Professional Documents

Culture Documents

Pipenet Vision Training Manual Spray: Chapter 4 Page 1 of 62 REVISION 2.1, SEP 2010

Uploaded by

ToyinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pipenet Vision Training Manual Spray: Chapter 4 Page 1 of 62 REVISION 2.1, SEP 2010

Uploaded by

ToyinCopyright:

Available Formats

PIPENET VISION TRAINING MANUAL

PAGE 1 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

PIPENET VISION SPRAY/SPRINKLER MODULE

CHAPTER 4

DESIGN OF FIREWATER SYSTEMS

1.

Introduction

This document sets out some guidelines for designing firewater systems using the

PIPENET VISION Spray/Sprinkler Module. It considers a firewater system on a process

plant. Typically, such systems contain deluge systems, monitors, hydrants, hosereels and

other items.

Although there is more than one approach for designing firewater systems, one approach

that is often followed by experienced fire engineers is to separate the design of deluge

systems from the design of firewater ringmains. There are essentially two reasons for this

approach.

The objectives of the calculations for the two requirements are somewhat different.

The main objectives are summarised in Sections 1.1 and 1.2 of this document. In

view of these differences, in order to optimise the design, it is a good idea to divide

the system into a deluge system and a firewater ringmain before the calculations

are performed.

Furthermore, it is sometimes the case that one company designs the deluge

systems and a different company designs the firewater ringmain.

In this chapter of the training manual, we consider two real firewater systems and show

how our tips and guidelines of Chapters 1 and 2 may be implemented in practice.

The systems used in this document are real applications for which the PIPENET VISION

Spray/Sprinkler Module has been used. The networks are relatively complex. For this

reason, the reader is encouraged to obtain the data files from Sunrise Systems or an

authorised representative.

1.1

Objectives of Deluge System Calculations

Check the velocities and keep them below the specified limits:

As firewater systems do not operate for 24 hours a day, they do not generally suffer from

erosion problems. However, in order to minimise the frictional losses in the pipes, it is still

important to keep the velocities below a reasonable limit. Normally, high velocities arise

because pipe diameters are too small. For a given flow rate, the frictional loss per unit

length is inversely proportional to the fifth power of the diameter. So, one must not merely

reduce pipe sizes solely for the purpose of cutting costs.

-1-

PIPENET VISION TRAINING MANUAL

PAGE 2 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Achieve a good flow balance between the nozzles:

Generally, a well-designed system will have a low flow imbalance between two nozzles. A

high imbalance would generally mean that the total flow demanded by the system is higher

than necessary. In an extreme case, this might even lead to a bigger fire pump being

required.

Optimise the inlet pressure and flow rate:

It is better to optimise rather than minimise. Naturally, the minimum frictional pressure loss

(and, hence, the minimum inlet pressure) could be obtained by maximising the pipe sizes.

This approach, however, could lead to an increase in the cost of the system and its weight.

It is, therefore, important to work close to the maximum velocity, but not to exceed it.

1.2

Objectives of Firewater Ringmain Calculation

Adequacy of pump performance:

The results of deluge-system calculations indicate the system requirements regarding the

pressure and flow rate. We need to make sure that the fire pump arrangement can meet

the requirements under a variety of conditions and a variety of demands. The skill in

designing a firewater ringmain system well lies in ensuring that it would work adequately

under a wide variety of circumstances.

Ability to generate sufficient pressure at the inlet to deluge systems:

It is not just the sizing of the fire pumps that is important. The pipes have to be sized

adequately too. They must be small enough to reduce the weight and cost, but large

enough to offer acceptable pressure drops.

Longest piping route by blocking pipes:

Firewater ringmains have isolation valves for maintenance, strainers and so on. It is often

necessary to ensure that the system would work adequately even if an isolation valve is

left closed or a strainer is blocked.

Integrity of the system if a pipe is broken:

This point may be important if a firewater ringmain system is being analysed. For

example, if the pipework near the helideck system is broken in a platform with several

levels, it is possible that the deluge systems at the low levels might still work properly,

albeit at a reduced efficiency. In such a scenario, the elevation difference might produce

enough static head.

Different fire scenarios:

One of the interesting aspects of the design of a firewater ringmain system is that the

same piping system must work under a wide variety of conditions. Clearly, calculations

should be performed for a wide variety of fire scenarios.

Different fire pump scenarios:

Usually, a system is designed in such a way that one or more pumps would be required to

meet the demand. It is necessary to ensure that this is possible.

It is clear that the objectives of the calculations for deluge systems and those for firewater

ringmains are somewhat different. The best designs are, therefore, obtained by

separating the deluge system calculations from the ringmain calculations.

