Professional Documents

Culture Documents

Distributed Control Systems Toc PDF

Distributed Control Systems Toc PDF

Uploaded by

Mahmoud ElmahdyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Distributed Control Systems Toc PDF

Distributed Control Systems Toc PDF

Uploaded by

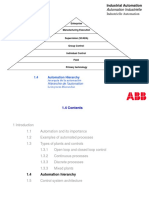

Mahmoud ElmahdyCopyright:

Available Formats

Contents

Chapter 1SCADA systems hardware (and firmware)

1.1 Introduction

1.2 Comparison of the terms SCADA, DCS, PLC and smart

instrument

1.3 Considerations and benefits of SCADA system

1.4 Remote terminal units

1.5 Digital output module

1.6 PLCs used as RTUs

1,7 System reliability and availability

Chapter 2 SCADA systems software and protocols

2.1

2.2

2.3

2.4

2.5

2.6

Introduction

The components of a SCADA system

The DCS and SCADA software package

New technologies in SCADA systems

The twelve golden rules

OPC

1

1

3

9

10

20

27

32

35

35

35

38

43

44

45

Chapter 3 Typical distributed control systems and SCADA systems 51

3.1

3.2

3.3

3.4

3.5

3.6

3.7

3.8

Introduction

Honeywell PlantScape system

Foxboro I/A series distributed control systems

Delta V system

Citect

Wonderware

Intellution iFIX v2.5 system

Comparison of vendors

Chapter 4 The basic controller

4.1

4.2

4.3

4.4

Introduction

Identification of the controller boards

Discrete and logic control

Sequential and batch control

Chapter 5 Basic DCS controller configuration

5.1 Historical

5.2 Control modes

5.3 Tracking and initialization in control slots used for

cascade control

51

51

62

70

72

80

86

86

87

87

87

90

91

95

95

95

95

2 Contents

5.4 Control functions

5.5 Control algorithms

5.6 Sequential programs for batch processing

5.7 Defining equipment procedures

5.8 Phase logic programming

5.9 Phase logic interface

5.10 Logic block functions in advanced controller

5.11 DCS controller configuration

Chapter 6 Introduction to communications for DCS & SCADA

systems

6.1

6.2

6.3

6.4

6.5

6.6

6.7

6.8

6.9

6.10

6.11

Purpose

Basic communications principles

Balanced and unbalanced transmission lines

EIA-232 interface standard (CCITT V.24 interface standard)

The EIA-485 interface standard

Open systems

Interoperability

ModBus protocol

HART protocol

The promise of FieldBus and DeviceNet

Benefits

Chapter 7 Local area network systems

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

7.10

7.11

7.12

7.13

7.14

7.15

Introduction

Network topologies

Bus topology

Star topology

Ring topology

Media access methods

IEEE 802.3 Ethernet

MAC frame format

High speed Ethernet system

100BaseT (100BaseTX, T4, FX, T2)

