Professional Documents

Culture Documents

Valve Seat Material Guide PDF

Uploaded by

Anonymous KpVxNXs0 ratings0% found this document useful (0 votes)

30 views1 pageOriginal Title

Valve Seat Material guide.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

30 views1 pageValve Seat Material Guide PDF

Uploaded by

Anonymous KpVxNXsCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

MODENTIC

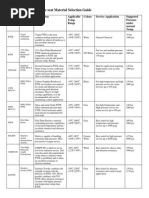

Valve Seat Material Selection Guide

Valve Seat Material Selection Guide :

SEAT

CODE

APPLICABLE

TEMP. RANGE COLOR

SERVICE

APPLICATION

SUGGESTED

PRESSURE

UNDER NORMAL

TEMP.

Virgin PTFEis the most common sealing material

and is suitablefor almost all media as it has excelent

chemical resistance.

-45 C~160 C

White

(-49 F~320 F)

General Chemical

70 bar

1000 psi

15% Glass Filled

Reinforced PTFE

15% Glass Filled Reinforced PTFEchemical

resistance is compatible to PTFEand improved

cycle life and greater pressure temperature rating

For low and medium

-45 C~180 C

Off-White pressure service for steam

(-49 F~356 F)

service up to 150 psig

TFM1600

Modified PTFE

(PFA & PTFE)

Second Generation PTFE,offers better creep. Lower

-57 C~180 C

coefficient of friction provides lower torque values

White

(-70

F~356 F )

and resist deformation. This is excellent application

Ideal for application

requiring higher purity

such as semi-conductor

140 bar

2000 psi

CTFE

MG1241

Carbon Graphite

Reinforced PTFE

Carbon Graphite Reinforced PTFEan excellent seat

material for steam and thermal services and having

good abrasion resistance.Due to its high cycling

capabilities, it is the reccomended soft seat for

modulating control application.

-45 C~200 C

Black

(-49 F~392 F)

For high temperature and

high pressure service for

steam service up to 450

psig

140 bar

2000 psi

MS02

MG1431

MS02 Filled PTFE

Glass and Metal Oxide PTFEfilled withstand

pressure than CTFE.Good resistance under load

and not reccomended for foodstuff.

-45 C~180 C

Grey

(-49 F~356 F)

For high temperature and

high pressure service for

steam service up to 450

psig

140 bar

2000 psi

PEEK

Poly Ether Keton

Poly Ether Keton a material which outstanding

pressure capabilities at elevated temperature and

has excellent chemical and abrasion resistance

-45 C~260 C

Grey

(-49 F~500 F)

Best suited for high

temperature and pressure

service up to 3000 psig.

400 bar

5000 psi

DELRIN

Dupont's Acetal

Homopolymer

(Delrin)

Delrin is capable of handling extremely high

pressure. Must not used for oxygen service.

-40 C~80 C Creamy

(-40 F~176 F) White

Best suited for high

Pressure service up to

6000 psig

425 bar

6000 psi

UHMW-PE

Ultra High

Molecular Weight

Polyethylene

UHMW-PEis ideal for use in low level radiation

service. This seat also meets the requirements of the -30 C~80 C

(-22 F~176 F)

tobbaco industry where PTFEis prohibited and its

offers an excellent resistance to abrasion medium.

Best suited for tobbaco

duty and abrasion

resistance

350 bar

5000 psi

SS/PTFE

Stainless Powder

PTFE

Stainless Powder is combines the strength of metal

with the lubricity of PTFE.50% SS316 powder

-28 C~220 C

combines with 50% PTFEoffers abrasion resistance

Grey

(-18

F~428 F)

of metal with higher pressure and temperature rating

than RTFE.