-2-

PIPENET VISION TRAINING MANUAL

PAGE 3 OF 62

1.3

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Principles of the Design Procedure

The following phases of hydraulic design are considered in this document. It is important

to emphasise that it would not be necessary to carry out all of these phases for every

design. In particular, it is quite common for the design engineer to set the pipe sizes

(diameters) and skip that phase. It should also be pointed out that, in this document, we

do not allow for safety margins in the design. For example, where the firewater ringmain

and the deluge system meet, we assume (in this document) that the match between them

is exact. In the real design case, it may be wise to allow a slight excess pressure on the

firewater ringmain side (because, for example, (a) the fire pumps may not perform as

expected or (b) during fabrication it may become necessary to re-route the pipes).

2.

Deluge System Design

Basically, we shall follow the procedure outlined in Chapter 1 of the Spray/Sprinkler

Training Manual. We select the optimal pipe sizes, and then perform analysis calculations

afterwards.

2.1

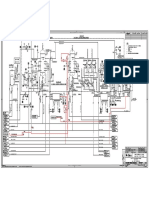

The Deluge System Network and Associated Data

The network for the deluge system is shown below. Although it does not have to be drawn

in this manner, it is done so for illustration purposes only.

-3-

PIPENET VISION TRAINING MANUAL

PAGE 4 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

-4-

PIPENET VISION TRAINING MANUAL

PAGE 5 OF 62

2.2

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Library Data

2.2.1 Pipe Schedules

Nominal Size

(mm)

Actual Internal

Diameter (mm)

25

24

32

32

40

38

50

54

65

66

80

82

90

95

100

108

125

not used

150

161

200

211

2.2.2 Nozzle data

Nozzle type

Wall Drench-4

K-factor

45 (lit/min,barg)

Minimum pressure 1.5 barg

Maximum pressure 3.5 barg

-5-

PIPENET VISION TRAINING MANUAL

PAGE 6 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

2.2.3 Pipe Network Data

Label Input

Node

A/1 A/1

A/2 A/2

A/3 A/3

A/4 A/4

A/5 A/5

A/6 A/6

A/7 A/7

A/8 A/8

A/9 A/9

A/10 A/10

A/11 A/11

A/12 A/12

B/1 B/1

B/2 B/2

B/3 B/3

B/4 B/4

B/5 B/5

B/6 B/6

B/7 B/7

B/8 B/8

B/9 B/9

B/10 B/10

B/11 B/11

B/12 B/12

C/1 C/1

C/2 C/2

C/3 C/3

C/4 C/4

C/5 C/5

C/6 C/6

C/7 C/7

C/8 C/8

C/9 C/9

C/10 C/10

C/11 C/11

C/12 C/12

V/1 V/1

V/2 C/7

V/3 B/7

Output

Node

A/2

A/3

A/4

A/5

A/6

A/7

A/8

A/9

A/10

A/11

A/12

A/13

B/2

B/3

B/4

B/5

B/6

B/7

B/8

B/9

B/10

B/11

B/12

B/13

C/2

C/3

C/4

C/5

C/6

C/7

C/8

C/9

C/10

C/11

C/12

C/13

C/7

B/7

A/7

Length

(m)

2.068

2.068

2.068

2.068

2.068

1.034

1.034

2.068

2.068

2.068

2.068

2.068

2.068

2.068

2.068

2.068

2.068

1.034

1.034

2.068

2.068

2.068

2.068

2.068

2.068

2.068

2.068

2.068

2.068

1.034

1.034

2.068

2.068

2.068

2.068

2.068

0.5

3.28

3.28

Elevation

Change (m)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0.5

3.28

3.28

-6-

C-factor

Status

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

120

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Normal

Pipe

Type

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

SPECIAL

Group

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

3

3

3

3

3

3

3

3

3

3

3

3

4

4

4

PIPENET VISION TRAINING MANUAL

PAGE 7 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

2.2.4 Nozzle Configuration

Label Input

Node

A/1 A/1

A/2 A/2

A/3 A/3

A/4 A/4

A/5 A/5

A/6 A/6

A/8 A/8

A/9 A/9

A/10 A/10

A/11 A/11

A/12 A/12

A/13 A/13

B/1 B/1

B/2 B/2

B/3 B/3

B/4 B/4

B/5 B/5

B/6 B/6

B/8 B/8

B/9 B/9

B/10 B/10

B/11 B/11

B/12 B/12

B/13 B/13

C/1 C/1

C/2 C/2

C/3 C/3

C/4 C/4

C/5 C/5

C/6 C/6

C/8 C/8

C/9 C/9

C/10 C/10

C/11 C/11

C/12 C/12

C/13 C/13

2.3

Nozzle

Status

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

YES

Nozzle Type Required Flow Rate

(lit/min)

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Wall Drench-4 65.4

Pipe Sizing for Deluge System

It should be emphasised here that the pipe sizes determined by PIPENET VISION are not

always ideal, as PIPENET VISION does not have the experience and intuition of an

engineer. The pipe sizes determined by PIPENET VISION should be regarded as initial

guesses. In most cases, the design engineer will simply set the pipe sizes based on past

experience.

