Professional Documents

Culture Documents

Smith Comparison Bit PDF

Uploaded by

Pither ZuritaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Smith Comparison Bit PDF

Uploaded by

Pither ZuritaCopyright:

Available Formats

Rock Bit Comparison Chart

5. SEALED ROLLER BEARING

GAUGE PROTECTED

FORMATIONS

Soft Formations/

Low-Compressive

Strength

Soft to Medium-Hard

Formations/

Low-Compressive

Strength

Types

Series

TCI

SMITH

GSi01B,GS01,GS01B

GS02B,GS02T,GS03B

Gi03B,G04B,GS04B

TCTi01

GS05, GS05B

GSi06B, G08B, GS08B

G10B, G10T

GS10B, GSi12B

GSi12UB, TCT10

GSi15B, G15, GSi18B

GSi20B, G11Y, M15S

15JS

G20, GS20B, G25

G20B, 20GMS, 2JS

GSi20B

G28B

G30, GS30B

3JS

Medium-Hard

Formations/

High-Compressive

Strength

2

3

4

7

8

Hard, Semi-Abrasive

and Abrasive

Formations

Extremely Hard

and Abrasive

Formations

3

4

1

2

3

ReedHycalog

GTX-00, GX-00

T41

MAX-GT00, MXL-00

EMS41H

GTX-03, GX-03

MAX-GT03, MXL-03

T42

GXT-03C

EMS42H

GTX-09, MAXGT-09

T43

MX-09, GTX-11, MX11 EMS43A

MX11S, MXL-09

EMS43H

MAXGT-18

MX-18

T44

EMS44H

EMS44A

Security

DBS

XT00-05

EBXT00-05

XT06-09

EBXT06-09

SMITH

GTX-20C

MAX-GT20CG

MX-20C, MX-28G

MX-30H

MAX-GT30

Hughes

Christensen

GF05, GF05B, GFi05B

GFSi06, MF05B

XT10-13 F10,F10B,F12,F12Y,GF08B

EBXT10-13 GF10B, GF10HB, GFS10B

GF12T,XR12,MF10T,MFS10T

XR10T, TCT11, TCT12

XT14-17 FH16,FH16B,FHi18,MF15M

EBXT14-17 F15T,MF15B,MF19,GF15

GF15B,GF15Y,GFS15B

XR15, XR15T, XRi15G

F25Y, GF20Y, XR20Y,TCTi20

GF26, F27, GFS28, FHi28

T52

XT24-27

GFi28B, FHi29, Fhi25, F26Y

EMS52H EBXT24-27 MF26Y, FHi24Y, F27A, F27IY

GF27Y, XR20TY

MXL-00, MXL-03

STR-05C, HX-05C

Security

DBS

FHi35, GFi35, F30Y, F37Y GT-30C, STR-30C, STRXT34-39

35C, STX-30C, HR-38C

EBXT34-39 FHi37Y,FHi38Y,F39Y,GFi35YG HR-30C, HR-35, GX-30C

F37Y, XR30Y, XRi35, XR35Y

R03A

GX-35, GX-38, MX-35C

TD42H

R07A

SL53,SL53A,TD53

TD53A, TD53B

TD53H, D53,HP53

HP53A, HP53H

JA53, R30,R30A

RD33

XS28-33, XL28-33

EBXS28-33

EBXL28-33

TD54A

XS34-39, XL34-39

TD54X, TD54

EBXS34-39

R34A, R35A

EBXL34-39

R36A

FH40, FHi45, F40, F45H,MF4H

SL61, SL61A

GF40H, GF40Y, Xr38, XR40 STR-40, HR-40, HR-44 TD61, TD61A XS40-45, XL40-45

XT40-45

STX-40, GX-44, MX-40

EBXS40-45

HP61A, HP61H

ETS61A EBXT40-45 XR45Y, F40Y, F40YA, F47Y

MX-44

EBXL40-45

R40A, R40

F47YA, FH43Y, GF47Y

G40, G40Y, G40YB

4JS

GT-40C, MX-44C

MX-55

EMS62

XT46-51

EBXT46-51

XT52-58

XT61-69

F50, FHi50, FHi50Y

F46HY, F47HY, GF45Y,

GF50Y, XR40Y, XR40YA,

XR45Y, XR50

STR-40C, STR-44C

STX-44C, HR-40C

HR-44C, GX-44C

GX-45C, MX-40C

MX-44C, MXL-44C

SL62,SL62A,SL62X

TD62, TD62A

HP62, HP62A

HP62H, JA62

R44A, R45, R48

GX-55, MX-50, MX-55