Fast Ethernet design considerations

Gigabit Ethernet 1000BaseT

Network interconnection components

TCP/IP protocols

SCADA and the Internet

99

104

117

119

120

123

126

129

131

131

131

135

137

145

150

154

154

159

163

164

169

169

170

170

171

172

173

174

181

182

183

186

187

191

196

200

Contents 3

Chapter 8 ProfiBus

205

8.1

8.2

8.3

8.4

8.5

8.6

8.7

8.8

8.9

8.10

8.11

8.12

8.13

8.14

205

207

210

212

212

213

214

218

218

218

218

219

220

220

Introduction

Architecture of the ProfiBus protocol

Application larger service specification

ProfiBus communication model

Relationship between application process and communication

Communication objects

FieldBus message specification

Network management

Fault management

Configuration management

ProfiBus FMS profiles

Performance

Diagnostics

System configuration

Chapter 9Foundation FieldBus

9.1

9.2

9.3

9.4

9.5

9.6

9.7

9.8

9.9

Introduction

Overview

Physical layer

Data link layer

Application layer

User layer block

System management

Device description

Application example

Chapter 10 Programming of DCS systems

225

225

225

227

237

239

243

259

260

261

263

10.1 Development and growth of programmable controllers (PLC) - an

introduction

263

10.2 Need for standardization in programming approach

264

10.3 Drawbacks in conventional programming methodology

265

10.4 Features of IEC-1131-3 language definition

271

10.5 Summary of IEC-1131-3

272

10.6 PLC software architecture - software quality attributes

272

10.7 IEC software architecture

273

10.8 Component parts of IEC software architecture

274

10.9 Functions and function blocks

275

10.10 Local and global variables

277

10.11 Mapping software model to real life systems-Examples

278

10.12 Applications

280

10.13 Summary of PLC architecture

283

10.14 Common elements in IEC-1131-3

283

4 Contents

10.15 Elementary data types

10.16 Generic data type

10.17 Derived data types

10.18 Variables

10.19 Variable initialization

10.20 Functions

10.21 Programs

10.22 Resource

10.23 Tasks

10.24 Summary of common elements in IEC-1131-3

10.25 Structured text

10.26 Statements used for assignments

10.27 Expressions

10.28 Evaluating an expression

10.29 Statements

10.30 Conditional statements

10.31 Iteration statements

10.32 Implementation dependence

10.33 Summary of structured text

10.34 Function block diagram

10.35 Basics

10.36 Methodology

10.37 Signal flow

10.38 Feedback path

10.39 Network layout

10.40 Function execution control

10.41 Jumps and labels

10.42 Network evaluation rules

10.43 Summary of function block diagram

10.44 Ladder diagrams

10.45 Basic concept

10.46 Graphical symbols used in ladder diagram

10.47 Boolean expressions using ladder diagrams

10.48 Integrating functions & function blocks.

10.49 Feedback paths

10.50 Jumps and labels

10.51 Network evaluation rules

10.52 Portability

10.53 Summary of ladder diagrams

10.54 Instruction List

10.55 Structure of IL programming language

10.56 Calling functions and function blocks

10.57 Portability and other issues

10.58 Summary of Instruction List

10.59 Sequential function chart (SFC)

10.60 Steps

284

288

289

291

294

295

300

301

301

303

304

304

305

305

306

307

309

311

311

311

311

312

313

314

315

315

316

316

317

317

317

318

321

322

323

323

324

324

325

326

326

330

332

333

334

338

Contents 5

10.61 Transitions

10.62 Actions

10.63 Action qualifiers

10.64 Action control function block

10.65 Execution rules

10.66 Design safety issues

10.67 Top down design

10.68 Summary of sequential function charts

Chapter 11 Alarm system management

339

341

343

347

347

347

349

349

351

11.1 An alarm system

351

11.2 Functions of the plant or process operator

352

11.3 Functions of an alarm system

355

11.4 An effective alarm system

355

11.5 Design overview

358

11.6 Human and ergonomic factors

359

11.7 Structure of a good alarm system

361

11.8 Safety integrity level (SIL)

370

11.9 Definition of strategy

371

11.10 Strategy for alarm system design

371

11.11 Strategy for alarm system maintenance and management at the

site/plant

372

11.12 Generation of minimum design documentation for each alarm 372

11.13 Measurement of the alarms

376

11.14 Field measurements for deriving alarms

377

11.15 Hardware for alarm processing

377

11.16 Alarm displays

378

11.17 Testing of alarms

380

11.18 Generation of various types of alarms

380

11.19 Selection of alarm settings

387

11.20 Setting alarm priority

389

11.21 Design of field sensors for generating alarms

395

11.22 Logical processing of alarms

400

11.23 Design of alarm list displays

406

11.24 Measurement of performance

411

11.25 Usefulness of alarms

414

11.26 Measurement of number of alarms and average rate of alarms 417

11.27 Measuring operator response

423

11.28 Management of improvement program

424

11.29 Alarm review

425

11.30 Elimination of spurious alarms

426

11.31 Intermittent and fleeting alarms

426

11.32 Processing alarms

427

11.33 Control of modifications

433

11.34 Hazard and operability studies (HAZOP)

433

6 Contents

11.35 Hazard assessment