-7-

PIPENET VISION TRAINING MANUAL

PAGE 8 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

For pipe sizing, the D Button must be selected on the Calculation Toolbar, as shown

below.

Pipe Sizing Button

-8-

PIPENET VISION TRAINING MANUAL

PAGE 9 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

The pipe data can be displayed in a Data Window, as shown below.

Note the

creation

of groups

Note that the

pipe sizes have

been left unset

-9-

PIPENET VISION TRAINING MANUAL

PAGE 10 OF 62

2.4

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Optimisation Trial 1: Maximum Velocity = 4 m/sec

The results below were obtained after the pipe-sizing phase was performed. The yellow

background indicates that these sizes have not been fixed. In this context, the term fixed

means the following. Once the sizes are fixed they can only be changed manually;

PIPENET VISION will not automatically change them, depending on the specifications.

During the Design Phase, the yellow background to the pipe sizes means that the pipe

sizes can change, depending on the operating conditions.

- 10 -

PIPENET VISION TRAINING MANUAL

PAGE 11 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

- 11 -

PIPENET VISION TRAINING MANUAL

PAGE 12 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

We note from the above figure that the maximum velocity is well below the specified

maximum of 4 m/sec.

This point can also be seen in a Data Window, in which the pipes are re-ordered on the

basis of velocities, as shown below.

- 12 -

PIPENET VISION TRAINING MANUAL

PAGE 13 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

The inlet conditions are shown below.

Depending on the design rules, there is scope for increasing the maximum velocity for pipe

sizing. Our next step is to increase this maximum velocity to 6 m/sec.

2.5

Optimisation Trial 2: Maximum Velocity = 6 m/sec

Please refer to the data below.

- 13 -

PIPENET VISION TRAINING MANUAL

PAGE 14 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

- 14 -

PIPENET VISION TRAINING MANUAL

PAGE 15 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

We note that the velocities in some of the pipes are more than the maximum of 6 m/sec.

Therefore, we have to increase the pipe sizes for some of these pipes, and this change is

carried out in Section 4 below. Please note the highlighted velocities in the screen shots

below.

The required inlet conditions are shown below.

As expected, the required inlet pressure is higher. However, the inlet flow rate is also

slightly higher. Please offer an explanation for this.

- 15 -

PIPENET VISION TRAINING MANUAL

PAGE 16 OF 62

2.6

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Analysis Phase Calculations

Clearly, the pipe sizes with a maximum velocity of 6 m/sec are considerably smaller than

those with a maximum velocity of 4 m/sec. We note from the output, however, that the

velocities in Pipes B/6, B/7, C/6, C/7 and V/1 exceed the maximum of 6 m/sec. This

indicates that optimal pipe sizes for the other pipes could be fixed at their current values,

provided the sizes of Pipes B/6, B/7, C/6, C/7 and V/1 are increased (in order to bring the

velocity below 6 m/sec).

The next step, therefore, is to fix the sizes of the diameters, and then increase the sizes of

Pipes B/6, B/7, C/6, C/7 and V/1. Firstly, click on the Analysis (or Calculation) Button.

Analysis Phase Button

The diameters will now be fixed at their current values. This ensures that the diameters do

not change automatically between different calculations; for example, because the

specifications have changed. At some point in the Design Phase calculations, the pipe

diameters become fixed, and can only be changed manually.

After fixing the diameters, we can turn our attention to Pipes B/6, B/7, C/6, C/7 and V/1.

The nominal sizes of Pipes B/6, B/7, C/6, and C/7 are to be increased from 40 mm to

50 mm, and that of V/1 is to be increased to 100 mm (as shown in the highlighted rows in

the screenshot below).

- 16 -

PIPENET VISION TRAINING MANUAL

PAGE 17 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Please note that the yellow background to the diameters has been changed to white, and

the diameters have been set manually.

The diameters of Pipes B/6, B/7, C/6 and C/7 are now set to 50 mm, and the diameter of

Pipe V/1 is set to 100 mm. These changes are indicated in the above Data Window. Also,

please note that the group data has now been set to unset, as only one diameter is

allowed in a given group.

- 17 -

PIPENET VISION TRAINING MANUAL

PAGE 18 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Some results are shown in the following two screen shots.

- 18 -

PIPENET VISION TRAINING MANUAL

PAGE 19 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Most remote nozzle

Most favourable nozzle

The required inlet conditions are as follows.

- 19 -

PIPENET VISION TRAINING MANUAL

PAGE 20 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

The nozzle deviations, in decreasing order, are shown below.

