection mode theory using relevant new

local or inlemational research 2s deemed appropriate by the ASI” Connecton models

\oveloped using the Handbook 1 theory follow a svised page format with a numbered DESIGN

CCHECK procecure to simpy connecton capacay asvosement, This Connection Senos, Pat 4

also revises the ‘hd oalion of Baling af steel structures in Design Guide 1 now known 9

Botting in siructural steel connections. Anather important design guise (Design Guide 2) has

been specticaly developed called Welding In structural steel connections. Design Capacity

Tables V2: Simple Connections ~ Open Sections consolidates design capacity tables conained

inthe navival conection design guides (specially Design Guide 2: Web Side Pate, Design

{Guide 4; Flenble End Piao and Design Guse 5: Angle Cleat Comections) and le known asthe

‘Simple Connection design capacty tables V3 ("Simple Cannection DCTs ¥2).

Engineering Systems has worked closely wit the ASI 10 futher dvelop Limcan as the

companion program for this new Connection Series. The latest version of Limcon (V2.5) fly

Implements the new connection design madels and was eimployed in checking the design

lables. The Limoon autpu for one er more othe worked examples s included in an appendix to

‘each design guide for each connection design type. The program is an efficent tool covering

the ful range of structural connections, inewsing those beyond the scope of capacity bles

Provided in the Connection Seri,

[An appendix to each publication inthe sores also contains an ASI comment for, Users ofthis

Connerons Series are encouraged te photocopy this one page form and forward. any

Suggested improvements which may be incorporated int futuro eations,

Ts. Hogan

SA Muntor

e lnc at sees een

ABOUT THE AUTHOR

‘Tim Hogan ie Ditector of SCP Consulting Ply Lid. His. gcademic achievements include a

Bachelor of Engineering from the University of NSW with 1" Class Honours ana the University

Medal Post graduate qualfiationsinctude a Master of Enginering Scionce and a Master of

‘Businses Adminstration Tim fe a Member ofthe Inston of Enginoers Austaia with CPENg

‘ane Fle Aust slau

His early experience was on brisge design and construction with the NSW Public Works

Deparimant and subsequently as Development Engineer and then Engineering Manager wih

the Austakan Insiute of Stel Construction unt 1960. Consuling experience wih SCP

CConsuting since 1960 hae inchided design and supervision of large sleal framed buildings,

inaustral buildings. il ullaings, ral govelopments, defence inastucture and composts

loctconerete bullngs. Hie published works. ceal primarly with the. areas. of composite

onstruction, steal connections fabrication and erection of stl structures and he was 8 malor

Contributor and eer of the Commentary to. AS 4100. He is a member of a number of

Standards Australia Comvitiees deaing with stool and composite structures and e curenly

Chairman of Commies BO.001 Slee! Strctires and 80-052 Compaste Censmuction. He

fected an award fiom Slandarde Ausiraa Tor hs controutons to wriing of Austalian

Standards

ABOUT THE CONTRIBUTING AUTHOR AND EDITOR

Scott Munter is naw the National Stecura Dacking Manager for BlueScope Lysauht He was

foumery the National Manager--Engineering & Construction for the Ausralian Stel Instuta

IASI) and worked im this role from 2000 fo 2007. Th key role iwalved selling the technical

leaderenp of ASI in support of design and construction fo enable the efficient specticaton and

tse of steel in consttuton, Responsibililes induged ASI technical publications, advice on

Industry best practice, ASI and Code commilees,preseriaions and lecturing,

Scott is a Member ofthe Insiuton of Engineors Australia with CP Eng & NPER (Siructra)

Salus He holds 2. Bachelor of Structural Engineering fom the University of Technolony,

SSyciney with 1 Class Honoure and the University Meda. His professional careor includes 15

years in consulting civ and siuctural engineering working fer Tim Hogan at SCP Consuling

His conculting experince includes a sttong stl focus with majo inssuctre, industrial and

commercial sevelopments plus domestic eonsinvcton,

e SEES aT on em

|

ACKNOWLEDGEMENTS:

“The auore would tke to extend spacial hanks to

‘Tne ASI Connections steering commitioe consisting of Richard Goins (Engineering Systoms)

Anthony Ng {Onestoo! Marko Mils) and Arun Syam (Smorgon Stoel Tube Mile) for thor

‘respective conirauions with the development and roview of te technical and editrial content

‘ofthe revised ASI Connection Publication

‘Significant contributions wore made by:

‘+ Richard Colins—Enginesting Sysioms inthe development and upgrade of the Lincon

softwaro code in parallal wih tha design they asing In th eating ane validation of

revised models,

‘+ Standards Australia fr providing thle ochalaltypasating oxportse,

‘+ whzzcad Pty Led with drating ana araphes for publishing

+ ASI. Stale Enginooring_& Constucion special Sub-Committees for progressive

‘engineering and ingusty review of manuscrits

“Together wih support of

+All facets of the ASI memborship Including design engineers, stoolwork detallers and

{abricators in contbuting industry best practice and standards through ASI surveys and

‘rock consultation to establish the theory and geomelty In this new ASI Connection

Pubteavon

¢ scrote cetera,

Re

|

|

|

i

|

1 CONCEPT OF DESIGN GUIDES 1.1 Background

‘The ASI was formed in 2002 through the merger of Australian Insitute of Steel Construction

(AIS) ans Stee! nstute of Austra (SIA). The former AISC published a design manual giving

Seisance an the design of structural connactons in stel (Ref 2)

[ASI updating Reference 2 by way of tho Connection Saris including design guides, deaing

Aah Sobnectcn parts and individual contection types. The overall series of Connections

publications wl be known as tre Connections Sere,

‘The former AISC also published @ manual contaiing standardised dotaiing for simple

Coanectons, accompanied by load tables (Ref. 3).

Winorever possiale each design guide for individual connection types contains standardod

YenShing sha design capacity Tables for the connection type covered by that design gue

ferived using the design models in hat design guide

‘Tho Connection Series is a specialist serles devote tothe dosign of connections in structural

Tresie'sccondanes with curent Australian Standard AS4100 (Ref) reflecting the curen state

Sf fowioage st eannecton behaviour from fest resus In some nsiances, the test evidence Is

Sharse and in her Instances the evidence i contradictory ot clouded. Each design guide in

Fe aube Senos has bean writen by weighing he evidence Io provide recommended

Teige'mocedures baced in par on the design procedures used in equivalent publications

‘dor published papers.

Each design uide Is intended fo provide a design model which gives a reasonable estimate of

Eanction devgn capaci and efor has boon expended in researching and developing design

weogck: anien san bo jusified on the basis of tho avalale research and current desin

Tracie." to Be emphasised that forthe connections adel presecied, the design model Is

Pathe oni possible model. tt therefore not intonded to suggest that other models may

Rot result in adequate, connection capacty and furthor reference is made to the

‘Bigoloiner on pogo ofthis publication ae to the required investigation and verification

by a competent professional person of persons in regards tothe accuracy, sultablity and

‘polfeabity of the matenals provided inthis Connections Series.

The connoctions dealt wih are those presently in comwron usa in Austalia and reflec the types

“teonmentions covered within te eater AISC Standardized Structural Connoctons (Ret),

‘The Simple Connection OCT V2 ie intended as a replacement for Reference 3.1 contains no

Micrel on the derign model used fran individual connection leaving tha othe inévidual

(Helge Guige for that connection but contains extracts of the typical detals and

(yea erp (Areca

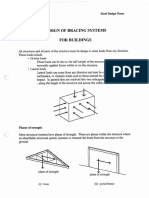

FIGURE 1 SELECTED CONNECTIONS

e oe ee ei eon &

2 GEOMETRICALDETAILS 24 Standard parameters

‘steel Grades

(@) Supported member

(©) Angle components

(1 Flatbar stip components

(8) Plate components

Botts

20 mm high sitength structural bots to AS 1252 (Rel. 10)

22 mm damier hoes

Wels

rage 300 to AS 3679 (Ret. 8)

Grade 300 0 AS 3679 (Ret 8)

Grade 300 0 AS 9679 (Ref. 2)

Grade 250 0 AS 9678 (Rel 9)

‘6mm or mm fet Wolds

E480 or WSOX welding locradies to the relevant Austvalan Standard (Refs 11, 12, 13,

”)

Hole geometry

Bott pitch 70 mm

Bo gouge thee 70 mm, 90 tom oF 140 mn as regu

‘other

Several cher gsometresl aspects such as cape sizes and edge sistancee have been

standardised. These are detailed in following sections, a

e see ee ae es

2 onourncaLverans 22. camatan compen

Set

cea

veal!

onnecnoncouonens ADOPTED

eo or

von = awe] Hele. | ae FIOURE 4 200 08 160» 10

waar ree] gee Es

ocean |e s ne

camer pawene| ee pe fe 8 «

es eee in

ween mars [eneeml s | @ LS fo Peat

r

| ADDITIONAL DETAILS OF COMPONENTS: FIGURE 5 100 x 100 x 8 EA ANGLE COMPONENT

| Type ‘Size Mass per metre, Yield stress: Tensile.

