Professional Documents

Culture Documents

Din 5401-1 PDF

Din 5401-1 PDF

Uploaded by

Luciano Fontes0 ratings0% found this document useful (0 votes)

1K views7 pagesOriginal Title

DIN 5401-1.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views7 pagesDin 5401-1 PDF

Din 5401-1 PDF

Uploaded by

Luciano FontesCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 7

UDC 621.622.71 :669.14,018.25

In case of changes this printout is nol taken into account!

‘Besides ths ls @ copy and only for irhouse purposes of

'SMS Schloamann-Siemag AG, (aco. lo DIN reference sheet 2)

(No art of tis standerd may be rsoreduead without the erie persion ck OW Osutsenes isi

th enze of Goubt the German-language otginal shatkd be conaiad a the author

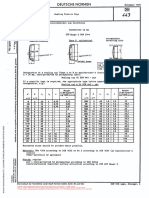

DEUTSCHE NORM

Finished steel balls for rolling bearings

\Walzlager; Kugeln aus durchhartendem Walzlagerstahl

This standard, together with

DIN $401 Part 2, Novernber 1993

edition, supersedes DIN 5401,

January 1978 dition.

In kooping with current practice in standards published by the Intemational Organization for Standardization (ISO),

‘a comma has been used throughout as the decimal marker.

See Explanatory notes for connection with Intemational Standard ISO 9290;1975 published by the International

Organization for Standarcization (ISO)

Dimensions in mm,

1 Scope and field of application

This standard specifies requirements for fished stool

balls for roling bearings. Such balls are also suitable

{or use in otter technical elds.

‘Subject to agreement, balls of sizes other than those

specified in table 1 may be ordered in accordance with

this standard.

2 Symbols and concepts

24 Nominal ball diameter, 2,

‘The diameter value used to identity a ball size.

2.2 Single diameter of a ball, D,,

‘The distance between two parallel planes tangent to

the surface of a ball

2.3 Mean diameter of a ball, Dy,

‘The arithmetic mean of the largest and the smallest

actual single diameters, Dy, ofa Dall.

2.4 Bali diameter variation, V:).,

The difference between the largest and smaliest actual

single diameters, D,., of one ball

2.5 Deviation from spherical form, i),

‘The greatest radial distance in any radial plano

between a sphere circumscribed around the ball

surface and any point on the ball surface,

Information regarding the measurement of the deviation

‘rom spherical form Is given in appendix B.

26 Lot

For the purposes of this standard, a lot is @ definite

‘quantity of balls manufactured under conditions which

‘aro presumed uniform, and which ig considered an

entity

2.7 Lot mean diameter, Dam.

The arithmetic maan of the mean diameter of the

Fargost ball and that of the smallest ball, Dre,

2.8 Lot diameter variation, Vin,

The citference between the mean diameter of the

targest ball and that of tho smallest bal, Dy. 19 lok

This definition only applies to ball grades G 3 t0 G 200.

‘Bauth rag GMBH, Deh, has We acres Nght taal er Garman Slandares (DI Norman)

a9,

2.9 Ball gauge tolerance, 5

Range within which Demy, may vary for a particular ball

gauge,

‘The amount Sis equal to the ball gauge interval, fg.

210 Ball diameter variation within a gauge,

Vows

The difference between the largest and the smallest

moan gauge diameters, yrs, established for a

particular gauge,

‘This definition only applies to ball grades G500 to

G70,

231 Gauge interval, /<;

One of the intervals into which the deviation of the

‘nominal diamotor of a bal is divided.

232 Ball grade

‘A specific combination of dimensional, form and sorting

tolerances, and of surface roughness.

A ball grade is identified by a number and the

preceding letter symbol G

213 Ball gauge, S

The amount by which a moan bal diameter of a iot (for

Vows) OF of SUBS of @ 10t (FOF Vow, ditfers from

tho" nominal ball diameter, D., rounded to a whole

rmaltiple of the ball gaugo interval.

244 Gauge deviation, AS

The dliference between the lot mean dlamoter, Dam

and the sum of the nominal diameter, L... and the bal

‘gauge, 5 (cl. appendix Aj, i.

