Professional Documents

Culture Documents

MSS 0060 V01 (Pouring of Raft Foundation in Zone HK, Main Hospital Building)

Uploaded by

raju_civileng0 ratings0% found this document useful (0 votes)

130 views70 pagesMSS 0060 V01 (Pouring of Raft Foundation in Zone HK,Main Hospital Building)

Original Title

MSS 0060 V01 (Pouring of Raft Foundation in Zone HK,Main Hospital Building)

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMSS 0060 V01 (Pouring of Raft Foundation in Zone HK,Main Hospital Building)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

130 views70 pagesMSS 0060 V01 (Pouring of Raft Foundation in Zone HK, Main Hospital Building)

Uploaded by

raju_civilengMSS 0060 V01 (Pouring of Raft Foundation in Zone HK,Main Hospital Building)

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 70

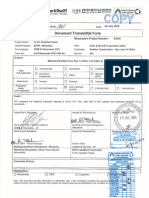

Oost Allen &Shariff

mMusanada orsen eos nae

Record Reference: MUSIAANDTF bate: 26 November 2014

Document Transmittal Form

Project Details: iusanadae Project Number 53040

Project Name: At Ain Hospi! Proect

on SEHA/Musanada PMC: Allen & Sharif Corporation (ASC)

Tho Emneer ICME Obermeyer (FO) Contator:_ Arable Constution ~ San Jose JV (ASJ)

TransNo: 2444 Revo: 0

88-080 ev

ye [El Teme Downe [2 cotiee [ED Tatra

cottenene) |e . on rn

Ferman D1 fey ooo 2

‘mamert [LS 1D ewes cate Da

“Ene” | ronmrorunron | FoR surmIen | sonmecon | 2 roRREvEW

ret heiab)

Plage nd atched ret ASJ MSS 0080 a. Foriflamaton, Ree ah An

f\

Teruody & Spat Tesla Rasa

teed Aer - Projet tor Dern Open Pasa uaagee

‘rabies & San Jose “JV lng an Peet agora

‘yy | ssanae

Tes By & Signi: TF sie Ressied

axn Ops — Project Manogor ‘Simon Asher Reson Eger

| suing and Project Management Mazansda | CME & Obemayer-s¥

Reference Document (tach my ver ‘lrk Lean pple)

Soeur 21S ptt Projet

‘anmens Fn

Distribution:

Ty Musanada TPC CD ainaer Ti conasior

em amet pes mato ona Hie Care ante ie at cae re

‘Gara han Coston ate at tance bm Caan of aac

SGRSTNET 0 CON Drom Tanz Farm Wer OUT a0 Pratt

Hoe sees (Ayre).

Mothod of Statement Submittal

Record Reternos ASS ANEOOT Dae ara

Pletal: [ sana’ rect Number 53040

Project Name An Hosp Wa Ws Package

lent SEHATMUSANADA ALLEN 8 SHARIF

Engineer FO. Contact abies Sao.

IRN: Hetod Stoner No: 680 Revo:

oF eo

Pouring af Raft Feundation In Zone HK, Maln Hospital Buln

2. Scope: Procedure fx Porn of Raft Feundaton in Zone — HK, Main Hospital Building

‘5 Lagllation and code of practice: 333,

4 Rotorences1,42.43,44

Detntlone: § = 89

6: Resources:

“6. Metre and ir approval 6.1.1~ 81.11

{8.2 Subcontractor approval 82.1625

8.3 Shop drawngsapprval 631-635

94 Egupment 64° "84.17

{8.5 Human Resoure. See tached

1 Safety Procautions: = 7-2

1 Detallod Construction Sequence (Mathodology): 818.13,

§ Construction Programme: Se aached

{O-Ingpection and Testing: 10-102

4H Related Forms: p13

#2: Attachments 121

aT

sine ai wae

tree \ ar

Tae t

GPa teres .&-Amovt win Conmdts C16 RevieandRenime C1. ic

He Nb am cnt

‘Comments: \

iba

mss ame Tengen Toone

‘JESTHT iT ~ GS Weed Siren GanmalFom Ve OTmy 20m Pape Th

Project Name

AL AIN HOSPITAL - MAIN WORKS PACKAGE

Subject

METHOD STATEMENT FOR

POURING OF RAFT FOUNDATION IN ZONE — HK,

MAIN HOSPITAL BUILDING

Document Number: MS-AAH-ASJ-CV-060

Revision: 01

Date: 26-Nov-2014

Project Name Tae na ERRATA

ALAIN HOSPITAL MAIN WORKS PACKAGE | gayoos

MNase ‘MerHO0 STATEMENT FOR a)

Pouring a att Fundatton in Zone HK,

Main Hospital Bling

page 1/34

METHOD STATEMENT FOR

Pouring of Raft Foundation in Zone — HK,

Main Hospital Buil

PROJECT NUMBER 53040

cuent :SEHA

EMPLOYER MUSANADA

PROIECT MANAGER {ALLEN AND SHARIFF

ENGINEER IFO

CONTRACTOR ARABTEC SANJOSE.V

SON STATUE

a

3 ers] Rome Ra PA

© [aT aE RSceovee [esanac | xsl omncin | pee

Seno fone fe

Project NameSSC* RR TT

[ALAIN HOSPITAL MAIN WORKS PACKAGE | gogsos

METHOD STATEMENT FOR =| ost 2n018|

Pouring uf Raft Foundation in Zone — HK) | sg

‘Main Hospital Building a

‘TABLE OF CONTENTS

1 PURPOSE

2+ SCOPE ..

'2- LEGISLATION AND CODE OF PRACTICE.

4 REFERENCES

5~ DEFINITIONS

{5- RESOURCES.

(6.1 MATERIALS AND THEIR APPROVAL

(6.2 SUBCONTRACTOR A?PROVAL.

6.3 SHOP DRAWINGS APPROVAL...

6.4 EQUIPMENT

6.5 HUMAN RESOURCE .

17 SAFETY PRECAUTION

CONSTRUCTION SECUENCE (METHODOLOGY)

‘9 CONSTRUCTION PROGRAM

10 INSPECTION AND TESTING

{11 -RELATED FORMS oon

22 ATTACHMENTS

Project Name BoE a SATO

[ALAIN HOSPITAL MAIN WORKS PACKAGE | gaysos

"METHOD STATEMENTFOR ‘| oate 252018

Pouring of Raft Foundation in Zone HK,

~ Main Hospital Building

rot 3/38

1, PURPOSE

This document defines the methodology, sequence, control measures, safety and quality control

Fequirements, and equipment Intended tobe used in performing the works as established inthe project

specications and relevant referenced documents.

2. SCoPE

‘The scope of work deserbedin this method statement is applicable fr Pouring of Raft Foundation in

Zone —HK, Main Hospital Bulding for construction associated with “A Ain Hospital ~Main Works

Package”

LEGISLATION AND CODE OF PRACTICE:

2 Engineer approval

32 Approval of raft foundation works fromn Al Ain Municipality prior to concreting works.

33 __Allpermits and licenses related to this work wl be obtained from local authorty prior to

star this pouring works

REFERENCE, all works shall comply with the relevant requirements standards Isted below

4.1 Project Specifcations Section 03 3000

421,85 1881 ~Testing Concrete

i, 85 8110 ~The structural use of concrete

Ti. BS EN 206 Concrete speciation, performance, production and conformity

In.ACI 205R 99 Hot weather concreting

\V-ASTM C127 Specie gravity and absorption of coarse aggregate ete. as mentioned in