ah er” [ca

) maa] ea ale

cee ns amie

1 Piate 908 585. 8 200 490

| a Fy ° o en ~ fol

| So an Thine we i rte en eon FIGURE © 18010 1OUAANELE couPonET

(stp maybe cut and holed by the fabricato's normal methods

(i) stip may be pre-holed in long lengths ane subsequently cropped to individual component

Tenatns.

bere 2

++

++

FIGURE 2 90» 8ORIOFLATBAROR FIGURE 3 100. 10 FLAT BAR OR PLATE

PLATE COMPONENT ‘COMPONENT

|

|

|

. j

e song apace ar s | igs cpty tes oes

RD tio intoasin ® e sing totes ope ea,

es

Z

2 GEOMETRICAL DETAILS 29° Bolting layout

“The toe types of supported member (beam) end preparation are shown in Figure 7 All end

proparatons may have either single bal ie or 2 double bal kine

Boling layout eres the folowing parameters

(2) imonsion a = 100 mm from top of Beam to conte of fist hole: except that for beam

Spins less than 240)mm a= 70-mm is used,

{©} 209e distance from a coped web to a hole of 96 mm,

{e) end distance forthe bolts nthe Beam web of 35 mm, eo 9s fo perm

ting

(8) all bot holes are 22 mm ciameter for M20 bots;

methods of beam

{0} bot piten of 70 mm,

“The bot pic of 70mm, combined wih te a" enonsion of 100 mm, maximises the number of

folts mat can be secommosatod wa Beam web while sill alowing suffcient clearance to

fsnabie bot te be istallos

Using hese parameters, the maximum number of Bok rows (Mn) that ean be accommodated

‘ona beam web are gen in Table 304

() Universal beam sections:

{i Univeral column sections downto 200 UC:

(i) Hot ote channel sections down to 200 mm deep.

TABLE 3

VALUES OF ton,

18 = 100 except a= 70 where * shown eu: #35, p= 70 (Fp. 7)

Secon (UB) | tmwonbeam | Section (UG) | Aomon beam | Section

es web channe

ious 7 3100e 3 30 « 109

53008 . 25006 2 3000

608 5 2o0ue r 290-90

1008 4 200 75 »

‘80ue 3 200475 2

31008 3

2s0U8 2

200u0 ze

ry tesa cna tls fr sratara eta! Rg?

inp armecbane~epenscton. rst eon

nn Ce

os

ce Tee

| Hite | z 7

(2) Sgt En, Urepo

eps

ic

casaet [os

{Dost eb Cope Ene DWC

NOTE: Al beam ond preparations may havea singe ne a ots Hao th two ins shown abow,

e270 here noted Tale 3

FIGURE 7 SUPPORTED MEMBER END PREPARATIONS

e ES ees, ee

2 GEOMETRICAL OETAS 24 aug ines os

5

sor role scons he gauges of eles been Ine fH sel be on of he

el sins es Tage user tows tee Tes gee be taste ¢

Sei as ne es od dances been bla ane heb aint ne ,

cr gent me bute, Web guges ae selected to provde adequate clerance fowees

ce eee nt tng hin an stan ot a

vein atest tt nso paler ona a er posse arava oe rm

1 ee ae Pe be comin eS Comedie O27 3 a : =

Serene tte Sandu tense ds an too Wad ee

ca amos | wo | ao 0 | wo] a

cy oonean | wow) a toe] ae

tone ‘oo aed

owomae | we | a0 wo | oe

‘tomes oe falas

rane 4 oman | so wo | ato te | aw

GAUGE LINES FORUNIVERSAL owes ‘© we

SECTIONS sow wo 90 a

tages rene os oe

a cr ia aes ce

Tae stow ww | wo =

‘51008 4090 | 1407 90 | 140 90 70 | 140 BD 70. 400 20, 140 280

8 Re Ss 8 Ble 8B seave 2

“oe nc reese aaa a

ie Se]S [Ss Rsye & OTE At deine a

Ea B/S |S Ris] s Bs

Bar ® eee] s Bs

me ® pewls 8

Buz 5 Be [es

aa : Be [BS

eae {GAUGE LINES Fon WELDED sterion

wane

sous wow lw ole m w]e ~ w eee ee

ae oe S12 88S gs

+2000 saa 90 | 140 90 | 90 70 9 70 ‘Section wt

Be ar |e |” i

Pees Sop preps ‘oe ww fw om

nore | sts 8 fm

“*Gauge listed for 250U825.7 and 200U618.2 are for M16 bolts. soot 40 80 70 140, 90 0

Te ots it roa ok trove Bo fe

ee rane were tete whe gwar otsommermare. |i es

‘amen wen eked ce

‘sone ww on fw mow

stone wo om fw

| emme oe on fw on

| Sesser

emery i sr . eon

e SSeS s e oe tt in Re

am

cy

co

7 TABLE 7

Ts cnuceunesyon ara sunce

‘CHANNELS

Flange Fr Web sen

Section wwe wao was | wie zo aa

Paralielfange chonnets

rennin sss 58 [140 90 70 [140 00 70 |140 99 70

300% 20 5 58 [sao 90 7040 99 70 [140 80 70

250% 90 585d |140 90 70 [140 a 70 [140 90 70

230 75 44s b |x 90 70] a0 70 %@ 70

200% 75 4 4b | 9 70 90 70 0 70

a0 75 sb | 10 9 ~

$300 75 4 > | 65

Proteorce ttt fs 2 att 2 8

‘NOTES:

‘tnscates hat the fang wi ot accommodate his se of Blt

“inaeates hat the wob al not accommedale tx Ines o bos wih a gauge of SO mene mor,

[At densi are.

e design conc be or ssh al

2 GEOMETRICAL DETAILS

25 Webcoping

“Tho connections in this Simpla Connections DCTs, V2 are detalad trom the top flange of the

‘boa withthe dimension '@ botwoen the tp of he steel beam and the cena of he fst hole in

the connection contaling the locaton of al hales. Dimension "a" hat been slandarcied at

{00 mm, wich allows sulsent cearance fo all beam-o-beam connections except where the

supported member depths fas than 240 mm for which a = 70 mm has been asopte,

|A standard method of co9ing beams in beam-to beam connections has bean adoptee. This ls

necessary sine the cope dela allects the design eapacty of some connections, and may ao

intence the esional and restraint provided bythe connection,

‘Te layouls of beam-o-beam connectons involving web copes are shown in Figura & for single

vwob copes (SWC) and in Figure 9 for double wab copes (OWC) Standard length of web copas

(engin = dimension ‘c) in beam-to-Deam connections for universal sections are given fn Tabes

Sand

“The dimension c's contd bythe Nange width of he suppoting member (member A), ant

nova varios botweon 80 and 160.mm (nerements of 19'mm have been adopted). For

fxample, 3 25008 supported membor (member 8) cannecion to 2 460UB (member A) roauires

4 SWCTOO web copo—the dimension ¢ = 100 provides clearance forthe coped 2500 from the

flange of tne 45008 which hae 8 ango width of 181 mm,

In aston o adopting the dimension a th edge cisiance fom the ist hole ofthe web hating

paltern fo the edge ofthe cope has been standarclsed at 36 mm to allow nand fame cuting ot

the cope (Figures 8 ana’),

‘Web copes have always presented a dificult and cosly ftriaton stage an have tadtonally

‘been hand flame cal. In ths Simple Comoctions OCTs, V3 ils recommended that the 19-

‘entrant comer ofthe cope tobe radused (as =) and ina:

510 mm minimum

‘Tho lecaniques of beam fabricaton curently avalable offer the possibilty of diling oF punching

‘hole atthe r-enrant commer ef the cope during the normal holing of beam webs. The cope is

than ebtaned by cutting Ta this hole (igure 10), Since 22 mm clametar hale for M20 bots

would normally te punched or died inthe beam web, a 22 mm diameter hola can ready be

Dunchod of dled a tha e-entant corner athe same tie, giving

= 11 mm waich exceeds the above minimum,

{tating ths cope hole, iti dosrabo thatthe cenresine ofthe hole so dled ie ouside the

root aus line ofthe Beam (Figure 10)—thus fe 11)>

‘An's’ mension of 100 mm will accommodate his roqutement, and thus allow ding of th

fertrant corner cope hole, for al UB and channel sections. and. all UC seclons except

Stouczes.

Punching ofthe cope hole requis sighly more clearance from the insite face of the beam

flange, depending upon the equipment used. This cope hole should generally be able 10 be

punchad on 6T0UBI01 sections and smaller, on 310UCS7 rections and smaller and on all hot

rolls channel sections,

Fr double web coped beams, the seme minimum dimensional requirements have be

‘adopted. Using he angth ofthe vemaining web az a multiple of tho Bolt ph, the dimensions at

the botlom cope ae suicient to always enable the same dling and punching arangements 3

forthe tp cope.

landard web copes assume that tops of beam Manges are level, Where this isnot the cate,

special consiceaton wil have tebe given to dealing ofthe conection,

Since all bong layouts assume thatthe top of beam Manges are lvel, the determination of

owen any boaree-beam connection wil be the value in Table 3 for mombor 'R (upperting

rretrbet) when Dy = Ds. However, when D,> Dy, the value of gu wil be that 9 Table 3 fot

rmember'B' supported member)

@ oe seats toa eae Be

tase 8

a

= WEB COPES_BEAN-TO.8EAM CONNECTIONS

|=} ““Universat seerions as surronteD

EMBERS

supp e - a se

mma | cs sau [con Fave

1 ue eas | om

| i : i= eco) ncn [ncn fone ref owe fone

| i rept ‘20ue [ancizo) ewer faweree nce] swome

Ke even} veoh —

% H ’ * TTE: We seinen ow een Raa oan GE TRUE T5006 way Fo NG

— ny

i petoart

|

t

i

FIOURE 9 DOUBLE WEB COPE

TABLE 9

WEB COPES—BEAM-TO-BEAM CONNECTIONS

; CHANNELS AS SUPPORTED MEMBERS

i a

as100 ic :

it fc =

a .

