Professional Documents

Culture Documents

Hasil Laser Fine Test: Wear Debris

Uploaded by

Iswan ArpadiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hasil Laser Fine Test: Wear Debris

Uploaded by

Iswan ArpadiCopyright:

Available Formats

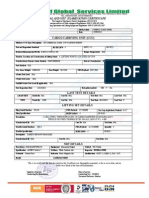

HASIL LASER FINE TEST

Customer / Site: KCMB

Machine: TF147 FUEL BF I

Equipment Name: FUEL

Port Sample Loc: BEFORE FLUSHING

Notes:

Overall Summary:

11/16/2013

Sample Date:

Analysis Date:

Sample #:

Operator:

Fluid Type:

Seq#:

Operating Hrs/miles:

Hrs/mile Overhaul:

Hrs/mile oil Change:

11/15/2013

11/16/2013

11:43 AM

11:41:16 AM

PRISTA OKTAVIA

PERTAMINA / FUEL

0

0

0

0

Address

PAMA ADARO

OSA WARA

TJG, KAL-SEL

Wear Debris Summary:

Wear Debris

Particle Count Nominal

Phone: VOIP. 1101627

Fax:

ISO 4406 (1999)

NAS 1638

Part/1 ml

Part/100 ml

>4um(c):

6,681.2

20 5-15um

>6um(c):

1,267.5

17 15-25um 14-21um(c):

>14um(c): 1.0

NAVAIR 01-1A-17

6-14um(c):

126,645

9 5-10um

100

2 10-25um

6-10um(c): 123,644

21-38um(c):

50-100um 38-70um(c):

00 50-100um 38-70um(c):

>100um

00 >100um

(Part/ml)

00 25-50um

>70um(c):

Max(um)

Mean(um) 20-25um

>70um(c):

25-50um

50-100um

>100um

Cutting Wear

Severe Sliding Wear

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

Fatigue Wear

Non Metallic Wear

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

0.0

Unclassified Wear

0.0

0.0

0.0

0.0

0.0

0.0

0.0

Free Water (ppm)

10-21um(c): 3,101

7 25-50um 21-38um(c):

Max Diameter Method

Part/100 ml

Viscosity (cP)

2.18

Wear Particle Map - Representative Selection

Cutting

Severe Sliding

Fatigue

Non Metalic

Unknown

You might also like

- Marine and Offshore Pumping and Piping SystemsFrom EverandMarine and Offshore Pumping and Piping SystemsRating: 4.5 out of 5 stars4.5/5 (2)

- Fluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceFrom EverandFluid Analysis for Mobile Equipment: Condition Monitoring and MaintenanceNo ratings yet

- Lampiran 4 Solar KeruhDocument1 pageLampiran 4 Solar KeruhIswan ArpadiNo ratings yet

- Ursa15w40 13052014 PDFDocument5 pagesUrsa15w40 13052014 PDFJose Miguel Bautista FigueroaNo ratings yet

- WRZK 4 Run@31-July 2011Document5 pagesWRZK 4 Run@31-July 2011Adel FawziNo ratings yet

- Data Sheet: LPG Filling Pump P-001/002/003/004/005/006Document5 pagesData Sheet: LPG Filling Pump P-001/002/003/004/005/006Denstar Ricardo Silalahi100% (1)

- P-90913 Vibration ReportDocument9 pagesP-90913 Vibration ReportPetroen100% (1)

- FSO Federal IIDocument65 pagesFSO Federal IIuud nasrulloh100% (2)

- Delivery: Properties:: Se AnexaDocument3 pagesDelivery: Properties:: Se Anexaangel gabriel perez valdezNo ratings yet

- TCR Arabia Company LTD: P.O BOX:3422 DAMAM 31471 (KSA)Document2 pagesTCR Arabia Company LTD: P.O BOX:3422 DAMAM 31471 (KSA)Ronel John Rodriguez CustodioNo ratings yet

- Marathon AC Motor Technical ParticularsDocument13 pagesMarathon AC Motor Technical ParticularslovelyshreeNo ratings yet

- EX3003 Hose Anaconda Line KDocument10 pagesEX3003 Hose Anaconda Line KJelski Hizkia IlatNo ratings yet

- Morning Report Rig 121 - 28 - Abril - 12 PLAB 043Document1 pageMorning Report Rig 121 - 28 - Abril - 12 PLAB 043Marce LitoNo ratings yet

- Pump Check List (P-2)Document8 pagesPump Check List (P-2)Kayra Riri ChirulNo ratings yet

- W13018-YT01-GDF-457110 Rev 5-APVDocument8 pagesW13018-YT01-GDF-457110 Rev 5-APVJosé santanaNo ratings yet

- Pump DatasheetDocument1 pagePump DatasheetNavneet SinghNo ratings yet

- Test Report: Brakes: Enquiries@vca - Gov.ukDocument103 pagesTest Report: Brakes: Enquiries@vca - Gov.ukMarsellusProbstNo ratings yet

- Sanmar Serenade Vessel DetailsDocument11 pagesSanmar Serenade Vessel DetailsChris MendosaNo ratings yet

- Visual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Document1 pageVisual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Michael OkwuwaNo ratings yet

- Well Testing Calculation Using AGA 3Document22 pagesWell Testing Calculation Using AGA 3Yusuf OktoviyantoNo ratings yet

