Professional Documents

Culture Documents

149-Workshop Hints & Tips PDF

Uploaded by

syllavethyjim0 ratings0% found this document useful (0 votes)

75 views1 pageOriginal Title

149-Workshop hints & tips.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

75 views1 page149-Workshop Hints & Tips PDF

Uploaded by

syllavethyjimCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

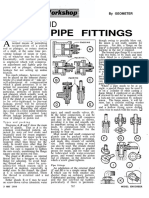

WORKSHOP HINTS AND TIPS

By GEOMETER

0

6

commercial studs,

screws and threaded rod

meet the requirements of

a large proportion of model work,

special items of this type must

necessarily be produced by the

constructor himself.

Unless he

has had previous experience of

this work, it can be far less straightforward than was thought, and

perhaps even more demandmg in

time and patience than some of

the more routine operations on

major components.

HILE

The second threading operation on

small, short studs, such as are used

for securing cyhnder covers, can

cause difficulty. A die must be used,

as for the first thread, but once the

rod material has been cut to-length

(with a small surplus for finishing the

To avoid this, plain rod should be

held in a split clamp, which can be

as at A for diameters larger than, say,

Rectangular material is

5/32 in.

drilled undersize, then reamed to size

and a saw cut made through the hole.

Pins can be fitted for the clamp to

hang on the vice jaws when adjusting

the rod horizontally for sawing, or

locate when pushed in sideways with

the rod standing vertically for threading. Easing the sides of the clamp by

filing just below the pins, ensures a

firm grip on the rod.

A clamp for small rod-for which

the saw cut would be disproportionately wide-can be made from two

pieces of material drilled and dowelled

together, then drilled at the joint line

-where they must be eased by filing

to grip the rod. With two pieces of

material, a clamp can be made, as at

B, to give good upward projectron for

Holding rod, studs and screws

n

TU

18 FEBRUARY 1960

end), there is very little plain diameter

on which to obtain a grip.

It may even happen that if the vice

is in general use, its jaws are chamfered and incapable of gripping the

plain diameter without damage to

the thread already cut. For the same

reason mounting the stud in a drill

chuck may not be possible. Even

with a good chuck it is difficult to

get a grip which will prevent the

stud from turning when the die is used

on it.

Use of two nuts-locked on the

thread already cut-poses the problem

of holding the lower nut, itself of small

depth in miniature sizes. If the stud

is screwed into a tapped hole in the

end of a rod, and locknutted there, it

will almost certainly slacken as soon

as the die is eased back.

A solution is to produce the first

thread longer than necessary, hold

on the surplus for making the second

thread, and cut it off afterwards.

This involves producing about twice

the length of thread that is really

required. Besides this, the grip on

the rod for the first thread may leave

it oval or at least bearing marks

which can be to its detriment for

other purposes.

193

working in a vice, or to hold like a

toolmakers clamp for screwing small

studs firmly into components. The

two pieces (which can be of mild

steel) are drilled at the joint line endwise, one end to grip the rod for the

first threading, the other end tapped to

hold studs for the second threading.

They are eased as required at the

joint line.

For lathe use, a. mandrel can easily

be made, as at C. Mild steel rod is

sawn and filed half through at the end,

and a loose piece similarly made.

The clamp is a collar with screw or a

split type with bolt. Thus prepared,

the mandrel is chucked with a mark

to No 1 jaw for replacement, or with

diameter Xrunning truly. It is centred,

drilled and tapped for studs or screws

-and if these are long, a hole is

drilled from the back for clearance.

As on clamps the joint line of the

step and loose piece must later be

eased.