FIOURE 10. HOLE AT RE-ENTRANT CORNER.

e ei casas rc al. Be" @ eosin copay ain rst to V3 Ru

2 GEOMETRICAL DETALS 26. Flange coping

“The most commen typeof lange cope Is shown n Figure 11. A suitable designation is:

orc,

anere ‘! and ara the dimensions shown in Figure 11, and DFC stands for double ange

cope.

Standard double flange copes requied for beam-column connections involving universal

sections are given in Table 10,

Detailing Note:

‘Were member ‘A’ is ether a 250UB or 250UC or smaller and lage bolts protrude within the

Potts one member (see Figure 12) care must be taken lo ensure suficient clearance fs

Preven! fo allow erection and lightening of flange connection bots

7 toa

FIGURE 11 FLANGE COPE DFC.

mses

Pe} “pian

FIGURE 12 BOLT CLEARANCE FOR FLANGE COPE

¢ Sra z

TABLE 10

DOUBLE FLANGE COPES—BEAM TO COLUMN WES FOR UNIVERSAL SECTIONS

ct

as

GME | wee | wo | ame | seve | save | some

a =

oS [8S | = | ae

mem Pa eT ee

450U8 - - - bre =

= | atoue - - - ore.

= s so-so | -

[ome [= | = T= [es [= | -

@ | sus - - = - - ~

i zoe | — — =

ove |= [Se [Se [RS | ae | aS

zouc | — = - |e] - =

"NOTE: — alco fange oo 5 requod

2 DESIGN BASIS 34 Design models

For the three connections incuded in this Smale Connections OCTs, V3 (web sido pla.

fietbte ond ise, angle lea) tho fllowing snlarmation has been extracted from the relevant

design guide foe ncusion

+ description of conection

+ typical detaing of connection

“+ recommended design model-—-summary of checks

+ dosign capacity tables for selected coniguiations

“The bass for scecing the recommends design models are dtaled in Sections 2.3 and 2.4 of

Te dscr "fet 7) A detalee exolnation ofeach recarmonded design models contained in

ths relovant Design Guide (Rels. 4.5, ).

For each connection, the Summary of Checks willindeate:

«which dosign checks have ben considered in preparing the design capacity tables

which design checks must be done after selecting the required connection deat trom

Tholdesign capac tables. These checks primariy relate fo checking focal ffcts onthe

supporting member

‘The design capac lables are presented 90 thal, knowing the supported member size and

ouign eacion Fb the connection, the tequfed connection compenents, bolt mers and

seid sos ae simpy ood rom the reievant ible forthe selected configuration

This Publication meets the requkements of AS 4100 by providing a rational ané recognised

{eign adel for 2 range of common ste! connections, the dasign model in each Design Guido

se conisocring erties and known connection Behaviour fom experimental data. The

cers erin Pusivaton Is on practical design models whose assumplions are transparent

Tree EER ine model in gach Design Guido is elated to current Codes of Standards Australia

Ie Mogae of member and fastener design, and member and fastener mechanical properies,

‘which are prosentod in Handbook 1 (Ret 7)

‘The philosophy of the Publcalion Is the same as that espoused in Reference 7, being o

fellows

1i) _ take ino account overall connection behaslour, cary out an appropriate analysis inorder

to determine a eaistie dstbulon of forces within the connection;

(i) nsure that each component oF fastener In each action path has sul

leaner the apotied action:

(a) recognise that ths procacure can only give a connection where equilbrum is capabe of

ting achieved but where compatiity 1 unlikely fo be satisfied, and Therefore ensure

that the conection slamonis ore capable of dute behaviour.

“The design models contained wihin thie publication are considered to be applicable ory to

Teinecttans umes are essentially satealy Hoades. Connections subject to dynamic Toads,

SSrnquane oads o fatigue appeatans may require addlional considerations

ent capaciy 10

« sete See ean a”

13 DESIGN BASIS 32. Minimum design ations on

|AS 4100 Clause 9.14 provides th

the groatr of

(2). the design action inthe member and

(@) the minimum design action effects exprasse eltner as the value or tha factor times the

Imomber design capacty for tie minimum size of member requite by the siren Hrit

Site, speci in tere (to () bolowe

(0 onwcione i fold comcton—a banding manent of 0.8 tres te mentar

connections shall be designed atthe strength iit stato for

(i) Connections to beams in simple consircton—a shear force of 40.N or

(0.15 * member design shear capaci, whichever fe the lessor.

(i) Connections atthe ends of tnsion or compression members—a force of 0.3 times

the momer design capacty. except tat forthe threaded rod acing as a bracing

‘momber wih turnbuckos, the minimum tencon forco shall Be aqua o tha mambor

Sesion capaci

() Spices in morbors sje! to all tensions free of 2 tes the aber

design capacity in tension. ™

(0) Splicos in mombors subject o alal comprassion—for ends prepared for fl contact

In accordance wth Caves 14-4.6.2 of AS 4100, t shall ba permissible to carry

Compressive actions by bearing on contact surfaces. When members ae prepared

{or tl contact to boar at splices, there shall be scent fastenore to hol al pats

securely n lace. The fasteners shall be suffient fo iansmi force of 0.75 mos

{he member design capactyn axial compression,

Jn adion,aplees located between pons of efectve ater sum

locive teal supped shal be

designed rhe design aa ere) pu a sin wendng morn holes an

‘the design bending moment (M") where— ‘a “3 *nottess

wee BNL

1000

5 = appropriate amplification factor §, or 6, determined in accordance with

Giause #4 of AS 4100,

1, = elstance between poins of efecve lateral support

vines amber a

90k propre for fl conic, the sce rat and ts

foteer shal be aranged toad all part ne an habe Seat Io Van

Sore 0 tes the ember eng capacly maul ampresson

(0) Saces in fenural menbers—a bonding moment of 0.2 tines the member design

Sper mbes insta a9 alts Senn ts wae

A splice subjected 10 a sher force onl shal be designed fo ans he desk

Shear fre ogetor with any bending moment sling om the eezony othe

tore wn respec foe centod ofthe connactr group

(0) Spices in members subet to combined actns—a sis ina member sujet oa

Sombwaton ef dengn sal feson or dean ala compression’ and Sse

Bending moment sha sat (i) and) smoot

The action to be designed for isthe gs

pected lai (vi), as appropiate

lr of the calculated design actons oF the minimum

e simp ccoecions open acne 48 0ON e™

. tor ne

‘The minimum is genealy expressed a8 a facor times the design capacty (ARs)

re un ca of ngmber tuted bythe sang i stat. Hence, = members ineeased in

ic et umn see for whatever reason (alonalsaon af member size, london

Seaton We uaoratons), Ws any haceseary to eo he design copacy of he minum

seen ie aren fn ate forte purpose ef elemining the moimum Seog"

cae eae mle, clumea whic may be sult tears compressive frees and ony minor

reser (Scan any pln nas to be designed for bth he spctd vale fr the minimum

seoal ice request reas the compression, at for he spaces vale forthe minimum

‘Member size requted to ress te onson

‘here the conection design is cari’ out by

Sons av os shown n Tables 11% 15, Thes mi

astos

‘here connection design it lf 10 the shop deta

Shout be shown n he onet document.

Simple consvucion——- — design eaconF*

onstruction and spices — design bending moment At

Soe — design shear force V"

= Sesign atl ore

(Citar combinations ofthese actons might nee tobe specified to encompass al hey lod

fembnatons)

the stuetural engineer, the minimum design

imma ace bated onthe above provisions frm

siabcicstor, the folowing design actions

. pcan ®

TABLE 11

UNIVERSAL BEAMS

‘GRADE 300

DESIGN SECTION MOMENT AND WES CAPACITIES

Tsong Woled ona Foled wo Waleal | Minimum desig acllone a

Uonoted "Stange flanges Unholeg ‘connections

Designation War ae | 0306 (0.15 8K oF Alen

wm tom nw | wx

‘sousias wr war 1100 218 ©

+ ko Ho ae 2

tet tart 100 238 °

saous a2 ST) sa 830 2 ©

a0 soar ie o

408 1 asa 8 ©

748 wo mee 1 2°

on so MS ar 0 2

“008 52.7 6 ast are 0

“ous ser] 7s oC ee rn

gr | ae fos ne °

aur | 2396 toa oe 0

‘ouB «62 | 197 7055 4 0

aos | te jer tak 30 se ry

mo | oe sts 2a 02 o

re ea o

po0uB 298 | 900 752~«wr0 as zo ry

a | ms Gat Sea 2a me m8

ma | 6&3 0 aati ioe 24

fez | sie te 188 Ba

yeas 2 |e ye 169) 29

wer | a2 + ist ne Br

wei | toe t ti ns 203

woe 10 | aaa Te Thr m2

wo fost ye a 195

‘Mga or wo 22m alae

gy elu for wo 22 mm aster hoes Loh Ranges

sof area in ange is bso AS 4700 int, 0 gross section value maybe veo.

