Professional Documents

Culture Documents

Elektronikon Mkiv User Guide: Elektronikon Mkiv Modbus: Atlas Copco Airpower NV

Uploaded by

hectorpazosOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Elektronikon Mkiv User Guide: Elektronikon Mkiv Modbus: Atlas Copco Airpower NV

Uploaded by

hectorpazosCopyright:

Available Formats

Atlas Copco Airpower NV

ELEKTRONIKON MkIV

User Guide : Elektronikon MkIV Modbus

Name

Secr. Class

User Guide : Elektronikon MkIV Modbus

1102 K/1

Detail

Owner

PC

Edition

01

Modified from

Family

Written By

Design Checked

Product Checked

AII

print date

31/01/03

Compare

Replaces

Approved

Date

Designation

CTE

19/07/2002

9820 3582 02

User Guide : Elektronikon MkIV Modbus

Document Information

Edition

00

01

..

Date

01/08/2002

14/01/2003

Description

First edition

Second edition

Added exception code Command Refused (07)

Added exception code Reprogrammed Refused (06)

Author

CTE

CTE-PDJ

ii

User Guide : Elektronikon MkIV Modbus

Preface

This document describes how to implement a Modbus connection to the Elektronikon MkIV compressor controller

network.

iii

User Guide : Elektronikon MkIV Modbus

Table of Contents

1. The Physical set-up ___________________________________________________________6

1.1

Modbus & the Network __________________________________________________________6

1.2

The Module (Combox-S) _________________________________________________________8

1.3

LEDs_________________________________________________________________________9

1.4

Connector lay-out ______________________________________________________________10

1.4.1

Power Supply _____________________________________________________________________

1.4.2

LAN connector ____________________________________________________________________

1.4.3

Modbus connection_________________________________________________________________

Pin Assignment Modbus _________________________________________________________________

1.5

RS485 connections _____________________________________________________________11

1.5.1

1.5.2

1.5.3

1.6

10

10

10

10

Modbus with MKIV________________________________________________________________ 11

Modbus with MKIV and MKIII_______________________________________________________ 12

Modbus with MKIV and Other Equipment ______________________________________________ 13

Software downloading __________________________________________________________14

2. Modbus protocol implementation _______________________________________________15

2.1

Supported modbus specification _________________________________________________15

2.2

Supported Modbus functions ____________________________________________________15

2.3

Modbus registers and coils for Data Reading _______________________________________16

2.3.1

System Overview __________________________________________________________________

2.3.1.1 General Compressor Condition______________________________________________________

2.3.1.2 Detailed General Compressor Condition ______________________________________________

2.3.2

Inputs & Outputs___________________________________________________________________

2.3.2.1 Analogue Inputs Sensors & Calculated ______________________________________________

2.3.2.2 Registers _______________________________________________________________________

2.3.2.3 Status register Interpretation ______________________________________________________

2.3.2.4 Value register Interpretation ______________________________________________________

2.3.2.4.1 Pressure Input ________________________________________________________________

2.3.2.4.2 Temperature Input_____________________________________________________________

2.3.2.4.3 Vibration Input _______________________________________________________________

2.3.2.4.4 Level Input __________________________________________________________________

2.3.2.4.5 Conductivity Input ____________________________________________________________

2.3.2.4.6 SPM Input___________________________________________________________________

2.3.2.4.7 Current Input_________________________________________________________________

2.3.2.4.8 Speed Input __________________________________________________________________

2.3.2.5 Digital (Voltage free contacts) Inputs _________________________________________________

2.3.2.6 Status register Interpretation ______________________________________________________

2.3.2.7 Value register Interpretation ______________________________________________________

2.3.2.8 Digital (Relays) Output (Not Yet Implemented)_________________________________________

2.3.3

Counters _________________________________________________________________________

2.3.3.1 Compressor Counters _____________________________________________________________

2.3.3.2 Multi Compressor Controller Counters________________________________________________

2.3.4

Special __________________________________________________________________________

2.3.4.1 VSD motor data _________________________________________________________________

2.4

Modbus registers and coils for parameters change __________________________________24

2.4.1

2.4.2

2.4.3

2.5

16

16

17

18

18

18

19

19

19

19

19

19

19

19

20

20

20

20

20

20

21

21

22

23

23

Load/Unload Pressure Band change ____________________________________________________ 24

VSD Setpoint change _______________________________________________________________ 24

MCC Pressure Band change __________________________________________________________ 25

Modbus registers and coils for remote control ______________________________________26

2.5.1

Control Commands _________________________________________________________________ 26

2.5.1.1 Compressor Control Mode Selection _________________________________________________ 26

iv

User Guide : Elektronikon MkIV Modbus

2.5.1.2 Compressor Commands ___________________________________________________________ 26

2.5.2

VSD external setpoint/speed control __________________________________________________ 27

2.5.3

Reset Initial Settings (Analogue , Digital , Counter Inputs) __________________________________ 27

2.6

Communication examples _______________________________________________________28

2.6.1

2.6.2

2.6.3

2.6.4

Analogue - Digital Inputs ____________________________________________________________

Commands description ______________________________________________________________

Present System Status _______________________________________________________________

Loopback Test ____________________________________________________________________

28

29

29

30

3. Exception Responses _________________________________________________________31

3.1

Function Code Data Field______________________________________________________31

3.2

Exception Codes _______________________________________________________________31

3.3

Example______________________________________________________________________31

User Guide : Elektronikon MkIV Modbus

1. The Physical set-up

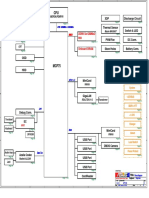

1.1 Modbus & the Network

In the Elektronikon MkIV system all compressors in an installation can be connected by a data and/or control

network. This is done according the Compressor Network Cabling Instruction (9820 3585 00). This instruction

explains what connectors and cables should be used to interconnect the different compressors/controllers in the

network. Basically this is a CAN-based local network.