EBXL52-58

HR-60, HR-66, HR-68 TD64, TD64H

HP64, HP64H

STX-60, MX-66, MX-68 R60, R65

XS61-69

EBXS61-69

XT71-75

STR-70, STX-70

HR-70

HR-80, HR-88, STX-80

STX-88, STR-80, MX-88

XT95-97

XR75Y

F80Y, GF80Y, XR80Y

F85Y

XT99

F90Y, FHi90Y, XR90Y

HR-90, HR-99, STX-90,STX-99

STR-90, HR-95, GX-95 ,MX-99

XT83-89

XT91-93

Seal and Bearing Prefix

Non-sealed (open) bearing

D

Single seal, roller bearing

S

Single seal, friction bearing

F

Single seal, roller bearing motor bit

M

Single seal, friction bearing motor bit

MF

Product Type

Milled Tooth

Milled Tooth

All

All

All

Example

DSJ

SDGH

F15

MSDGH

MFDGH

Premium Product Type Prefix

FH, single seal, friction bearing

FH

Gemini twin seal, friction bearing

GF

Gemini twin seal, roller bearing

G

Ideas

i

Xplorer, single seal, friction bearing

XR

Xplorer Expanded

XR+

Insert

All

All

All

Insert

Milled Tooth

FH23

GF30

G18

Fhi21

XR25

XR+

Milled Tooth Cutting Structures

Soft formation type

S

Soft to medium formation type

T

Medium formation type

G

Medium to hard formation type

V

Self sharpening hard facing

S

Heel inserts

H

Premium Milled tooth cutting structure

+

Milled Tooth

Milled Tooth

Milled Tooth

Milled Tooth

Milled Tooth

Milled Tooth

Milled Tooth

FDS

DTJ

FDGH

SVH

MSDSSH

SDSH

FDS+

Insert Cutting Structures

Shamal design

S

00-99 Insert bit digits (00 Softest - 99 Hardest)

Insert

Insert

GFS10

FH50

Cutting Structure and Feature Suffix

Air application bit

A

Binary carbide gauge

B

Binary diamond gauge

BD

Center jet

C

SRT diamond gauge

D

Fully diamond enhanced cutting structure

DD

DD2

Fully diamond enhanced cutting structure (Premium)

Extended Nozzle Tubes

E

Super-D Gun cone coating

G

Heavy set gauge design

H

Inclined chisel on gauge

I

Dome Jets

J3

Lug Pads pressed with tungsten carbide inserts

L

Lug pads pressed with diamond inserts

LD

Nominal gauge diameter

N

Diamond heel (50%)

OD

Diamond heel (100%)

OD1

Modified PS Feature

P

SRT tungsten carbide legback protection

PS

SRT diamond legback protection

PD

Q-Tubes

Q

Upper and Lower tungsten carbide legback protection

R

Upper and Lower diamond legback protection

RD

Shaped diamond gauge and 50% Diamond heel

SD

Shaped diamond gauge and 100% Diamond heel

SD1

Trucut carbide gauge

T

Trucut diamond gauge inserts

TD

Unconventional cutting structure/feature

U

V-Flo hydraulics

V

Vectored Extended Nozzle Tubes

VE

Softer than standard insert grades

W

Conical cutting structure

Y

2-7/8 connection (not SMITH default size 2-3/8")

3

6-5/8 connection (not SMITH default size 7-5/8)

6

7-5/8 connection (not SMITH default size 8-5/8)