+ NO bats wit at

notes one ange

esan capac als for stra tae V3

sip anmectons open Seton, teat

TABLE 12

(WELDED BEANS

‘GRADE 300

DESIGN SECTION MOMENT AND WEB CAPACITIES

3 DESIGN BASIS 33° Coped sections

“The desl capacty tables in his Simple Connections DCTs, VI also apply for coped sections,

Tonoies Wold ono Wed avo Unhoadl]|_Winimam design eons Fee lan tx coved sectors ae noun ip Fase 13 (ovade ono coped sestons

mame Sanseamoee™ Hoes onnectone | Tha Bure 14 (Oto woo coped ecto) The denn enpoctinasod srg ta engn

aration | ty, Hix ie Me | 00, (0.188 0 he 2apackytebles ar sod In Tables 14 (SWC) and 16 (OWE), and were dorved 2 etoed

nim Nm ams | x eatpene (oo 7

wmoneas [Tne aon | 220 wo

| cero Seto ost eoo. | tess, o

| Soto Sete sono: soo | rts io

So | dno fans Saeer a0 1088 FA a

Siz | soo soo: soo" dao | so o le. Jom a

ma | rao oor Stor baon | te © ne ad

soso Sass so_—taeo_| “ors ° “«

a0 4190" atgo" aso | ea ‘o I

fas Gre ran dase) a ° |

Seo oro aaso | 30 “o

dieu aueor sso 2a | ra

aaa aaa" e790 [4050 °

Soo dost tao | “set ra

Bro des anes | 88 e

gr Hegre iso | toe fa FIGURE 13. SINGLE WEB COPED (SWC) SECTIONS

oso amar 930" 80 | «80 1

fo iota tise | Ste ‘

io yao tattoo er ‘a

foo two ost too_ |e ia

Toowsi7s | tea toro" 1610" 100 | 482 ©

im | isso tas trop | ae °

13 | tem fe fox oo |e %

Hs | tooo ‘nates oo | ‘

titel for e024 mm camel halen one ange f le

jg alate or to 24m moter ots in bah Ranges

2MBsscrare tang ow AS 410 so seston vue may bo vse

fe ¢

TABLE 13

PARALLEL FLANGE CHANNELS

‘GRADE 300 le ;

DESIGN SECTION MOMENT AND WEB CAPACITIES 4

FIGURE 14 DOUBLE WEB COPED (OWC) SECTIONS

Designation | permetre | yy ow 020 6, DAS HV Atlan

om ne fo itm a

were [ss 238 cy Ta 0

‘sooprc | aot ca a6 6 @

aeoprc_ | 355 ta Ea m2 ae

ope | 254 3328 220 wer

aoopre | 229 aE 119) au

sore | 708 0 t8T 47, 23

wworre | 177 mae 4 Ev]

¢ aac ee ct iron e*

ae cases esse ton Be

TABLE 158

DOUBLE WEB COPED UNIVERSAL BEAMS

‘GRADE 300,

DESIGN SECTION MOMENT AND SHEAR CAPACITIES

TABLE 14a,

SINGLE WEB COPED UNIVERSAL BEAMS

‘GRADE 200 COPE DEPTH d, = 65 WM

DESIGN SECTION MOMENT AND SHEAR CAPACITIES

we a a

tonaton | nwm | aw dl mm | om | ne som [a

creams | 22 | o0 woes | oe | ss | 2 ar | tes

ve) ae | ve | to | oo | 8 we | te

forse] ses wm | om | es | & two | to

we ee | ms |e moos | on [es | 8 vas | to

seme | ae | 8 so | | | 8 iie_| Sr

“ave sf tor oom vous 21 | ao] ss | a ua | ae

ma | te | Se me | ie | os | 8 ir | te

i a | fos |e ar | ite

“ous sey | sea | 308 ous 597 | we] ss | st a2] me

So | m2 | si | im |e | 8 a

oor ey [mes | ose ous 587 | ase | ss | ry

Sr | Bi | se sr | se | es | ot Fa

ar | sa |e 7 ie | os | 8 3

swe ea | te | Be wea | se | ss | s | ws | si | iso

go | us | i eo | os | is | 8 | wo | fs | es | ie

ews | za | sous ars | ame | ss | | wo] sa | so | wo

woes | ea | te aa | oe | es | & | is | si | a8 | ve

Be | ee |S ar |e |e | s |i | fo | ot | he

|

| mous ae | 150 | 190

i Bi] aa | ir

| wee Ls | TABLE 150

| DOUBLE WEB COPED PARALLEL FLANGE CHANNELS

"GRADE 300

DESIGN SECTION MOMENT AND SHEAR CAPACITIES

TABLE 140

ea SINGLE WEB COPED PARALLEL FLANGE CHANNELS Bestraton To Tae [ode Pm |e [ae | om

| “GRADE 300. COPE DEPTH a, = 65 ul wm | om | om | wm | wm | onm | on

| DESIGN SECTION MOMENT AND SHEAR CAPACITIES seorre [wo [es | so | zes | 100 | sve | wee

ad —— oe 2500FC 250 5 50, 125) 20 | 105 16,

| ore 1 zaorrc | 20 | es | | 15] 6s] 62] 108

00PF 76

oF 218

oP rm

PFC 7

|

|

1

|

design cacy es esr ste sos canny te struct et “

« 1 ee Sr ean * ¢ fas acy bles x scaly 2

4 WEBSIDE PLATE CONNECTION 4:1 Description of connection

‘The wab side plate connocton consists ofa tength of plat or fat bar, filet welded on both

idee to # supporting member, with bos connecting the supported beam web fo the web side

Date (rte to Figure 15 for pica sxarplos ofthe connection),

‘Te supported member may requis the flange andi the web to be coped in order 10 enable

tho connection tobe flected (iusiratad in Figure 15(b).

Features ofthe conection ae

Welds ae fillet welds to both sides a he component, connecting to the supperting membs

—The component is either a standard size fat bar or pate cut 0 sult

The boing category normally used is 8.8

tha connection ean be usod with skew beams

FIGURE 15 TYPICAL WEB SIDE PLATE CONNECTIONS

. nae en ®

“& WEBSIDE PLATE CONNECTION 42. Typical dotaling of connection

1

a4

Square ede a e ea

ar or pale component barerple conpenet

——

FIGURE 16. SINGLE LINE OF BOLTS TO BEAM WEB, BEAV-TO-COLUMN OR BEAM-TO.

BEAM CONNECTIONS UNCOPED, SINGLE AND DOUBLE (NOT SHOWN) WEB COPED

BEAMS

Suara at

Barer ts congenent

‘rote conpenert

FIGURE 17_ DOUBLE LINE OF BOLTS TO BEAM WER, BEAW-TO-COLUMN OR BEAM-TO-

[BEAM CONNECTIONS UNCOPED, SINGLE (NOT SHOWN) AND DOUBLE WEB COPED

‘BEAMS

e Sei cess ae aes pe

4 WED SIDE PLATE CONNECTION 43 Recommended Design Model—

Summary of Cnocks,

Design Is based on determining Vier the design eapacty of the connection, which is the

Iminimum ofthe design eapactios Vy, Va. Ve an Ver Va Vy. Ve

“The design requirements then Vax 2 V*(Gosign shear force).

From AS 4100, Clause 9.14(b4i) (Ref. 1) thie connection must be designed for @ minimum

‘Sculgn shear fren of 40 KN. of 0.15 » member design shear capac. whichever iste lessor,

Summary of checks required (Ref. 4)

DESIGN CHECK NO,

DESIGN CHECK NO.

DESIGN CHECK NO,

DESIGN CHECK NO,

DESIGN CHECK NO.

DESIGN CHECK NO.

DESIGN CHECK NO.

DESIGN CHECK NO.

DESIGN CHECK NO.

