Professional Documents

Culture Documents

TSK 1

Uploaded by

Avif PutraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TSK 1

Uploaded by

Avif PutraCopyright:

Available Formats

The Purpose of this paper :

TPM philosophy requires the development of a preventative maintenance program for the

life-cycle of theequipment and the involvement its overall efficiency and aeffectiveness. The

TPM impementation methodology is suggested for improvement in the availability,

performance efficiency and the quality rate, result in improvement of the overall equipment

effectiveness of the equipment. The aim of this papes isto suggest and study the

implementation of the TPM programm in the spinning industry.

The papaer topic is overall structure of TPM is discussed with its practical approach. All the

techniques which are responsible for the efficient and affective operation of machines.

The methode that be used :

The methodology concept of Total Productive Maintenance (TPM) in outline to be succesfull

for helping to increase the productivity and overall equipment effectiveness. TPM can be

defined as a program for fundamental improvement of the maintenance functions in an

organization, which involves its entire human resource.

A. Step of TPM Implementation

- Preparation Stage

- Introduction Stage

- Implementation

- Institutionalising Stage

B. Pillars Of TPM

- Pillar 1 within 5S

Seiri, Seiton, Seiso, Seiketsu, and Shitsuke the quivalent S term Sort, Systemize,

-

Sweep, Standardize, and Self-Dicipline.

Pillar 2 Jishu Hozen (Autonomous Maintenance)

Thus freeing up the skilled maintenance people to spend time on more value added

activity and technical repaires.

Pillar 3 KAIZEN

Basically kaizen is for small improvements, but carried out on a continual basis and

involve all people in the organization.

Pillar 4 Planned Maintenance

Preventive Mtc, Breakdown Mtc,Corrective Mtc, and Maintenance Preventation.

Planned Mtc we evolve our efforts from reactive to a proactive method and use their

equipment

Pillar 5 Quality Maintenance

Pillar 6 Training

The employees should be trained to achive the four phases of skill. The goal is to

create a factory full of experts.

Pillar 7 Office TPM

Pillar 8 Safety, Health and Environment

Why choose overall Total Productivity Maintenance Methode

Employees confidence level increases, A cleas,neat and attractive work place, and favorable

change in the attitude of the operators.

Conclusion

For this paper total productive maintenance succesfully gives the improvement in the

avalibility, performance efficiency and the quality rate, result in the improvement of the

overall equipment effectiveness of the equipment. TPM is the effective tool to increase the

productivity of indian industries. We can compete with the other countries in this increased

globalization. Spinning industries can also have the benefit of TPM for the improvement in

all aspects.

The aim of this paper tospread awareness about TPM methodology in modern technocrats

and industries in india. This paper research trying to understand the TPM concepts for the

indian scenario.

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5796)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- L-B-R-P For Psychic Self DefenceDocument2 pagesL-B-R-P For Psychic Self DefenceTemple of the starsNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Magazine of The U.S. Navy February 1990Document52 pagesMagazine of The U.S. Navy February 1990Fred NoeyesNo ratings yet

- The Ultimate Closed SicilianDocument180 pagesThe Ultimate Closed SicilianJorge Frank Ureña100% (4)

- Obesity in Children & AdolescentsDocument14 pagesObesity in Children & AdolescentsAvif PutraNo ratings yet

- Always Sunny SpecDocument35 pagesAlways Sunny SpecSamuel KapustNo ratings yet

- Hydraulic Design of Spillways - EM 1110-2-1603Document70 pagesHydraulic Design of Spillways - EM 1110-2-1603bdawgg100% (1)

- Turla v. CaringalDocument2 pagesTurla v. CaringalTrina RiveraNo ratings yet

- Shock AnaphylaticDocument15 pagesShock AnaphylaticAvif PutraNo ratings yet

- OutputDocument4 pagesOutputAvif PutraNo ratings yet

- Jurnal GilutDocument11 pagesJurnal GilutAvif PutraNo ratings yet

- Odontogenic Cysts - A Descriptive Clinicopathological StudyDocument6 pagesOdontogenic Cysts - A Descriptive Clinicopathological StudyAvif PutraNo ratings yet