For popular thread sizes two pieces

of flat material can have several

tapped holes at the joint line. They

can be used in a vice or in a chuck,

as at D, for which it is convenient if

the main piece is stepped for permanent hold by two of the jaws.

q

MODEL ENGINEER

You might also like

- Tap and Die - WikipediaDocument43 pagesTap and Die - WikipediaAditya Singh100% (1)

- Thread Basics - GO-No GoDocument2 pagesThread Basics - GO-No GoKundan Kumar MishraNo ratings yet

- 3M™ Lapping Film, 266X TP PSA DiscsDocument2 pages3M™ Lapping Film, 266X TP PSA DiscschainleighNo ratings yet

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- Assy of Ball TurnerDocument1 pageAssy of Ball TurnerAntónio OliveiraNo ratings yet

- TK's Accuracy Seminar - April 30 2007Document8 pagesTK's Accuracy Seminar - April 30 2007LloydDobblerNo ratings yet

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- Louis Belet Cutting Tools Watchmaking Jura Suisse Vendlincourt Switzerland Brochure Hob Cutters enDocument16 pagesLouis Belet Cutting Tools Watchmaking Jura Suisse Vendlincourt Switzerland Brochure Hob Cutters enLogan RaoNo ratings yet

- Techcatalogue EbookDocument87 pagesTechcatalogue EbookPablo Valenzuela ArredondoNo ratings yet

- CatalogDocument235 pagesCatalogcustomerx50% (4)

- Constants For 5in Sine BarDocument7 pagesConstants For 5in Sine BarIM_JohnnyVNo ratings yet

- Solder Alloy ChartDocument2 pagesSolder Alloy ChartDiane PaceNo ratings yet

- 3m SUPERABRASIVESDocument40 pages3m SUPERABRASIVESGaurav BediNo ratings yet

- Lapping tapers and seatings to improve fit and finishDocument1 pageLapping tapers and seatings to improve fit and finishsyllavethyjimNo ratings yet

- Understanding Cemented Carbide MaterialsDocument20 pagesUnderstanding Cemented Carbide MaterialsIrfan Yahya IkhsanudinNo ratings yet

- Broaching Operations Guide for Rotary BroachingDocument2 pagesBroaching Operations Guide for Rotary BroachingpeterNo ratings yet

- Wiha Pliers CatalogDocument44 pagesWiha Pliers CatalogCarbide Processors IncNo ratings yet

- 1.1 Introduction To Fixed Limit GagingDocument6 pages1.1 Introduction To Fixed Limit GagingpchakkrapaniNo ratings yet

- (B) Testing Machine ToolsDocument100 pages(B) Testing Machine ToolsHyeonggil JooNo ratings yet

- CuttingTools 1 Materials PDFDocument38 pagesCuttingTools 1 Materials PDFsyarifNo ratings yet

- How To Use A Dial Caliper: Activity Sheet 6Document5 pagesHow To Use A Dial Caliper: Activity Sheet 6Anoj pahathkumburaNo ratings yet

- 33 - Making Clocks PDFDocument65 pages33 - Making Clocks PDFBruno DelsupexheNo ratings yet

- Section 8 Bevel Gearing DesignDocument5 pagesSection 8 Bevel Gearing DesignLiniel de JesusNo ratings yet

- Balanci GrindingDocument18 pagesBalanci GrindingAnonymous JzEb8CXErNo ratings yet

- Ebook Tapping Away Guide To Tapping and Threading Xometry SuppliesDocument19 pagesEbook Tapping Away Guide To Tapping and Threading Xometry SuppliesAli KhubbakhtNo ratings yet

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- Taper Turning OperationDocument17 pagesTaper Turning OperationRenmer N. Debil100% (2)

- Grinding FundementalsDocument47 pagesGrinding Fundementalstenjoe_38No ratings yet

- Asme B5.11-1964 (2018)Document16 pagesAsme B5.11-1964 (2018)vijay pawarNo ratings yet

- Good Cutting Punch and Die Maintenance: Follow Good Grinding PracticesDocument10 pagesGood Cutting Punch and Die Maintenance: Follow Good Grinding PracticesBaziNo ratings yet

- DR KAISER Grinding WheelsDocument20 pagesDR KAISER Grinding Wheelsnestor333No ratings yet

- Measuring tools and techniques in metalworkingDocument2 pagesMeasuring tools and techniques in metalworkingInstruktur MesinNo ratings yet

- Slotting MachineDocument32 pagesSlotting Machinesanaashraf91% (11)