2.7

Optimising Pipe Sizes by Fine Tuning

In the above scenario, it is clear that the nozzles at the lower levels are discharging too

much water (which can be seen by looking at the nozzle percentage deviation shown in

the above screen shot). This is to be expected. We can try to reduce some of the pipe

sizes and check the implications.

- 20 -

PIPENET VISION TRAINING MANUAL

PAGE 21 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

It can be seen from the Data Window below, in which the nozzles have been re-ordered on

the basis of the nozzle deviation, that there is better balance.

We can also see this improvement in the inlet conditions (in the schematic below), as there

is better balance between the nozzles.

- 21 -

PIPENET VISION TRAINING MANUAL

PAGE 22 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

It is, of course, not good news all they way round. There is a price to pay. The velocity in

some of the pipes now exceeds the maximum value. It is a matter of engineering

judgement as to whether or not this system is acceptable.

The pipe velocities, re-ordered in decreasing value, are shown in the following screen

shot. Please note that the velocities below are positive. Since the system is symmetric,

there will be corresponding negative velocities in other pipes. However, these negative

values do not appear in the table below, as only the top ten values are present. Negative

velocities indicate that the flow is in the opposite direction of the pipe; i.e., directed from

the output node of the pipe to the input node.

Nozzle percentage deviations are shown in the schematic below.

- 22 -

PIPENET VISION TRAINING MANUAL

PAGE 23 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

At this stage, it is the decision of the design engineer as to the extent to which the deluge

is to be optimised and fine-tuned. For the purpose of this document, we shall assume that

the design of the deluge system is frozen at this point.

The equivalent K-factor for the deluge system is recorded in the output file, an extract of

which is shown below.

FLOW AT INLETS

-------------Inlet Node

Pressure

Flowrate

Equivalent K-factor

(bar G

)

(lit/min )

(lit/min , bar G

)

-----------------------------------------------------------V/1

3.635

2519.

1321.2

Note: A * after a value indicates that this is a specification

We note that the value of the equivalent K-factor is 1321.2 (lit/min, bar). This value can be

readily used if this deluge system is to be modelled as a nozzle. As we saw in Chapter 3

of the Spray/Sprinkler Training Manual (entitled Fire Protection Systems Design Firewater Ringmain Systems), this value is typical for deluge systems that are to be

modelled by equivalent nozzles where clack shut deluge valves are used.

- 23 -

PIPENET VISION TRAINING MANUAL

PAGE 24 OF 62

3.

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Firewater Ringmain System Design

As mentioned in the introduction, firewater ringmain system calculations are typically

carried out after the deluge system calculations. In this section, we show the typical

calculations associated with firewater ringmain systems design.

3.1

Pipe Sizing for Firewater Ringmain Systems

By this stage, all of the deluge systems have been designed, and all of the monitors,

hydrants and hosereels have been chosen. Their equivalent nozzles and, hence, their

equivalent K-factors have all been determined. It is entirely possible that these designs

and selections are preliminary, and so could be modified. However, in order to perform

design calculations for firewater ringmain systems, we should at least know the results

from preliminary designs and selections. If they are not known, typical values or estimated

values must be assumed.

One of the earliest tasks in the hydraulic design of the firewater ringmain system is to

determine the pipe sizes. Clearly, the difficulty in this step is due to the fact that the

firewater ringmain system has to work under a wide variety of conditions. For example,

the system should be able to deal with a number of potential fire scenarios and pump

scenarios (in other words pumps working in different combinations).

Experienced fire engineers know through their own experience as to which diameters to

use. Their experience is often a better guide to the optimal design, and so it is typical for

all the pipe sizes to be set by the fire engineer. Typically, the diameters are input by the

user, rather than being calculated using PIPENET VISION.

However, for the sake of completeness of the design procedure, the pipe sizing procedure

is described here.

- 24 -

PIPENET VISION TRAINING MANUAL

PAGE 25 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

- 25 -

PIPENET VISION TRAINING MANUAL

PAGE 26 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Working

Working

- 26 -

PIPENET VISION TRAINING MANUAL

PAGE 27 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

3.1.1 Pipe Sizing Case 1

Use the file named pipe sizing for area 301.sdf.

- 27 -

PIPENET VISION TRAINING MANUAL

PAGE 28 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

3.1.2 Pipe Sizing Case 2

Use the file named pipe sizing for area 302.sdf.

3.1.3 Pipe Sizing Case 3

Use the file named pipe sizing for area 303.sdf.

3.1.4 Pipe Sizing Case 4

Use the file named pipe sizing for area 304.sdf.

- 28 -

PIPENET VISION TRAINING MANUAL

PAGE 29 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

3.1.5 Pipe Sizing Case 5

Use the file named pipe sizing for area 305-1.sdf.

