Professional Documents

Culture Documents

Din 1014

Din 1014

Uploaded by

Luciano Fontes0 ratings0% found this document useful (0 votes)

1K views3 pagesOriginal Title

DIN 1014.ppt

Copyright

© © All Rights Reserved

Available Formats

PPT, PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

1K views3 pagesDin 1014

Din 1014

Uploaded by

Luciano FontesCopyright:

© All Rights Reserved

Available Formats

Download as PPT, PDF or read online from Scribd

You are on page 1of 3

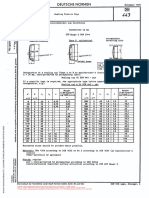

July 1978

‘Stee Sars

Hot Rolled Squares

for Special Purpose

Dimensions, Permissible Deviations on Dimension and Form

‘Stabstanl, Wormgewatrter Vierkantstahl far besondere Verwendung: Masse, ruléstige Matt- und Formabrrtichungen

Oimensions in mm

1 Scope

‘This Standard applies to hot rolled squares intended for special purpore (e.g. for further processing by drawing,

for manufacture of chains etc.) in straight bars of 17 to 103 mm side length made from the steel grades listed in

Section 4.

2 Designations

Lie

Designation of hot rolled squares With # tise length 2 = 23 mm made from a steel with the code number St 41-3

#88, the materiat pumber 1.0219 according to DIN 17 195:

Square DIN 1014 —St 41-3—23

or Square DIN 1014 = 1.0219 ~ 23

Instead of the denomination “square” the abbreviation “aki” secording to OIN 1383 Part 2 may be used,

3 Dimensions and permissible deviations on dimension and form

3.1. Side lengths

3.1.1 The side lengths included in this Standard and the permissibie deviations on them are given in Table 1.

‘Table 1. Side length, permissible Ceviations, cross-section, weight and surface area

1} The side lengths in Brackets should be avoided 25 far 28 possible,

2) See Section 5

3.1.2 Aroundingoff of the edges r as given in Table 2

is permissible for hot rolled squares according to this

Standard.

Table 2. Permissible rounding-off of the edges r

3.1.3. The difference between the two diagonals of a

given cross-section shall not exceed 4%; the rounding-off

of the edges r shall be taken into sccount in determining

this,

3.2 Straightness

The permissible deviations as given in Table 3 apply for

straightness of squares according to this Standard,

tb

‘Table 3. Permissible deviations trom the straightness

More stringent requirements on straightness shat! be

wgreed when ordering.

4 Material

{According to this Standard shall be manufactured

for preference from the steel graces according to

DIN 1651, DIN 17100, DIN 17 115, DIN 17200 and

DIN 17210.

‘The required steel grade shail be specified in the

designation.

S Weight

‘The weight given in Table 1 has been calculated on the

basis of a density of 7.85 kg/dm®. In the case of alloy

steels the density specified in the appropriate quality

standards should be uted for the weight eaiculation,

6 Mode of delivery

6.1. The data on lengths given in Table 4 spply to the

Gelivery of hot rolled squares according to this Stendard.

6.2 When ordering by weight, the length may vary

between maximum and minimum dimensions specified

for manufacturing lengths,

6.3. Example of order,

100 t of hot roited squares of side length = 23 mm

made from steel with the code number St 41-3 08 the

material number 1.0219 secording to DIN 17 115 in

manufacturing lengths:

100 t Square DIN 1014 —St 41-3 — 23

or 100 t Square DIN 1014 — 1.0219 — 23

7 Testing for accuracy to size

7.1 Extent of testing

‘The number of bars which shail be tested for accuracy to

size Dy mesturements at the manufacturer's works

prior to Gespatch shall be agreed when ordering.

7.2 Testing procedure

7.2.1 The side length according 10 Section 3.1 shall be

measured at least 160 mm from the end of the bars when

manufacturing lengths are supplied, and at any point

when fixed or exact lengths are supplied.

7.2.2 When testing the straightness according to

Section 3.2, the dimension ¢ shall be measured over the

full length of the bar, aes

6000 512000

6000 512000

3000 3 9000

3000 3 9000

£100 preterred:

250.2 26,£ 10,52) | peemissibie deviation in mm

1) Enquiries should be made to the manufacturer es to whether shorter of longer lengths can be wpplied.

