Professional Documents

Culture Documents

X6CrMoS17 1.4105 ENG

X6CrMoS17 1.4105 ENG

Uploaded by

Vahid SarfarazOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

X6CrMoS17 1.4105 ENG

X6CrMoS17 1.4105 ENG

Uploaded by

Vahid SarfarazCopyright:

Available Formats

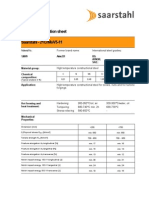

STAINLESS

STEELS

X6CrMoS17 - Nr. 1.4105

www.rodacciai.com

STANDARD REFERENCE:

EN 10088-3: 2005 (Hot-rolled and bright products)

rodacciai references and comparable standards

EUROPE

ITALY

GERMANY

FRANCE

UK

USA

EN 10088-3: 2005

(UNI 6900: 71)

(DIN 17440 - 85)

(NF A 35-574-90)

(BS 970 pt.3 -91)

AISI

Z 8 CF 17

430F

Grade

X6CrMoS17

1.4105

X 10 CrS 17

Werkstoff

X6CrMoS17

1.4105

chemical composition (cast analysis) (%)

C / max

Si / max

Mn / max

P / max

Cr

Mo

0,08

1,50

1,50

0,040

0,150,35

16,018,0

0,200,60

mechanical properties - Rough turned (1X) in the annealed condition

Size max

(mm)

Hardness HB max*

Rp 0,2 (MPa)

min

Rm (MPa)

A5 (%) min

100

200

250

430630

20

Resistance to intergranular corrosion

in the delivery condition

in the welded condition

NO

NO

*only for guidance

mechanical properties - Cold drawn (2H, 2B) and ground bars (2G) in the solution annealed condition

Size max (mm)

Rp 0,2 (MPa) min

Rm (MPa)

A5 (%) min*

10

330

530780

> 10 16

310

500780

> 16 40

250

430730

12

> 40 63

250

430730

12

> 63 100

250

430630

20

* Values valid only for size 5 mm

mechanical properties - Cold drawn wire and coils (2H)

Tensile strength levels

Rm (MPa)

+C 500

+C 650

+C 800

+C900

500700

650850

8001000

9001100

Note: the desired tensile strength level shall be evaluated depending on diameter required

mechanical properties - Cold drawn wire and coils in the solution annealed condition (2D)

Size

Rm (MPa) max

A (%) max

0,10 d 0,20

0,20 d 0,50

0,50 d 1,00

1,00 d 3,00

3,00 d 5,00

5,00 d 16,00

900

850

850

800

750

700

15

20

10

15

15

15

Note: If skin passed, R m might be increased by up to 50 MPa

Operation

Hot forgings deformation

Annealing (air)

8001100

750850

STAINLESS STEELS

FERRITIC

Rodacciai name

1.4105

6102

rev. 04/2013

working temperatures recommended

You might also like

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- DIN 1681 Chemical CompositionDocument12 pagesDIN 1681 Chemical CompositionAshish Kesharwani100% (1)

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-4 EN 10084 EN 10297-1Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-4 EN 10084 EN 10297-1farshid KarpasandNo ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- European Steel and Alloy Grades: 36nicrmo16 (1.6773)Document2 pagesEuropean Steel and Alloy Grades: 36nicrmo16 (1.6773)farshid Karpasand100% (1)

- BSC Legirani Celici Za Kotrljajne LezajeveDocument12 pagesBSC Legirani Celici Za Kotrljajne LezajeveradankezNo ratings yet

- Steel Symbol/Number: X90Crmov18/1.4112: Metal Forming Data - Ferrous Alloys - Deformation BehaviourDocument5 pagesSteel Symbol/Number: X90Crmov18/1.4112: Metal Forming Data - Ferrous Alloys - Deformation BehaviourrezaeibehrouzNo ratings yet

- 50 CRV 4Document2 pages50 CRV 4saptotoNo ratings yet

- L001E HTM Leaflet enDocument8 pagesL001E HTM Leaflet enMohd HassanudinNo ratings yet

- 8.12.01.03 - Technical Data CH890Document8 pages8.12.01.03 - Technical Data CH890gytoman100% (1)

- European Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-3 EN 10087Document2 pagesEuropean Steel and Alloy Grades: Alloy Standards Search About Us EN 10277-3 EN 10087farshid KarpasandNo ratings yet

- 304 - X5CrNi18 10 Nr.1.4301 ENG PDFDocument2 pages304 - X5CrNi18 10 Nr.1.4301 ENG PDFGaurav AggarwalNo ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- 0737 11SMnPb37Document1 page0737 11SMnPb37rgi178No ratings yet

- PTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1Document4 pagesPTE LTD: Dimensional Specification (Inch) For Stud Bolts As Per Asme B18.2.1Balderas Rosas WilibaldoNo ratings yet