AS= Dum, ~ (Du * 3)

245 Arithmetical mean deviation of the profile,

R

Surface roughness comprises all those irreguiwities of

‘the surface which are conventionally defined within a

section of the area where doviations of form and

waviness are eliminated,

‘The surface roughness tolerances given in table 3 refer

to the arithmetical mean deviation of the profile, Ry,

evaluated according to the method specified in

DIN 4768.

Continued on pages 210 7

November 1993

‘DIN 5401 Part! Engl Price group &

Sale No. 0108

Page 2 DINS401 Part 1

216 Hardness

Moasure of resistance to penetration as determined by

‘specific methods.

The values indicated in table 2 refer to Vickers hard-

ness (HV) and. Rockwell hardness (HRC) determined

by the methods specified in DINSO103 Part1 and

DIN 50133 respectively.

3. Dimensions and designation

The nominal diameters of steel balls to which pret-

erence should be given are epeciied in table 1.

Designation of ball with a nominal diamow, Di, of

5 mm, assigned to grace G5

Ball DIN 5401 - 6G5.

‘Table 1: Nominal diameters and mass of stee! balls

Approximate mass

Approximate mass

‘Nominal ball diameter, ar 1000 units ‘per 1000 units

Dy (785 g/cm), (785 g/om?),

in kG

03 0.00014

0397 0,000 26

04 0,000 26

Os 0.00051

9508 0,000 54

og 0,000 89

9835 0,001 05

or 0.001 41,

0,794 0,002 06

of 9.00210

1 0,004 11

4191 0.00694

12 0.0071

15 90139

1588 o0165

1,984 0032 1

2 00329

2381 9,055 5

25 0.0642

2778 0,088 1

3 ott

3178, 0,132

35, 0176

3572 0,187

3969 0.257

4 0.263

4366 0,342

45 0,75

4762 O4aa

5 514

55. 0684

S556 0,708

5953 0967

6

625

65

6747 1,26

7 tah

7148 1,50

173

176

206

(continued)

la

DINS401 Pant} Pages.

Table 1 (concluded)

Teonaiones

roproiate mas canal

vominavorcanew. | “Ree oberfe ein dame, | peu

Dy (785 g/cm?), Dy ak

‘inkg aes

rr wa was us

Hae ae ate ‘$3

# Ba 8 a

ma 4 son 359

26 722 ‘53,975 646

26,388 808 55 684

28 90,2 S715 ‘767

(28575 95,9 60 888

30 At 60,325 902,

20387 ug 5 rose

ae iS By 1%

7 S Sars ie

33,338 152 6985 1401

= ‘e Se, 1

Seas e me iho

3 176 79375 2056

36 192 8255. 2312

(36512 200 85,725 2589

38 228 wa 2688

92,075

95,25

4 Material and hardness

Balls shall be made of steel as specified in DIN 17 230 and have a hardnoss as specified in table 2

Table 2: Hardness

Dy 7

Hardness")

Upto

127 740 ta 900 HV10"+)

508 60to 66 HRC

70 S910 6SHRC

70 120 S7to 63HRC

150 9510 61 HRC

*) Surface hardness.

‘The hardness valves specilied are achieved by heat treatment,

During subsequent processing, work hardening in tne surface zone may lead to the upper

hardness limit in that zone being slightly exceeded

The core hardness of big balls may be slightly lower than the values measured In the sur

face zone.

"*) The hardness may, instead, be 62 to 67 HAC, the Vickers hardness being relevant

Page 4 DIN 5401 Part 1

5 Design

5.41 Dimensional and form tolerances, and

‘surface roughness

‘Table 3: Dimensional and form tol

ind surface roughness,

fei Sp Preterred gauges

ym Bm

0s [5-05] 0 | +05 +5

1 -1 fo] iss

1 <1 fo | +149

2 feo..-2 fo} 42...+10

2 |-1..-2 [of +2..+10

2 |-v..-2 | o | +2.+12

4 fewca fo | +4. +16

10 |-40...-10 | 0 [+10..+40

15 [-60...-15 | 0 | -15...+60

= | | sn so] 50 <0 fo] +50

2 | 50 | sis 75 | 75 <1 fo] +75

so | 7 js | | 2 | - | — | 100} 100 | -100 | o| +100

7m | 190 Jsws faz [ae | - | - | ssf | -12 fo] +15

wo | ws |sas fs3 [3a | - | - | 150] 150 | -159 | o |] +150

we | 50 | +res fas fae | - | = | as fas | ss |o] sss

Goon) | ausizes. | £200 - | -]- | wl] - = 0 -

e700) | Ausies | 1000 - | - | = [em] - = 0 =

1) In some cases and subject to agreement between customer and manufacturer, hall the gauge interval values