3.1.6 Pipe Sizing Case 6

Use the file named pipe sizing for Condensate Unit.sdf.

All users (nozzles) are off. However, the user on Node Equip/3 requires a flow of

648 m3/hr at a pressure of 8 barg.

Node Equip/3 is defined as an output node, and does not have a nozzle attached.

- 29 -

PIPENET VISION TRAINING MANUAL

PAGE 30 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Node Equip/3

3.1.7 Pipe Sizing Case 7

Use the file named pipe sizing for Fire Fighting station.sdf.

- 30 -

PIPENET VISION TRAINING MANUAL

PAGE 31 OF 62

3.2

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Worst-case Scenario with Fixed Diameters

We can compare the diameters calculated by PIPENET VISION for all the above cases,

and then decide which diameters are the best to use. The fixed diameters are shown in

the table in Appendix 4, at the end of this chapter.

The requirements for the worst-case scenario and, hence, the nozzle data and status are

as shown below.

In the first instance, no orifice plates are inserted, as we wish to establish whether the pipe

sizes determined in this section produce a well-balanced flow in the system.

The calculated results for the above users are shown below. It is clear that there is

significant imbalance in the supply to the users. In the next section, we shall see how to

correct this imbalance using orifice plates.

- 31 -

PIPENET VISION TRAINING MANUAL

PAGE 32 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

The inlet flow-rate and pressure requirements are shown on the screenshot of the input

node results:

It is clear that the inlet conditions can be made less demanding by balancing the flow

through the deluge systems (which can be easily achieved by placing orifice plates in the

inlets to the deluge systems).

3.3

Orifice Plate Sizing

The sizes for orifice plates can be determined using the following steps.

Firstly, remove the nozzles.

Next, define the required flow rate at the outlets, as required.

At the inlet of the worst nozzle from the previous calculation, define the required

pressure as well.

Perform a calculation.

This calculation will result in the pressures at the outlet nodes. These pressures are

the available pressures. Subtract the required pressures from the available

pressures, to yield the required pressure drops in the orifice plates.

Input the orifice plates, and assign the required pressure drops. Now, perform a

calculation to obtain the orifice plate diameters. These diameters can now be fixed,

the outlets can be removed, and the nozzles can be placed back again.

Before working through the above steps, we first need to specify the flow rates and

pressures required for the systems that are working.

- 32 -

PIPENET VISION TRAINING MANUAL

PAGE 33 OF 62

Nozzle

Label

FH/56

TANK/13

FH/86

FH/85

TANK/10

FH/84

FM/13

Input

Node

279

168

309

308

169

307

170

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Required Flow

Rate (m3/hr)

36

421.2

36

36

1278

36

144

K-factor

20.78

317.6

20.78

20.78

404.14

20.78

54.43

Required

Pressure (bar)

3.00

1.76

3.00

3.00

10.00

3.00

7.00

The dialog boxes for defining the outlet conditions are as follows.

The dialog boxes for the output nodes created by removing the nozzles are all assigned

the specifications that are shown above.

- 33 -

PIPENET VISION TRAINING MANUAL

PAGE 34 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

At the critical outlet node, both the pressure and the flow rate are given.

All the calculation specifications that have been input are shown in the screen shot below.

Please note that Node 209 is the inlet and, at this stage, we are not interested in making a

specification at this node.

- 34 -

PIPENET VISION TRAINING MANUAL

PAGE 35 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

We can now draw up a table that shows the required pressures against the actual

available pressures. The difference between these pressures is the amount by which the

pressures need to be dropped in the orifice plates.

Input

Node

279

168

309

308

169

307

170

Required

Pressure (bar)

3.00

1.76

3.00

3.00

10.00

3.00

7.00

Available

Pressure (bar)

10.054

10.028

10.059

10.048

9.997

10.059

10.022

Pressure

Difference (bar)

7.054

8.268

7.059

7.048

0

7.059

3.022

The orifice plates are now input, and the pressure losses are assigned to them. Please

ensure that the Crane Option is chosen for orifice plates.

The calculated orifice diameters are shown in the screen shot below.

- 35 -

PIPENET VISION TRAINING MANUAL

PAGE 36 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

The calculated flow rate and pressure results at the output nodes are shown below. It can

be seen from the table that the pressures and flow rates at the output nodes are exactly as

required. The relevant nodes are highlighted.

3.4

Pump Selection Procedure

This system is to be driven by two 50% duty pumps. The inlet node, therefore, must be

separated into two nodes as required. In practice, this is essential because the pumps

- 36 -

PIPENET VISION TRAINING MANUAL

PAGE 37 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

may be located in different places, or they could be at different elevations. So it may not

be possible to combine them into a single node.