- 20160323110453-11SMn30 (9SMn28)Document1 page20160323110453-11SMn30 (9SMn28)novkovic1984No ratings yet

- Crom Plated BarsDocument24 pagesCrom Plated BarschonubobbyNo ratings yet

- European Steel and Alloy Grades: X6Crni18-10 (1.4948)Document3 pagesEuropean Steel and Alloy Grades: X6Crni18-10 (1.4948)farshid KarpasandNo ratings yet

- C43Document1 pageC43rudramansingh123No ratings yet

- Common Steel StandardsDocument3 pagesCommon Steel Standardsva3ttnNo ratings yet

- A193 B7 A193 B7M Eng PDFDocument1 pageA193 B7 A193 B7M Eng PDFRECEP ÇETİNKAYANo ratings yet

- Hardox 450: General Product DescriptionDocument2 pagesHardox 450: General Product DescriptionTeodor EzaruNo ratings yet

- European Steel and Alloy Grades: 16Mncr5 (1.7131)Document3 pagesEuropean Steel and Alloy Grades: 16Mncr5 (1.7131)farshid KarpasandNo ratings yet

- 4340Document1 page4340ralishNo ratings yet

- Hardox 450 Data SheetDocument2 pagesHardox 450 Data SheetmatthewpincottNo ratings yet

- Free Cutting Cold Drawn 11SMnPb30 Calibrated AUSADocument2 pagesFree Cutting Cold Drawn 11SMnPb30 Calibrated AUSAsobheysaidNo ratings yet

- 168 - HARDOX - 450 - UK - Data Sheet PDFDocument2 pages168 - HARDOX - 450 - UK - Data Sheet PDFemad sabriNo ratings yet

- 20160323110402-11SMnPb30 (9SMnPb28) PDFDocument1 page20160323110402-11SMnPb30 (9SMnPb28) PDFjoseocsilvaNo ratings yet

- Material 11SMnPb30 (9SMnPb28)Document1 pageMaterial 11SMnPb30 (9SMnPb28)joseocsilvaNo ratings yet

- EN10113 S460ML Steel Plate/sheet: Henan BEBON International Co.,ltdDocument1 pageEN10113 S460ML Steel Plate/sheet: Henan BEBON International Co.,ltdDinesh GuptaNo ratings yet

- European Steel and Alloy Grades: X17Crni16-2 (1.4057)Document2 pagesEuropean Steel and Alloy Grades: X17Crni16-2 (1.4057)farshid KarpasandNo ratings yet

- HC340LADocument1 pageHC340LAPrashantha RajuNo ratings yet

- 36nicrmo16 (1.6773) : SearchDocument3 pages36nicrmo16 (1.6773) : SearchdexterisNo ratings yet

- EN 10083 C60 Steel Plate High Carbon SteelDocument1 pageEN 10083 C60 Steel Plate High Carbon SteelArtaniArtaniNo ratings yet

- 3 SpringDocument66 pages3 Springall_meca_allNo ratings yet

- 20200618100734-11SMnPb30 EnglischDocument1 page20200618100734-11SMnPb30 EnglischTuff qualityNo ratings yet

- Compozitie MaterialeDocument25 pagesCompozitie MaterialeGross Meltiade AlexanderNo ratings yet

- EN8 SteelDocument1 pageEN8 SteelDeep Narayan JaiswalNo ratings yet

- European Steel and Alloy Grades: 10crmo9-10 (1.7380)Document3 pagesEuropean Steel and Alloy Grades: 10crmo9-10 (1.7380)farshid KarpasandNo ratings yet

- Weldable Structural SteelDocument1 pageWeldable Structural SteelchinnaiitmNo ratings yet

- Werkstoffe E PDFDocument12 pagesWerkstoffe E PDFirajfarji2481No ratings yet

- European Steel and Alloy GradesDocument3 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- 20160323110156-11SMnPb37 (9SMnPb36)Document1 page20160323110156-11SMnPb37 (9SMnPb36)Богдан ЛекарьNo ratings yet

- 2 Fcaw-AllDocument51 pages2 Fcaw-AllAhmad ShaheenNo ratings yet

- Catalogo de Ejes CromsteelDocument20 pagesCatalogo de Ejes CromsteelJhonFerneyBohorquezSaldarriagaNo ratings yet

- 21 CR Mo V511Document1 page21 CR Mo V511uksrajNo ratings yet

- 107 - WELDOX - 700 - UK - Data Sheet PDFDocument2 pages107 - WELDOX - 700 - UK - Data Sheet PDFDaniel CringusNo ratings yet

