Professional Documents

Culture Documents

1 Input Data: Profis Anchor 2.6.6

Uploaded by

Collin NguOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 Input Data: Profis Anchor 2.6.6

Uploaded by

Collin NguCopyright:

Available Formats

Profis Anchor 2.6.

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Engineer 360

Collin

|

Page:

Project:

Fastening Point:

Date:

1

12/21/2016

Specifier's comments:

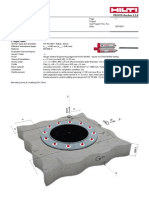

1 Input data

Anchor type and size:

HIT-RE 500 + HIT-V (8.8) M20

Seismic/Filling set or any suitable annular gap filling solution

Effective embedment depth:

hef,opti = 259 mm (hef,limit = 400 mm)

Material:

8.8

Approval No.:

ETA 04/0027

Issued I Valid:

6/26/2013 | 5/16/2018

Proof:

Engineering judgement SOFA BOND - based on ETAG BOND testing

Stand-off installation:

eb = 0 mm (no stand-off); t = 42 mm

Baseplate:

Custom; E = 210000.00 N/mm2; fyk = 265.00 N/mm2; gMs = 1.000

lx x ly x t = 526 mm x 526 mm x 42 mm; (Recommended plate thickness: calculated (42 mm))

Profile:

Pipe; (L x W x T) = 324 mm x 324 mm x 13 mm

Base material:

uncracked concrete, C35/45, fc = 45.00 N/mm2; h = 1000 mm, Temp. short/long: 30/30 C

Installation:

hammer drilled hole, Installation condition: Dry

Reinforcement:

No reinforcement or Reinforcement spacing >= 150 mm (any ) or >= 100 mm ( <= 10 mm)

no longitudinal edge reinforcement

Geometry [mm] & Loading [kN, kNm]

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.6.6

www.hilti.com.sg

Page:

Project:

Fastening Point:

Date:

Engineer 360

Collin

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

12/21/2016

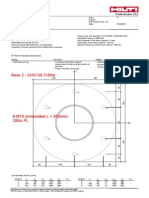

2 Load case/Resulting anchor forces

y

5

Load case: Design loads

Anchor reactions [kN]

Tension force: (+Tension, -Compression)

Anchor

Tension force

Shear force

Shear force x

1

26.965

10.515

10.500

2

0.000

10.515

10.500

3

0.000

10.515

10.500

4

0.000

10.515

10.500

5

26.965

10.515

10.500

6

57.443

10.515

10.500

7

70.162

10.515

10.500

8

57.443

10.515

10.500

max. concrete compressive strain:

0.50 []

max. concrete compressive stress:

15.11 [N/mm2]

resulting tension force in (x/y)=(-139/0):

238.979 [kN]

resulting compression force in (x/y)=(210/0): 242.079 [kN]

Shear force y

0.563

0.563

0.563

0.563

0.563

0.563

0.563

0.563

x

3

Compression

Tension

8

1

3 Tension load (EOTA TR 029, Section 5.2.2)

Load [kN]

70.162

Capacity [kN]

130.667

Combined pullout-concrete cone failure**

238.979

Concrete cone failure**

238.979

N/A

Steel failure*

Splitting failure**

* most unfavourable anchor

Utilisation bN [%]

54

Status

OK

270.084

89

OK

239.062

100

OK

N/A

N/A

N/A

**anchor group (anchors in tension)

3.1 Steel failure

gM,s

1.500

NRk,s [kN]

196.000

NRd,s [kN]

130.667

NSd [kN]

70.162

3.2 Combined pullout-concrete cone failure

Ap,N [mm2]

638124

A0p,N [mm2]

256000

2

t Rk,ucr,25 [N/mm ]

12.00

scr,Np [mm]

506

ccr,Np [mm]

253

yc

1.061

2

t Rk,ucr [N/mm ]

12.73

k

3.200

y g,Np

1.454

y g,Np

1.243

ec1,N [mm]

33

y ec1,Np

0.884

ec2,N [mm]

0

y ec2,Np

1.000

y s,Np

1.000

N0Rk,p [kN]

207.104

NRk,p [kN]

567.177

gM,p

2.100

NRd,p [kN]

270.084

NSd [kN]