‘may be used for grades G 16, G 20 and G 28,

2) Not spacified in 180 9290. Grade is not identical with class V as specified in DIN 5401, January 1978 edition,

except or Vows vahies for D,, up to $0 mm,

2) Not specified in ISO 3290, Grade is identical with clascos VI and Vil as specified in DIN S401.

4) Vaiuos rotate to tho mean diameter of a ball, yn

5) ‘Cut-off as in DIN 4768, May 1990 edition.

NOTE: The quatty of rolling bearings is also a functon of the waviness and anpearance of the surface. Since

there is no recognized practice at international level in this field, the requirements for these characteristics,

should be agreed between customer and supplier.

5.2 Condition on supply

Balls shall bo supplied with corrosion protection appliod,

Each gauge lot shall be packed separately. When indicaling the gaugo, the letter P may be used to denote plus, M,

minus and ¥. 2e°0,

Where no particular agreement has been made, the ball gauge supplied shall be at the manufacturers discretion,

f a consignment consists of several packs, gach pack shall contain balls of one particular gauge, Different packs may,

however, Contain balls of diferent gauges

Packs containing balls of the same gauge should not be mixed up, since the gauge deviation, AS, may vary.

The package shail bear an inscription giving the bali nominal diameter, grade and gauge.

Example of marking for balls with a nominal diameter, L,.. ot 6 mm, ball grade G 5 and gauge + 5{P3):

6G5P3

DIN S40} Part Page S

Appendix A

illustration of gauges and sorting principles

‘Ai. Gauge, gauge interval and sorting tolerance

Figure At

A2_ Details of sorting parameter, Vinx, (applies to grades G 3 to G 200)

Vow.

~ ‘Smallest ballin a lot

Largest ballin a lot

Lotwity minimum Danas F—F—7 $=] Lotwith maxirum Dyas

toberelenedio garge’s L_1 |

Dent.

Be tobe retenedto gauge 8

Figure A

AS Details of sorting parameter, V‘p,,, (applies to grades G 600 to G 700)

Vows

Gauge scale

Gauge §

Figure A3

Page DIN 5401 Part 1

Appendix 8

Measurement of deviation from spherical form

B41 Method using roundness measuring

instrument

(relevant test method)

Considering the wide range of sizes of steel balls for

rong bearings. measurement ot deviation trom sphert

gal form may be a ciffcult and lengthy process requi-

ing special equipment.

In practice, this measurement is made by numerically

evaluating the ball profil, in two or three equatorial

planes at 90° to each ether, as recorded on a polar

chart which shows the measured protlos.

The measured profile is a graphical representation of

the bals radial deviations, nighly magnified, which are

recorded as other the ball or a contacting stylus is

precisely rotated about the ball axis,

The accuracy of spindle rotation and the sensitivity of

the transducer should be within 0,025 um. Because of

the high radial magnification, some care must be taken

in interpreting the polar charts, and there are several

‘commonly used procedures for finding the radial separ-

ion of the measured profile trom a perlect circle. The

‘mminimum circumscribed. circke' method is_relatvely

simple and generally satisfactory for ball proties, as 1s

also the assumption that two or three equatorial profiles

‘at 80" to gach other are a good indicatton of doviation

{rom spherical form,

1 the test method described in clause B1 is not prac-

{icable, measurement may be cavried out as specified

in clause 8.2 In arbiration cases, the method

described in this clause shall be relevant.

B.2 Method using Vee-block measurements

(optional)

Deviation trom spherical form of steet balls for roling

bearings may result in equatorial proties having two or

‘moro waves or radial deviations rom a pertect ciel.