Project Specifeations Section 03 3000, Clause no. 1.2

43. Shop Drawingno.

see S30s0 MIOSK-B2-ASI-ARC-SPO-10005, _53040-MHOSK-B2-ASHARC-SPD-10790,

Main Hospital Part HK Basement 802-Foundation Achtectural General

‘Arrangement

1 SSOAOMHOSK-S2-ASISTRSPD.01010, Main Hospital Part HK Basement 802-

Foundation Structural General Arrangement

Ti, S30H0MHOSK-B2-AS)STR-SPD-2183 to 02180, Main Hospital - Part HK Basement

{802 Foundation Slab Reinforcement

|v. 53010 MINOSK-2-AS) SEW-SPD-00%2, Main Hospital Part - HK Floor Plan Second

Basement Plumbing Drainage

.$30#0-MHOSK-82-ASI-MICO-SPD:25264, Hospital-Part HK2nd Basement Raft MEP

Coordination Orawings

si, $3040.MHOSK-82-ASI-MBW.SPD-25818, Hosptal- Part HK Second Basement Ra

MEP Eullders Work

44 Project Quality Plan, PAP-AAH-ASH-OO1, Rev 02

Project Name Ba EERE

[ALAIN HOSPITAL™MAIN WORKS PACKAGE | goysox

WNissxO)| | — enon srarenen ron se sr

agente 14/24

DEFINITIONS

54 CUNT: Sea

5.2. EMPLOYER: MUSANADA

53. PROJECT MANAGE: Allen & Shariff Corporation

54 ENGINEER: row

55. CONTRACTOR: Arabtec San Jose 1 (AS!)

56. Hse: Health, Safety and Environment

57 1: Inspection and Test Plan

58 aNac: ‘quality Assurance/Quality Control

59 EXOVA: Independent Testing Laboratory (TU)

6. RESOURCE

6.1 Materials and their approval

(6211 Mix Design for concrete (M3). The mix code is "rial 18 for NBH Modem Est. for Ready Mix

(Material submit no. 13) and “ral 2 for Ready Mx Abu Dhabi Lt. (Material submittal no

a)

6.1.2 Reinforcement ste (Material submital, MSF No.5 & 6)

6.1.3 Concrete cover block (Approved material submittal, MSF No, 1)

644 Water (for curingand other construction purposes)

{61.5 Polyethylene Shest 1000 g/m? (Approved material submittal, MSF No. 9)

6.2.6 Polystyrene Board (Approved material submittal, MSF No. 18)

6.217 Hessian Cloth

G18 UPVC drainage pes and fines (Approved watera subritel, MSF No, 20)

6.19 Thermocouple (Approved material submittal, MSF Ho. 48)

6.1.10 Evaporation material- MASTERKURE 11 CF (Approved material submittal, MSF No. $5)

6.111 Curlng compound ~ Fosroc Concute WE (Approved material submittal, MSF No. 23)

6.2 Subcontractor approval

62:1. Subcontractor for Concrete works: Concrete willbe supplied by approved conerete supplier,

INBH Moder Est. for Ready Moc and Ready Mix Abu Dhabi Ltd. Concrete placement wil be

done by main contractor. (ATC STRUCTURE DIVISION)

Freee Name Sr

ALAINNOSPRAL MAIN WORKS PACKAGE | n.

ANsaxcne'Q) | weervon sateen FoR

Pouring of Rat Foundation in zone Hk,

‘Main ost Bulding

apn 15/3

22. Subcontractor for Reinforcement works: Rebars willbe supplied, cut and bent by approved

Subcontractor CICON. Relnforcement steel fabrication at site willbe done by main contractor.

62.3. Subcontractor for Form works and supporting system: The high ribbed form works wil be

Supplied by TA and installed by contractor. The edge form works willbe supplied and

installed by approved subcontractor Al Quebesi SGB LAC (Harsco).

6.24 Subcontractor for waterproofing: All waterproofing system wil be provided and installed by

Western international

6.25 Subcontractor for drainage system: The placement and supply of all drainage system will be

done by EFECO.

6.3 Shop Drawing approval

{G21 General arrangement drawing: 53040-MHOSK-B2-ASHARCSPD-10006, $3040-MHOSK-B2

ASI-ARCSPD-10790,

1632. Reinforcement rowing: 58040-MHOSK-B2-AS)STRPD-02183 to 02190

{6.3.3 Drainage System: 53040-MMOSK-83-AS)-SEW-SPO-0042

6.3.4 Builders Drawing: 53040-MHOSK-B2-AS)-MBW-SPO-25818

635. Co-ordination Drawing: 53040-MHOSK-B2-ASI-MICO-SPD-25264

6.4 Equipment

{Ga.1_ Concrete Truck Mixers (30-35 nos. for each concrete supplier)

64.2. Concrete Pump

IL Ready mixAbu Dhabi: a. 1 no.52 meter mobile pump

10.42 meter mobile pump

‘1no. 42 meter mobile pump on standby.

ii. NOH Moder Est, for Ready mix: 2.3 no. 42 meter mobile pump

b. 1 no, £2 meter mobile pump on standby

“Third party cetifeation forthe concrete pump will be submitted 24 hours prior to pouring

‘works. Whip chains will be fixed to protect the fll of flexible hoses

6.43. Survey Equipment

64a Hand rowel.

6.45 Scabbling needle

6.46 Aircompressors

64.7 Concrete Spreader

648 Cubemoulds

849 vinatrs

i. inch dia~06 nos. plus 2 spare. 4 dese 4 electrical

ii 25 inch ia ~07 nos. plus 2 spare. 4 dese 5 electrical

Ti, Binchdin~ 02 nos plus 1 spare. 1 diesel 2 electrical

6.420 Power lets

"7 nos. Single Power floats, 3 nos, stand by

6.4.11 Steel brush with handle (to remove concrete on top of rebars)

Tapa ame a

aLamwoseraramworeseactact |i,

A Nessie) | —wreron srarenenr ror estore

rautrgarnen roinseten zener, | nvera

‘an Hospital Bulg

“GAD Additional pipes forHK: 200 n05,

{6.4.33 Hangers for HK: 02 nos.

6.4.14 Flexible hoses for HK 09 nos.

6.4.15 Tyres for HK: 200 nes.

6.4.16 Clamps for HK: 2000s

6.4.17 Mechanical distributor fr HK: 02 nos.

6.5 Human Resources

‘The ASI Prolect Manager shall review and approve the methodology forthe execution of the works, and

ensure that the works are Implemented In an effient manner. The Project Manager is generally

responsible for the overall project execution, quality and safety

“The Construction Manager Isresponsible forthe implementation of method statement and ensures that

ail involved site construction personnel are aware of ths method statement and shop drawings are

followed. He shall ensure that the execution of works shal be cated outin safe manner. Ho will aso be

responsible for the monitoring of the work progress on dally basis to ensure activities are accomplished

‘as per the construction program.

“The Site Engineer shell ensue thatthe works ae carried out according tothe design, approved shop

drawings and procedures. H= wl bo responsible on behalf of the Contractor to coordinate, check and

follow up the work with relevant parties and ensure that proper sequence of activities are followed in

‘order to achieve target completion. He wil ensure that safe work practices are followed forall works

under his eae.

‘The MEP Coordinator! Engineer will coordinate with the Construction Manager/ or Site Engineer in

‘advance of all MEP services interfacing wth the work schedules and progres. He wil coordinate with

the MEP subcontractor and ensure that ll MEP services/ sleeves/ openings are identified and completes.

Inspection Request will be rlsed tothe Engineer for MEP services/sleeves/openings installations were

‘show inthe approved shop drawings. copy willbe forwarded tothe QA/GC Engineer fr all submitted

Inspection Request with pes of approvals.

“The QA/OC Engineer shall ensure that Works are carried outin accordance with the Quality Pan. He shall

ensure that al IT requirements are met. The QAYQC Engineer shall ensure thatthe inspection request

forinspections and testing are raised and submitted tothe Enginceron time He wil Inspect the activity

bs per approved drawing and method statement and ensue all requirements are met and then submit

the inspection request to the Engineer along with check ist, He shall ensure that materials being used

tein accordance with projet specifications and approved bythe Engineer. He will coordinate with third

pany independent laboratory to accomplish all tostng activities as per approved ITP and ensure the

toncrete check points, cube preparation room, curing facies are in pace

Project Name Dic as HEARTS ED

ALAIN HOSPITAL MAIN WORKSPACKAGE | goycoy

(AsO) ‘METHOD STATEMENT FOR ey

Pouring of Raft Foundation in Zone HK,

7/38

‘Te Surveyor shall be resporsble for setting out the location, fine and levels, plus other dimensional

equirements in accordance wth the design drawings and approved shop drawings.