11.36 Hazard and operability studies (HAZOP)

434

436

Chapter 12Distributed control system reporting

439

12.1 Introduction

12.2 Operation of advanced DCS using multi-screen displays,

cross screen invocation and linking

12.3 Alarm reporting, generation and acceptance

12.4 Alarm reporting

12.5 Generation of alarms

12.6 Different types of logs and reports configurable on a DCS

Chapter 13Distributed control system (DCS) configuration

13.1 Introduction

13.2 An engineering station

13.3 System/project tree structure

13.4 DCS system database

13.5 Configuration of control functions

13.6 Configuration of operator/monitoring functions

13.7 Configuration of system hardware structure

13.8 Configuration of system software

13.9 Documentation

13.10 Commissioning

Chapter 14Maintenance consideration

14.1

14.2

14.3

14.4

14.5

Introduction

Maintenance requirements of system and system elements

Requirements for in-built diagnostic and maintenance routines

Requirement for installation of UPS system

Recovery of a DCS following power outage

Chapter 15Distributed control system applications

15.1

15.2

15.3

15.4

Introduction

Use of DCS in pulp and paper environment

Use of DCS in petroleum-refining environment

Use of DCS in oil and gas processing environment

439

439

445

446

449

450

459

459

459

460

461

462

465

466

466

468

468

471

471

471

478

485

486

487

487

487

507

521

Contents 7

Chapter 16Distributed control systems implementation

16.1

16.2

16.3

16.4

16.5

16.6

523

Introduction

System strategy

Automation plan

Project implementation

Installation and commissioning

Change management

523

523

524

532

535

538

Chapter 17The future of distributed control systems

539

17.1 Introduction

17.2 Creation of E-commerce solution

539

541

Appendix AFundamentals of control systems

457

Appendix BIntegration of the complete FieldBus system

469

Appendix CAdaptive and predictive control

483

Appendix DCentral site computer facilities

497

Appendix EFuzzy logic control

511

Appendix FStability and control modes of closed loop

515

Appendix GDCS and process control exercises

529

Glossary

541

You might also like

- 03192005214235Document0 pages03192005214235Daniela Buse0% (2)

- Tensor Catalogue USA PDFDocument72 pagesTensor Catalogue USA PDFdavev2005No ratings yet

- Treon Introduction - Industrial NodeDocument11 pagesTreon Introduction - Industrial NodeAibek AltynbekNo ratings yet

- Training Curriculum of DcsDocument2 pagesTraining Curriculum of DcssoetrisnoNo ratings yet

- Vickers DG4V-3 DG4V-3S 6xDocument32 pagesVickers DG4V-3 DG4V-3S 6xCarlos Javier Torrico BarreroNo ratings yet

- Basic Instrumentation and Process ControlDocument2 pagesBasic Instrumentation and Process ControlathariqubalNo ratings yet

- 2012-10 - Industrial Ethernet - CP 343-1 LeanDocument68 pages2012-10 - Industrial Ethernet - CP 343-1 LeanAbez FiveNo ratings yet

- DCSDocument16 pagesDCSAnonymous AEYlyuzNo ratings yet

- Acceleration &velocityDocument125 pagesAcceleration &velocityRodolfo HernandezNo ratings yet

- Matlab Robust Control ToolboxDocument168 pagesMatlab Robust Control Toolboxgravity_eng100% (1)

- Rich Operation Experiences and New Technologies On Adjustable Speed Pumped Storage Systems in JapanDocument8 pagesRich Operation Experiences and New Technologies On Adjustable Speed Pumped Storage Systems in JapanR0B0T2013100% (1)

- Distributed Control SystemDocument6 pagesDistributed Control SystemslowdogNo ratings yet

- Scada Systems For Industry 4.0 in RefrigerationDocument17 pagesScada Systems For Industry 4.0 in RefrigerationAnand PavithranNo ratings yet

- ALSPA Controcad - S6 V5.2&Oracle11 - Server&Client Stations - InstallationDocument201 pagesALSPA Controcad - S6 V5.2&Oracle11 - Server&Client Stations - Installationmanh nguyen ngoc vuNo ratings yet

- CPU Structure and Function: Arithmetic Logic Unit Control Unit Control Registers DatapathDocument47 pagesCPU Structure and Function: Arithmetic Logic Unit Control Unit Control Registers DatapathSuhaila NajibNo ratings yet

- UPS 300 Flywheel CATDocument4 pagesUPS 300 Flywheel CATVlade Kljajin0% (1)

- APCDocument25 pagesAPCTawanda Precious SingiziNo ratings yet

- Process Control SystemDocument8 pagesProcess Control SystemIno JohannisNo ratings yet

- Uniflow 2200 PDFDocument9 pagesUniflow 2200 PDFsam123potterNo ratings yet

- DELTA IA-PLC As Manual de ProgramacionDocument1,332 pagesDELTA IA-PLC As Manual de ProgramacionFranciscoBarichivichNo ratings yet

- Presentasi HSD Feed PumpDocument15 pagesPresentasi HSD Feed PumpfirmanallisanNo ratings yet

- Syllabus 0f Maintenance and Protection SubstationDocument4 pagesSyllabus 0f Maintenance and Protection Substationdeepu kumarNo ratings yet

- I 3 SDocument13 pagesI 3 SSudhanshu PahadiaNo ratings yet

- EL-O-MATIC Brch-EngDocument24 pagesEL-O-MATIC Brch-EngLadysAmaris100% (1)

- ABB DCS 140 - HierarchyDocument16 pagesABB DCS 140 - HierarchyMatthewNo ratings yet

- DCSDocument57 pagesDCSRanjita SinghNo ratings yet

- ESP Basics & FundamentalsDocument5 pagesESP Basics & FundamentalsMahadev KovalliNo ratings yet

- TSOP Based Obstacle Detector SensorDocument4 pagesTSOP Based Obstacle Detector SensorSachin Sharma100% (1)