In order to setup a modbus connection to one or several of the compressors in this network, a special module as to

be inserted in this network.

This module will then behave as a modbus-proxy that allows access to all compressors in the network, whereby

each compressor has its own modbus address (proxy concept).

-6-

User Guide : Elektronikon MkIV Modbus

Node Id 1

Node Id 2

Node Id 5

Node Id 11

Atlas Copcos

Modbus-Proxy Server

Node Id 1 2 5

Modbus 4 8 10

Customer PLC

Modbus

In this drawing the proxy is used to access the compressors with Node Id 1,2 and 5, by using the modbus addresses

4,8 and 10. (This proxy-conversion table has to be set with proper tools). The Node Id the Proxy itself if 11 on the

CAN side.

-7-

User Guide : Elektronikon MkIV Modbus

1.2 The Module (Combox-S)

For the modbus connection a so-called Combox-S module has to be used (AC n 19000711 41). This is a general

purpose serial communication module. By downloading the correct software in it, it will perform the modbus proxy

function.

Because this is a general purpose module, not all connections/switches will be used for this connection.

For modbus the following will be used

10x14 :

to connect a 24Vac supply

2 top address switches (LAN)

to set the Atlas Copco Lan address (= CAN side address !!), the Fieldbus switches are NOT used,

because the Modbus addresses (proxy) are defined by software and programmed with an external (PC)

software.

10x1:

to connect to the compressor network (CAN)

10x16 :

to connect the RS485 modbus line

The other connectors/switches are NOT used for this application

Application

LEDs

24Va

Node Id

CAN side

Compr.

Network

-8-

Modbus

Network

System

LED

User Guide : Elektronikon MkIV Modbus

The module itself can be mounted on a DIN-rail inside one of the compressor cubicles, or on a separate location.

Before installation check the available power of the 24Vac transformer, if connecting to an already supplied

transformer inside a cubicle..

1.3 LEDs

The module also has a number of LEDs on type. They are used as follows :

System LED

Blinking : no program loaded or not running

Lit continuously : program running OK

Application LEDs from left to right

1.

not used

2.

not used

3.

CAN receive (Combox receives CAN message)

4.

CAN transmit (Combox transmits CAN message)

5.

Modbus receive (Combox receives Modbus message)

6.

Modbus transmit (Combox transmits Modbus message)

7.

not used

8.

not used

9.

not used

10. Modbus Mode

11. not used

-9-

User Guide : Elektronikon MkIV Modbus

1.4 Connector lay-out

1.4.1 Power Supply

This is a two pole Wago (type ) connector. Power supply is 24Vac, 10VA

1.4.2 LAN connector

Connect here the cable of the compressor network, according AC instruction : Compressor Network Cabling

Instruction (9820 3585 00).

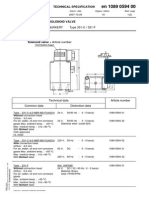

1.4.3 Modbus connection

The module supports the RS485A variant of modbus, with the following pin-layout and termination requirements as

specified

Pin Assignment Modbus

Sub-D 9 pole female

Pin

6

1

1

2

3

4

5

6

7

8

9

Function

GND

Reserved

TxD/RxD +

RTS

GND*

+5V*

Reserved

TxD/RxD Reserved

* galvanic isolated

- 10 -

User Guide : Elektronikon MkIV Modbus

1.5 RS485 connections

1.5.1 Modbus with MKIV

Customer, Modbus Master

Elektronikon MkIV, 1900 0711 41

8

R=120 Ohm

R=120 Ohm

RS-485 ground

1

10x16

- 11 -

User Guide : Elektronikon MkIV Modbus

1.5.2 Modbus with MKIV and MKIII

Customer, Modbus Master

Elektronikon MkIV, 1900 0711 41

8

R=120 Ohm

RS-485 ground

1

10x16

Elektronikon MkIII, 1900 0701 82

8

R=120 Ohm

3

1

7x15

3

7x16

- 12 -

User Guide : Elektronikon MkIV Modbus

1.5.3 Modbus with MKIV and Other Equipment

Customer, Modbus Master

Elektronikon MkIV, 1900 0711 41

8

R=120 Ohm

RS-485 ground

1

10x16

Other Modbus equipment

R=120 Ohm

- 13 -

User Guide : Elektronikon MkIV Modbus

1.6 Software downloading

Before the module can be used for a modbus connection the appropriate software must be loaded. This can be done

by AC Service personal with the AC Field Downloading Program (FDP).

With this program it is also possible to program the modbus/CAN address conversions.

After programming , put power off/on of the combox-S to activate the modbusaddresses.

Before powering the Combox S module , check all cables.

- 14 -

User Guide : Elektronikon MkIV Modbus

2. Modbus protocol implementation

2.1 Supported modbus specification

The Combox-S when downloaded with the proper modbus software supports the following modbus- variant

RTU mode of transmission

Coding system : binary

Mode : half duplex ( RS485 )

Number of start bits : 1

Number of data bits : 8

Baudrate : 300,600,1200,2400,4800,9600*,19200*,38400

Parity control : even*,odd*,none *

Number of stop bits : 1 or 2

Error checking : CRC-16

* These parameters are defined during downloading of the controller.