“The Safety Engineer will montor and implement all HSE related issues, He shall ensure that all necessary

requirements regarding health, safety and envconment concerns risk assessment are met and adhered

tor the Safety Engineer shal ensure that all permits and authorization are on hand (as per Project HSE

Plan} prior to starting any site operation (f required).

‘he Foceman/ Supervisor wil be responsible o cary ut the work n safe manner an to supervise the

work free together withthe proper execution and monitoring of work, and all appropriate checks will

be carried out during each tage ofthe works.

‘The independent Testing Laboratory IT) shall be responsible for sampling, esting and reporting the test

results as per the project spesfcatlons.

7. SAFETY PRECAUTION:

7.4. Allwotks shal be performed in accordance with the Engineer's HSE Manval and Contractor's HSE

Plan and Procedures.

112 Sie Engineer/ Supenssor wil ensure that Mandatory Personal Protective Equlpmentis worn by

site personnel at all times within the designated construction areas

73. Prior to commencement of any activity, all operatives will be given in 2 general site safety

Induction by HSE Personne, the Site Engineer/ Supervisors wil also conduct daly Tool Box talks

‘and method statement briefings to the personnel involved in operation.

7.4 General PPE is mandatory forall personnel will consist of safety boots or shoes safety helmet,

Safety gloves, HLVI2 vest or shirt and overalls (for workers). Other PPE requirements will be

determined by Rsk Assessment as the work proceeds and other hazards are anticipated i

working at height/orat the leading edge of a structure.

7.5 iting equipment wil have a valid test certificates from a third party agency or manufacturer. The

‘operator will have competency certiiat from third party

116 Where required rige edge protection willbe provide, if it's not practicable to provide ede

protection, safety hamesses will be worn fixe to suitable anchor points

7.7 tthe event ofan accident or incident immediately notify the Project Manager and HSE Manager.

‘The accdent file, which i situated in the Site Office, must be completed, by the AS! HSE

Manager Trained Fist Aideror Trained Construction Managers

7.8 There san AS! Trained Fist Aide available on sit.

[Project ame acne ERAT |

[ALAIN HOSPITAL MAIN WORKS PACKAGE | gogo

ANoszQ) | ——iwerion saremenr ron oan asnonou

Pouring of Raft Foundation in Zone—HK | ay van

‘Main Hospital Building

7.9 Incase offire/ emergency evacuate the work area tothe designated assembly pints.

“740 Safety inspection and certification of a scaffolds wl be done prior to puting them to use, Workers

vill be trained accordingly not to se scaffeld without safety tag

721. HSE induction traning shal be conduct for all staffs prior to enter at sit. AS! will maintain the

‘records on Safety induction training forall staffs (AS) entering ste.

742. Environmental.

Ambient noise wil be checked BY Nolse Meter In four surrounding pants of the casting rea, in

sequence of one hou, folowing the attached drawing,

Project Name Tic as ESCO

ALAIN HOSPITAL MAIN WORKS PACKAGE | gy

PN) | eran srarenemrron | owns ore

Pouring of Raft Foundation in Zone HK,

‘Main Hospital Bulaing

eo 39/28

0 CONSTRUCTION SEQUENCE (METHODOLOGY):

84 General

8.1.1 Pouring at level Basement 2 in Zone ~ HK, Main Hospital

Bulng wil be poured in ane continuous operation.

8.1.2 Concrete mi type I¢ C40/20 (M3) a5 approved by the fgei— 9] — +

Engineer. The mix cade is "ial 18 for NBH Modem Est, for H

‘Ready Mix (Material sabmittal no. 13) and "Trial 2'for Ready. 706

‘Mix Abu Dhabi Ld, (Material submittal no. 14, [

8:13. ASI shall ensure that adequate dinking water supply i f| | i

svalabe stat, aa alt and resing ares vl beady for Pt] = T=

thenumbrforier dives, oebavenmeabmisreatr H]|| |

at the area, following the logtic plan and safety

requirements.

8.2 Survey Setting out / prior activities

1.2.1 Temporary bench mais and grids hall be established based on reference survey control points

‘ven by Municipalty. ASI will submit inspection request to the Engineer for confirmation of|

‘temporary bench mars.

8:22 The layout and level for formwork shall be established using high precision survey Instruments

such as: Total Station, theodolte and Auto Levels. AS wil ensure the control points are correct

places.

83 Formwork

83:1. The form work / high ribbed metal sheet and supporting system wil be installed for both types

of Edge type, construction Joint type and walls kickers type. Detaled high sibbed form work and

Supporting system will be folowed as per approved drawing. Required anchors, sleeves, dowel

bars and other inserts shall be provided as well

32. Sulit number of access lad

access / ext from theactivity are.

temporary staircase / oxi point wl be installed forthe easy

18.33. Lines, levels and dimension shall be checked by ASI Surveyor before placing the concrete. Bars

‘extending beyond the pour zones are to be fully supported to avaid vibration.

183-4 ASI shall submit inspection request tothe Engineer for the form works for raft foundation.

1835 The high ibbed form work will be checked and signed off bythe Engineer. AS! wil certify high

ribbed form work completed and checked by ASL

Project Name Toe ENED

ALAM HOSPTAL MAN WORKS PACKAGE | pay.

A NzsQ)| | ———nrernon sraranenrrox | on srore

pour of Rat Foundetion —_—

‘Main Hospital Bul

FIGURE 03: Typical High Ribbed Formwork

AER RST PHASE POUR

FIGURE 02: Typical ins.allaton of High Ribbed metal sheet

edtame SC TSC

ALAIN HOSPITAL ~ MAIN WORKS PACKAGE

METHOD STATEMENT FOR | owt: 25xera018

Pouring of Raft Foundation in Zone HK,

Main Hospi

oy pages 238138

FIGURE 03: Typical installation of High Ribbed Formwork in construction Joint. Details willbe

{allowed 3s per approved drawing

8.4. Reinforcements

184.2. Reinforcement steel shal be stored properly either on concrete sleepers, wooden runners or

scaffold racks with provision of polythene sheet underneath as required, to protect it from

tsuthing the ground and Al the Stet shall be coverel with polythene sheet/tarpaulins

8.4.1. Reinforcement stel shall be cut and bent to the shape and dimension shown in contract

documentation or te schedules approved by the Engineor in accordance withthe requirements

‘and tolerances of 58666 (Project Specifications Section 03 3000, Clause no, 3.11.8.3).

84.2. Steel fabrication shall be cartled aut as per the fabrication schedules and drawings. Al the

anchorage shal bon accordance with BS 8666 and approved drawings (Project Specifications

‘Section 03 3000, Clause no. 3.31.8.)

Project Name

[ALAIN HOSPITAL MAIN WORKS PACKAGE | pogsox

ANizsexO) | erin srarenent ron oe 2c

Pouring of Raft Foundation in Zone ~11K,

“Main Hospital Building rasan

|

‘BAS Lap length and location shall be maintained s per approved shop drawing,

844 75mm clear cover shall be maintained according to the approved shop drawing,

8445. The concrete spacer blocks of 75mm thik as approved by the Engineer (Material submittal no.

(MSF No.1) shallbe wsed at site

BAG Allthe necessary spacers and chalr shall be provided to maintain the specified covers. tis to be

ensured thatthe chais are provided as per approved shop drawing to maintain level of top rebar

mesh to required level during concreting. Spacing of spacers shal be such that excess loading is

rot occurring.

8.47 The fabricated bars sal be kept in position as per approved drawings and the ends of wires shall

be bent in to concrete. 1.2mm dia binding wire (Material submittal no, MSF No.20) as approved

by the Engineer wil be used for reinforcement works

848 After completing the installation all the loose materials shall be removed and inspection request

shall be submited tothe Engineer for approval.

85 Waterproofing approval

8.5.1. Clearance from waterproofing subcontractor willbe attached with the final inspection request.

8.6 MEP Approval

8.6. Approved materials wil be used in accordance with the latest reviion of the approved drawings

‘and specifications

86.2 MEP instalation shll be executed in compliance with approved drawings and specications

[Refer to shop drawing no, 53040-MHOSK-B3-ASI-SEWSPD-0042, 53040-MHOSK:62-AS)-MBW-

‘SPD. 25818, 53040.MHOSK-82-ASI-MICO-SPD:25264 and ather MEP service drawing).