In principle, several pump combinations can meet the required duty. In order to ensure

that the pumps must be of equal size, we need to define the flow rate through one of the

pumps to be 50% of the total required flow rate.

By adding up the required flow rates through all the outputs, we can calculate that the flow

rate though the two pumps should be a total of 2552.4 m3/hr. So, each pump must deliver

1276.2 m3/hr, which must be given as the flow rate for one of the input nodes, for both the

design specification and the calculation specification. The other input node must be left

completely free, and simply be defined as an input node.

The specifications for Input Nodes 209 and 183 are defined below.

Input Node 209

Input Node 183

- 37 -

PIPENET VISION TRAINING MANUAL

PAGE 38 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

The calculated results for the two input nodes can be easily determined by sorting the

Data Window for the nodes. It can be seen that each pump must deliver 1276.2 m3/hr at

10.514 barg.

- 38 -

PIPENET VISION TRAINING MANUAL

PAGE 39 OF 62

Appendix 1:

Label Input

Node

1

1

2

1

3

4

4

5

5

6

6

7

7

8

12

7

13

2

15

10

16

11

17

12

18

13

19

10

20

14

21

15

22

16

23

135

26

19

27

20

28

21

29

22

31

23

32

24

33

205

34

25

35

26

36

27

37

28

38

29

39

30

40

31

41

32

42

33

43

34

44

35

45

36

47

31

48

33

49

35

50

30

51

32

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Pipe Data

Output

Node

86

91

97

105

112

119

133

140

3

64

57

54

44

210

213

215

11

17

28

9

17

144

80

90

24

20

25

26

27

19

31

32

33

34

35

36

37

38

39

40

41

42

Length

(m)

20.67

29.72

17.97

7

9.14

9.1

25

19

17

8.44

16.22

11.25

24.2

44.73

46.8

13.41

16.48

9.84

15

24

14

26.2

5.12

36.51

20.67

49.2

27.7

29.9

29.9

20.4

8.8

17.4

12.3

11.73

9.33

10.7

27.5

22.7

22.7

22.7

1

1

Elevation

(m)

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 39 -

Pipe Roughness Fitting Eqivalent

(mm)

Length (m)

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

4.57E-02

0

PIPENET VISION TRAINING MANUAL

PAGE 40 OF 62

52

53

54

55

56

57

58

59

60

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

91

93

94

95

96

97

98

99

34

44

45

46

47

48

49

50

51

52

53

54

55

51

57

58

59

60

61

62

54

64

65

66

67

68

69

70

71

72

73

72

75

76

77

78

79

80

82

83

85

86

24

87

89

90

43

46

9

47

48

45

55

49

50

51

62

53

13

56

58

59

60

61

331

52

63

65

66

222

68

69

16

10

70

71

72

74

76

77

78

2

82

75

83

84

79

85

87

88

3

89

1

28.32

6.5

27.52

28.18

29.42

29.8

28.34

16.8

16.45

30.34

10.1

28.45

1

28

28

28

28

28

30

15.3

25

23

20.72

22

25

7

21.57

55

29.53

25.48

34.7

8.03

50.11

46.23

8.7

7.2

41

22.7

22

20.43

60

23.49

50

35.1

50

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 40 -

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PIPENET VISION TRAINING MANUAL

PAGE 41 OF 62

101

102

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

123

124

125

126

127

129

130

131

133

134

135

136

137

138

139

140

141

143

144

145

146

147

148

149

150

151

92

93

95

96

97

98

98

95

101

101

103

104

105

106

107

108

109

110

111

112

114

108

116

117

118

120

118

117

124

125

126

127

128

127

128

123

125

134

136

137

138

139

9

140

141

142

93

4

96

5

98

94

99

100

103

102

104

6

106

107

101

109

110

111

7

113

108

115

328

120

327

8

121

122

127

128

125

123

124

129

130

131

132

21

135

136

137

138

139

141

142

22

50

30.83

26.31

25.03

30

29.96

1

1

30

1

30

29.26

28

28

28

28.93

30

30

26.6

30

28.84

1

11.23

27

13.45

20.2

1

1

16.5

28.28

21

13

12.74

4.77

4.77

25.2

1

15.5

25

25

25

30

18.5

19

20.7

12

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 41 -

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PIPENET VISION TRAINING MANUAL

