Professional Documents

Culture Documents

Sap PP Course Content

Uploaded by

Sandeep Kumar PraharajOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Sap PP Course Content

Uploaded by

Sandeep Kumar PraharajCopyright:

Available Formats

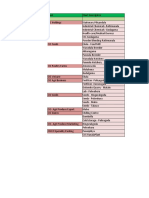

Section 1

Overview of ERP & About SAP, Manufacturing

Execution for Discrete and Repetitive.

Planning

Introduction

Make-to-Stock Production

o Make-to-Order Production

o Repetitive Manufacturing

o Co-operative Business Scenarios

o

o

Section 2

SAP

o

o

o

Hierarchy Structure Master Data

Material Master

Bill of Material BOM

Work Centre

o

o

o

o

o

o

o

Routing Diferent types of Routing

Production Version.

Person responsible.

Parameters

Standard value key

Control key

Shift sequence.

Section 3

Discrete Manufacturing Transactional data configuration

o Define Order Type

o Define Number Range for Order type

o Define Scheduling Parameter for order type

o Define confirmation parameters

o Define Default Values

o Number range for conformation

Section 4

MRP configuration

o

o

o

o

o

o

MRP Controller

Number Ranges (planned order, purchase requisition).

Planning horizon

Rescheduling

Special Procurement Key

Activating MRP and Planning file entries.

and

Section

Production Orders

o

o

o

o

o

o

o

o

Overview

Order Structure and Processing

Order Creation/ Order Change

Order Release

Printing Order Documents

Material Staging

Order Control

Confirmations Goods Receipt

Section 6

Costing

o Introduction.

o Reference and Simulation Costing.

o Material Costing with Quantity Structure.

Section 7

Production Planning

o

o

o

o

o

o

o

o

o

Overview

Demand Management

MRP Run

Processing MRP Results

Master Production Scheduling

Long-term Planning

Sales operation planning

Technical Information on How the Planning Run Works

MRP Areas

Section 8

o Typical Customer Use Cases

o Most common support phase Issue

You might also like

- End User For JSP2Document26 pagesEnd User For JSP2Sandeep Kumar PraharajNo ratings yet

- SAP PM Interview QuestionsDocument6 pagesSAP PM Interview QuestionsSandeep Kumar PraharajNo ratings yet

- Overview of Transport RequestsDocument11 pagesOverview of Transport RequestsSandeep Kumar PraharajNo ratings yet

- Cic PM KDS V1Document31 pagesCic PM KDS V1Sandeep Kumar PraharajNo ratings yet

- Overview of Transport RequestsDocument11 pagesOverview of Transport RequestsSandeep Kumar PraharajNo ratings yet

- End User For JSP2Document26 pagesEnd User For JSP2Sandeep Kumar PraharajNo ratings yet

- LSMW Eh7 ZFNCLDocument13 pagesLSMW Eh7 ZFNCLSandeep Kumar PraharajNo ratings yet

- End User For CalibrationDocument14 pagesEnd User For CalibrationSandeep Kumar PraharajNo ratings yet

- Road Map For PP ProjectDocument1 pageRoad Map For PP ProjectSandeep Kumar PraharajNo ratings yet

- JSW Energy Plant Maintenance BBPDocument46 pagesJSW Energy Plant Maintenance BBPSandeep Kumar PraharajNo ratings yet

- SAP Solution Manager (Support Manual) PDFDocument4 pagesSAP Solution Manager (Support Manual) PDFSandeep Kumar PraharajNo ratings yet

- Upload FileDocument7 pagesUpload FileSandeep Kumar PraharajNo ratings yet

- JSP Sap PM Configuration DocumentDocument30 pagesJSP Sap PM Configuration DocumentSandeep Kumar PraharajNo ratings yet

- RICEF PresentationDocument10 pagesRICEF PresentationSandeep Kumar Praharaj100% (1)

- JSW Energy Plant Maintenance BBPDocument46 pagesJSW Energy Plant Maintenance BBPSandeep Kumar PraharajNo ratings yet

- MSNL FS PP Routing UploadDocument10 pagesMSNL FS PP Routing UploadSandeep Kumar PraharajNo ratings yet

- SchedulingDocument2 pagesSchedulingSandeep Kumar PraharajNo ratings yet

- SchedulingDocument2 pagesSchedulingSandeep Kumar PraharajNo ratings yet

- Define Production Order TypesDocument2 pagesDefine Production Order TypesSandeep Kumar PraharajNo ratings yet

- Book 1Document1 pageBook 1Sandeep Kumar PraharajNo ratings yet

- RICEF PresentationDocument10 pagesRICEF PresentationSandeep Kumar Praharaj100% (1)

- KdsDocument18 pagesKdsSandeep Kumar PraharajNo ratings yet

- Sandep (To Gaurav) :: Chat Log C:/Users/Sandep/Documents/Chatlog Sap S4Hana Simple Logistics 2016 - 09 - 25 20 - 30Document1 pageSandep (To Gaurav) :: Chat Log C:/Users/Sandep/Documents/Chatlog Sap S4Hana Simple Logistics 2016 - 09 - 25 20 - 30Sandeep Kumar PraharajNo ratings yet

- SAP PP Config Guide - Production Order Types & ParametersDocument2 pagesSAP PP Config Guide - Production Order Types & ParametersSandeep Kumar PraharajNo ratings yet

- Sap PP Course Syllabus in ChennaiDocument5 pagesSap PP Course Syllabus in ChennaiSandeep Kumar PraharajNo ratings yet

- Book 1Document1 pageBook 1Sandeep Kumar PraharajNo ratings yet

- Composition of The ASAP Methodology FrameworkDocument3 pagesComposition of The ASAP Methodology FrameworkSandeep Kumar PraharajNo ratings yet

- ChatLog SAP S4HANA Simple Logistics 2016-10-09 19 - 36Document1 pageChatLog SAP S4HANA Simple Logistics 2016-10-09 19 - 36Sandeep Kumar PraharajNo ratings yet

- BDC Recording StepsDocument4 pagesBDC Recording StepsSandeep Kumar PraharajNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)