8.63 The Installation procedure for underground drainage pipes wil be followed as per approved

mmethod statement. no. MSS-022 (Installation & Gravity and Pressure Test of Underground

Drainage Pipe work)

1864 The area where heavy plant wil be placed on top rebar, will b barricaded by warning tape to

snake safe protectionto the persons workingup and dwn of op rebars. Nobody is allowed work

Inside the barricaded area til the pant i in place

8.65 Allthe MEP sleeves/eut outs, sizes and locations shallbe Inspected and approved by the Engineer.

‘Conereting works wil not be proceeded until MEP Gearance is obtained from tngineer.

8.6.6. Pressure test wil flow method statement no. MSS-22, all the works will be witnessed by the

Engineer

Project Name Dos a AAS

[ALAIN HOSPITAL MAIN WORKS PACKAGE | gaycos

AN") | ———wrernon statement ron | one:asnovane

Pouring of Raft Foundation in Zone HK,

‘Main Hospital Building

rage 238/34

BET Water willbe Kept withn drainage pipes at all times units instructed by the Engineer to remove

868 After completing all evil and MEP works, Municipality applicaton form willbe submitted to

Municipality to praceed for raft foundation concreting works

8.7 Conereting

8.7.1 Pumps willbe provided by NBH Modern Est. for Ready Mix and Ready Mix Abu Dhabi Ld. AS! will

censure that all pumps vibrators, tools, man power including all arrangement isin place prior to

frder the concrete to supplier. AS wil also ensure both the batching plants are fully operational

prior to pour concrete,

181.2. Tre pump locations and transit mixer movement plan in attached. No traffic restriction

required, as both ext and entrance of ste road are strictly controlled by site security guard. For

ech conerete pump, one flag man / banks man wil work

8.7.3. Mobile pumps will cover whole raft area, but mechanical distributor / addtional hose wil be

connected tothe boc If required to reach tothe expected location

{87.4 The sequence ofthe pour is reflected in plan attached in clause no. 8.9. The concreting work wit

be started from the centr af the pouring area and proceeded to the edge.

8:75 As far as possible, in the event of equipment break down, our mechanics shall ensure that

contamination of sol by hydraulic ols avoided by laying an impervious layer of plastic sheet

below the equipmen

{8.6 Two batching plants Ready Mix Abu Dhabi Ltd. and NBH Modern Est. for Ready Mix) willbe used

‘on the pour and concrete wil be supplied ata rate of 60 to 65 m3/h fr each pump, depending

tpon site conditions. Sufficient number of transit mbeers (50 to 65) shall be deployed to ensure

continuity of the peur. Batching plant concrete coordinator will be available on site during

concreting to coordinate the trucks discharge from plant and during transport.

182.7 Total area ofthe pour for zane HK = 2,540 m*

Height of pour=15

Total volume of zone HK= 3810 m®

‘The discharge for ech pump = 50 m3/h

‘otal numberof purps=5 nos.

Total discharge of tha pumps = 250m3/h

‘Total duration of the pour for sub one HK 01 = 3,810/250 = 15,26 hours = Approx. 16 hours

ach Pour wil be executed in two shits including the finishing works. Each shift (Twelve hours)

twill overlap one hour with the previous shift, Additional shit ville made ready to employ at se

ifrequired,

187.8 Sufficient manpower will be employed for each shift to execute the works property. The key

positions are menticned below foreach shift

| Construction Manager =1

roject ame —~S~S~*«*i ANRC

[ALAIN HOSPITAL MAIN WORKS PACKAGE | yg. o:

=O] | —reeroo sree ron | ner

eee

ft ‘Main Hospital Building

‘a Zuhair Abushaaban (Mobile no. 050-8074883)

. Gheath Souleman (Mobile no, 055-3206538)

Page 234738

“The two construction managers will work alternativaly for each shift

Project Engineer 2:0.

W, QAVAC Engineer 3 no.

Ii. Laboratory Teehrcian ~6 nos.

Supervisor from two batching plant ~2 nos.

187.9 Concrete check point wl be set up Tor this raft concreting works in the location as mentioned in

the attached sketch in clause no. 8.10, Total four (08) sets of measuring tots willbe setup inthe

check point for slump test and concrete temperature for delivered concrete from each transit

river The above mertioned fed tests canbe done fo four transit mixers together withthe four

set of tools. Cube preparation willbe executed ina porta cabin In sizeof 12 meter * 3meter. The

sine of curing tank wil be 2 meter * 1 meter * 1 meter wil be placed in a site laboratory with

continuous AC faclites. The temperature of curing water wil be maintained at 20° (+/-) 2%:

“Total nos. of cube moulds (150mm * 150mm) required for testing are mentioned as below:

7

a] sumectimn | tamiwrat | Mimtertere | ta snes

te

re | sitet

152 | asmrecbsutbe | antes

1 | comprssvestrengn | Meubeswitbe | takenforevry 00 | from rsh conerete:

pressive strensth | taken for every | m’,ifany cube fails | 851881116 for

100m) | toachieverequired | determination of

result) compressive strength

34 1% 5 1881 108 for

Geubes wil be | 2sparecubeswallbe | making test cubes

uraity | wier | tFenforevery | taken forevery500 | from fresh conrete:

Fence | absorpion | 500m) | m?,(fanyeube falls | 95 2681-208 for

to achleverequited | determination of

result) Water Absorption

ProjectName Doe, nas WE RAR ARTEL OGD

ALAIN HOSPITAL MAIN WORKS PACKAGE | gags ox

AN saseee'Q)| | wero srarenenr Fon | onan

Pouring of Raft Fourndation in Zone ~11K,

“Main Hospital Building

agen 15/38

cn is BS 188i 08 for

{Bcubeswillbe | spare cubes willbe | making test cubes

taken for every | taken for every 500 | from fresh concrete;

Water

8 pemesstty| 500m") | mfanyeubefais | DIN 2048 for

toachieve required | determination of

result) Water Permeabilty

7m i ‘1881108 for

ropia | @Beubeswilbe | (2sparecubeswillbe| making test cubes

‘chinnda | taken forevery | taken for every S00 | from fresh concrete;

a pemesbiey| 300m") | mi ifanycbe fails | AASHTO277 for

aa ee to.achleve required | determination of

result) CPT

| %% BS 188 — 108 for

{Bcubeswillbe | (2sparecubeswillbe | making test cubes

intiar | t2Kenforevery | taken for every S00 | from fresh conrete;

surface 500m!) | _m?,ifanycube fails | 8S.1881-208 for

. ‘Absorpton to achieve required | determination of

‘Test (ISAT) rest) Initial Surface

Absorption of

Total mi “ao

L a“

2.7.1. the pourwill be started atthe agreed time between the contractor andthe Engineer.

87.2. Concrete works shallbe started after completion of formwork and reinforcement activities. The

inspection request sal be submitted tothe Engineer for approval ofthese activites.

187.3. Surveyor shall ensure that the formworks provided fr the required shape and dimensions arein

accordance with the approved drawings, 53040-MHOSK-B2-ASLARC-SPD-10006 and $3040-

[MHOSK-82-ASI-ARC-SPD-10790.

1.74 _Allthe surfaces shall be cleaned Fornign materials such as saw dust, wooden peces, binding wie,

concrete residue, cut rebars et. shall be removed.

8.7.5 Adequate lighting shall be provided during night conerete. Tower lights, hand rallghts and tower

crane lights wil be fied as per attached Lights Pan (See cause no. 80)

8.26 Allthe safety precaution shall be fllowe as per Risk Assessment for ths actity

8.7.7 ASivill ensure that suficient amount of hessian clothes, polystyrene boardsand polythene sheets

(4500 each) are avalable at ste prior to pour

8.7.8 The concreting of raft foundation will be done layer by layer maintaining each layer of maximum

400 mm, Maximum allowed time to pour the succeeding layer is 30 minutes from placing the |

Project Name [Bac ma HEATERS

[ALAIN HOSPITAL—MAIN WORKS PACKAGE | ggy.ot

METHOD STATEMENTFOR | pate Wov2014

Pouring uf Raft Foundation in Zone “HK,

- ‘Main Hospital Building

- previous layer. The rat foundation of 1500mm height wal be poured by four (0) ayers; each of

fist three layers willbe 400 mm thick and the top layer wl be 300 mim thick. Vibration wil be

done to penetrate the vibrating poker 100mm inside the previous layer. Layers must be flowable

lve prior to placing conerete on top. But, vibrators shall not be used as a means to cause

concrete to flow tots poston in ie of placing. 2nch dia vibrator wil be used inthe area where

congestion of installed steel bars, MEP Installation or corners of forms makes narrow area.