238.979

cmin [mm]

y re,Np

1.000

3.3 Concrete cone failure

Ac,N [mm2]

1164737

A0c,N [mm2]

603729

ccr,N [mm]

389

scr,N [mm]

777

ec1,N [mm]

33

y ec1,N

0.921

ec2,N [mm]

0

y ec2,N

1.000

y s,N

1.000

k1

10.100

N0Rk,c [kN]

282.408

gM,c

2.100

NRd,c [kN]

239.062

NSd [kN]

238.979

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

y re,N

1.000

Profis Anchor 2.6.6

www.hilti.com.sg

Page:

Project:

Fastening Point:

Date:

Engineer 360

Collin

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

12/21/2016

4 Shear load (EOTA TR 029, Section 5.2.3)

Load [kN]

10.515

Steel failure (without lever arm)*

Steel failure (with lever arm)*

Pryout failure**

Utilisation bV [%]

14

Status

OK

N/A

N/A

N/A

N/A

84.120

863.113

10

OK

N/A

N/A

N/A

N/A

Concrete edge failure in direction **

* most unfavourable anchor

Capacity [kN]

78.400

**anchor group (relevant anchors)

4.1 Steel failure (without lever arm)

VRk,s [kN]

98.000

gM,s

1.250

VRd,s [kN]

78.400

VSd [kN]

10.515

4.2 Pryout failure (concrete cone relevant)

Ac,N [mm2]

1383865

A0c,N [mm2]

603729

ccr,N [mm]

389

scr,N [mm]

777

k-factor

2.000

ec1,V [mm]

0

y ec1,N

1.000

ec2,V [mm]

0

y ec2,N

1.000

y s,N

1.000

N0Rk,c [kN]

282.408

gM,c,p

1.500

VRd,cp [kN]

863.113

VSd [kN]

84.120

y re,N

1.000

5 Combined tension and shear loads (EOTA TR 029, Section 5.2.4)

Steel failure

bN

1.000

bV

0.134

Utilisation bN,V [%]

95

a

1.000

Status

OK

(bN + bV) / 1.2 1

6 Displacements (highest loaded anchor)

Short term loading:

NSk

51.972 [kN]

dN

0.287 [mm]

VSk

7.789 [kN]

dV

0.312 [mm]

dNV

0.424 [mm]

Long term loading:

NSk

51.972 [kN]

dN

0.575 [mm]

VSk

7.789 [kN]

dV

0.467 [mm]

dNV

0.741 [mm]

Comments: Tension displacements are valid with half of the required installation torque moment for uncracked concrete! Shear displacements

are valid without friction between the concrete and the baseplate! The gap due to the drilled hole and clearance hole tolerances are not

included in this calculation!

The acceptable anchor displacements depend on the fastened construction and must be defined by the designer!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.6.6

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Engineer 360

Collin

|

Page:

Project:

Fastening Point:

Date:

4

12/21/2016

7 Warnings

Load re-distributions on the anchors due to elastic deformations of the anchor plate are not considered. The anchor plate is assumed to be

sufficiently stiff, in order not to be deformed when subjected to the loading!

Input data and results must be checked for agreement with the

existing conditions and for plausibility!

Checking the transfer of loads into the base material is required in accordance with EOTA TR 029, Section 7!

The design is only valid if the clearance hole in the fixture is not larger than the value given in Table 4.1 of EOTA TR029! For larger

diameters of the clearance hole see Chapter 1.1. of EOTA TR029!

The accessory list in this report is for the information of the user only. In any case, the instructions for use provided with the product have to

be followed to ensure a proper installation.

Characteristic bond resistances depend on short- and long-term temperatures.

Please contact Hilti to check feasibility of HIT-V rod supply.

The design method SOFA assumes that no hole clearance between the anchors and the fixture is present. This can be achieved by filling

the gap with mortar of sufficient compressive strength (e.g. by using the HILTI Seismic/Filling set) or by other suitable means

The compliance with current standards (e.g. EC3) is the responsibility of the user

An SLS-check is not performed for SOFA and has to be provided by the user!

Fastening meets the design criteria!