Best suited for abrasion

resistance and control

steam application

150 bar

2130 psi

MATERIAL

DESCRIPTION

PTFE

Virgin

Polytetrafluoroethylene

RTFE

White

140 bar

2000 psi

You might also like

- TECHLOK Clamp Connector Technical WebversionDocument32 pagesTECHLOK Clamp Connector Technical WebversionAndresNo ratings yet

- Torque FlexitallicDocument2 pagesTorque FlexitallicLuis Arturo Ramirez Esteban100% (1)

- Valve Seat Selection GuideDocument4 pagesValve Seat Selection Guideim4uim4uim4uNo ratings yet

- Seat Material Selection in Ball ValvesDocument2 pagesSeat Material Selection in Ball Valvescoolguy12345No ratings yet

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection GuideHo Minh VietNo ratings yet

- Seat Leakage Article Valve WorldDocument2 pagesSeat Leakage Article Valve WorldjshadwanNo ratings yet

- Valve Selection Guide: - ContentsDocument12 pagesValve Selection Guide: - ContentsAnonymous R23prjoKnoNo ratings yet

- Products Valves Sanitary PBM Series 9, 2 WayDocument40 pagesProducts Valves Sanitary PBM Series 9, 2 Waydingobk1No ratings yet

- DAC-REQ-08: Accreditation Requirements of Inspection Bodies For Pressure EquipmentDocument21 pagesDAC-REQ-08: Accreditation Requirements of Inspection Bodies For Pressure EquipmentPmohamedFazilNo ratings yet

- MuellerDocument24 pagesMuellerAhmad NasserNo ratings yet

- File-1452328935 DBBDocument2 pagesFile-1452328935 DBBSalman100% (1)

- To Rerate or Not To RerateDocument6 pagesTo Rerate or Not To ReratekblaxtonNo ratings yet

- Global Valve & Controls: Depend On Us, We Can Handle The PressureDocument4 pagesGlobal Valve & Controls: Depend On Us, We Can Handle The PressurealeeimeranNo ratings yet

- Flow Tek C4700 Series Cryo Ball ValveDocument8 pagesFlow Tek C4700 Series Cryo Ball ValveDanielle JohnsonNo ratings yet

- Shell and Tube Ref - AnandDocument6 pagesShell and Tube Ref - Anand7761430No ratings yet

- Lateral Tee 16'' Sch. 20 With Reinforcement Rev 01Document1 pageLateral Tee 16'' Sch. 20 With Reinforcement Rev 01HarryNo ratings yet

- Triple-Offset Butterflyvalves PDFDocument8 pagesTriple-Offset Butterflyvalves PDFDiwakar NigamNo ratings yet

- Valve and Pipeline Design Notes - Part 1Document29 pagesValve and Pipeline Design Notes - Part 1vikky123100% (1)

- 32 Samss 031 PDFDocument9 pages32 Samss 031 PDFFlorin Daniel AnghelNo ratings yet

- Safety ValvesDocument3 pagesSafety ValvesGiovanni LerasNo ratings yet

- 01 Saip 38Document14 pages01 Saip 38Arjun RawatNo ratings yet

- Needle ValveDocument8 pagesNeedle ValveMuhammad Chilmi100% (1)

- 316 316L 317L Spec SheetDocument3 pages316 316L 317L Spec SheetLinnie McleodNo ratings yet

- Valves 101: Gobind KhianiDocument56 pagesValves 101: Gobind Khianikongara_inst1118No ratings yet

- BP GS162-1 Valves PDFDocument24 pagesBP GS162-1 Valves PDFMohd Khairul100% (1)

- API 660 Vs TEMADocument2 pagesAPI 660 Vs TEMAloqNo ratings yet

- Valve Selection GuideDocument5 pagesValve Selection Guiderajeshn1100% (1)

- Retriever Manual PDFDocument49 pagesRetriever Manual PDFJanneth Herrera FloresNo ratings yet

- 10 Types of ValvesDocument7 pages10 Types of ValvesLamar TwitchNo ratings yet

- TD42 Thermodynamic Steam Trap-Installation Maintenance Manual PDFDocument12 pagesTD42 Thermodynamic Steam Trap-Installation Maintenance Manual PDFAnonymous FZs3yBHh7No ratings yet

- LESER - Pilot Operated Safety Valve From LESERDocument2 pagesLESER - Pilot Operated Safety Valve From LESERAgis Rijal AtmawijayaNo ratings yet

- L&T Process Ball Valves PDFDocument16 pagesL&T Process Ball Valves PDFUnna MalaiNo ratings yet

- Valve HandbookDocument52 pagesValve Handbookshivam100% (1)