Frame synchronization in the RTU mode is done by simulating a synchronous message. The slave device monitors

the elapsed time between receipt of characters. If three character time elapsed without a new character, then the

device assumes that the message is completed and the next byte will be the address

The message frame format is following :

T1 T2 T3

ADDRESS

Message body

CRC

T1 T2 T3

2.2 Supported Modbus functions

The Elektronikon MkIV modbus implemenentation supports the following message type , depending on the type of

data involved (see details below)

Function 01 : read coil status

Function 03 : read holding register

Function 06 : preset single register

Function 08 : loop back test

- 15 -

User Guide : Elektronikon MkIV Modbus

2.3 Modbus registers and coils for Data Reading

2.3.1 System Overview

2.3.1.1 General Compressor Condition

Function to be used : Read Coil Status (01)

Modbus Coil

0001

0002

0003

0004

0005

0006

0007

0008

0009

0010

Status Information

Stopped (=0) / Running (=1)

Unload (=0)/ Load (=1)

General Warning

General Shutdown-Warning

General Shutdown

General Service

General Start Failure

Emergency Stop

Manual (=0) /Automatic (=1)

Local (=0)/ Remote (=1)

Load/Unload

X

X

X

X

X

X

X

X

X

X

- 16 -

VSD

X

X

X

X

X

X

X

X

X

User Guide : Elektronikon MkIV Modbus

2.3.1.2 Detailed General Compressor Condition

Function to be used : Read Holding Register (03)

Modbus register

0401

0402

0403

0404

High Byte

Low Byte

CMS

COM

CS

CCM

GENERAL STATUS

CS_MCC

0

Parameter

General status

CCM

(Compressor Controller Mode)

CMS

(Compressor Mechanical State)

CS

(Compressor State)

Load Unload

CS MCC

(Compressor State)

MCC

CS

(Compressor State)

VSD

Bit

0

1

2

3

4

5

6

7

8

9

10

11

Pre Warning

General Warning

General Shutdown-Warning

General Shutdown

General Service

General Start Failure

Emergency Stop

Manual/Automatic (COS1)

Local/Remote

Timer Not Active/Active

Pre-warning Service Running Hours

Pre-warning Service Accumulated M3

CCM2a

CCM2b

CCM3a

CCM3b

CCM4a

CCM4b

CCM4c (Speed control )

CCM4d (MCC)

No Valid Data

Stopped

Unloaded

Loaded

No Valid Data

A

.

V

No Valid Data

A

D

No Valid Data

A

00

10

01

11

02

12

22

32

00

01

02

04

0

1

.

22

0

1

.

4

0

1

.

22

Very Important Note !!!!!.

When CS is 0 or CMS is 0 ALL data for that compressor is not Valid. Check Cables .

When there is bad communication , only the detailed general compressor condition will be set to 0.

- 17 -

User Guide : Elektronikon MkIV Modbus

2.3.2 Inputs & Outputs

2.3.2.1 Analogue Inputs Sensors & Calculated

The Elektronikon MkIV supports up to 55 analogue sensor inputs and 5 additional analogue calculated (virtual)

inputs. Each input has a value and a status register assigned.

The contents of these registers depend on the actual type of sensor that is connected. This can be different for every

type of compressor. E.g. standard compressors may have 1 to 4 pressure inputs, 1 to 10 temperature inputs, up to 7

SPM inputs, Also, features and options may increment the number of sensors that are actually installed on your

compressor.

Before using the modbus system it is therefore required to find out what sensors are really connected to your

compressors. This can e.g. be done with the FDP program. This program has a function that lists the sensors +

modbus registers for a selected compressor type (including features and options).

Once the list of sensors is known, the contents of the registers can be interpreted as described below.

2.3.2.2 Registers

Sensor Inputs

Function to be used : Read Holding Register (03)

Modbus

register

Information

0001

0002

0003

0004

0005

0006

0109

0110

Analogue Input

Analogue Input

Analogue Input

Analogue Input

Analogue Input

Analogue Input

Analogue Input

Analogue Input

1 Status

1 Value

2 Status

2 Value

3 Status

3 Value

55 Status

55 Value

Calculated (virtual) Inputs

Function to be used : Read Holding Register (03)

Modbus

register

Information

0111

0112

0113

0114

0115

0116

0117

0118

0119

0120

Calculated Input

Calculated Input

Calculated Input

Calculated Input

Calculated Input

Calculated Input

Calculated Input

Calculated Input

Calculated Input

Calculated Input

1 Status

1 Value

2 Status

2 Value

3 Status

3 Value

4 Status

4 Value

5 Status

5 Value

- 18 -

User Guide : Elektronikon MkIV Modbus

2.3.2.3 Status register Interpretation

High order byte = 00

Low order byte = Input Status

The Input Status must be interpreted as Binary data (bit coded).

Each part ( bit ) of the data ( byte ) is indicating a specific item that applies on the Input function. In the following

table, an overview is given of all bits together with the corresponding meaning and interpretation.

Function

Description

Bit 7

Input

Set/Not Set

Bit 6

Sensor

Error

Bit 5

Permissive

Start

Bit 4

Service

Bit 3

Shutdown

Bit 2

Shutdown

Warning

Bit 1

Warning

Bit 0

PreWarning

Bit 1

Bit 0

Set

Not Set

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

2.3.2.4 Value register Interpretation

This depends on the type of inputs.

2.3.2.4.1 Pressure Input

The Pressure Input Value is a 2 byte integer, and contains the actual reading in mbar (0.001 bar)

For negative values, standard 2-complement notation is used.