Measuring single diameters of a ball wil give a good

indication of out-of-roundness for two waves or even

numbers of waves but may fail to detect or properly

measure out-of-roundness having odd numbers of

waves.

For medium and large balis it \s practical 19 use a

Vee-block measuring arrangement (arranged as shown

in figure B.) to measure tho out-ol-roundness of tho

profile having odd numbers of waves.

Table 81

The angle of the Vee has a pronounced infiyence on

the indicator reading and no one angle is adeauale fer

all wave numbers,

The most practical Veo angles appear to be 90" and

120°, and the magnification factor which expresses the

ratio’ of the indicator reading to the actual wave height

9F ceviation from spherical form is shown i table Bt

‘To determine the deviation from spherical form, divide

the indicator reading by this factor.

Where the number of waves in the profile is unknown,

which is most usual, readings in three planes at 90° to

each other should be taken using a single diameter

(two-poini) measuring arrangemont and on both the

90 “and 120" vee-block (three-point) measuring

arrangements.

Dividing the highest reading obtained with elther Vee~

block measuring arrangement by a factor of 2 to dolor

‘mine the deviation trom spherical form for odd num

bers of waves is considered acceptable,

4

i i

A 8

Figure B1: Vee-block measuring arrangement

The point of stylus/ball contact shall be on axis A— A

which is the bissector of the Vee and axis BB which

is the axis of the ball; algo the spindle of the indicator

shall be in alignment with axes A~ A and BB.

Magnification factor

DIN S401 Pan’! Page 7

Standards referred to

DIN 4768 Determination of surtace roughness parameters X,, R,, and Ring using electric stytus insite

ments; concepts and measuring conditions

iN 17230 Stee! for roling beavings; technical delivery condivons

DIN 50103 Part + Rockwell hardness testing of metalic materia; C. A,B, F scales

DIN 50133 Vickers hardness testing of metalic materials; HV 02 to HV 100

180 8290:1975 Rolling bearings; bearing parts; balls fer coling bearings

Previous editions

DIN’ $401-01:53, 0456, 1159, 0164, 0178.

Amendments.

In comparison with the January 1978 odition of DIN 5401, this standard has been revised on the lines of International

Standard ISO 3290: 1975 and split into Part 1 and Part 2, Part dealing with steel balls (except stainless steel}, and

Part 2, with balls of other selected materials.

International Patent Classitication

F 16 039/32

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Din 443 PDFDocument1 pageDin 443 PDFLuciano Fontes100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Din 3963 PDFDocument18 pagesDin 3963 PDFLuciano Fontes0% (1)

- Din 17671Document0 pagesDin 17671Niculescu Marian50% (2)

- Din 17223-2 PDFDocument9 pagesDin 17223-2 PDFLuciano FontesNo ratings yet

- DIN 2391-2393 - Composição e Resistência Mecânica PDFDocument4 pagesDIN 2391-2393 - Composição e Resistência Mecânica PDFLuciano FontesNo ratings yet

- Din 7168 PDFDocument8 pagesDin 7168 PDFLuciano FontesNo ratings yet

- Din 5401 PDFDocument12 pagesDin 5401 PDFLuciano FontesNo ratings yet

- Din 1693Document11 pagesDin 1693vitor7hugo100% (3)

- Din 1014Document3 pagesDin 1014Luciano FontesNo ratings yet

- Norma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesDocument13 pagesNorma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesJuan Rivera100% (1)

- Cagcelik Kesit ToleransiDocument4 pagesCagcelik Kesit ToleransiAnonymous ep7LE5ZdP5No ratings yet

- Din 470 PDFDocument6 pagesDin 470 PDFLuciano FontesNo ratings yet

- Din 509 PDFDocument6 pagesDin 509 PDFLuciano FontesNo ratings yet

- Din 267-24 PDFDocument7 pagesDin 267-24 PDFLuciano FontesNo ratings yet

- Din 509Document6 pagesDin 509Luciano FontesNo ratings yet

- Din 267-24Document7 pagesDin 267-24Luciano FontesNo ratings yet