- Machining FundamentalsDocument32 pagesMachining FundamentalsCh TalhaNo ratings yet

- MD Profiler Instruction ManualDocument11 pagesMD Profiler Instruction ManualTatiana Trenogina100% (1)

- General Carbide Designer GuideDocument60 pagesGeneral Carbide Designer GuideEmmanuel Lugo BeltranNo ratings yet

- Griding Types and Lapping, Honing SuperfinishingDocument135 pagesGriding Types and Lapping, Honing SuperfinishingIndra Pratap Singh100% (1)

- Identifying Lathe Cutting Tools and ToolholdersDocument38 pagesIdentifying Lathe Cutting Tools and ToolholdersWilliam SalazarNo ratings yet

- Lathebeddesign00hornrich PDFDocument56 pagesLathebeddesign00hornrich PDFLatika KashyapNo ratings yet

- Jigs and Fixtures OCRDocument252 pagesJigs and Fixtures OCRGyörgy MurvaiNo ratings yet

- Diamond and CBN English 07Document26 pagesDiamond and CBN English 07Vk PrabakranNo ratings yet

- Sheet Metal StructuresDocument40 pagesSheet Metal StructuresVandane ReyesNo ratings yet

- Operating: Maintenance ManualDocument18 pagesOperating: Maintenance ManualAnonymous reYe6iCCNo ratings yet

- 0208 DressingforsuccessDocument4 pages0208 DressingforsuccessNatKThNo ratings yet

- Lathe ToolslideDocument2 pagesLathe ToolslideFrenchwolf420No ratings yet

- Shaper Used As Surface GrinderDocument1 pageShaper Used As Surface Grinderradio-chaserNo ratings yet

- Riding Mower PartsDocument17 pagesRiding Mower PartsDwight MorrisonNo ratings yet

- PowerTIG 250EX 2016Document32 pagesPowerTIG 250EX 2016Bob john100% (1)

- Manuale CZ200Document11 pagesManuale CZ200gatto61No ratings yet

- Functional Composite Materials: Manufacturing Technology and Experimental ApplicationFrom EverandFunctional Composite Materials: Manufacturing Technology and Experimental ApplicationNo ratings yet

- American 180 Rifle PDFDocument25 pagesAmerican 180 Rifle PDFValeriy ZadorozhnyiNo ratings yet

- Floating Reamer InstructionsDocument1 pageFloating Reamer InstructionsAndrew DeutschmanNo ratings yet

- Cold Setting The Valves On A 1953 Dodge M37 Power WagonDocument2 pagesCold Setting The Valves On A 1953 Dodge M37 Power Wagoncriag100% (1)

- LeBlond Regal Lathes Manuals AvailableDocument60 pagesLeBlond Regal Lathes Manuals Availablejulie2420140% (1)

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- Directions for Using Bottum's Patent Improved Universal Lathe Chucks and Improved Lathes for Turning and Finishing Every Description of Watch Pivots, Pinions, Staffs, EtcFrom EverandDirections for Using Bottum's Patent Improved Universal Lathe Chucks and Improved Lathes for Turning and Finishing Every Description of Watch Pivots, Pinions, Staffs, EtcNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- IMP Workshop ManualDocument336 pagesIMP Workshop Manualsyllavethyjim67% (3)

- 2885-Dent & Bulge Removal PDFDocument1 page2885-Dent & Bulge Removal PDFsyllavethyjimNo ratings yet

- 2881-Radii Functions and Checking PDFDocument1 page2881-Radii Functions and Checking PDFsyllavethyjimNo ratings yet

- 2889-Further Drilling Methods PDFDocument1 page2889-Further Drilling Methods PDFsyllavethyjimNo ratings yet

- 2890-Nuts & Spanners PDFDocument1 page2890-Nuts & Spanners PDFsyllavethyjimNo ratings yet

- 2886-Stud Fitting & Removal PDFDocument1 page2886-Stud Fitting & Removal PDFsyllavethyjimNo ratings yet