- Hardox450 380Document2 pagesHardox450 380pedroNo ratings yet

- Mim-Material Specification and Applications: Material: Heat Treatable Steel Standards: Aisi 4140, Din 42crmo4, 1.7225Document1 pageMim-Material Specification and Applications: Material: Heat Treatable Steel Standards: Aisi 4140, Din 42crmo4, 1.7225ducthien_80No ratings yet

- Potential For MN in New Automotive SteelsDocument35 pagesPotential For MN in New Automotive Steelsxabarin_81No ratings yet

- BS3100 A2Document11 pagesBS3100 A2AlexNo ratings yet

- Data Sheet 173 Armox 440T 2016-04-22 34 371857150 enDocument3 pagesData Sheet 173 Armox 440T 2016-04-22 34 371857150 enJose ManuelNo ratings yet

- Chemical Composition % of Steel C15 (1.0401) : EN 10277-2-2008Document1 pageChemical Composition % of Steel C15 (1.0401) : EN 10277-2-2008Ashutosh PandeyNo ratings yet

- 2015 187 X-BT - DFTM 2015 Engpdf Technical Information ASSET DOC 2597837Document8 pages2015 187 X-BT - DFTM 2015 Engpdf Technical Information ASSET DOC 2597837Difa LiuNo ratings yet

- Cavitalloy: Technical Data Sheet Cored Welding WireDocument1 pageCavitalloy: Technical Data Sheet Cored Welding WireMAURO MORESCONo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Joining of Polymer-Metal Hybrid Structures: Principles and ApplicationsFrom EverandJoining of Polymer-Metal Hybrid Structures: Principles and ApplicationsSergio T. Amancio FilhoNo ratings yet

- Metal Matrix Composites: A Modern Approach to ManufacturingFrom EverandMetal Matrix Composites: A Modern Approach to ManufacturingNo ratings yet

- China Railway Tielong Container Logistics English VersionDocument23 pagesChina Railway Tielong Container Logistics English VersionVahid SarfarazNo ratings yet

- How Do Acid Prices Affect Smelter Revenues in Different Regions of The WorldDocument11 pagesHow Do Acid Prices Affect Smelter Revenues in Different Regions of The WorldVahid SarfarazNo ratings yet

- How Do Acid Prices Affect Smelter Revenues in Different Regions of The World - 2Document2 pagesHow Do Acid Prices Affect Smelter Revenues in Different Regions of The World - 2Vahid SarfarazNo ratings yet

- JPCB Salt Praveen - 4Document2 pagesJPCB Salt Praveen - 4Vahid SarfarazNo ratings yet

- JPCB Salt Praveen - 2Document2 pagesJPCB Salt Praveen - 2Vahid SarfarazNo ratings yet

- Temperature-Dependent Solubility Transition of Na2So4 in Water and The Effect of Nacl Therein: Solution Structures And..Document2 pagesTemperature-Dependent Solubility Transition of Na2So4 in Water and The Effect of Nacl Therein: Solution Structures And..Vahid SarfarazNo ratings yet

- RoRo Cum GCB DFR 16.09.15 Revised 2 PDFDocument2 pagesRoRo Cum GCB DFR 16.09.15 Revised 2 PDFVahid SarfarazNo ratings yet

- RoRo Cum GCB DFR 16.09.15 Revised 14Document2 pagesRoRo Cum GCB DFR 16.09.15 Revised 14Vahid SarfarazNo ratings yet

- Reference List of DEMISTER PAD: Azar Energy CoDocument4 pagesReference List of DEMISTER PAD: Azar Energy CoVahid SarfarazNo ratings yet

- RoRo Cum GCB DFR 16.09.15 Revised 16Document2 pagesRoRo Cum GCB DFR 16.09.15 Revised 16Vahid SarfarazNo ratings yet

- RoRo Cum GCB DFR 16.09.15 Revised 2Document2 pagesRoRo Cum GCB DFR 16.09.15 Revised 2Vahid SarfarazNo ratings yet

- REF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 9Document2 pagesREF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 9Vahid SarfarazNo ratings yet

- RoRo Cum GCB DFR 16.09.15 Revised 19Document2 pagesRoRo Cum GCB DFR 16.09.15 Revised 19Vahid SarfarazNo ratings yet

- REF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 10Document2 pagesREF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 10Vahid SarfarazNo ratings yet

- REF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 11Document2 pagesREF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 11Vahid SarfarazNo ratings yet

- REF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 2Document2 pagesREF-ProposedConstruction of TwoBulkLiquidStorageTanks-Dec2009 2Vahid SarfarazNo ratings yet

- RoRo Cum GCB DFR 16.09.15 Revised 15Document2 pagesRoRo Cum GCB DFR 16.09.15 Revised 15Vahid SarfarazNo ratings yet

- RoRo Cum GCB DFR 16.09.15 Revised 11Document2 pagesRoRo Cum GCB DFR 16.09.15 Revised 11Vahid SarfarazNo ratings yet