Vibration will not be applied by way of reinforcement; and contact with steel bars, waterproofing

and MEP installatonswillbe avoided. Vibration wil be done 4SOmm away from high ribbed form

to.aold damage tothe form (soe Figure = 04).

During inserting the pokorin the concrete, the head willbe put in quickly and alowed to penetrate

tothe bottom of the layer as quickly as posse under its own weight. The head ofthe poker will

bee inserted vertically. Ensure that compaction to be caried out with poker adapting “fat sow

ut” process. Vibrators wil not be eld in place for long duration,

Proper co-ordination with the concrete suppliers shall be ensured to deliver the concrete trucks

in regular interval to avoid cold joints.

agen 15/34

Project Name’ Bos as HEARST

ALAIN HOSPITAL = MAIN WORKS PACKAGE

‘WiETHOD STATEMENT FOR a5 novo

Pouring of Raft Foundetion in Zone—HK, | osu 17/38

‘Main Hospital Building

‘VORATION COMPRETOR

sendetvteaton te

‘ones

—

FIGURE 04: Concrete vibration agjacentt high ribbed form

aed Name | Ban ERNST]

[ALAIN HOSPITAL™MAIN WORKS PACKAGE | gyu.ot

~ METHOD STATEMENTFOR | pats 2stovsmne

Pouring of Raft Foundation in zone HK,

Main Hospital Bullding

Nx)

geno 38/34

FIGURE 05: Concrete placement procedure adjacent to high ribbed form

18.19 The delivery ends ofthe concrete pumps hoses shal be kept as close as possible tothe delivery

points; concrete shal be poured vertically in maximum 2 meter height to avoid segregation. The

Uelivery ends of the conerete pumps hoses shall be 2 meter away from high ibbed form (see

Figure ~ 05). Concrete shall be placed and compacted on its final postion at site within 2 hours

after the introduction of the cement to the aggregate. The compaction of concrete shall be

Completed within 30 minutes of dlscharge from the miber. Regular cleaning ofthe bars wl be

done by brushing to avold concrete setting on the top bars as coneret ls poured in,

8.7.10 During concreting, fe (05) no, carpenters wll monitor formwork bulgingandto prevent sippages

‘of formwork. These workers will be used only as-a backup in case of emergency

£87.11 Three (03) nos. tee fixers shall be avaliable to ensure concrete covers being maintained duting

| pouring of concrete. These warkers wil be used only as a backup incase of emergency:

1.7.12 ASI will establish the arrangement as below to determine the heat ofhyération of concrete during

the concreting activtes. In sub zone HK 02, the thermocouples shall be installed on three (03)

Tocations on the conerete surface; one shal be installed on axis X18/Y27 (near sump pit), one shall

be on centre and the remaining one shal be installed (as per Figure 06) atthe opposite comer of

he conereting area't meter * 2 meter from the comer) The location of the thermocouples can

Project Name Fo as EASA D

[ALAIN HOSPITAL MAIN WORKS PACKAGE | guys

W==8) ———yaeTHOD STATEMENT FOR ie 25 Hott

Pouring of Raft Foundation in Zone — HK, a

‘Main Hospital Building ee

ie changed ai per site stvation oF a per Engineer's instruction. Thermocouples wil be placed

‘with a spare steel bar in order to protect them during the casting,

For location no. 1 and? of sub zone HK; the conductors ofeach thermocouple wil be placed prior

fo concreting works on five (05) points in a line perpendicular to the concrete surface; one

Conductor ofthe thermocouple wil be placed 100mm below the conerete top surface, one will

bein the center of concrete section, one will be 100mm from the bottom ofthe foundation and

the remaining two (02) will be placed between these points to maintain approximately 300mm

from eachother (see attached Figure 08)

For location no. 3 of sb zone Hk, the conductors consist nine (09) points where conductors of

thermocouples wil be placed in diferent heights of foundation (see atached Figure 03)

Vibration willbe avcided adjacent to the points of thermocouples to secure the monitoring

stem. Injection hoses wil be fixed withthe injection flanges very tightly to ensure the injection

Stem in place during the vibration, An automatic data logger wil be connected to the

‘Thermocouples to logall temperature data. The acceptance criteria ofthe measured values are

asbelow

|. Maximum temperature difference between the core and surface of any pour willbe 35°C for

design target and 20° for field maximum,

|i Maximum temperature difference between a new pour and a previous pour willbe 328C for

design target and 15° for fold maximum.

Ii, Absolute maximum temperature anywhere in a pour i 60% for design target and 7O%C for

field maximum.

ue Rebar willbe marked directly overruns of drainage pipe work. One toolbox tak willbe sed

to explain the procedure for vibration inthis sensitive area,

‘Te following thermoccuples and datalogger wil be used ast

instrumentation Tee ake Parameter

emacoupl wre we Labtec ux | Temperature Heat of

cae betty, UK| aration —

ata topper ‘arnpbail | Logging the temperature

icone or1000 | sient, USA_| automaticaly

“The calibration certifiates ofthe data loggers and thermocouples are avaliable at site,

Project Name Tac nas WEAATASTORD |

[ALAIN HOSPITAL MAIN WORKS PACKAGE | goy,03

NeO) METHOD STATEMENT FOR ‘| oste2510ran4

vouringot ate Fouratin Zone MK |e ney

rain Hospital Bulding J

esate

Seana |

atig|ta

Figure 06: PLAN of sub zone HK In Main Hospital Building conereting,

area showing the location

(ae

tet

|rounsation height = 1500"m

Figure 67:SECTION AA (fr location no. 1.8.2 of HK) showing the tive

(05) points where conductors of thermocouples will be placed

in diferent heights of foundation

Project Name a ASOT |

[ALAIN HOSPITAL™ MAIN WORKS PACKAGE | pays

Wisse) | ——irernon sinranenr ror oat

Male Hospital Building peste!

sesso | Foundation height= 250mm

Figure 08: SECTION 8-0 (or location no. 3) n HK showing the nine (3),

points where conductors af thermocouples wil be placed

inlferent heights of foundation

1.7.13 The vibrators shall be operated at regular intervals to produce dense, compact, homogeneous

concrete surface, The vibration works will ensure consistent massis obtained without segregation

for the entre concrete area, All rebar willbe marked directly over runs of drainage pipe works

‘Mo aeration of concrete shall be undertaken on these lines

8.7.14 Temperature of concrete shall be maximum 32°C at the time of pouring and maximums ambient

‘temperature wil be 40°C Concrete wil be protected from moisture lass after placing by covering

‘he surface immediately with polythene sheet and wet Hessian coth

8.7.5 The final working up ofthe surface shal be done by power Floating machines, to tain uniform

surfaces free from regularities.

18.7.6 Surface finishes shallbe fiat and level. The tolerance limit forthe top levelof the aft foundation

wil be +5 mm / 10mm [Refer to project specification Section 03 3000, Clause no. 3.7 A)

8.7.17 alter placing the concrete, leveling of concrete willbe started by skilled masons and labours AS!