Example:

Value = 7040 decimal or 0x1B80 hexadecimal = 7.040 bar.

Value = -1000 decimal (2-complement) or 0xFC18 = -1.000 bar

For sensor error the value the value 32767 or 7FFF (hex) is returned.

On some high pressure compressors (with working pressures above 30 bar) a special Pressure Input can be defined

that returns data in cBar (0.01 bar) in stead of mBar.

2.3.2.4.2 Temperature Input

The Temperature Input Value is a 2 byte integer, and contains the actual reading in 0.1C

For negative values, standard 2-complement notation is used.

Example:

Value = 855 decimal or 0x0357 hexadecimal = 85.5 C

Value = -250 decimal (2-complement) or 0xFF06 = -25.0 C

For sensor error the value the value 32767 or 7FFF (hex) is returned.

2.3.2.4.3 Vibration Input

tbd

2.3.2.4.4 Level Input

tbd

2.3.2.4.5 Conductivity Input

tbd

2.3.2.4.6 SPM Input

The SPM Input Value is a 2 byte register that must be seen as 2 x 1 byte.

Byte 1 : carpet value (in dB)

Byte 2 : peak value (in dB)

Example:

Value = 0x1120 = > carpet value = 0x11, peak value = 0x20

For sensor error the value the value 0xFFFF (hex) is returned.

SPM values cannot be negative

- 19 -

User Guide : Elektronikon MkIV Modbus

2.3.2.4.7 Current Input

tbd

2.3.2.4.8 Speed Input

tbd

2.3.2.5 Digital (Voltage free contacts) Inputs

The Elektronikon MkIV supports up to 18 digital (voltage free) inputs. Each input has a value and a status

register assigned.

The contents of these registers is for digital inputs always the same, if the input is used. Before using the modbus

system it is therefore required to find out what inputs are used on your compressors. This can e.g. be done with the

FDP program. This program has a function that lists the digital inputs + modbus registers for a selected compressor

type (including features and options).

Once the list of inputs is known, the contents of the registers can be interpreted as described below.

Function to be used : Read Holding Register (03)

Modbus

register

Information

0201

0202

0203

0204

0205

0206

0241

0242

Digital Input

Digital Input

Digital Input

Digital Input

Digital Input

Digital Input

Digital Input

Digital Input

1 Status

1 Value

2 Status

2 Value

3 Status

3 Value

21 Status

21 Value

2.3.2.6 Status register Interpretation

High order byte = 00

Low order byte = Input Status

The Input Status must be interpreted as Binary data.

Each part ( bit ) of the data ( byte ) is indicating a specific item that applies on the Input function. In the following

table, an overview is given of all bits together with the corresponding meaning and interpretation.

Function

Description

Bit 7

Input

Set/Not Set

Bit 6

Sensor

Error

Bit 5

Permissive

Start

Bit 4

Service

Bit 3

Shutdown

Bit 2

Shutdown

Warning

Bit 1

Warning

Bit 0

PreWarning

Value 1

Value 0

Set

Not Set

Active

Not Active

Active

Not Active

Active

Not Active

Active

Not Active

Not used

Not used

Active

Not Active

Active

Not Active

2.3.2.7 Value register Interpretation

Value: 00

Value: 01

Digital input is Open

Digital input is Closed

2.3.2.8 Digital (Relays) Output (Not Yet Implemented)

tbd

- 20 -

User Guide : Elektronikon MkIV Modbus

2.3.3 Counters

2.3.3.1 Compressor Counters

The Elektronikon MkIV supports up to 28 counters (32-bit counters). Each input as 2 x 16bit value register

assigned, to allow a 32-bit value to be read.

Not all types of compressors use all types of counters. The list in this chapter provides an overview of the used

counters / compressor type, and the units that are used

Function to be used : Read Holding Register (03)

Modbus

registers

Information

Units

Load/Unload

VSD

0301+0302

0303+0304

0305+0306

0307+0308

0309+0310

0311+0312

0313+0314

0315+0316

0317+0318

0319+0320

0321+0322

0323+0324

Running Hours

Loaded Hours

Motor Starts

Module Hours

Accumulated Volume

Load cycle

VSD 0-20% RPM

VSD 20-40% RPM

VSD 40-60% RPM

VSD 60-80% RPM

VSD 80-100% RPM

Not yet used

s

s

number

s

1000 m

number

%

%

%

%

%

X

X

X

X

X

-

X

-/X *

X

X

-/X *

X

X

X

X

X

0355+0356

Not yet used

yes, if VSD has unloading cycle (e.g. Z-VSD)

Interpretation of data in the registers

Example Running Hours

301

302

Higher Byte Lower Byte

B4

B3

B2

B1

DWORD : Running Hours B4 B3 B2 B1

00 2C 93 45

2921285 sec 811 hrs

- 21 -

User Guide : Elektronikon MkIV Modbus

2.3.3.2 Multi Compressor Controller Counters

The Elektronikon MkIV contains 4 counters (32-bit counters) to perform the MCC load balancing between up to 4

compressors. Each such counter as 2 x 16bit value register assigned, to allow a 32-bit value to be read.

Only units where the MCC master function is active contain real data for this registers.

Function to be used : Read Holding Register (03)

Modbus registers

Information

unit

501+502

503+504

505+506

504+507

Compressor 1 counter

Compressor 2 counter

Compressor 3 counter

Compressor 4 counter

s

s

s

s

Data interpretation is the same as for the other counters

- 22 -

User Guide : Elektronikon MkIV Modbus

2.3.4 Special

2.3.4.1 VSD motor data

The Elektronikon MkIV on VSD units contains some important data about the motor speed.This data can be read

over the modbus system.