DESIGN CHECK NO

The design capacity

3

5

6

7

a

9

= Detaing tations

— Design eapacty of weld to supsorting member

— Design capacity of bol group—Alornativos A&B

— besign capacity of wad side plat (Shear, bending, block shea)

— Design capacity of suppocied member (Shear—Uncoped or coped)

= Design capacity of supported member (Block she

sections)

coped

— Design capacity of supported member (Bending of coped sections)

= am roaton check

— Local stability of coped supported menber

10— Local eapacty of supporting member

tables in this Simple Connections DCTs, V3 are based on DESIGN

CHECKS 1 to 6 nchisiv., DESIGN CHECKS 7 fo 10 must be cared out in addon,

texan cacy aie fr rt atl VS

ne rmectone= pen secon a econ

g 7

WEB SIDE PLATE CONNECTION 44 Configuration A~Single line of

boltsDesign capacity tables

“Component : 90 » 8 flat bar or plate

‘6 mo flat bath sides, E48XX electrodes, catagory SP

N20 8 B/S bolting category (threads included in the shear pane)

* 100 used fora dimension fr al sections except 200UB, 2000C, 200°FC

os, 38

urcspat Sigh we coped

Date web copes

FIGURE 18 GEOMETRY CONFIGURATION ASINGLE LINE OF BOLTS.

rye eat ean ee

TABLE 16

\WE® SIDE PLATE DESIGN CAPACITY TABLE—CONFIGURATION A,

SINGLE CINE OF BOLTS/O MM COMPONENT/S MM FW's,

MEMBER > 300 NM DEEP

ea Design capaaiy

Sunporied | Coniege pao [ase | ast | nze | ass a8

hia | nee | not | nee | naa

‘ny [oes] 66 —

‘any | as | so | aoe

my [eas | see _|_404

my [es _| one | oe [ os

[any [ses [ao [ana

any au_| acs | 359

Bay aa | a | ae

any on | 209

ny 20 | 0

Bo, 20 | 10

ov 120

a00erc | Any 190

~s0ue | Any 190

srouses2 | Ay 0

sroueto | 0 “0

sor owe ve

arouse |, we

NOTES

Devt eaacty in tbe dered om DESIGN CHECKS 11 8 ony. DESIGN CHEGKS 7 10 must be

arte oun ater

Shny Esher uncoped, SWC, DWE

SHC singe web copes

}) Teta mame tbe a=) OE

Tran spaces to ight of bois fine component dapth is lss than SO% beam cesth, configuration

pot vecommensed

Empty spaces tt of bol in-comganent wil nt nto supported menor web wth

0.

Component +90 8 fat bar or pate

wold am filet both sides, 40% electrodes, category SP

Bolts 1208.8 bolting category (!weads included in the shear pane)

Dimensions.» Refer'o Figure 18,2 * 100 mn

. OES en e

TABLE 17

WEB SIDE PLATE DESIGN CAPACITY TABLE—CONFIGURATION A,

SINGLE LINE OF BOLTSI8 aM COMPONENTIC NIM FW's

MEMBER < 250 MM DEEP

“unponea | coping on | Dan spas

: ‘member naz | a

ee | mim

avers |_aw 10

2508257 | Ary

Bapec [ay 708)

opec | Any 70

a0Pec | Any

wauceas | ay | _s00 | 100

asaueres | Ary | 100

aoavese.s | any | 100 | 70

‘o0ues22 | Any | 100,

‘2nucas2 | Any | 100

NOTES:

Design cansety In lade dere tom DESIGN

‘CHECKS Ti 8 ony, DESIGN CHECKS T lo 10 mast

‘ay Ether uncoped, SC, OWE

Me) Talal eum fat norm

Component : 90» 8 fat bar or pate

Weld 6 filet both sides, E48Xx electrodes, category SP

'N20 8.85 bolting catogory (threads included inthe shear plano)

Dimensions ; Refer to Figure 18,2 dimension varies 23 noted

e Somme at, te

WEB SIDE PLATE CONNECTION 45 Configuration B—Single line of

bolts—Design capacity tables

TABLE 18

WEB SIDE PLATE DESIGN CAPACITY TABLE—CONFIGURATION 8,

Component £0 10a Berar ato Co SINGLE LINE OF BOLTSHO MM COMPONENTS MM Fw

Weta 8 mm filet both sides, EABKX otcades, category SP oo MEMBER > 300 MM DEEP

10 8.8 bong category read inclied inthe shear lane) cc freer en ;

+100 sed ft mansion fr al sections oxen 20008, 20000, 200PFC = ee wilds | act

me Srwoe | ay [ar |

patna man ft

i ie = 100" - scowe pay

anne [any

= 700WB ‘Any

rou8 | any

“ 53008, Any.

| #1008 poy

00 | — toy

seu | toy

| i — tices [or

| arouses | 0 729

| Sie we cont wes one FA

oom] 0 20

| a swccone a

sign capacty in ae served om DESIGN CHECKS 1 06 only, DESIGN Cl to 10 mane

arse oun adaeon HECKS 71 10

|

| fay Ether nsiped, 6, OWE

| © Ueped

| Seto Sat coped

i OWE Dan wet coped

| Mn) Taal umber ool nn) ons

| Etoy sce to va of bs Ine—canponet dah te an 40% team ph, cotooton

| rt sacs ool ine—eamponant lil to upped ener nob wna = 10

| Component : 99 {0 baror pate

i Wold: om at bo soe, £48% olocrdes, category 6

‘ Bolte W208./8 boing category (read ncided inte shear pana)

Dimensions = Raerto Figure 19, = 100 mm

out we coped

FIGURE 19. GEOMETRY CONFIGURATION 8SINGLE LINE OF BOLTS

exon canst abies fr raul tual Vs

inl somactoer= open secon eon

eso capcey oer seta tal V9

fale anmacions pon secant eaion

; 4 WEBSIDEPLATE CONNECTION 46. contgursion Dost tine ot

TABLE 4 _ Soits"Songn cape abe

WEB SIDE PLATE DESIGN CAPACITY TABLE—CONFIGURATION

SINGLE LINE OF BOLYSI40 NM COMPONENT/S MM FW’s,

(MEMBER 2 250 MM DEEP

yoonent 180 10 fat bar o plate

“Meld Beit ah in, E85 daca, exon SP

peg x04 totig cargo (vis need eum

womter [REE | oo DY tto metre cnenoon tov al scion wnt 2000, 2006, 200FC

waueers | ay | von | ae

zsouesi «| any [100 ane sss

sous 7] any | 06 5 a

ouezne| my [100 70 of

2000684 | am | 9 oe

oousiza | any | 0 oS

zowsiez [ay | 7 - t

were [ a | : ae ct L

zaoere | Ay [100 | 70 : et 1

some | toy

oscmes [my [e100 \ ay

aewerae| an | 100

| zooucees | ay | wo} 7

aonvese2 | am | 00

aonvoie2 | ay [00 ® 7%

‘NOTES: Uncoped ‘Single web coped

ange cnscty in ble dened fon DESIGN

SETS. desion Gieexs Foto mek

saa tn ston sss,

m

Total numberof bats t=

rome

‘Component: 90 10 fat ba or plate

weld manila both sides, E48XX electrodes, category SP

Bolts 120 8.28 bolting cetegor (threads included inthe ehesr plane)

Dimensions Refer to Figure 19," dimension vais as noted

Doxa web coped

FIGURE 20 GEOMETRY CONFIGURATION C-OOUBLE LINE OF BOLTS

ry esgn capac tle seta sol Vs g”

cus, e sensei mane ae

TABLE 20 a TABLE 24

s10N CAPACITY TABLE CONFIGURATION ©, a fone oe

WERSOUBLE LINE OF BOLTS/I NM COMPONENTS MM Fs, WEBSSUBLE CINE OF BOLTON MM COMPONENT/S MTFs

MEMBER > 200 MM DEEP a MEMBER < 250 bla DEEP 7

TARA suppres | coningon | Pesan pst

mcr [immer | ete [ate | tate ani [ass | a ‘member | ‘nemo’ | ne? [4

oF 200873 | ane 7 00

"20006 ot ae ‘2souna1 4 [Any oy

1000WB fe 2s0up257 | any | 1 |

scone a aooveza6 | any | 51 70

om 7 ee ra

ave ee eae le

¢ 53008 28 if ‘250PFC Any ot 100

| seu = ' ‘tere [any [1] 0

| saves Se [ioe i “ao0ree [any |

| coy sa |e oe

lee mauene | iy [a

| a ow es erm

aoe slic ' eres area

| ane = se

| a a : rs

i ovens! ae 88) Ls ores:

i Sips | Dane = ’ Cd sweety ects for C881

an 7 : Crab aay oS ace

— is eae

wee 2 Any Etherancopea, Se. DWC

Le see ey N(= na) Total number of bolts in {= n,) rows

wares

ign eapaty i ble dered fom DESIGN CHECKS 1 06 ony DESIGN CHECKS 71010 mustbe

E 4 fom DESIGN © : 180 10 fat bar or plate

fared tin aaeion

fer ancoped, SWC, DNC 8 mm filet both sides, £48%X electrodes, category SP

Unest Bo 'M20 8.8/8 bolting category (threads included in the shea plane)

eee p Refer to Figure 20, dimension a8 nate

Dost wo coped : Figure 20.3 a "

=x) Tota numer af bts in =) roms

Toots spaces to ight of ols no -componant depth 4 less than SO% beam depth, contguraion

“Erpty paces of of Sold ne —companont wl nat it sported menber web ith 2

‘Component: 160 10 flat bar or pate

Weld £8 mm il both ses, E48XX electrodes, elegory SP

Botts M20 8.8 toting category (threads incuded nthe shear plane)

Dimensions = Refer to Figure 20, = 100.mm

sgn copay es for sect th design capaci ies for str sta V2 Fy

¢ smb Santa open sete es eon singe comets ope soca eaten ®

5 FLEXIBLE END PLATE 54 Description of connection

‘CONNECTION

“The flexble end pate connection consists of langth of plate oF flat Ba, filet welded on both

Tides to the web ofthe suoported member, with bots connecting the end plat tothe supporting

member (eter lo Figure 21 for peal examples ofthe connection)

‘The supported member may requle the flange andlor tho web to be coped in erder to enable

reconnect to be fecied

Features of he connection are

— Wilds are filet welds to bot ges ofthe suppeled beam web.