‘Surveyor wil periodealy check the top level of raft surface after concreting ofthe top layer and

vill ensure the correct level is achieved. Approved evaporation material, MASTERKURE 111 CF

{approved materia submittal, MSF No, $5] wile sprayed on leveled concrete surface by spraying

machine and then eonerete surface willbe covered by polyethylene sheet (1000 gauge), Power

floating wil be started after 4-5 hours from the time of placing the concrete, but always it

mandatory to checkthe surface of cancete in order to ensure the proper toughness to stat the

finishing of surface. After power floating works, approved curing compound, Fostoc Concure WS

Project Name Doe FEAST

ALAIN HOSPITAL MAIN WORKS PACKAGE | pyycos

A NcsseneQ)| | ——wernon srarewienr Fon | oa ase

pouring o Rat Foundation nZone Mk,

‘Main Hospital Building

agate 22/38

“Approved material acbmital, MSF No. 23), will be sprayed on the concrete surface. When the

concrete will achieve fll hardness after final setting time, wet hessian cloths will be laid on

‘concrete surface with 2cm depth water and then the surface wil be covered by polystyrene board

(Expanded polystyrene ~ SF 20 WA, Scm thick, material submittal no. MSF No.38) to prevent

femission of heat from the concrete surface tothe air and to control the difference in concrete

temperature, Acess to poured area to be restricted upon finishing. Al foremen will be fully

trained to implement the above activities. The labours to be employed to operate vibrator and

‘power float, wil be trained by Tool Box Talk and it will be ensured they have achieved suficent

skis to operate the vibrators and power float

8.7.18 Record shall be mantained by Exova Technilans for slump test, concrete and ambient

temperature and grade of concrete in the concrete check point (Refer to Project Specifications

Section €3 300, clause no 3.4 G.P). Delivery mixer trucks arrival time, time of discharge and

departure time tobe recorded on delivery tickets

1827.29 Concrete test cubes shal be de-moulded not less than 24 hours and shall be transferred to

laboratory for testing not less than 48 hours from the time of mould preparation, Exova wil

prepare the cubes, de-mould and put the cubes for compressive strength Insite curing tank. The

‘Cubes for durability test wll be transferred to Abu Dhab laboratory by vehicle. The cubes wil be

‘continuously covered by hessian cath and polythene sheet during transportation

8.7.20 One Supervisor willbe at site fram each batching plant. He willbe responsible fr controling the

ordering concrete end coordinating the truck discharge from plant and during transport.

37.21 One technician from EXOVA will be present in the batching plant during pouring. Wester

Intemational will cenfiem the approval of the waterproofing system. Clearance letter from

‘Wester International wl be attached withthe ial inspection request piar to pouring of raft

‘foundation.

87.22 Concrete gang not toleave worksite untilconereter pour completed or handover to next working

shift conerete gang.

18.7.3 Total two (02) shift work (12 hours each shift and 1 hour overlap) Is planned forthe pouring

activity including the finishing activity, Ths Is planned considering any unforeseen delays during

| outing, The shift timing inctudes handing ove, breaks ec. Additional shift wll be ready to work

at site, if require.

1.1.24 Concrete fish on high ribbed form work wil look tke the Figure—9. No need to distr oF brush

tn the fresh concrete on the face of high ribbed sheet, If access mortars coming out ofthe high

ribbed form work, it wil be cleaned by light brushing (as per Figure ~ 10) before the concrete

hardens.

"Project Name

[ALAIN HOSPITAL = MAIN WORKS PACKAGE | oy. 03

oO ‘METHOD STATEMENT FOR one Hr 204

| meena [om

Figure 09: Typical concrete fish on high ribbed form work

CLEANING

Figure 10: Clearing of acess fresh concrete on high ribbed form work

“projec Named BRR RRA

[ALAIN HOSPITAL MAIN WORKS PACKAGE | guy. o3

AzazO HEROD STATENGRTGR | en

resi 4/0

tL

[8 Scope of The Pumps withrange And Transit Wikers Movement: See attached Figure 1 and 22

Figure 11: Location ofthe Pumps and

Transit Miners Movement for HK

Project Name —=~=S~S~S*dS DESHI |

ALAIN HOSPITAL MAIN WORKS PACKAGE | yg.o

(METHOD STATEMENTFOR ae asetn014

Pouring of Raft Foundation in Zone HI,

rage 225/38 |

Figure 12: Location ané range of concrete pump for HK

Project Name

(Ws)

[ALAIN HOSPITAL MAIN WORKS PACKAGE

METHOD STATEMENT FOR

Pouring of Raft Foundation in Zone HK,

‘Main Hospital Bulding

ag £26138

18.9 Pouring Sequence:

LEGEND:

@ concrete Punp (with number)

(5) conta ean stat

FIGURE 13: POURINGPLAN FOR HK

NOTE: Delivery ends of Pump will

bbe 2 meter away from high ribbed

form work

rae tae

— ALAIN HOSPITAL MAIN WORKS PACKAGE | sy

(AO) |] rico saree] ora

rouringut Ret Founcation in zone 16, | yey

[BaD UghtsPian

LEGEND:

@ concrete Pump

@ Banks man traffic control

@ Tower tshts

[Ey Concrete ruck wash area

Ha Wheel wash Area

@ Tower crane light

& Hand rll ight

FIGURE 14: LIGHT PLAN FOR HK

Project Name

[ALAIN HOSPITAL—MAIN WORKS PACKAGE — | goysot

METHOD STATEMENT FOR ‘| oxe25ov2014

Pouring of Raft Foundation in Zone — HK,

‘Main Hospital Building,

geno 28/34

Project Name

ALAIHOSPTAL MAN WORKS PACKAGE — | eas

Mawes TETTOD STATEMENT FOR ue 24004

poutingotRaftFoundationin 206 HK, | rng

Main Hospital uldng

Jun Jin 52m pump specification

itil ress weight 2.6 tones.

ech ore of 2706,

“eal eth of Vite 150 440mm

and its work range.

The proven SCHWING 42 m boom

rae

sxanosrna ons eee

(sss) | —— eon sreenrron

wna

rete 90/38

Project Name Tac aa HERERO]

[ALAIN HOSPITAL™ MAIN WORKS PACKAGE | gyusot

~ METHOD STATEMENTFOR =| pate 2sNovsoxe

Pouring of Raft Foundation in Zone WK, | ape 34/38

4)

Technical data:

yearns Acar een

‘rh Wltsuced nee ano

ee

Project Name

ALAIN HOSPITAL MAIN WORKS PACKAGE

~ METHOD STATEMENT FOR

Pour

1g of Raft Foundation in Zone — HK,

Main H

rage 52138

pital Bulli

ora enon wrt 2 egos 3504

82 Removal of form work

8.12.1 Removal of supporting system of high ribbed form works will be done after 48 hours of concrete

placing of 2s agreed with the Engineer, After removal ofthe supporting system, the side ofthe |

igh sbed metal sheet willbe covered by polystyrene board to avoid heat lossand then covered

by polyethylene sheet

8.12.2 The edge type form works wil be removed ater obtaining permit to strip from the Engineer.

1812.3 Removal of form werk shall be conducted without disturbing, damaging or overloading the

Structure orthe form work. And also especialy care withthe waterproofing membrane

18.124 The area shall be deened tobe ready forthe next pouring. For any repa work required in other

area the approved concrete repair material shall be used and that will be done immediately

8.125 No repair works willbe caried out. Contractors method of making good any defects shall be

submitted to Engineer’ for approval prior to start remedial works.

8.13 Curing

1.13.1 after placing the coniete, leveling of concrete wal be start by sila masons and labours.

‘Approved evaporation material, MASTERKURE 111 CF (Approved matetal submittal, MSFNo. 55}

ull be sprayed on leveled concrete surface by spraying machine and then concrete surface wll

be covered by polyethylene sheet (2000 gauge). Power floating will be started after 4-5 hours

‘rom the time of placing the concrete, bt always tls mandatory to check the surface of concrete

in order to ensure the proper toughness to start the finishing of surface. After power floating

works, approved cuting compound, Fosroc Concure WB (Approved material submittal, MSF No.

23), willbe sprayed on the concrete surface, When the concrete wil achieve fullhardness after

Project ame Fo a EEN D

| aL oserrat— MAIN WORKS PACKAGE

~~ METHOD STATEMENT FOR

Pouring of Raft Fourwation In Zone 1K,

Main Hospital Building

pues 238/38

| final setting time, wat hessian cloths wil be laid on concrete surface with 2 em depth water and

‘then the surface wil be covered by polystyrene board (Expanded polystyrene ~SF 20 WA, Som

thick, material submittal no. MSF No.18) to prevent emission of heat from the concrete surface

tothe alr and to contol the difference in concrete temperature. The surface wil be sprayed by

potable water in regular interval to ensure the hessian cloth continuously wet. The polystyrene

board willbe removee after analyzing the daly temperaturelogreportand as per mutual consent

between the Engineer and the Contractor.