Function to be used : Read Holding Register (03)

Modbus registers

0801

0802

0803

0804

Information

Required motor speed

Actual motor speed motor 1

Actual motor speed motor 2

Actual motor speed motor 3

unit

rpm

rpm

rpm

rpm

Each register contains a 16-bit value that is directly readable as the equivalent rpm.

- 23 -

User Guide : Elektronikon MkIV Modbus

2.4 Modbus registers and coils for parameters change

2.4.1 Load/Unload Pressure Band change

It is possible to change the operating pressure band inside the Elektronikon MkIV, or to switch between the two

available pressure bands. These registers are only valid for Load/Unload compressors

Functions to be used :

For reading : Read Holding Register (03)

For writing :Preset Single Register (06)

Modbus

registers

1061

1062

1063

1064

1065

Description

Pressure Band Selection

Loading pressure band 1

Unloading Pressure band 1

Loading pressure band 2

Unloading Pressure band 2

Pressure Band Selection : 1 = band 1, 2 = band 2

Attention : when writing values the following relations should be maintained :

Loading pressure < unloading pressure (per band)

Loading pressure should not be below the minimum setting that was factory defined.

Unloading pressure should not be above the maximum setting that was factory defined.

Values not fulfilling this will be refused.

2.4.2 VSD Setpoint change

It is possible to change the operating set point inside the Elektronikon MkIV, or to switch between the two available

pressure set points. These registers are only valid for VSD compressors

For reading : Read Holding Register (03)

For writing :Preset Single Register (06 )

Modbus

address

1051

1052

1053

Description

Setpoint Selection

Setpoint 1

Setpoint 2

Setpoint Selection : 1 = Setpoint 1, 2 = Setpoint 2

The set point must be within the limits that are factory defined for your machine type.

Values not fulfilling this will be refused by the MKIV.

- 24 -

User Guide : Elektronikon MkIV Modbus

2.4.3 MCC Pressure Band change

In Elektronikons where the MCC master function is active it is possible to change the operating pressure band for

this master, or to switch between the two available pressure bands.

Functions to be used :

For reading : Read Holding Register (03)

For writing :Preset Single Register (06 or 16 for multiple registers)

Modbus

registers

1081

1082

1083

1084

1085

Description

MCC Pressure Band Selection

MCC Loading pressure band 1

MCC Unloading Pressure band 1

MCC Loading pressure band 2

MCC Unloading Pressure band 2

Pressure Band Selection : 0 = band 1, 1 = band 2

Attention : when writing values the following relations should be maintained :

Loading pressure < unloading pressure (per band)

Values not fulfilling this will be refused by the MKIV.

- 25 -

User Guide : Elektronikon MkIV Modbus

2.5 Modbus registers and coils for remote control

2.5.1 Control Commands

2.5.1.1 Compressor Control Mode Selection

The Elektronikon MkIV has a number of control modes that define the behaviour of a compressor in relation to

external inputs (pressure reading, start/stop commands,).

Each mode has a main type (= number 1 to 4), and a sub-type (a,b,c,..). The number of sub-types is different for

each main type.

When Modbus has to be used to control a compressor the main type ust be set to 4 (=remote control over

communication line). This has to be done through the display, select LAN Control. By default the compressor

will then enter the 4a mode.

Through Modbus it is now possible to activate the other sub-types.

Functions to be used : writing method: Preset Single Register Function 06

Modbus address

2002

Value to write

1

2

3

Description

Switch from 4a or 4c to 4b

Switch from 4b or 4c to 4a

Switch from 4a or 4b to 4c

Accepted in mode

4a 4c

4b

4a 4b

Note

Mode 4a : remote control of start/stop but pressure control is done by the controller

Mode 4b : remote control of start/stop and pressure control is done from remote (Supervisory control) (also for

VSD setpoint control)

Mode 4c : remote control of start/stop with external speed (only vsd) speed control)

2.5.1.2 Compressor Commands

The commands that are described here are only available in the defined Compressor Control Modes.

Carefully consult the control concept of the compressors before using them.

Functions to be used : writing method: Preset Single Register Function 06

Modbus address

2001

2004

Value to write

1

2

3

4

5

6

7

1

2

Command

Start

Stop

Load

Unload

MCC Start System

MCC Stop System

MCC Local

Reset Shutdown

Reset Start Failures

- 26 -

Accepted in mode

4a / 4b

4a / 4b

4a / 4b

4b ( in 4a = Manual unload )

4a / 4d

4d

4d

In all Modes

In all Modes

User Guide : Elektronikon MkIV Modbus

2.5.2 VSD external setpoint/speed control

On VSD units extended external control is possible whereby either the main motor speed of the pressure set point is

directly controlled from remote over Modbus.