- 2880-Supporting & Steadying PDFDocument1 page2880-Supporting & Steadying PDFsyllavethyjimNo ratings yet

- 2883-Metal Working PDFDocument1 page2883-Metal Working PDFsyllavethyjimNo ratings yet

- 2872-Circular Clips #2 PDFDocument1 page2872-Circular Clips #2 PDFsyllavethyjimNo ratings yet

- 2887-Broken Drills & Taps PDFDocument1 page2887-Broken Drills & Taps PDFsyllavethyjimNo ratings yet

- 2871-Circular Clips #1 PDFDocument1 page2871-Circular Clips #1 PDFsyllavethyjimNo ratings yet

- 2879-Clamping & Holding PDFDocument1 page2879-Clamping & Holding PDFsyllavethyjimNo ratings yet

- 2884-Panel Beating PDFDocument1 page2884-Panel Beating PDFsyllavethyjim100% (1)

- 2888-Oblique Drilling PDFDocument1 page2888-Oblique Drilling PDFsyllavethyjimNo ratings yet

- 2875-Belt Drives PDFDocument1 page2875-Belt Drives PDFsyllavethyjimNo ratings yet

- 2876-Belt Fasteners PDFDocument1 page2876-Belt Fasteners PDFsyllavethyjimNo ratings yet

- Contours 1: Hile It CannotDocument1 pageContours 1: Hile It CannotsyllavethyjimNo ratings yet

- 2878-Chains & Sprockets PDFDocument1 page2878-Chains & Sprockets PDFsyllavethyjimNo ratings yet

- 2874-Fitting Core Plugs PDFDocument1 page2874-Fitting Core Plugs PDFsyllavethyjimNo ratings yet

- 2873-Cotters & Wedges PDFDocument1 page2873-Cotters & Wedges PDFsyllavethyjimNo ratings yet

- Roller Chains and Sprockets GuideDocument1 pageRoller Chains and Sprockets GuidesyllavethyjimNo ratings yet

- 2868-Glands & Pipe Fittings PDFDocument1 page2868-Glands & Pipe Fittings PDFsyllavethyjimNo ratings yet

- 2867 Case HardeningDocument1 page2867 Case HardeningEr Sukhwinder SinghNo ratings yet

- 2861-Wheel & Shaft PullersDocument1 page2861-Wheel & Shaft PullersSandra Barnett CrossanNo ratings yet

- 2865-Testing & Facing Valves PDFDocument1 page2865-Testing & Facing Valves PDFsyllavethyjimNo ratings yet

- 2869-Fitting & Joining Pipes PDFDocument1 page2869-Fitting & Joining Pipes PDFsyllavethyjimNo ratings yet

- 2870-Simple Screw Assembly PDFDocument1 page2870-Simple Screw Assembly PDFsyllavethyjimNo ratings yet

- 2866-Hardening & Tempering PDFDocument1 page2866-Hardening & Tempering PDFsyllavethyjimNo ratings yet

- 2864-Poppet Valves & Seating PDFDocument1 page2864-Poppet Valves & Seating PDFsyllavethyjimNo ratings yet

- 2863-Valve Seating Tools PDFDocument1 page2863-Valve Seating Tools PDFsyllavethyjimNo ratings yet

- Timber: Name:-Yash.H.SutharDocument35 pagesTimber: Name:-Yash.H.SutharYash SutharNo ratings yet

- wj089 Salt-Pepper ShakersDocument5 pageswj089 Salt-Pepper ShakersRileyNo ratings yet

- Kreg Catalog Volume 35Document76 pagesKreg Catalog Volume 35Jean Delima AssaeNo ratings yet

- ASME B 18.6.5M - 2000 (R2010) Metric Type IA Cross-Recessed Flat Countersunk Head Tapping Screws (Table 10)Document1 pageASME B 18.6.5M - 2000 (R2010) Metric Type IA Cross-Recessed Flat Countersunk Head Tapping Screws (Table 10)Mahmut ErdönmezNo ratings yet