— The component i ether a standard size Nat bar or pate cut to sul.

— Tho boting category normally uses i 88,

— tne component does not extend to the bellom flange ofthe supporid beam in order to

hours atthe baam can rotate wihout touching tne supporting member,

_— The connection can be used ta holo section columns If studs or special bolls are used (oot

Within te scope a hie Simple Connections DCTs, V3).

— The connection canbe used with skew boams fo aiited

ange awe

ped os eaured

‘immmin rs

requred scope come

FIGURE 21. TYPICAL FLEXIBLE END PLATE CONNECTIONS

¢ Ee en +

"CONNECTION

"FLEXIBLE END PLATE 52 Typical dealing of connection

Page tof

Copstorath ce Ania ttprset

eat Steam mae

FIGURE 22, UNCOPED AND SINGLE WEB

"COPED BEAM (end pate ocated towards top

Ce

{ He

FIGURE 23_UNCOPED AND SINGLE WEB

‘COPED BEAM (end plate located towards

‘or beam) bollom of beam)

ty

FIGURE 24 DOUBLE WES COPED BEAM

(end plate depth matchos romaining depth of web)

Seat pens een a

153. Recommended Design Model—

Summary of Chocks:

5 FLEXIBLE END PLATE

‘CONNECTION

Jan capaciy of the connecton, which is the

Vows My

Design is based on determining Vay the 4

‘inimum ofthe design capacities Va, Vo, Yo Va

‘The design roqurement is thon Vg = V"(design shear force)

From AS 4100 Clause 9-44(0{i) (Ref, 1) ths connection must be designed for @ minimum

‘eslgn shear force of #0 RN. 019.18 = member design shear capacy, whichever is ho laser.

‘Summary of checks required (Ref. 8)

DESIGN CHECK NO, 1 — Dstaing imitations

DESIGN CHECK NO.2. — Design capacity of weld o supported member

DESIGN CHECK NO. 8 — Design capacity of bot group

DESIGN CHECK NO, 4 — Design capacity of end plato (Shes

DESIGN CHECK NO. 5. — Design capacity of supported member web (AL end pate)

DESIGN CHECK NO. 8 — Design capacity of supported member (Shear-—Uncopet or copes)

DESIGN CHECK NO. 7 — Design capacity of supportad member (Bending of coped section)

po 4 DESIGN CHECK NO. 8 — Beam rotation check

i DESIGN CHECK NO. 9. — Loca stabil of coped supported member

DESIGN CHECK NO. 10 — Local capacity of supporting member

‘Tne design capacity tables in this Simple Connections DCTs, V3. are based on DESIGN

GHeGke wo 8 incusive DESIGN CHECKS 7 to 10 must be carted out in addon,

block shear)

nig apacy tates or sical iV

see cate apen extant eon

54 Configuration A—Sections >

500 mm

200 10 fat bar or pate

6 mm filet both sides, E48XX electrodes

1NZ0 B/S bolting category (threads included in the shea pane)

For connections le column flanges or webs enc preferrd gauge tin

toTables #107) refered gauge lines (Refer

{jz

ts

J}. EES |

a

3

to

‘Sng wa cpa ea

2, 0

“TE Hl

a It ten"

ir pee

sic 4

en “en

Dae we eset ba ‘Comore 005 ft bar

FIGURE 25 GEOMETRY CONFIGURATION A-MEMBER > 500 MM DEEP

eign opacy tbs ests sel Vs

TABLE 22

FLEXIBLE END PLATE DESIGN CAPACITY TABLE

CONFIGURATION A~MEMBER > 500 MM DEEP

5 FLEXIBLE END PLATE.

CONNECTION.

150 » 10 at bar or pate

58. Configuration Sections

‘<500 mm deep

‘svppares | Coning on Sete = Wed 6 mm lt both sides, E408X crocs

menoet_ | memoet sou | set nee "Bats $2088 bong category (eats ineuced in the sear plane}

an Noise adimenson 100 geneay

owe _| 70 for sections 200m deop

“oom ° we For connacions column tnges ow

ey aa enn anges or webs check preferred gauge lines (Ref

owe Ps

or ° ‘se

swe 8

awe Es

| ‘800WB ° 20, 7o3)

swe so | 73 30 piso

|e sea_| ise \

Taw ° ‘eo | 700 | ss + 5

sve eo | me | "

owe aa 586. 488 _ Hi at {ra *.

waver | 0 us) er0 | ers Fh nee 4 le

sie me | a0 | 8s 7 ra 7 a

awe [| te | os_| ee — TK, 4

wou | 0 ano | ose | os

swe feo | te | a

| owe s_| os | sa0

aoa | © oa] 368

swe te | fee | ett 7

owe re | o_| se le 1

sume} 0 10 |e | 08

she m | or | tse rcp nn seve wsb ea aan

awe fr | sw | an 4 oon

wove] —_o cars|

swe om [sa | oe

owe so | ea |r

nove : 2 pain sonm wo

Tere capaciyn ble dried om DESIGN CHECKS 11 6 on. DESIGN CHECKS 710 mus be N/m ose

Po Tf amber oben om

OUneapes 38

Swe Sia web pes nm [TE 4

Dive Dose wed covet ae yd

ey spacer to at of blsne—ciponen ep es han SOX beam dei, contouatin ot Eat.

‘common pacts) Cl

Component

Wea

Bolts

Dimensions

S 2

‘rely spnas to eof bo re—canponent wi ot tino supported mambar web with

“ men nd 20 mm (ax) are requred between the ene

SERED Teh an may ater value indesign copacy table

200 x 10 at bar or pate

‘Smile both sides, E&BXX electrodes, category SP

M20 6.88 bolting category (threads inclused in shear plane)

Refarto Figure 25, a= 100 mm

ata support (atin et

RULERS too iret 1) regres the vominal at shea capscty (V) Be

‘secon 109 of Rt 6

design cps al er stra tee VO

inl armas open Seton el eton

out wo oped beam

sign cosy ables for ruc sel VS.

simple comes” open secon ie etn

Componact 1010 pote

FIGURE 25 GEOMETRY CONFIGURATION BMEMBER < S00 MM DEEP

TABLE 23

FLEXIBLE END PLATE DESIGN CAPACITY TABLE

CONFIGURATION B--MEMBER > 350 mm BUT < 500.mm DEEP

TABLE 24

| _FLEXIBLE END PLATE DESIGN CAPACITY TABLE

—_MGonFicuRATion b—MeMBER > 250 ww BUT

oe "<350 MM DEEP

Supponed | covingon [pag _ i

member | member | gato oo oping on

Tae) ad Component = 15010 fat bar or

swe | Se omer |S pate

pwe__| 49. i swe Weld: 8mmfilt both

avers | 0 [80 a owe Sidon, E40

snc |B ewes secrodes,

pwc | 0 oe swe fategory SP

qauRTT | 0 oie - Bolts M208.8/S boing

one | 9 saw agony (aveads

owe__|_ ae ee tretdea nthe

woemr{ eee [| = oul

Si eer Dimensions : Refer to Figure 26

TaUEST | 0. SWE oF

owe 20 ae

BGR ° ocr

swe es a

awe 302 Samer

weounssy | 0. swe 20 aul

‘onc | ba awe

BeUBSDT | ~O, swe a a

‘one. Pa :

—samuaT |. Swe Tz _ Srouceee

owe io :

vores aoe |

Desoncapscy table derives tom DESIGN CHECKS 1 106 ony. DESIGN .

Beds Po to manne ced ou ation ——_

Men) Tlatnanber otha f=) 248 ca

8 acon 1) emxr |

So Swe coed oS na es

De Dobie wb coped ) aa fe

Chey saces tora of bls ne—conponon depth less than 60% beam . ‘owe ca

{inn coniursion rot econ _ oucses)~o. swe ee

fey epuce to to 91 Ira zoreonot wl rot bo spared member a

webu a 100 / a

Tr ottere ve mm an 20cm (mae) av egured atween te end pat ond a

4 ue es wt canon paca) Gauve 2.925 01 AS 400 (et 1) ere

re bl ses cpeay (oe fedbend by 18K and may ater or

Suen tte csaty olor Scion 0.3 °F | __ Drs asc inte crs fm DESION CHECKS 1106 on. DEION CHECKS 710 mast

Component: 150 = 10 at bar or plate

Weld {6 mam file both sides, EABXK electrodes, category SP

Bolts M20 8.85 botng category (threads included in the shear plane)

Dimensions: Refero Figure 26, @* 100 mm

Y SPSS en ct in

*

Remy toaente ttn

(8 Uncoped “n

he Sonnet

“Empty soscos o 9h of Bol ln

2 eee component dap i es than SO% bear et, confgwratin nl

-—_Enpy spaces oe ot old ine

_ Ey spac camgonset wil no tint sported mambor web wh 8 = 100.