- TH I Gian Làm Bài: 180'Document17 pagesTH I Gian Làm Bài: 180'Duy HảiNo ratings yet

- 2022 VersaDocument508 pages2022 Versaedhi9175No ratings yet

- Khao Yai Draft 1Document4 pagesKhao Yai Draft 1Phimthida KodcharatNo ratings yet

- Noda 1996Document5 pagesNoda 1996Enthroned BlessedNo ratings yet

- Hapter Stereochemistry: Lesson 1Document15 pagesHapter Stereochemistry: Lesson 1Ej FerrerNo ratings yet

- Questionnaire Financial LiteracyDocument6 pagesQuestionnaire Financial LiteracyAmielyn Kieth L. SarsalejoNo ratings yet

- 2023 WARN Notice ListingsDocument15 pages2023 WARN Notice ListingsMasonNo ratings yet

- Brochure PerformanceDocument11 pagesBrochure PerformanceprabumnNo ratings yet

- TQ G10 POST TEST CompleteDocument2 pagesTQ G10 POST TEST CompleteLorenz Gallo VillaseranNo ratings yet

- For Larger Pictures and More Information, Please VisitDocument4 pagesFor Larger Pictures and More Information, Please VisitArun kumarNo ratings yet

- Mitchell - Heidegger and Terrorism (2005)Document38 pagesMitchell - Heidegger and Terrorism (2005)William Cheung100% (2)

- Tarc Acc t2Document4 pagesTarc Acc t2Shirley VunNo ratings yet

- Chowdhury Fatima Rokon Tuli Former Manager Training & Development. Mobile:880-01615769895 Website: Address:483/1, Shewrapara, Mirpur, Dhaka-1216Document4 pagesChowdhury Fatima Rokon Tuli Former Manager Training & Development. Mobile:880-01615769895 Website: Address:483/1, Shewrapara, Mirpur, Dhaka-1216Rabiul AwalNo ratings yet

- STT Tecnica QuirúrgicaDocument5 pagesSTT Tecnica QuirúrgicaNathaly GuevaraNo ratings yet

- Nike's Effective Brand Contact Process and Internal Marketing: The Role of Employee Involvement and Opportunities For ImprovementDocument11 pagesNike's Effective Brand Contact Process and Internal Marketing: The Role of Employee Involvement and Opportunities For Improvementreyramsha1993No ratings yet

- Why Should We Cast Vote in IndiaDocument3 pagesWhy Should We Cast Vote in IndiaKrishna Prince M MNo ratings yet

- 3306 Mayfair ST.: RFI'sDocument9 pages3306 Mayfair ST.: RFI'sRobbieMaxwellNo ratings yet

- Assignment 2 DC Machines-SolutionsDocument6 pagesAssignment 2 DC Machines-SolutionsBRUNO TUMBANANo ratings yet

- Maximus Price ResumeDocument2 pagesMaximus Price Resumeapi-491233681No ratings yet

- Business Proposal (Ulfly)Document14 pagesBusiness Proposal (Ulfly)Ulfly Nuarihmad AsminNo ratings yet

- Writing Skill - B1.Khung Trình Đ Chung Châu Âu (CEFR)Document4 pagesWriting Skill - B1.Khung Trình Đ Chung Châu Âu (CEFR)dongxugioNo ratings yet

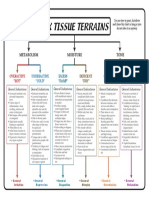

- 6 Tissue Terrains ColorDocument1 page6 Tissue Terrains Colorஆ.க.கோ. இராஜேஷ்வரக் கோன்No ratings yet

- O Rei Esta Voltando (Mara Lima) - Score and PartsDocument41 pagesO Rei Esta Voltando (Mara Lima) - Score and PartsSidionir FalcheteNo ratings yet

- SEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDocument3 pagesSEMINARS AND FIELDTRIPS (59041, 59042, 59071) : Electronics Engineering DepartmentDaniel TamisenNo ratings yet