This can be done with the following Modbus registers

-> reading method: Read Holding Registers Function 03

-> writing method: Preset Single Register Function 06

Modbus

address

1071

1072

Description

External Setpoint

External Speed

2.5.3 Reset Initial Settings (Analogue , Digital , Counter Inputs)

-> writing method: Preset Single Register Function 06

Modbus

address

2101

Description

Reset Initial Settings

- 27 -

User Guide : Elektronikon MkIV Modbus

2.6 Communication examples

2.6.1 Analogue - Digital Inputs

-> reading method: Read Holding Registers Function 03

Example: read from Analogue input 1, Status and Value

Query

Field Name

Device Id Nr

Function

Starting Address High

Starting Address Low

Number of points High

Number of points Low

CRC

Example ( Hex)

04

03

00

00

00

02

C4 5E

Response

Field Name

Device Id Nr

Function

Byte Count

Data register 0001

Data register 0002

CRC

Example ( Hex)

04

03

04

00 80 Status

1D 15 ( = Value : 7505 mbar )

DF CA

Example: read from Digital input 1, Status and Value

Query

Field Name

Device Id Nr

Function

Starting Address High

Starting Address Low

Number of points High

Number of points Low

CRC

Example ( Hex)

22

03

00

C8

00

02

42 46

Response

Field Name

Device Id Nr

Function

Byte Count

Data register 0001

Data register 0002

CRC

Example ( Hex)

22

03

04

00 88 Status (Set , Shutdown)

00 00 ( Input Open )

68 DB

- 28 -

User Guide : Elektronikon MkIV Modbus

2.6.2 Commands description

-> writing method: Preset Single Register Function 06

Example: Send a Start command

Query

Field Name

Slave address

Function

Register Address High

Register Address Low

Preset Data High

Preset Data Low

CRC

Example ( Hex)

01

06

07

D0

00

01

Response

Field Name

Slave address

Function

Register Address High

Register Address Low

Preset Data High

Preset Data Low

CRC

Example ( Hex)

01

06

07

D0

00

01

2.6.3 Present System Status

-> reading method: Coil Status Function 01

Example: Read present compressor status ( = read 8 coils )

Query

Field Name

Slave address

Function

Starting Address High

Starting Address Low

Number of points High

Number of points Low

CRC

Example ( Hex)

01

01

00

00

00

08

3D CC

Response

Field Name

Slave address

Function

Byte Count

Data Coils 1 to 8

CRC

Example ( Hex)

01

01

01

00 ( Coils 1 to 8 are = 0 )

51 88

- 29 -

User Guide : Elektronikon MkIV Modbus

2.6.4 Loopback Test

Query

Field Name

Device Id Nr

Function

Starting Address High

Starting Address Low

Number of points High

Number of points Low

CRC

Example ( Hex)

04

08

00

00

A5

37

Response

Field Name

Device Id Nr

Function

Starting Address High

Starting Address Low

Number of points High

Number of points Low

CRC

Example ( Hex)

04

08

00

00

A5

37

- 30 -

User Guide : Elektronikon MkIV Modbus

3. Exception Responses

3.1 Function Code Data Field

In a normal response, the slave echoes the function code of the orginal query.

In an exception response 80hex is added to the function code.

At the same time an exception code is added in the Data Field.

3.2 Exception Codes

Code

01

Name

Illegal Function

02

Illegal Data Address

03

Illegal Data Value

06

Reprogramming Refused

07

Command Refused

08

Data Not Available

09

Illegal Command

Meaning

The function code received in the query is not

an allowable action for the slave.

The data address received in the query is not an

allowable address for the slave

A value contained in the query data field is not

an allowable value for the slave

Command Refused because previous command

was not yet executed

Command Refused because previous command

was not yet executed

Check communication cable between MKIV and

Combox-S .

An unknown command is being sent

3.3 Example

Example: read from Analogue input 1, Status and Value

Query

Field Name

Slave address

Function

Starting Address High

Starting Address Low

Number of points High

Number of points Low

CRC

Example ( Hex)

01

09 ( Wrong function, should be 03 )

00

00

00

02

5C 0A

Response

Field Name

Slave address

Function

Exception Code

CRC

Example ( Hex)

01

89 ( Exception reply )

01 ( Illegal Function in query )

86 50

- 31 -

You might also like

- Ingersoll Rand X-IRI Communications Gateway Operators ManualDocument81 pagesIngersoll Rand X-IRI Communications Gateway Operators ManualWilliam PachecoNo ratings yet

- 7 7000 Pamod 05eDocument18 pages7 7000 Pamod 05eJose LunaNo ratings yet

- Manual Irn 7-15 PDFDocument37 pagesManual Irn 7-15 PDFairmacmex100% (1)

- Airtelligence 2.0 Modbus Anbindung enDocument9 pagesAirtelligence 2.0 Modbus Anbindung enPiotrNo ratings yet

- IR Serv Software ManualDocument26 pagesIR Serv Software ManualWer Ad100% (1)

- Surescan SR Power Converter: Fault Investigation ManualDocument107 pagesSurescan SR Power Converter: Fault Investigation Manualfauzy syaeful100% (1)

- User Guide: Mk5 Gateway Module As Profibus InterfaceDocument27 pagesUser Guide: Mk5 Gateway Module As Profibus InterfaceErnesto Sta AnaNo ratings yet

- Manual ALUP FU EmotronDocument88 pagesManual ALUP FU EmotronfacebookszitykaNo ratings yet

- Es6 Version 2.33 and HigherDocument72 pagesEs6 Version 2.33 and HigherAchr FF100% (1)

- Mk5 Gateway Modbus User Guide en 294620700Document27 pagesMk5 Gateway Modbus User Guide en 294620700Ernesto Sta AnaNo ratings yet

- Original Operating Manual - SCC Compressors: Version 1.0 E - 28.05.2017Document104 pagesOriginal Operating Manual - SCC Compressors: Version 1.0 E - 28.05.2017lucasNo ratings yet

- RatioDocument31 pagesRatioRUN GONo ratings yet

- Many0915a.gb X-Iri Operators Manual 80445596 enDocument81 pagesMany0915a.gb X-Iri Operators Manual 80445596 enBen Schumacher100% (1)