- Woodturning - Issue 357, 2021Document108 pagesWoodturning - Issue 357, 2021dug100% (1)

- WhipsawDocument11 pagesWhipsawUTpenguinNo ratings yet

- Wooden Clocks: 31 Favorite Projects & Patterns (Fox Chapel Publishing) Cases for Grandfather, Pendulum, Desk Clocks & More with Your Scroll Saw; Includes Beginner, Intermediate, and Advanced Designs - Editors of Scroll Saw Woodworking & CraftsDocument5 pagesWooden Clocks: 31 Favorite Projects & Patterns (Fox Chapel Publishing) Cases for Grandfather, Pendulum, Desk Clocks & More with Your Scroll Saw; Includes Beginner, Intermediate, and Advanced Designs - Editors of Scroll Saw Woodworking & Craftskesalyci0% (1)

- Philippines Carpentry TestDocument3 pagesPhilippines Carpentry Testchricyl mae leganadNo ratings yet

- Introduction To Carpentry:: All About WoodDocument2 pagesIntroduction To Carpentry:: All About WoodRodolfo MaddelaNo ratings yet

- 2022 - KSEIBI Full Line CatalogDocument135 pages2022 - KSEIBI Full Line CatalogGoran IlievskiNo ratings yet

- American Woodworker #157 December 2011-January 2012Document68 pagesAmerican Woodworker #157 December 2011-January 2012Brian Neill100% (2)

- Wood FramingDocument92 pagesWood FramingBarjam KafexhiuNo ratings yet

- Lathe MachineDocument11 pagesLathe Machinesean cutshawNo ratings yet

- Alternatives To Wood Packaging MaterialDocument2 pagesAlternatives To Wood Packaging Materialcole santosNo ratings yet

- Drilling Machine Types & Operations GuideDocument37 pagesDrilling Machine Types & Operations GuideRavichandran G100% (4)

- Product Catalog: Waso WasoDocument169 pagesProduct Catalog: Waso WasoNay Lin နေလင်းNo ratings yet

- Plywood Media Console DIYDocument8 pagesPlywood Media Console DIYDairo Cifuentes Orozco100% (1)

- Carpentry Tools GuideDocument19 pagesCarpentry Tools GuideSuchit Bhansali100% (1)

- Easy Glider: Build A Comfortable Outdoor Seat in Time For SpringDocument5 pagesEasy Glider: Build A Comfortable Outdoor Seat in Time For SpringDerek Frost100% (1)

- Tools CatalogDocument138 pagesTools CatalogtoufikNo ratings yet

- Mikes Resume Update June 2020 (With New Address) PDFDocument6 pagesMikes Resume Update June 2020 (With New Address) PDFMike RideoutNo ratings yet

- Atlas Copco Air Compressor Parts CatalogDocument591 pagesAtlas Copco Air Compressor Parts CatalogYacine CherifiNo ratings yet

- Table Saw Roller StandsDocument13 pagesTable Saw Roller StandsDastgeer ShamsNo ratings yet

- BCM Block BoardDocument34 pagesBCM Block BoardNidhi JoshiNo ratings yet

- Section - 06 20 00 - Finish CarpentryDocument2 pagesSection - 06 20 00 - Finish CarpentryEliseo LagmanNo ratings yet

- In Depth Guide 2020 2Document56 pagesIn Depth Guide 2020 2ej ArchNo ratings yet

- Ott-Jakob HSK-B Pe 2017-04Document33 pagesOtt-Jakob HSK-B Pe 2017-04VladimirAgeevNo ratings yet

- Jerk Box For Olympic WeightliftingDocument27 pagesJerk Box For Olympic WeightliftingArie Emmanuel ListonNo ratings yet

- Lathe Machine Definition Introduction Parts Operation Specification PDFDocument19 pagesLathe Machine Definition Introduction Parts Operation Specification PDFahsan aliNo ratings yet

- Workbook: Wood Frame Construction Manual Wood Frame Construction ManualDocument85 pagesWorkbook: Wood Frame Construction Manual Wood Frame Construction ManualLuciano Dodl100% (1)