- Daily Drilling Report No.28 Pozo La Colpa 2XDDocument6 pagesDaily Drilling Report No.28 Pozo La Colpa 2XDJuan Pablo Sanchez MelgarejoNo ratings yet

- Lf-A 014 Inventaris Kapal Tb. Aryaloka Juli 2015Document3 pagesLf-A 014 Inventaris Kapal Tb. Aryaloka Juli 2015alsitor100% (1)

- E4 - 54R - 0021803 (Pnevmatika)Document12 pagesE4 - 54R - 0021803 (Pnevmatika)Jony M. TemnikarNo ratings yet

- Bom Chìm 20m3Document5 pagesBom Chìm 20m3thanhlangdaiNo ratings yet

- Motor 350 TmiDocument1 pageMotor 350 TmiGolbert GolbiNo ratings yet

- Sop of TG & AuxilliariesDocument29 pagesSop of TG & Auxilliarieschcrr67% (3)

- Attachment-6 TBE ANSI Pump BCUDocument31 pagesAttachment-6 TBE ANSI Pump BCURanu Januar100% (1)

- E03 Bay SF6 Gas Purity TestDocument1 pageE03 Bay SF6 Gas Purity TestgavinilaaNo ratings yet

- Karnataka Power Transmission Corporation LimitedDocument1 pageKarnataka Power Transmission Corporation LimitedSanthosh RMNo ratings yet

- Sharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportDocument2 pagesSharda Engineers & Constructions: Liquid Penetrant Test Inspection ReportAmol KhatateNo ratings yet

- Re MT Ocean Hero and SistersDocument2 pagesRe MT Ocean Hero and SistersMoe Myint0% (1)

- Senarai Nama Industri Pembuat Pressure Vessel Dan Air Compressor Bagi Rumah Pam SyabasDocument6 pagesSenarai Nama Industri Pembuat Pressure Vessel Dan Air Compressor Bagi Rumah Pam SyabasayyeeyanNo ratings yet

- Dpico: Inj. Pump Calibration DataDocument6 pagesDpico: Inj. Pump Calibration DataGiovaniBalzaniNo ratings yet

- API Datasheet 101-PA-18 18ADocument1 pageAPI Datasheet 101-PA-18 18Arameshkarthik810No ratings yet

- Specs DHC6-msn-846Document10 pagesSpecs DHC6-msn-846Bob DENARDNo ratings yet

- Vertical Tubine Fire PumpDocument24 pagesVertical Tubine Fire PumpPrince Zubair SulehriaNo ratings yet

- Primo Stealth Q88Document12 pagesPrimo Stealth Q88kiyotakaaya67% (3)

- SEC7Document12 pagesSEC7Benmorsli AhceneNo ratings yet

- Submittal Chiller COP 6.02Document3 pagesSubmittal Chiller COP 6.02juan yenqueNo ratings yet

- Km. Bahar MasDocument2 pagesKm. Bahar MasAditya Jalasena JiwandhonoNo ratings yet

- Mini Excavator-Nov 23Document1 pageMini Excavator-Nov 23Akash vimalNo ratings yet

- 06 - Dosing Pump Clearance - 04Document7 pages06 - Dosing Pump Clearance - 04Lakshmanan VenkateswaranNo ratings yet

- Fire Water Make Up PumpDocument7 pagesFire Water Make Up PumpAlvin SmithNo ratings yet

- Visual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Document1 pageVisual and NDT Examination Certificate: Cargo Carrying Unit (Ccu)Michael OkwuwaNo ratings yet

- Easa Aw119 TCDSDocument45 pagesEasa Aw119 TCDSAnonymous ucJM9AGda100% (1)

- 12 Hidrostal 4ta. Bomba Io - M Book Rev. 1Document82 pages12 Hidrostal 4ta. Bomba Io - M Book Rev. 1Marcos Gonzales100% (1)

- Blue ZoneDocument5 pagesBlue ZoneUrvish ChauhanNo ratings yet

- LPG Annapurna Ships ParticularsDocument2 pagesLPG Annapurna Ships ParticularsAvinash Mudrika100% (1)

- Instructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentDocument13 pagesInstructions & Guidelines On Sampling of Oil From Oil Filled Electrical EquipmentsorabhNo ratings yet

- GDI DENSO InjectorsDocument19 pagesGDI DENSO InjectorsPāvels SmilgaNo ratings yet

- Equipment List Dated 20150314Document12 pagesEquipment List Dated 20150314Junior Ortega RomeroNo ratings yet

- 2009 02 M HD 319 0Document5 pages2009 02 M HD 319 0ZoebairNo ratings yet

- Type Approval Certificate: Imo AbDocument4 pagesType Approval Certificate: Imo Abtester12344321No ratings yet

- Co-Gen Plant DataDocument29 pagesCo-Gen Plant DataSarah FrazierNo ratings yet

- 1068714150Document6 pages1068714150ForteLubNo ratings yet

- P-1809B Mechanical Seal Leak RCFADocument18 pagesP-1809B Mechanical Seal Leak RCFAMuhd Fadzlee Z100% (1)

- Power Plant SpecsDocument72 pagesPower Plant Specsnapo0% (1)

- Pipe Testing of Navdhenu SwiftDocument3 pagesPipe Testing of Navdhenu SwiftfrenskiranNo ratings yet

- Sample Self Monitoring ReportDocument9 pagesSample Self Monitoring ReportChen Agtarap67% (15)

- 125 HP MotorDocument5 pages125 HP MotorParasPatel80No ratings yet