PAGE 42 OF 62

152

153

154

155

156

157

158

160

161

162

163

164

165

166

167

168

169

170

171

172

173

174

175

176

177

178

179

180

181

182

183

184

185

186

187

188

189

190

193

194

195

196

197

198

199

200

141

144

145

146

147

148

149

145

148

146

149

155

156

157

158

159

160

161

162

163

164

156

157

158

161

162

163

171

172

173

174

175

176

177

178

179

180

181

174

176

177

181

179

180

190

191

143

145

146

147

148

149

150

151

152

153

154

156

157

218

159

160

161

162

163

164

12

165

166

167

168

169

170

172

173

174

175

176

177

178

179

180

181

182

184

185

186

187

188

189

195

190

1

20.67

15.85

9.5

12.12

18

18

6

6

1

1

22.95

5.74

10.45

18.9

30

6.2

5.74

21.15

23.9

18.4

19.95

4.45

1

19.95

4.45

1

15.25

11.86

17.9

6.4

28

21.74

7.65

7.07

22.93

11.7

12.2

18.64

1

18.64

18.64

14.7

1

29.71

30

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 42 -

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PIPENET VISION TRAINING MANUAL

PAGE 43 OF 62

201

202

203

204

205

206

208

209

210

211

212

213

214

215

217

219

220

221

222

223

224

225

227

FM/2

FM/3

228

92

90

229

230

231

232

233

234

235

236

237

238

239

240

241

242

243

244

245

246

192

193

194

195

196

197

190

195

191

193

196

204

207

206

209

210

211

212

213

214

215

216

218

219

19

222

81

83

222

205

204

78

77

76

80

81

82

85

86

91

92

93

97

94

96

105

191

192

193

196

197

198

199

200

201

202

203

23

205

204

206

219

212

14

214

15

216

217

158

220

221

67

23

81

223

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

240

15.2

18.88

11.13

21.6

8.3

23.96

1

1

1

11.9

11.9

20.43

30.69

22.41

6.82

14.3

53.53

7.98

56.73

37.1

53.45

48.5

22

18.1

26.9

9.3

39.9

17.32

15.3

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 43 -

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PIPENET VISION TRAINING MANUAL

PAGE 44 OF 62

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

289

290

291

292

106

107

103

104

112

113

114

109

110

111

119

116

120

133

134

135

136

137

138

139

36

37

29

28

27

26

25

20

45

48

47

46

44

55

49

50

52

62

53

61

60

59

58

57

69

68

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 44 -

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PIPENET VISION TRAINING MANUAL

PAGE 45 OF 62

293

294

295

296

297

298

299

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

327

328

329

330

331

332

FH/1

FH/2

333

334

335

336

67

66

65

64

70

71

73

89

90

87

88

198

197

192

194

182

178

175

173

171

164

160

159

218

155

150

147

144

142

140

124

126

210

211

212

213

214

215

216

217

327

328

328

327

331

331

287

288

289

290

291

292

293

294

295

296

297

298

299

300

301

302

303

304

305

306

307

308

309

310

311

312

313

314

315

316

317

318

319

320

321

322

323

324

325

326

116

117

329

330

12

332

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

1.5

16.55

18.77

5.2

5.2

24.1

1.5

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 45 -

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

PIPENET VISION TRAINING MANUAL

PAGE 46 OF 62

FH/3

218

9

8

216

14

191

103

207

122

30

46

226

128

142

25

24

132

159

11

100

219

209

4

88

207

3

182

94

198

113

21

37

217

119

133

18

17

22

150

6

91

211

207

194

1

206

73

11

95

10

114

126

18

16

118

134

29

30

123

13

155

92

34.12

6.82

31.95

13.6

6.92

28.6

18.2

27.66

18.1

30

28.2

11.6

44.66

15.7

30

29.3

28

25.2

18

23.7

50

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

0

- 46 -

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

4.57E-02

0

0

0

0

0

0

0

0

0

0

0

0

11.89

0

0

0

0

0

0

0

0

PIPENET VISION TRAINING MANUAL

PAGE 47 OF 62

Appendix 2:

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Fittings on Pipes

Pipe Label, Number of Fittings, Types of Fitting, Equivalent Length (m)