- ABB Acs 600 - 2Document182 pagesABB Acs 600 - 2eddieipenzaNo ratings yet

- 3100 PDFDocument40 pages3100 PDFKabul Abdullah100% (1)

- Intellisys MODBUS RTU User ManualDocument82 pagesIntellisys MODBUS RTU User Manualromelmorera67% (6)

- Instruction Manual IRN37 160K ofDocument94 pagesInstruction Manual IRN37 160K ofLêDuyNo ratings yet

- Compresor - ManualDocument220 pagesCompresor - ManualVictorNo ratings yet

- Focus2 0Document2 pagesFocus2 0SHIFT MANAGER SUGEN MEGA POWER PROJECT50% (2)

- MAM6070Document45 pagesMAM6070Vitor FreitasNo ratings yet

- Almig Flex GB Web 1 2Document8 pagesAlmig Flex GB Web 1 2sebastianNo ratings yet

- 7 - 7005 - 10 - USE Sigma Control BasicDocument36 pages7 - 7005 - 10 - USE Sigma Control BasicWilliam BeadenkopfNo ratings yet

- User Manual Modi5Document22 pagesUser Manual Modi5MJ AvalardNo ratings yet

- Maestro: User'S ManualDocument36 pagesMaestro: User'S ManualamalalaouNo ratings yet

- Air Control 3 Dynamic: ManualDocument53 pagesAir Control 3 Dynamic: ManualmadiNo ratings yet

- 357 Basic Xe-M Onboard ControllerDocument300 pages357 Basic Xe-M Onboard ControllerSelamet Rezki100% (3)

- Central Controller Connection GuideDocument30 pagesCentral Controller Connection GuideAirpowerService100% (3)

- SR Mam 860 ManualDocument24 pagesSR Mam 860 ManualGrmaye AsfawNo ratings yet

- Delta VFD-VEDocument316 pagesDelta VFD-VEJoao Stuard Herrera QuerevalúNo ratings yet

- SOP-20-CP Smart Operation Panel User GuideDocument2 pagesSOP-20-CP Smart Operation Panel User GuideTrinnatee ChotimongkolNo ratings yet

- ALMiG Screw-Compressors en Web PDFDocument35 pagesALMiG Screw-Compressors en Web PDFТимур КуманцовNo ratings yet

- Software Specification: Standard S1 ControllerDocument40 pagesSoftware Specification: Standard S1 ControllerAnonymous 6VCG1YRdNo ratings yet

- FXDocument8 pagesFXjhedjesiNo ratings yet

- Service Manual: Controller Sigma Control 2Document184 pagesService Manual: Controller Sigma Control 2arturo neiraNo ratings yet

- Kaeser Sigma Controller SimensDocument128 pagesKaeser Sigma Controller SimensKrzysiek Podsiadło100% (3)

- Delcosxl R1Document85 pagesDelcosxl R1Daniel Arbeláez100% (2)

- Elektronikon ManualDocument40 pagesElektronikon ManualMark CarterNo ratings yet

- Atlas Copco Mkiv-Ethernet-Ip-04 PDFDocument46 pagesAtlas Copco Mkiv-Ethernet-Ip-04 PDFsdk00No ratings yet

- Elektronikon Instr. IDocument74 pagesElektronikon Instr. IRenārs BērtiņšNo ratings yet

- GA37 Troubleshooting GuideDocument1,449 pagesGA37 Troubleshooting Guidetechbiomed100% (1)

- 20142400Document40 pages20142400Max BibikovNo ratings yet

- CPA Triplex H EN 1Document20 pagesCPA Triplex H EN 1Nguyễn Tấn KhiêmNo ratings yet

- SB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFDocument3 pagesSB Priority IV APP 2848 ACCIPX v3.14 Updated in CAT and Mercedes Driven Compressors PDFNoufou DarankoumNo ratings yet

- Mapa de Memória Profibus DPDocument23 pagesMapa de Memória Profibus DPVinniciusNo ratings yet

- ZT SeriesDocument66 pagesZT SeriesWell Countryson Lumban TobingNo ratings yet

- GD Pilot MK Electronics For Stationary Screw Air CompressorsDocument36 pagesGD Pilot MK Electronics For Stationary Screw Air Compressorsandy habibiNo ratings yet

- X Series Interconnect Guide IR Compressors 80443864Document116 pagesX Series Interconnect Guide IR Compressors 80443864giovanny silvaNo ratings yet

- Xe-90M Series Rotary Compressor Controller PDFDocument2 pagesXe-90M Series Rotary Compressor Controller PDFbijendra moharanaNo ratings yet

- SLAD-MXf ManualDocument10 pagesSLAD-MXf ManualReiky Aji ShaputraNo ratings yet

- CD 25+ To 145 + PDFDocument44 pagesCD 25+ To 145 + PDFMelwin widodoNo ratings yet

- GA110 Instruction Book - Apf154028Document118 pagesGA110 Instruction Book - Apf154028ahmedshameer100% (1)

- IR Modbus Manual NVC Refrigrated DryerDocument11 pagesIR Modbus Manual NVC Refrigrated DryerFranklin BaldalloNo ratings yet

- ZR 315 VSDDocument154 pagesZR 315 VSDLIDAIRNo ratings yet

- 2946 7002 07 MB Mk5 Graphic Unit ControllersDocument48 pages2946 7002 07 MB Mk5 Graphic Unit Controllersali100% (2)

- AN0009v04-UC20-WL2000 ModbusTCP Master Implementation in Node-REDDocument32 pagesAN0009v04-UC20-WL2000 ModbusTCP Master Implementation in Node-REDJirawat JumpathongNo ratings yet