‘edule betwen the end plate ard susp (which i ot

ign ape birt Sactons0¢ReE

Shemirssseres, ee

i

TABLE 25

FLEXIBLE END PLATE DESIGN CAPACITY TABLE

‘CONFIGURATION 5—MEMBER 200 MM DEEP

NOTE: 1 =70 for thore suction

‘Design capacity AN)

supported | coping on |

2008208

weoveae a

yooueee

008

2300Fe

Bower

Baum?

7o0uGNe? | 0. 8Ne

we

Nores

Destgn capac in ble deed fom OESIGN CHECKS # 106

Days DESIGN CHECKS "0 FO mist be cared ou mado

Men) Toll numberof ots nom) ms

‘uncoped

Single woo coped

DWE Double web coped

packs 28 mm and 20 rn (an) ae equa btwn tho

{aipate and serpent (ame tne common prctes) Care

Sods ens 4100 (eat) resus the-namnal bot shear

apacty (be reduced by #5 ad may aller value In SION

(Spaciy able roerSocton 10.9.0" Re.

component: 160. 10 al bar or plate

Wild

Bolts

{6 rm ite both sides, E48XX electrodes, category SP

M20 8.18 bolting category (threads included in the shea plane)

Dimensions: Refer o Figure 26, a 70 mm

simi ldonectens open scion, ton

6 ANGLE CLEATCONNECTION 61_Descripton of connection

‘The angle cleat conection consists of either single angle bolted to @ supposed member web

oF Iwo anges bolted each side of @ supported memoar web, The angle or angles ar in tun

bolted to the supporting member (refer to Figure 27 for typical examples ofthe cancion).

The supporied member may requ to have the flange andlor the wab to be coped in order to

‘enable the connection to be effected (efer to Fare 27)

Features ofthe connection ae

= The components a standaré angle, grade 300 (one or two angles),

— The bong category nocmaly used i 8.8,

— The component doos not extend to the batiom flange of the supported beam in oder to

‘ensure that the beam can tat without tvehing the supporting member

— The connection can only be used to hollow section columns H studs or special bots a

used. Such suds or batts are nat considered inthis Simple Connections DCTS, Va

FIGURE 27 TYPICAL SINGLE AND DOUBLE ANGLE CLEAT CONNECTIONS

e Scone aaa, pe

62 Typical dtaiing of

[once -Oaute angle

6 ANGLE CLEAT CONNECTION

‘earto-un and beamto-boam connections,

ae eit wal peu Doane, apes, angle end Soule web coped boas,

inoped, gle and Sable wb coped Doss

| r

| ‘A FIGURE 29 ALTERNATIVE ‘B'—DOUBLE

/ HOURE 28 ATEGRATWE'A.-SNOLE —FOURE, weg 00

h LINE OF BOLTS TO BEAM WEB: LINE OF BOLTS:

i 29 tle

‘ Ht

‘el

Le

FIGURE 30 DOUBLE LINE OF BOLTS TO SUPPORTING MEMBER

. ORs at ne an e*

5 ANGLECLEATCONNECTION 6.3. Recommended design model—

Double angle cleats~ Summary

of checks

Desian is based on determining Vay. the design copacty of the connection, which 1 the

‘nim ofthe design capaclles Vs, Va, Vos Vn Ve Va VV

‘The sesign requirement is then Vaa > V"(design shear force)

From AS 4100, Clause 9.1 4(0(i) (Ref. 1) this camnection must be designed for a minimum

‘sgn shear free of 40 KN, of 0.15 membar design shear capacity. whichever ise loseor

Summary of checks—Double angle cleats (Ret. 6)

DESIGN CHECK NO. — Detalng lmiations

DESIGN CHECK NO. 2 — Design capacty of bolts o supporting memte

DESIGN CHECK NO. 3 — Design capacty of bots to supported member

DESIGN CHECK NO. 4 — Design capacity of angle cleats (Shear, bending, block shoo)

DESIGN CHECK NO. 5 — Design capaciy of supported member (Shear—Uncoped ot coped)

DESIGN CHECKNO.6 — Design capacity of supported member (Black shear—Coped

section)

DESIGN CHECK NO. 7 — Design capacty of supoortad member (Bending of coped section)

DESIGN CHECK NO. § — Beam rtaion check

DESIGN CHECK NO. 9 — Local stability of coped suppored member

DESIGN CHECK NO, 10— Local capacity of supporting member

‘The dosian capacity lables in ths Simple Connections OCTs, V3 are based on DESIGN

[CHECKS 1108 inclusive, DESIGN CHECKS 7 to 10 must be carried ulm edation

¢ sims cones" open secant, eon fe

© ANGLE CLEAT CONNECTION 6.4 Configuration A Double angle

Cleat single fine of tts to

Supported member-Desiga

capacity tables

component: 100% 100% 8 EA Grade 300

Bolts M20 2. bong category (threads included in the shear plane)

Note * 100 used fora mension forall sections except 200UB, 200UC, 200PFC

eel] HE

3

aR

f

4

a cis

on oot | TET a oot

a e

20 a wo

7

Sian

See web ope Dove we cove

FIGURE 51. GEOMETRY CONFIGURATION A—DOUBLE ANGLI

‘SINGLE LINE OF BOLTS TO SUPPORTED MEMBER

desgn pny len sci

e “simple connections ~ open sections, frst edition

EOLEAT

TABLE 26

ANGLE CLEAT DESIGN CAPACITY TABLE—CONFIGURATION A

DOUBLE ANGLE CLEAT SINGLE LINE OF BOLTS TO SUPPORTED MEMBER

MEMBER > 500 MM DEEP

suppertes — ENT

member Wea | Waa wee | wats

Taam ‘ais ate

ts | teat

ewe | tae | tase

owe_|_taer_| tte

ame opis] tase

awe | tos | se

owe | toss_| ser

‘on Of tare) tase

swe | te | tee

swe ‘ne

OWE me

soups} 0

swe

waa} 3

wousrar] "9

swe

bu.

oo ar

swe

owe

noes

Design capt in table dred rom DESIGN CHECKS 1 06 ony DESIGN CHECKS 7 0 10 must bo

n) Teta umber of Bot in. (=) om

SiC Single wob coped

we ube wed cored

Empty epates to ight of bold ine—comgonent depth is ss than 50% beam depth. contguation not

mot paces feo tld ine-companent wl at ile supprted memar wed wih 2» 100,

Component 109% 1008 EA Grace 300

Botts N20 8.8 boting category (threads Incuded in the shear pane)

Dimensions : Refer to Figue 31, = 100 mm

e eee yet cin an Be

TABLE 27

[ANGLE CLEAT DESIGN CAPACITY TABLE—CONFIGURATION A

DOUBLE ANGLE CLEAT SINGLE LINE OF BOLTS TO SUPPORTED MEMBER

MEMBER > 260 MM BUT < 500 Ml DEEP

‘Supportes

‘member

oping on

‘eau | O ero

swe | 505

owe | 480

‘eouera [0 oe

swe | dee

owe | _a58

rr eer | 85

swe | oa | See

pwc |e | sas

wroussy | _0 488

swe a8

owe 38

auEsaT | 0. a5

suc a

DWE 306

FFE o 6

we 0

she

_ wc

seouesa7 | 0

she

we Za

aeoueaa7 | 8. cn Be

suc aed

pwc 200

BSSSSB ESERIES E

nores

Desian capaci in able dered from DESIGN CHECKS 1 o 8 nly. DESIGN

CHEEKS Ts 10 rat be cared out auton. ee

m)

°

swe

DWC Double web coped

Emply spaces to right of bold ine—component depth se som

beam depth, confgutaion nol recommended, i a

tray sas ee f bl ne-conpmt wl at le spot

rember eb win a= 100

Component : 100» 100 «8 EA Grade 300 a

Botts

Dimensions: Referto Figue 3, a* 100 mm :

t od

1120 6 818 boting category (treads included inthe shear

TABLE 28

[ANGLE CLEAT DESIGN CAPACITY TABLE—CONFIGURATION A

DOUBLE ANGLE CLEAT SINGLE LINE OF BOLTS 10 SUPPORTED MEMBER

(MEMBER > 250 MM GUT «250 MM DEEP

aj Besa psy ORL

renee nea fire

‘sioupaez | 2st

swe 216

owe, 23

sues | 0. oe

we 185,

saueme] 0 206

swe ‘eo

We, 166

ote ° 0

sve 248

we 2a

‘siouciss | 0, swe faa

siovers7_ | “pwe bea

a a) See

swe me

we, saa

wauees | 0. 3

swe 308

we 20

BeavEs7s | 0, swe a

wc 120

TaHBsTe | —O, SWE te

ove. as

7008257 | 0, We ry

‘owe oa

BaPrE 9, swe “80

we 0.

sHICeES | 0, SHE 176

‘Owe. 16,

BaUETAS | 0. SWE or

we. eh

vores

Design capacity in tbe doived from DESIGN CHECKS 1 10 6

‘ony DESIGN CHECKS 7 to "0 must be cara out ation

srs) Total numberof ots nate) ome

° copes

SW Sing web coped

DWE Double web cope

{0 igi of bod e—camponent ep sess than

50% beam depth, contgutaon nt esommongeds

Empty spaces to lt of told brecomponert wll not ite

Component 109 190.8 EA Grade 300,

ots

[M20 6.8/8 bolting category tveads included inthe shear plane)

Dimensions : Referto Figure 31, a= 100 mm

¢

sing aprecto apo sesans fe won

eso capac ais fer area tel Va g

ANGLE CLEAT DESIGN CAPACITY TABLE—CONFIGURATION A

DOUBLE ANGLE CLEAT SINGLE LINE OF BOLTS TO SUPPORTED MEMBER.