1

2

3

4

5

6

7

12

13

15

16

17

18

19

20

21

22

23

26

27

28

29

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

47

48

49

53

54

55

56

57

58

59

60

61

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

4

4

4

4

4

4

4

4

3

4

4

4

4

5

4

4

4

4

4

4

4

4

4

4

4

3

4

4

4

3

4

4

4

4

4

4

4

4

4

4

5

4

4

4

4

4

4

4

4

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

16.29

54.31

54.31

54.31

54.31

5.408

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

16.29

54.31

54.31

54.31

16.29

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

5.408

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

1 x

1 x

5

4

5.408

54.31

1 x

54.31

1 x

54.31

- 47 -

1 x

5.408

PIPENET VISION TRAINING MANUAL

PAGE 48 OF 62

62

63

64

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

81

82

83

84

85

86

87

88

89

91

93

94

95

96

97

98

99

101

102

104

105

106

107

110

112

113

114

115

116

117

118

119

120

121

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

4

4

4

4

5

4

4

4

5

4

4

5

4

4

4

4

4

4

4

4

5

4

4

4

4

3

4

4

5

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

54.31

54.31

54.31

54.31

5.408

54.31

54.31

54.31

5.408

54.31

54.31

5.408

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

5.408

54.31

54.31

54.31

54.31

16.29

54.31

54.31

5.408

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

1 x

54.31

1 x

5.408

1 x

5.408

- 48 -

PIPENET VISION TRAINING MANUAL

PAGE 49 OF 62

123

125

126

127

129

133

134

135

136

137

138

139

143

144

145

146

147

148

149

150

151

153

160

161

164

165

166

167

168

169

170

171

172

173

174

175

177

178

180

181

182

183

184

185

186

187

188

189

190

192

193

196

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

4

4

4

4

3

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

5

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

5

4

4

54.31

54.31

54.31

54.31

16.29

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

5.408

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

5.408

54.31

54.31

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

1 x

54.31

1 x

5.408

- 49 -

PIPENET VISION TRAINING MANUAL

PAGE 50 OF 62

197

199

200

201

202

203

204

205

206

211

212

213

214

215

219

220

221

222

223

224

225

227

FM/3

228

92

90

229

FH/1

FH/2

333

334

335

FH/3

9

8

216

14

191

103

207

122

30

46

226

128

142

25

11

100

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

x

4

4

4

4

4

4

4

4

4

5

5

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

4

5

5

4

4

4

4

4

4

4

4

4

4

5

4

4

5

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

5.408

5.408

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

5.408

5.408

54.31

54.31

54.31

54.31

54.31

54.31

54.31

54.31

10.67

54.31

5.408

54.31

54.31

5.408

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

1 x

5.408

1 x

5.408

1 x

5.408

1

1

1

1

1

1

x

x

x

x

x

x

5

5

5

5

5

5

5.408

5.408

5.408

5.408

5.408

5.408

1 x

1 x

5

5

1.219

5.408

1 x

1 x

5

5

5.408

5.408

- 50 -

PIPENET VISION TRAINING MANUAL

PAGE 51 OF 62

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

The fitting types are as follows:

1

2

3

4

5

6

7

8

9

45 Deg Elbow,

90 Deg Standard Elbow,

90 Deg Long Radius Elbow,

Tee or Cross (Flow Turned Thro 90 Deg),

Gate Valve,

Swing Check Valve,

Non-Return Valve,

Ball Valve,

Butterfly Valve.

- 51 -

PIPENET VISION TRAINING MANUAL

PAGE 52 OF 62

Appendix 3:

SPRAY: CHAPTER 4

REVISION 2.1, SEP 2010

Fire Protection System Demands - Fire Monitors,

Deluge Systems and Fire-hydrant Equivalent-nozzle

Data

The equivalent-nozzle data is as follows.

Label

FM/1

FM/2

FM/3

FM/4

FM/5

FM/6

FM/7

FM/8

FM/9

FM/10

FM/11

FM/12

FM/13

FM/14

FM/15

FM/16

FM/17

FM/18

FM/19

FM/20

FM/21

FM/22

FM/23

FM/24

FM/25

FH/1

FH/2

FH/3

FH/4

FH/5

FH/6

FH/7

FH/8

FH/9

FH/10

FH/11

FH/12

FH/13

FH/14

FH/15

FH/16

Input

Node

200

199

201

99

100

184

186

187

189

185

102

167

170

56

115

154

153

143

121

122

131

132

41

42

43

224

225

226

227

228

229

230

231

232

233

234

235

236

237

238

239

Nozzle

Type

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

1

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

K-factor

(lit/min, bar)

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

54.4269

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

Required Flow

Rate (lit/min)

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

144

36

36

36

36

36

36

36

36

36

36

36

36

36

36

36

36

- 52 -

Minimum Pressure Maximum Pressure

(barg)

(barg)

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

1.00E+00

1.00E+01

PIPENET VISION TRAINING MANUAL

PAGE 53 OF 62

FH/17

FH/18

FH/19

FH/20

FH/21

FH/22

FH/23

FH/24

FH/25

FH/26

FH/27

FH/28

FH/29

FH/30

FH/31

FH/32

FH/33

FH/34

FH/35

FH/36

FH/37

FH/38

FH/39

FH/40

FH/41

FH/42

FH/43

FH/44

FH/45

FH/46

FH/47

FH/48

FH/49

FH/50

FH/51

FH/52

FH/53

FH/54

FH/55

FH/56

FH/57

FH/58

FH/59

FH/60

FH/61

FH/62

FH/63

FH/64

FH/65

240

241

242

243

244

245

246

247

248

249

250

251

252

253

254

255

256

257

258

259

260

261

262

263

264

265

266

267

268

269

270

271

272

273

274

275

276

277

278

279

280

281

282

283

284

285

286

287

288

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846

20.7846