- Level Measurement: Spring 2019Document23 pagesLevel Measurement: Spring 2019ULAGANATHAN MNo ratings yet

- In STEP 7 (TIA Portal) V11, How Can You Upload Blocks From The CPU To The PGDocument4 pagesIn STEP 7 (TIA Portal) V11, How Can You Upload Blocks From The CPU To The PGAndrew Dela CruzNo ratings yet

- Final IoT Protocol StackDocument72 pagesFinal IoT Protocol Stack19DIT023 DHRUV JOSHINo ratings yet

- Catalog of Vortex (Tianjin China.)Document23 pagesCatalog of Vortex (Tianjin China.)Waqas JawaidNo ratings yet

- Fuzzy Logic Expert System For Diagnose Decreased Efficiency of Power PlantDocument1 pageFuzzy Logic Expert System For Diagnose Decreased Efficiency of Power PlantKingRogerNo ratings yet

- Dresser-Rand Control Systems: Easy To Use, Understand and OperateDocument6 pagesDresser-Rand Control Systems: Easy To Use, Understand and OperateNistha ChakrabortyNo ratings yet

- MECHATRONICSDocument16 pagesMECHATRONICSSHIVAJI CHOUDHURY95% (19)

- CollegepptDocument38 pagesCollegepptneethurj9No ratings yet

- Bently Hydrobrochure r3 LR Ok For Website 11.2.18Document12 pagesBently Hydrobrochure r3 LR Ok For Website 11.2.18Deepen SharmaNo ratings yet

- Isa-Scada OverviewDocument11 pagesIsa-Scada OverviewMuhammad JamilNo ratings yet

- Power Plant AutomationDocument135 pagesPower Plant AutomationVishal100% (1)

- Power PlantDocument24 pagesPower PlantARUNGREESMANo ratings yet

- Design and Tuning of Fuzzy Logic PID ControllerDocument19 pagesDesign and Tuning of Fuzzy Logic PID ControllerPriya BhardwajNo ratings yet

- IMI Norgren CatalogueDocument252 pagesIMI Norgren CatalogueAdverNo ratings yet

- PM5500 User Manual PDFDocument146 pagesPM5500 User Manual PDFLuu Hoang ChungNo ratings yet

- ADRE DatasheetDocument31 pagesADRE DatasheetEduard RamosNo ratings yet

- cl02 - CCCDocument29 pagescl02 - CCCteutash100% (1)

- Distributed Control System (DCS) : Heriyanto 9 - 11 Oktober 2012 Golden Flower Hotel BandungDocument3 pagesDistributed Control System (DCS) : Heriyanto 9 - 11 Oktober 2012 Golden Flower Hotel BandungRiskaHerliafifahNo ratings yet

- CMMS NR 2 2013 PDFDocument180 pagesCMMS NR 2 2013 PDFnacachimbandiNo ratings yet

- Summer Training Proposal - pdf12Document3 pagesSummer Training Proposal - pdf12Kanchi_chouhan3No ratings yet

- PRESENTATION Plant Control System Display and SupportDocument22 pagesPRESENTATION Plant Control System Display and SupportcarneoliaNo ratings yet

- Online Monitoring DevicesDocument17 pagesOnline Monitoring Devicesyogi_swarnNo ratings yet

- Fieldbus Tutorial Part12-Advanced Functionality-101111064147-Phpapp01 PDFDocument17 pagesFieldbus Tutorial Part12-Advanced Functionality-101111064147-Phpapp01 PDFthrone001No ratings yet

- 1106-E66TAG Sales PresentationDocument13 pages1106-E66TAG Sales Presentationakheel201No ratings yet

- OpcDocument13 pagesOpcsanjuNo ratings yet

- AU TOC REsdsdsdV4.1Document6 pagesAU TOC REsdsdsdV4.1vextersNo ratings yet

- Prelims - PMD - PHIDocument504 pagesPrelims - PMD - PHIDaniel TremblayNo ratings yet

- Automation Substation GuidelineDocument4 pagesAutomation Substation GuidelineYudo Heru PribadiNo ratings yet

- ) Utzktzy: 6xklgik O 1 5/KX/OK)Document5 pages) Utzktzy: 6xklgik O 1 5/KX/OK)floredaNo ratings yet

- List of ContentsDocument3 pagesList of Contentslokesh_045No ratings yet

- Integration and Automation of Manufacturing SystemsDocument593 pagesIntegration and Automation of Manufacturing SystemsAlejo LalvayNo ratings yet

- Practical Distributed Control Systems (DCS) For Engineers & TechniciansDocument6 pagesPractical Distributed Control Systems (DCS) For Engineers & TechniciansAnonymous NwnJNO0% (1)