[after removal ofthe polystyrene boards, the curing will continue for total 14 days with wet

hessian doth

£8,13.2 Concrete gang not to leave work site unt curing placed and confirmed as acceptable by section

manager

1843.3 Water used for curing shall be potable water, free from salt, harmful matters and other

impurities, Water takers wl be ready to start withthe curingas soon as possible.

8.13.4 Water for curing shall be similar to the concrete placed. This water will meet the criteria as

specie in Project Spacifications Section 03 3000, cause no 2B,

9, CONSTRUCTION PROGRAMME:

|As per ASS Contract program / Working program submitted tothe Enginect

410, INSPECTION: TESTING

toad The QA/QC Enginces/inspector shall ensure thatthe inspections are completed in sccordance

vith the IT requienent. They wil conduct random inspections as per the TP requirements to

‘ery compliance with the specication and design drawings.

402 The QC Engineer/Inspector shall ensure thatthe latest revisions of approved drawings!

documents are used an site by the Site Construction Team.

40.3 Any discrepancies found during an inspection wil be immediately communicated to the

Construction banager/ Projet Engine Site Cagineer for rectification and compines with

Spectied requirements, Discrepancies shall be rected prior tothe Engineer's inspection.

11, RELATED FORMS,

11.1 Check Sheet

11.2 Concrete Pour Card (E:0va)

1113 Concrete Compressive Strength Register

Project Name Yd RR WANTASTOOD

[ALAIN HOSPITAL MAIN WORKS PACKAGE | pg.o1

ANestex'O)| | ~~~ wernon srarewenr For oa aeaneae

Pouring of Raft Foundation in zone. Hk,

‘Main Hospital Building

Page 34098

12, ATTACHMENTS

12.4 Risk assessment

4122 nspeetion and Testing Plan

323 check sheet

42.4 Sample fr Concrete Pour Card (Exova)

1255 Template for Concrete Compressive Strength Register

1126 Template for MEP clearance form

4127 Material safety datasheet for concrete release agent and curing compound.

11 6 RISK ASSESSMENT and ENVIRONMENTAL ae

"ASPECT & IMPACT ASSESSMENT Goji ee

NS ‘o

Pro-Checit or Re aseooner

‘Mr Garo Cots ca

Mi eee Ueto ose 20

“a per Orginial Chat

ie Rach a 52168

cba Des 05548008 |

‘Mr Pabl Omazaba 061 O57

Sechin Moat ono s2iT

orn fa oundationn Zone a ssa

“100

‘apr oraoonScele

‘Ae pet pour aches

Yee

Retro MS fl eqlpmet Amati

Yer

"Yeo ona tusk mbes cone PUM

[Bf ss, oar al pues, ves, Nv,

tat lr eto wore

Conerelaoe

Yes eatin oe

cre

a [Yes Any itd nese h

“fh Hoard Fencha/Earesang Denise | Yearning caution tpo, eras man pple wi baton _|

Geigee ees Spee soem a

1B [Sooty Requremen NA —

js "ee a panta aide Hering buck bare an tar

2 ie "Swonbnatiface nar ponpe oad ceshoe

21 | arta Wo Resa Ys Go Won Pert Ho Pmt

| Wk ore NA -

alee Con ee oa eT WEP aa

[| Beas je =

2 | nea ead cnr owe Cao Wei Grane ee tan, bt

aa_| sree Enos none a

21 | nant ones Ne

“EE ra)

SREB

(eunga one

‘2 baran)

ea | rere + |e | eoonamey «| ous) pmecroy

som oo

wea | pepe |e | stevie) setaenaes «| Sele

sito + Ses +] yopesedaid

are Buunod

eBeu2H voRENAsu09‘aquNH0"TeIUEDIA seBeueyy 3567 seINeG nea | J88UU3 BSH 'sreOO OMEUEE | EAL WOUsDeBEY IRE

“evdey em 9 zw vonepuog WRU Buunog eek honey

erro WD | wowdeg og ao cuss oe

Tea seceO rev Neve | _ouRUVA] (Weirson ure) 9H 2007 u vonepunea weu.e BuLnod DISEL

a

Ose SRERETSGmoR aioT | RR | creico

EP ESB

Too r=a0o rev vee | SHU (Geudso} wien) 4H eu07 ul vonepune we jo BuLMog DISEL

T SSaeee

— ee ee a

USSSA SREGSTSGNEERTaeoT | BiessOR | Circe

EBPs Ta a

i

i

roo ew-oea/revinwaive | ouyeu vu (Edson wren) 9H 8u07 ul uonepune weuj0 Buunod DISEL

mrumasr' vecymereen mm sti or = ——— Sal

Ceres) EGE wT UaGnuaco mT “TOT one

Hueusguony

PTET

‘400 AEU-OS! PSY HYWINE sou ‘(ieudsoy urevi) 4H eu07 UI UOREPUNCY yey jo BuLuNog ose L

— epeuesnul

ease J) GRINS aT WaKnuaco mT “FW-OT em irg

HPT

TTS TOTS

[oo neeroee rev HWW rou ou (ievdsoy UreW) MH 2U0z Uj UOREpUNC WEY jo BuLNog Ose L

SSEs=

awenstce scurry my vestamss vars same Fueusgnesyer | eneuesnuy

OSeA | SU GSGnuacomT GWOT iiieassie gm icc

RT > ‘ana sews

soayod

sasaubes «|

pausts sa

as toed

wa] pepe | sam | MOM SIMIE | apeatad

“inod sees «| ele

vor

nme

cn tose uses oop 29 eisuoeatrad

ESA a SSUES GTA

Taree | wm Cee ABH] EL

aap | Sst

OSA BUNS iT isGnuzcoml © TREES | meicey

‘|

SPER RATT AT

‘so607 pue weusBevey SweiL Or 409 su Kojo Ska RENO NAY

8 Buypuey enuey~r1 429 —neunt Acjndoy SHS RENO Ney

unin 0 2en a) ¥e 200 —Heenas Kae HS NEU NY

uring Supea aioueD 9 Fo ~eUnuSu ney SH RENO OY

‘ouoesonay Buns

soumituco 265)

0

ge a

sos puto ean yea eben Sanupansunag | Are Bunecue> uo a | ne se. peurbe Cue)

anbnxon Supueuneuey | Soumaaucs edn | “Basen ayes peeeaions eum | _dotenpl wasenoivaid| STIDNS ADNLRANOO BOO

‘eo oe aS ‘suaeu"wENEED = ‘anjense Howden) fou ny ‘muueor

TooneuaeO rev MVE | uRuvE (Weudsoy wren) »H eue7 ut uonepuney wea jo BuLNog DISEL

fame seus serene pOUeSN

ULES) SRST GsSncom GWOT | BeSEHIVI | TS

SPER

Tea ma90/ Rey iHwiva | SUV (Weds0H Ue) HH oue7 ul wOREPUNO WEN jo GuUNod

sopra nar

uananusgom) -GN-O-T

SRN

&

=

Ost

"]

errors ‘a0 oo noo sy

Senmsnemant | SeeaemamnAeC eR =

en powwnryopunatent | pennant manenner | siutumase ete =

es | tren rh States | enmanecene | prema | ramen tamums

peta men Pamieronaeees | yyuereeaimumseey | eemumraman| demersal

vaio soot searommreunt | jayrampennaants | puontageare

eens ‘nutans nr0 | pagina tote memeem| Suances

wemntrnen ere Serna | peers “Sree | ananassae | miamandy

laa unvmgnnesianass | Muemomaesteectes | | amarante "oe

= celts | "emma MMAR | anne uo | mx

“oun zu Sey ame | teens ned | mauris

manana techies | wenn mn,

astemetatoniat | cum angonce a ot

moeumpetnca apes | wemreeatepsacun xin | cunt amamgnon | PMP Sa,

a

scoartioeraaes | | irae | ee |g ageng SOA ns

Aa | onan r eee | Saget | ustmmimagn | wees sears | am

cotemn gcc | “Sharauaes Sie | “a ain amt cocoa | agentes

a | | Tae | eens

darmennre a eonisiname on

Toomarearevanwner |= muve

nuance a sovsmy — 2 | iresce | Speueshll

Ose A/) BRESTSGNM wicor | BARSEI | orc |

are onsen

aoa ee rr

deus sors ntewen ze sont

peemugomea: sum munya

Aaperatey L ununedeg ai ay fae

.