TABLE 29

MEMBER 20

MM DEEP

ore: 22 70 tr hes ecto

Sunpacea | coping on | —Pesion ass

oes [OSH tie

owe ms

| meee 8. HE =

} we 108,

| ‘aooueaas | 0. 8¥e m

| one “

\ men? | 0-5 7

| owe 4

Tt ‘220PFC 0, 5We 12

a owe wz

aoopre | 6. SWE Te

waves | aw ie

woes | Ow a

“emer |e. i

one is

Men)

°

swe

component 100% 100 «8 EA Grade 300

Bolts 120 8.6/8 bating catogary(teads included in the shear pans)

Dimensions : Refer to Figue 31, @= 70 mm

“otal aumbir oan (8) ons

scoped

Single wed coped

Double web coped

See aes con eon

Design capaciy i able dares rom DESIGN CHECKS 1108

nin DESIGN CHEEKS 7 lo 0 must be cared oul

6 ANGLECLEAT CONNECTION 65

Configuration B—Doubte angle

leat double line of bal to

‘supported mombor—Design

Capacity tables

Component + 150. 100 10 UA Grade 300

Bolts N20 8.818 bolting category (threads included inthe shear plane)

Note * 100 used for ‘a dimension fora section except 200UB, 20006, 200°C

i

+

+4

3

=

+5

i

ves

nospas

8:

Single wed cape

End vow

2s

Daste web cope

FIGURE 92 GEOMETRY CONFIGURATION DOUBLE ANGLE CLEAT DOUBLE LINE OF

‘BOLTS TO SUPPORTED MEMBER

¢ sino cotactns pon sc ein es

TABLE 30

ANGLE CLEAT DESIGN CAPACITY TABLE—CONFIGURATION &

ouBLE ANGLE CLEAT DOUBLE LINE OF BOLTS TO SUPPORTED MEMBER

MEMBER > 500 MM DEEP

Design cps)

Supported | Coping on | aay asa] nee

‘emer | member eae Nm | sei6

Taiawe | _o ‘482

swe 1328

‘oon | 0 ae

we 210

anc 102

OWE, 931

wove | 0 1272 TH

svc ‘st 6

she 31 58

_ pwc | 73 88

swans | 0 wn

os v0

ae ors_| 02

sues | 0 Ca

aan ms | 609

We, as | 520

sous] 0 in| eae

ac ma | cor

sauew| 0 aa) sae | 7a

a ter | see |

we er_| si | an

Tuam} 0 are [ere | tar

eae cs | sae | asa

acl sex | sex | er

nove:

Design capacity in table devas fom DESIGN CHECKS 1 16 ery. DESIGN CHECKS 7 to 10 must be

‘aad oom aaaton

=m) Total number of Bats =) ows

° Uncopes

SNC Shale web copes

Emoty spaces tht of bod line—componant depth cls than 60% beam depth, configuration nol

Empty spaces tf of bald ne—component wi et t nto suppres

with 2= 100,

Component : 150 x 100 10 UA Grade 300,

Botts N20 8.8/8 bolting category (threads included in the shear plane)

Dimensions : Refer Figue 32, 8= 100 mm

¢ Se eaten e*

TABLE 31

[ANGLE CLEAT DESIGN CAPACITY TABLE—CONFIGURATION B

DOUBLE ANGLE CLEAT DOUBLE LINE OF GOLTS TO SUPPORTED MEMBER

‘MEMBER > 250 MMM QUT <500 MMDEEP.

Supported | Coping on a

cael renee vets | om | noe

eae] 0 7a

she ior

ne 38

wae]. 78

ita 36

7eaueaTi] —0. 367

Owe. 38

wrouesa7] 0 sir | aa

swe see | 209

Trae] 0 so} ase

ane ae | zee

one sos_| 230,

sears} 0 sr] a0

wc ar | on

seouese7] 0 “1

- owe 22

6008507] 0 a

swe ms

we za

wana] 0 3o7

owe 8

Dosa capscy ible dened fom OESIGN CHECKS 1 0 6 enh, DESIGN

‘HECKS Tio 10 mst be cried ot neon ~

Mem) Total numberof at n=) roms

° scored

SWC Single web coped

DWC Douie wed coped

Emoty spaces to ight of bold tne—compenert depth & lass than £0% beam

{5 congutatn not commenses

Emel sane to

Component

Bolts

Dimensions

of bold ne—component wil ot inte sippetes member

150 + 100 10 UA Grage 300

N20 8.85 bolting category (treads included in the shear pone)

Refer to Figure 32

100 mm

sgn capac bles or stu sel Vs

slnolecomectane open scion, tein

Rs

TABLE 92

ANGLE CLEAT DESIGN CAPACITY TABLE—CONFIGURATION B

Empty space to ight of bls Hnecompanent dep i ss than

ti beam depth, contguaton not ecorimended.

Empty spaces to let of Do ne—componart ill not into

oppoted member we whe = 100,

Component : 150» 100 « 10 UA Grade 300 |

Bolts [M20 8.85 bong category (thveads included in the shear plane) |

a Dimensions : Refer to Figae 32, = 100-mm

Component 180 » 100» 10 UA Grade 300

Botte 20 B.S bolting category (threads included in the shear plane)

Dimensions : Refer lo Figura 32, 2 = 70 mm

eee

DOUBLE ANGLE CLEAT DOUBLE LINE OF BOLTS TO SUPPORTED MEMBER id

Eo rote Sealant ey

‘Supperted | Coping on | Desir eapeciy AN — ‘MEMBER 200 tm DEEP

sent | Sa [SPP oes

oem ss sere orn

ele feed feos

ase} |

Srv ‘swe 216 ‘2000829.8 °°

rie cs

somes} 8 ore

es wamaz|

we 242 ‘2000822 3, oo

sacar] oe =

FL ae

nora as S

: cee

‘S1OUGS6 & oO. ‘sod DHE

sacle 2 a

mama} aT 7 Be

‘swe 1s ‘200PFC oO ‘207

amnr} oe 2 oe

i _ owe - 123 muses | 0 209

ol i owe it

vet swe 189, ‘swe 188

a a | puEKse | 0 256

sms} 8 es es az

owe aa | ‘Design canaciy in table deriv rom DESIGN CHECKS 1 1 6

fares | sacs ceca eis iiaee cael

———— nS

enum esas smannecncas | a

Sas mesos

ec | a

vc Boule web cond | -

: ¢ oe nee pet sans et aon e* e seater ee ey ®

ANGLE CLEAT CONNECTION 6 Typleal detailing of

cconnection-Single angle cleat

sanvo-clu and teamo-beas connections, Beams-clunn end bean-o-Beam comactons,

nsoped single ae dacba web copes beams, ‘uncope, sie and double web coped beams

FIGURE 33 ALTERNATIVE 'C'—SINGLE FIGURE 24 ALTERNATIVE ‘D_DOUBLE

LINE OF BOLTS TO BEAM WES LINE OF BOLTS TO BEAM WEB.

FIGURE 36. SINGLE LINE OF BOLTS TO SUPPORTING MEMBER

i a ee ee s

© ANGLECLEAT CONNECTION 6.7 Recommended design model—

Single ange clest—Summary of

Sesign checks

Design |s based on determining Vax, the design capacity of the connection, which is the

‘minimum ofthe design eapaciios eV, VV Ver Vs Vm Ve.

‘The design requirments then Vax V* (design shear force),

From AS 4100 Clause 9.1.4({,) (Rf. this connection must be designed fer @ minimum

‘Sesign shear fores of 40 KN, of 0.15» member design shear capacly, whichever isthe lesser,

‘Summary of checks—Single angl cleat (Re. 6)

DESIGN CHECK NO. + — Detatingtimtations

DESIGN CHECK NO. 2 — Design capecly of bots supporting member

DESIGN CHECK NO. 3 — Design capacity of tots o supported member

DESIGN CHECK NO. 4 — Design capacty of anole cleat (Shear, bending lock shear)

DESIGN CHECK NO, 5 — Design capaciy of supported momber (Shear—Uncaped or coped)

DESIGN CHECK NO.6 —Design capacity o! supported member (Block shear—Coped

section)

DESIGN CHECK NO. 7 — Design capacity of supperied member (Bending of coped section}

DESIGN CHECK NO. 8 — Beam rotation check

DESIGN CHECK HO. © ~ Local stability of coped supnered member

DESIGN CHECK NO, 10— Local capac of suppertng member

The design capacity tables in this Simple Connections DCTS, V3 are based on DESIGN

(CHECKS 1 to 6 inclusive, DESIGN CHECKS 7 1010 must be cari out in aon,

e Fin foes acta te

6 ANGLECLEAT CONNECTION 6.8. Configuration C—Singleanalo

SiatSnate eae

Supported member—Design TABLE 36

Eecoinael ANGLE CLEAT DESIGN CAPACITY TABLE-CONTIOURATION ¢