7

Insert

Insert

Insert

All

Insert

Insert

Insert

All

Insert

Insert

Insert

All

All

All

All

All

All

All

All

All

All

All

All

Insert

Insert

Insert

Insert

All

All

All

Insert

Insert

All

All

All

F47A

GFS10B

GS03BD

F10C

XR30D

MF37DD

XR40DD2

XR+E

F12YG

F37H

F27I

GS12BVEJ3

FH45L

MF15LD

GF05N

F57OD

XR25OD1

FH28P

FH28PS

F37PD

GS18BQ

GS18R

F50RD

G25SD

MF20SD1

XR20T

XR32TD

GS18U

FH35V

GSi01VE

XR15W

F59Y

XR30-3

XR-6

XR-7

XS71-75, EBXS71-75

F7, XR68Y

XR68HY, XR70Y

XT77-81

XS46-51, XL46-51

EBXS46-51

EBXL46-51

SL63, TD63 XS52-58, XL52-58

STR-50, STR-50A

F57Y, F57HY

EBXS52-58

GF50YB, F50YA, XR50Y STX-50, HR-50, HR-55 HP63, R50

F59Y, F59HY, F67Y

GF67Y, XRi65Y

SMITH ROLLER CONE BIT NOMENCLATURE

EBXL00-05

XS06-09, XL06-09

EBXS06-09

EBXL06-09

SL43H, TD43 XS10-13, XL10-13

GT-09, STR-09

STX-09, STX-09H TD43A, TD43H

EBXS10-13

HX-09, GX-11, MX-09 D43, HP43A

EBXL10-13

HP43H, R09A

MX-11, MX11H

R12A, RD12, R14

MXL-09, MXL-11

GT-18, STR-18

TD44, TD44H

XS14-17

STX-18, H-18, HX-18 TD44X, D44

XL14-17

GX-18, MX-18

HP44H, HP44X

EBXS14-17

MXL-18

R14A,RD15

EBXL14-17

R15A, R15

SL51H,TD51

XS18-23

GT-20, STR-20

TD51A,TD51H

XL18-23

STX-20, H-20, HX-20 TD51X,D51,HP51H

EBXS18-23

GX-20, MX-20, GX-22 P51A, HP51H

EBXL18-23

MX-22, GX-23, GX-25 HP51X,R19A,R20A

R21A,R22A,RD21

MXL-20

GT-20C, GT-28, H-28 TD52,TD52A,TD52H

TD52i, TD52X, HP52 XS24-27, XL24-27

HX-28, GX-20C

HP52X, R24A, R25A

EBXS24-27

GX-28, MX-20C, MX-28 R26A, RD25, R27

R28A

EBXL24-27

MXL-28

F3, F30, FH30, F30T

T53

XT28-33

STR-30, STX-30

EMS53 EBXT28-33 FHi30, FHi31, FH32, GF30 GT-30, STX-35, GX-30

GF30B, GF30T, MF30T H-30, HX-30, MX-30

EMS53A

ETS53A

XR30, XR32, F30Y, FH30Y

MXL-30

T54

ReedHycalog

GT-00, MX-00, GT-03

GFSi01, GFS04, GFS04B MX-03, GX-00, GX-03 TD41H, TD41 XS00-05, XL00-05

TD41A, R01A

EBXS00-05

MFS04, MFi04

STR-03, H-03

F15H, F2, MF2, MF15H

GTX-20, MAXGT-20

T51

XT18-23

MX-20, MXL-20

EMS51A EBXT18-23 FHi20, FHi21, FHi23, GFi20

GTX-22

EMS51H

GF21, GF25, GFS20

MX-22

MFS20, XR20, XR20B, XR25

GTX-30C, GTX-33

MAX-GT30CG

MX-33CG

4

1

Hughes

Christensen

7. SEALED FRICTION BEARING

GAUGE PROTECTED

HR-89

SL73

HP73

XS77-81

EBXS77-81

TD74,HP74,R75 XS83-89, EBXS83-89

TD81, HP81 XS91-93, EBXS91-93

R80, R85

XS95-97, EBXS95-97

SL83, TD83

HP83, R90, R95

XS99, EBXS99

SMITH BITS

Rock Bit Comparison Chart

FORMATIONS

Types

Series

MILLED TOOTH

4. SEALED

ROLLER BEARING

1. STANDARD

ROLLER BEARING

SMITH

DSJ

ReedHughes

Christensen Hycalog

R1

Y11

Security

DBS

SMITH

XN1

SDS

ReedHughes

Christensen Hycalog

Security

DBS

GTX-1

Soft

Formations/

LowCompressive

Strength