- Modbus Converter User ManualDocument21 pagesModbus Converter User Manualdhavan hNo ratings yet

- MODBUS BACNET ConversionDocument8 pagesMODBUS BACNET Conversionfelipecam5No ratings yet

- Redlion MP2300Siec Modbus Configuration v004Document15 pagesRedlion MP2300Siec Modbus Configuration v004cuteykumar100% (1)

- Redlion MPiec Modbus Configuration W Crimson2 v007Document14 pagesRedlion MPiec Modbus Configuration W Crimson2 v007minhtutran1983No ratings yet

- Champion Industrial 2012Document56 pagesChampion Industrial 2012pcbyk_mroNo ratings yet

- Bürkert Type 331-C / 331-F: Technical SpecificationDocument2 pagesBürkert Type 331-C / 331-F: Technical SpecificationEvgeny TumalevNo ratings yet

- En 1089 0376 00 Ed27Document16 pagesEn 1089 0376 00 Ed27Evgeny Tumalev100% (1)

- DGT Cube User ManualDocument8 pagesDGT Cube User ManualEvgeny TumalevNo ratings yet

- OnPC and Wing SetupDocument3 pagesOnPC and Wing Setuporlando_d56No ratings yet

- Raspberry Practical Manual SachinDocument49 pagesRaspberry Practical Manual SachinVaibhav KarambeNo ratings yet

- Telecom Interview Questions Answers Guide PDFDocument10 pagesTelecom Interview Questions Answers Guide PDFtom2626No ratings yet

- Ru Dublgis DgismobileDocument131 pagesRu Dublgis DgismobileАяна ТабалдиеваNo ratings yet

- pcs7 Compendium Part B en-US en-USDocument188 pagespcs7 Compendium Part B en-US en-USEmerson KleemNo ratings yet

- Service Manual: Trinitron Color TVDocument17 pagesService Manual: Trinitron Color TVohukNo ratings yet

- The Use of Artificial Intelligence in The Information Retrieval System Epoch-MakingDocument4 pagesThe Use of Artificial Intelligence in The Information Retrieval System Epoch-Makingvishalbhavar1No ratings yet

- Handout Lab1 AssignmentDocument2 pagesHandout Lab1 AssignmentCan KurtulanNo ratings yet

- Stephen Kasina CVDocument4 pagesStephen Kasina CVStephen KasinaNo ratings yet

- B-85314EN-1 01 (Alpha-DiA5 Custom PMC) PDFDocument242 pagesB-85314EN-1 01 (Alpha-DiA5 Custom PMC) PDFmastorres87No ratings yet

- MA5600T MA5603T V800R010C00 Feature DescriptionDocument824 pagesMA5600T MA5603T V800R010C00 Feature DescriptionCutui MariusNo ratings yet

- Vinafix - VN - ASUS K50IN PDFDocument91 pagesVinafix - VN - ASUS K50IN PDFAnonymous JOsfWBa3dXNo ratings yet

- Adobe IllustratorDocument56 pagesAdobe IllustratorAbdul Raheym AhmadNo ratings yet

- Entoto Polytechnic College: Sector: Economic Infrastructure Sub-Sector: Business and Finance Basic Clerical Work Level-IDocument17 pagesEntoto Polytechnic College: Sector: Economic Infrastructure Sub-Sector: Business and Finance Basic Clerical Work Level-Iembiale ayaluNo ratings yet

- ProjectDocument22 pagesProjectSandeep SharmaNo ratings yet

- CIVE50003 Computational Methods II - Lecture VII - 200223 V2Document21 pagesCIVE50003 Computational Methods II - Lecture VII - 200223 V2TwinyNo ratings yet

- MIS PresentationDocument21 pagesMIS PresentationKring SandagonNo ratings yet

- 05 Steps To Successful Adoption of Cloud Services PDFDocument17 pages05 Steps To Successful Adoption of Cloud Services PDFLuisNo ratings yet

- PLSQLDocument68 pagesPLSQLSharathRajNo ratings yet

- CLI Management User GuideDocument25 pagesCLI Management User GuideerickgugoNo ratings yet

- TaskUS WhitePaper Security-Compliance 1.4Document10 pagesTaskUS WhitePaper Security-Compliance 1.4JE GazbarNo ratings yet

- Revive DX Computer User GuideDocument4 pagesRevive DX Computer User GuideregreeNo ratings yet

- OpenSees Future Direction 2017Document39 pagesOpenSees Future Direction 2017fariasgarciarojasNo ratings yet

- Protect Your Source Code From Decompiling or Reverse Engineering .NET Assemblies - CodeProjectDocument19 pagesProtect Your Source Code From Decompiling or Reverse Engineering .NET Assemblies - CodeProjectYsaacx AliagaNo ratings yet

- Costing Versions and Trade AgreementsDocument6 pagesCosting Versions and Trade AgreementsSanjay Kumar PathakNo ratings yet

- Using The SAP .NET ConnectorDocument9 pagesUsing The SAP .NET ConnectorvicearellanoNo ratings yet

- Final Requirement - MS Powerpoint ActivityDocument13 pagesFinal Requirement - MS Powerpoint ActivityAbegail Terillano InfanteNo ratings yet

- BGA Breakout Challenges: by Charles Pfeil, Mentor GraphicsDocument4 pagesBGA Breakout Challenges: by Charles Pfeil, Mentor GraphicsBenyamin Farzaneh AghajarieNo ratings yet

- PHP Exercise 2013Document4 pagesPHP Exercise 2013Helloworld King0% (1)