oe

wnt Ut

seres09 "g 18409

pe

srortanee | ions | soa ftl%, ge

Too rosa rov vive | Suu

OSESES AG) SOMES ET GsGiseom

Trav

I

| xe edt

lejuewuonau,

__ — _

em “Teurdeoy wen) 9H #402 ul uopepuned yeu Buunoa | SEL

~ ~ === |

reso: epeuesniy |

[CNS BRESTGGNasomT TOT | BRERA | orice

SPH REE

syne usta 29 sie RH a, AN |

°

cxunop oan 4 geome oa (34) Wout Moen RIN

ay sonjod werosid ude prepare SuueH -Ros00 aNeEENRUPY

‘peseg/ ope a8

Trew ee ania yee Som SPHERES

Sarai poe Ra

Bang Fe ATES

‘gua 090 40,

~UneW ISR SSH

= Cason uEW) pw SUEZ vl vonepUnoTWRAe Bspreg]| ———_DISEL.

Sas

veceayscee ma muonans sonra ~ Faeaggaagye | epeuestul |

SRST eGnuisom ENOT | HAS RCIVI gm 10 |

Sa pe

“Tuipina edo Wenn Sued ul LONepUnOG yeu Jo Buunod so uela BuNeeL = uonsed=ul

CEE) aunasansy ima SE

“Dajpima Teudson ies yH ~ Suez ui vonepunoa weu yo Banned 04 uela Bune Vonsedst

Ca) siatisean i Tika”

SE oT GS

veo |e | mene cane wen lapentaee | someon | SAREE

rlalele

z

gq,

Buypina son UA uN ovez ul vonepunod usu Te Bupog og uvla Bunsel WonseeaAl

CEREM) senmanin weeny

SET Sar gS wes

ame] ome | zeae

|

ey —— peg ae en aan

“Bulpling leIdson NeW 5H — suoz Ul NONepUnOT Ueu jo SuUnoa 164 UBid BuNSeL @ UoRSedsUL

(CE2REV) sansseant ese” SRY Feu gy ES

Bujpine mudsen Wiew an ~ puez Wj Wonepunos Wee Bulinod 104 weld Banal wuCNsEdeA

CREE) aunt STV TRE TE eS

“| Berio | iting eerie

pa k

esac |

|sxmars ane on] I

meus |e ilay |ymimiomba) Memes sonra women | E

soe - i

ae =

ee ae et =

= ee saath

Ee =a a =

CEE) satan inact SeeY Oey Gy wae

Bujpina Ieidson WEIN i ~ 8uoz W uONepUnea Hew Jo BUENO’ Jog Weld Bupser vonsedeus

CARE) asian Gey SHES oO gS ee

ay) ote Sa oped 6 LAL SOP

eS ee ee

ey —— ae

E a eae =

oS wee

Boipiina waidson Grew. TW] Uonepinod Wow Jo Bunog vod dara Sunsey w uonsedsul

(OSSEA/) caansains RR

Tease sess Fes

SP Se

ALAIN HosPrTaL.- MAIN worKs PACKAGE || J \%rrionc

‘Quatty Check Sheet for

Pouring of Raft Foundation in Zone ~ HK, Main Hospital Building

RIA Ne:

SUBCONTRACTOR CONTRACTOR Rev. Na.

Date

Lovatn(tack sketches feces)

Level Yantai)

um /Srsare Dereon

st Gheckedy | Chek [Date

re

Na

7 | Foss ind contin goad enti fo ek

mse per ope ving

2 | tami sntrpt amas hod

>| AME svi comitt woud ance cig

‘hr erdnr oper ws

1p Renfro ples: sey et eds

Sinan ipsa pe approve! i

5 | Waser ten pt peri Sbentact’s ONC sit!

eben eet ipoved ye ape

«| Alster wi col sto ek ad eet

ve dig

7 | Wee ayo sl sn rete hr a og

‘ sig cour sin pov.

1 | Sree ce gee ma ey pi

1p | meses pene cnt ewig, Hog] me

|__| fring ten eh

7 Weta eee ol aes me so i dot

y_| Theda cnet mgt hung sean ces ace

ofc hrs roped raed eid TP

| eases pn oie. Vir pind dts eh

‘Smpcion a hed frat ws ce

aE titer yh oe sit pace a

‘gta nn corns conned Vays os

Cama if

i eee Poemvcse

‘a 0 mer

ae ‘ate “Spm

(heck ia» PAA ASC 8, er

ui tone

Safety Data Sheet

NO

Sane.

gota es

SE oe

ES aC coat. wnaciah ue pomctied ata ba

ens TEE te axle

ints Hei

ae ot IMEC

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Method 24 Rev 01 PDFDocument3 pagesMethod 24 Rev 01 PDFraju_civilengNo ratings yet

- MSS 0003 V00 (Site Cabin Installation For Temporary Site)Document3 pagesMSS 0003 V00 (Site Cabin Installation For Temporary Site)raju_civilengNo ratings yet

- Normas de AcerosDocument7 pagesNormas de AcerosEduardo LandaNo ratings yet

- ThermocoupleDocument6 pagesThermocoupleUma MageshwariNo ratings yet

- PCL Aah Asj CV 180 Rev 00 - Check SheetDocument1 pagePCL Aah Asj CV 180 Rev 00 - Check Sheetraju_civilengNo ratings yet

- MSS-041 Rev 03 RDocument2 pagesMSS-041 Rev 03 Rraju_civilengNo ratings yet

- BS 598-Part 101-87Document10 pagesBS 598-Part 101-87raju_civilengNo ratings yet

- BS 10223-Part 2-88Document10 pagesBS 10223-Part 2-88raju_civileng0% (1)

- Material 1 2 Rev 1&4 Rev 2Document7 pagesMaterial 1 2 Rev 1&4 Rev 2raju_civilengNo ratings yet

- Method State 14Document3 pagesMethod State 14raju_civilengNo ratings yet

- BS 1881-119-1983Document8 pagesBS 1881-119-1983raju_civilengNo ratings yet

- BS 594-1Document30 pagesBS 594-1raju_civilengNo ratings yet

- Method of Statement 063 Rev 00Document56 pagesMethod of Statement 063 Rev 00raju_civilengNo ratings yet

- BS 1600Document11 pagesBS 1600Rajan SteeveNo ratings yet

- BS 12Document15 pagesBS 12Rajan SteeveNo ratings yet

- Method 24 Rev 01Document3 pagesMethod 24 Rev 01raju_civilengNo ratings yet

- BS 4-1Document20 pagesBS 4-1Rajan SteeveNo ratings yet

- Thermal Cracking of ConcreteDocument2 pagesThermal Cracking of ConcreteChatchai ManathamsombatNo ratings yet

- Concrete Vibrators 1003 HandbookDocument8 pagesConcrete Vibrators 1003 HandbookMohammad Saleem ZahidiNo ratings yet

- Method 32 33Document8 pagesMethod 32 33raju_civilengNo ratings yet

- Thermal Cracking of ConcreteDocument2 pagesThermal Cracking of ConcreteChatchai ManathamsombatNo ratings yet

- BS 4-1Document20 pagesBS 4-1Rajan SteeveNo ratings yet

- PSD 01.01 UAE-n Limits-Of-Authority 2012-11-08Document6 pagesPSD 01.01 UAE-n Limits-Of-Authority 2012-11-08raju_civilengNo ratings yet

- Concrete GuideDocument38 pagesConcrete GuideAdnan JadoonNo ratings yet

- Temporary GeneratorDocument11 pagesTemporary Generatorraju_civilengNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)