Med. to Med.-Hard

Formations/

HighCompressive

Strength

Hard, SemiAbrasive

Formations

DTJ

DGJ

1

2

3

1

2

3

4

R3

Y13

MGG

XN3

SMITH

Hughes

Christensen

XR+

GSSH+

TCTi+

GTX-G1

MAX-GT1

MX-1

MXL-1

MXL-1V

GGH+

MSDGH

GTX-3

XN4

M4N

OFM

5. SEALED ROLLER BEARING

GAUGE PROTECTED

GTX-G3

MAX-GT3

MX-3

ReedHycalog

Security

DBS

T11

EMS11G

ETS11G

XT1

XT1S

XL1N

T13

EMS13G

ETS13G

6. SEALED

FRICTION BEARING

SMITH

Security

DBS

FDS

HP11

XS1

XSC1

FDT

HP12

XSC2

XT3

EBXT3

HP13

XT4

XT4S

SVH

ReedHughes

Christensen Hycalog

M44NF

ATJ-4

7. SEALED FRICTION BEARING

GAUGE PROTECTED

SMITH

XR+

FDS+

TCTi+

Hughes

Christensen

ReedHycalog

Security

DBS

GT-1

MX-1

MXL-1

MXL-1V

STR-1

STX-1

TC10

TC11

SL11

TD11

D11

XSC1

XLC1

EBXS1

EBXSC1

EBXLC1

SL12, HP12

MFDGH

FDGH

MX-3

HP13G

D13

XS3

XL3

GFVH

FVH

ATJ-G4

HP21G

XS4

XL3

DR5

XN5

H77F

R7

ATJ-G8

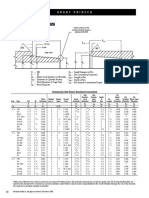

IADC DULL BIT GRADING

Inner

1

Inner Cutting Structure (1) (All Inner Rows)

(For fixed cutter bits, use the inner 2/3 of the bit radius)

Cutting Structure

Outer

Dull Char.

2

3

Location

4

Other Dull

Char.

7

Gauge

6

Reason

Pulled

8

Reason Pulled or Run Terminated (8)

Gauge (6)

Outer Cutting Structure (2) (Gauge Row Only)

(For fixed cutter bits, use the outer 1/3 of the bit radius)

Dull Characteristics (3)

(Use only cutting structure related codes)

In columns 1 and 2 a linear scale from 0 to 8 is used to

describe the condition of the cutting structure according to the

following:

Steel Tooth Bits

A measure of lost tooth height due to abrasion and/or damage

0 - No Loss of Tooth Height

8 - Total Loss of Tooth Height

Insert Bits

A measure of total cutting structure reduction due to lost, worn

and/or broken inserts

0 - No Lost, Worn and/or Broken Inserts

8 - All Inserts Lost, Worn and/or Broken

Fixed Cutter Bits

A measure of lost, worn and/or broken cutting structure

0 - No Lost, Worn and/or Broken Cutting Structure

8 - All of Cutting Structure Lost, Worn and/or Broken

Bearings/

Seals

5

*BC

BF

BT

BU

*CC

*CD

CI

CR

CT

ER

FC

HC

JD

*LC

LN

LT

Broken Cone

Bond Failure

Broken Teeth/Cutters

Balled Up Bit

Cracked Cone

Coned Dragged

Cone Interference

Cored

Chipped Teeth/Cutters

Erosion

Flat Crested Wear

Heat Checking

Junk Damage

Lost Cone

Lost Nozzle

Lost Teeth/Cutters

OC - Off Center Wear

PB - Pinched Bit

PN - Plugged Nozzle/Flow

Passage

RG - Rounded Gauge

RO - Ring Out

SD - Shirttail Damage

SS - Self Sharpening Wear

TR - Tracking

WO - Washed Out Bit

WT - Worn Teeth/Cutters

NO - No Dull

Characteristics

* Show cone number(s) under

location (4)