2} Squares can also be supplied in limited manufacturing lengths with 3 length range to be stated when ordering,

“The span between the shortest and longett length in this range must be at least 2000 mm (

2} The total spans for the permissibie deviations may, by agreement, be arranged enticely On the plus side,

2g. 7 2 (instesd of 2 100) in the cate of fixed lengths oF

DIN 1014 Part2 Page a

(6000 to 8000).

* §P instead of 2 25) in the case of exact lengths,

Explanations

In conjunetion with the negotiations on the revision of

Euronorm 59 — Hot rolied squares for general purpove

DIN 1024 (October 1963 issue) has also been revised.

A predominant consideration wes the éxtent to which

it whould be postible to reduce the number of

standardized side lengths. The bacis of the discussions

‘was the statistics on ordered and delivered quantities in

recent years and the content of the international standards,

‘The scope of Euronorm 89 and alto of ISO Recommen:

dation ISO R 1035/II (March 1969 issue, currently being

revised) covers only hot rolled squares for general

purpose, whereas DIN 1014 tormeriy covered #

imensions. .2. used for various spplicitions. To provide

comparability with the international regulations and to

{ive curtomers a better view of supply pombilities, the

DIN Standard has been divided, with the agreement of

al! the German bodies represented, into # Part 1 = Hot

rolled squares for genersi purpose — and a Part 2 — Hot

rolied squares for soecial purpose (€.. for furtner process:

ing by drawing, for chain manufacture ete.). DIN 1014

Part I theretore in naw civectly comparable with the inser-

ational standards, but there #e still ng international

sequlations for squares for special purpose,

‘The October 1863 ise of BIN 1014 contained G2 side

lengths. Of nese the following 17 dimensions have been

deleted

Part 1 covers 29 side lengths, which alto appea? in the

new issue of Euronorm 59 (1977) with the exception

‘of the nominal dimensions 15 ~ 19 = 28 ~ 65 and

110 mm. A further 16 side lengths for special purpose

are standardized in Part 2.

In Part 1, the nominal dimensions have been subcivided

into Series A and B. The side lengths in Series A

‘should be ordered for preterence. The dimensions in

Series B are used to a lesser extent and in some cores

they will require longer delivery dates.

In addition, the following amendments and additions

have been made compared with the October 1963 iswe:

1, Provision of maximum values for the difference in

‘the length of the two diagonals (i, limitation of the

aviations from the exact square cross-section);

2. Specification of maximum valves for twist in the exe

‘of squares for general purpose (experience will have

to be acquiced as to the messurability of these form

deviations:

42. Extention of the provisions on the peemissibie

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5820)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Din 443 PDFDocument1 pageDin 443 PDFLuciano Fontes100% (1)

- Din 3963 PDFDocument18 pagesDin 3963 PDFLuciano Fontes0% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Din 5401-1 PDFDocument7 pagesDin 5401-1 PDFLuciano FontesNo ratings yet

- Din 7168 PDFDocument8 pagesDin 7168 PDFLuciano FontesNo ratings yet

- Din 17671Document0 pagesDin 17671Niculescu Marian50% (2)

- Din 17223-2 PDFDocument9 pagesDin 17223-2 PDFLuciano FontesNo ratings yet

- DIN 2391-2393 - Composição e Resistência Mecânica PDFDocument4 pagesDIN 2391-2393 - Composição e Resistência Mecânica PDFLuciano FontesNo ratings yet

- Din 5401 PDFDocument12 pagesDin 5401 PDFLuciano FontesNo ratings yet

- Din 1693Document11 pagesDin 1693vitor7hugo100% (3)

- Din 934Document0 pagesDin 934mjinspectorNo ratings yet

- Norma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesDocument13 pagesNorma 1691 DIN 1691 1985 Flake Graphite Cast Iron Grey Cast Iron PropertiesJuan Rivera100% (1)

- Cagcelik Kesit ToleransiDocument4 pagesCagcelik Kesit ToleransiAnonymous ep7LE5ZdP5No ratings yet

- Din 509 PDFDocument6 pagesDin 509 PDFLuciano FontesNo ratings yet

- Din 267-24 PDFDocument7 pagesDin 267-24 PDFLuciano FontesNo ratings yet

- Din 509Document6 pagesDin 509Luciano FontesNo ratings yet

- Din 470 PDFDocument6 pagesDin 470 PDFLuciano FontesNo ratings yet

- Din 267-24Document7 pagesDin 267-24Luciano FontesNo ratings yet