- Seamless Carbon Steel Boiler Tubes For High-Pressure ServiceDocument2 pagesSeamless Carbon Steel Boiler Tubes For High-Pressure ServiceChandra ClarkNo ratings yet

- CARGAS B31.4 Sostenidas Ocasionales Constructivas Transitorias Valores de Esfuerzos PermisiblesDocument6 pagesCARGAS B31.4 Sostenidas Ocasionales Constructivas Transitorias Valores de Esfuerzos PermisiblesFREDYTOAPANTANo ratings yet

- MSDS 001139212Document7 pagesMSDS 001139212danny_sosa_3No ratings yet

- UL/FM Gate Valves - Firewall Valve Model F-507-W OS&Y Gate Valve Resilient Wedge300 PSI PDFDocument1 pageUL/FM Gate Valves - Firewall Valve Model F-507-W OS&Y Gate Valve Resilient Wedge300 PSI PDFAlyssa RiveraNo ratings yet

- LT Valves Triple Offset Butterfly ValvesDocument20 pagesLT Valves Triple Offset Butterfly ValvesamoldholeNo ratings yet

- Nondestructive TestingDocument27 pagesNondestructive Testingapi-3764139No ratings yet

- Is Thicker Gasket Material Better Than ThinnerDocument2 pagesIs Thicker Gasket Material Better Than ThinnerSteven LiparotoNo ratings yet

- SWI Products MetalDocument21 pagesSWI Products MetalPrasanth PrasadNo ratings yet

- Plug ValvesDocument14 pagesPlug Valvesashish.mathur1100% (1)

- HIC Requirement VVVimpDocument6 pagesHIC Requirement VVVimpSenthil KumarNo ratings yet

- Individual Solutions: Air-Cooled Heat ExchangersDocument22 pagesIndividual Solutions: Air-Cooled Heat ExchangersMiguel SoteloNo ratings yet

- Introduction To Different Types of Strainers PDFDocument7 pagesIntroduction To Different Types of Strainers PDFRalyn BasisNo ratings yet

- MSS SP 6Document6 pagesMSS SP 6d1a9v8i3d100% (1)

- Paper 4 Part 1 Mock Paper PDFDocument11 pagesPaper 4 Part 1 Mock Paper PDFNikhilNo ratings yet

- Chemical Resistance GuideDocument32 pagesChemical Resistance GuidevsvineeshNo ratings yet

- The A To Z of Valve MaterialsDocument4 pagesThe A To Z of Valve Materialscool47guy09No ratings yet

- Teflone (PTFE) Seat SuggetionDocument1 pageTeflone (PTFE) Seat SuggetionBharat PrajapatiNo ratings yet

- Valve Seat Material Selection GuideDocument1 pageValve Seat Material Selection Guidemurtuza5No ratings yet

- 5L E45 Purch Guidelines R0 201306Document1 page5L E45 Purch Guidelines R0 201306Ansuman KalidasNo ratings yet

- Valve Seat Material GuideDocument1 pageValve Seat Material GuidewawanNo ratings yet

- Valve Seat Seal Selection GuideDocument2 pagesValve Seat Seal Selection Guideecovarrubias1No ratings yet

- Valve Seat Material Guide PDFDocument1 pageValve Seat Material Guide PDFmolinachNo ratings yet

- Engineering Bulletin: Rev. 10/07 Page 1 of 4Document5 pagesEngineering Bulletin: Rev. 10/07 Page 1 of 4Iván López PavezNo ratings yet

- Valve Seat Seal Selection GuideDocument4 pagesValve Seat Seal Selection GuideDhim131267No ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typescoolguy12345No ratings yet

- Seats and Seals Selection Guide: Share ThisDocument4 pagesSeats and Seals Selection Guide: Share ThisArjed Ali ShaikhNo ratings yet

- Valves Eat Seal Materials and Service TypesDocument3 pagesValves Eat Seal Materials and Service Typess.mladinNo ratings yet

- Ball Valve SeatDocument2 pagesBall Valve Seatmrkadu_61No ratings yet

- Non-Intrusive Magnetic Pig SignallerDocument2 pagesNon-Intrusive Magnetic Pig SignallerAndresNo ratings yet

- 1990 Palmer Upheaval BucklingDocument10 pages1990 Palmer Upheaval Bucklingppyim2012100% (1)