Location (4)

Roller Cone

N - Nose Row

M - Middle Row

G - Gauge Row

A - All Rows

Cone #

1 2 3

Fixed Cutter

C - Cone

N - Nose

T - Taper

S - Shoulder

G - Gauge

A - All Areas

Measure to nearest

1/16 of an inch

I - In Gauge

1 - 1/16 Out of Gauge

2 - 2/16 Out of Gauge

4 - 4/16 Out of Gauge

Other Dull Characteristics (7)

Refer to column 3 codes

Bearings / Seals (5)

Non-Sealed Bearings

A linear scale estimating bearing

life used

0 - No Life Used

8 - All Life Used, i.e., no

bearing life remaining

Sealed Bearings

E - Seals Effective

F - Seals Failed

N - Not Able to Grade

X - Fixed Cutter Bit

(Bearingless)

BHA DMF DTF DSF DST DP CM CP FM HP LIH HR LOG PP PR RIG TD TW TQ WC -

Change Bottom-Hole Assembly

Downhole Motor Failure

Downhole Tool Failure

Drillstring Failure

Drill Stem Test

Drill Plug

Condition Mud

Core Point

Formation Change

Hole Problems

Left in Hole

Hours on Bit

Run Logs

Pump Pressure

Penetration Rates

Rig Repair

Total Depth/Casing Depth

Twist Off

Torque

Weather Conditions

SMITH BITS

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Technical Data Handbook: and Much More TablesDocument6 pagesTechnical Data Handbook: and Much More TablesPither ZuritaNo ratings yet

- Halliburton Sand Control MCS Closing SleeveDocument41 pagesHalliburton Sand Control MCS Closing SleevePither ZuritaNo ratings yet

- Halliburton Sand Control MCS Closing SleeveDocument41 pagesHalliburton Sand Control MCS Closing SleevePither ZuritaNo ratings yet

- Land 3000HPDocument24 pagesLand 3000HPPither Zurita100% (1)

- Dull Grading TriDocument15 pagesDull Grading TriCamilo SanchezNo ratings yet

- Completion Technology For Unconsolidated FormationsDocument256 pagesCompletion Technology For Unconsolidated FormationsengrkrisNo ratings yet

- GrantPrideco Drill Pipe Data TablesDocument24 pagesGrantPrideco Drill Pipe Data TablesMaximo Biarrieta RodriguezNo ratings yet

- Casing Scraper PDFDocument6 pagesCasing Scraper PDFahmedNo ratings yet

- Torque de Trepanos Smith (PDC - Tricono) PDFDocument1 pageTorque de Trepanos Smith (PDC - Tricono) PDFPither ZuritaNo ratings yet

- TFA & TorqueDocument1 pageTFA & TorquePither ZuritaNo ratings yet

- Ejercicio Interactivo de M BodyDocument1 pageEjercicio Interactivo de M BodyPither ZuritaNo ratings yet

- Ejercicio Interactivo de How ManyDocument1 pageEjercicio Interactivo de How ManyPither ZuritaNo ratings yet

- Calculo TFADocument1 pageCalculo TFAMarcialgonzalezpNo ratings yet

- There Is - There AreDocument6 pagesThere Is - There ArePither ZuritaNo ratings yet

- Torsional Tensile Value For Tool Joints PDFDocument12 pagesTorsional Tensile Value For Tool Joints PDFPither ZuritaNo ratings yet

- Monobore Design Can Benefit High-Rate Gas Wells: Remedial AdvantagesDocument2 pagesMonobore Design Can Benefit High-Rate Gas Wells: Remedial AdvantagesPither ZuritaNo ratings yet

- Tool Joint Dimensional Data: Grant PridecoDocument3 pagesTool Joint Dimensional Data: Grant PridecoPither ZuritaNo ratings yet

- FormularioDocument26 pagesFormularioPither ZuritaNo ratings yet

- Griffit Oil ToolDocument34 pagesGriffit Oil ToolPither ZuritaNo ratings yet