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

Profis Anchor 2.6.6

www.hilti.com.sg

Page:

Project:

Fastening Point:

Date:

Engineer 360

Collin

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

12/21/2016

8 Installation data

Anchor type and size: HIT-RE 500 + HIT-V (8.8) M20

Baseplate, steel: Custom; E = 210000.00 N/mm2; fyk = 265.00 N/mm2

Profile: Pipe; 324 x 324 x 13 mm

Installation torque: 0.150 kNm

Hole diameter in the fixture: df = 22 mm

Hole diameter in the base material: 24 mm

Plate thickness (input): 42 mm

Hole depth in the base material: 259 mm

Recommended plate thickness: calculated (42 mm)

Minimum thickness of the base material: 307 mm

Drilling method: Hammer drilled

Cleaning: Compressed air cleaning of the drilled hole according to instructions for use is required

8.1 Recommended accessories

Drilling

Suitable Rotary Hammer

Properly sized drill bit

Cleaning

Compressed air with required

accessories to blow from the bottom of

the hole

Proper diameter wire brush

y

263

43

263

Setting

Dispenser including cassette and mixer

Seismic/Filling set

Torque wrench

65

263

155

263

155

2

65

43

43

65

155

155

65

43

Coordinates Anchor [mm]

Anchor

1

2

3

4

x

0

155

220

155

y

-220

-155

0

155

c-x

-

c+x

-

c-y

-

c+y

-

Anchor

5

6

7

8

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

x

0

-155

-220

-155

y

220

155

0

-155

c-x

-

c+x

-

c-y

-

c+y

-

Profis Anchor 2.6.6

www.hilti.com.sg

Company:

Specifier:

Address:

Phone I Fax:

E-Mail:

Engineer 360

Collin

|

Page:

Project:

Fastening Point:

Date:

6

12/21/2016

9 Remarks; Your Cooperation Duties

Any and all information and data contained in the Software concern solely the use of Hilti products and are based on the principles, formulas

and security regulations in accordance with Hilti's technical directions and operating, mounting and assembly instructions, etc., that must be

strictly complied with by the user. All figures contained therein are average figures, and therefore use-specific tests are to be conducted

prior to using the relevant Hilti product. The results of the calculations carried out by means of the Software are based essentially on the

data you put in. Therefore, you bear the sole responsibility for the absence of errors, the completeness and the relevance of the data to be

put in by you. Moreover, you bear sole responsibility for having the results of the calculation checked and cleared by an expert, particularly

with regard to compliance with applicable norms and permits, prior to using them for your specific facility. The Software serves only as an

aid to interpret norms and permits without any guarantee as to the absence of errors, the correctness and the relevance of the results or

suitability for a specific application.

You must take all necessary and reasonable steps to prevent or limit damage caused by the Software. In particular, you must arrange for

the regular backup of programs and data and, if applicable, carry out the updates of the Software offered by Hilti on a regular basis. If you do

not use the AutoUpdate function of the Software, you must ensure that you are using the current and thus up-to-date version of the Software

in each case by carrying out manual updates via the Hilti Website. Hilti will not be liable for consequences, such as the recovery of lost or

damaged data or programs, arising from a culpable breach of duty by you.

Input data and results must be checked for agreement with the existing conditions and for plausibility!

PROFIS Anchor ( c ) 2003-2009 Hilti AG, FL-9494 Schaan Hilti is a registered Trademark of Hilti AG, Schaan

You might also like

- Hilti AnchorDocument6 pagesHilti AnchorantonioNo ratings yet

- H 200mm Thick Slab - Pa2Document6 pagesH 200mm Thick Slab - Pa2ihpeterNo ratings yet

- 290mm Thick Slab and 540mm EcenDocument6 pages290mm Thick Slab and 540mm EcenihpeterNo ratings yet

- Hilti AnchorDocument5 pagesHilti AnchorGopi KrishnanNo ratings yet

- Hilti Bolt DesignDocument7 pagesHilti Bolt Designcheligp1981No ratings yet

- 1 Input Data: WWW - Hilti.co - UkDocument6 pages1 Input Data: WWW - Hilti.co - UkihpeterNo ratings yet

- Canopy M16 HIT-RE500Document5 pagesCanopy M16 HIT-RE500marchus09No ratings yet

- PROFIS Anchor 2.2.6: WWW - Hilti.inDocument6 pagesPROFIS Anchor 2.2.6: WWW - Hilti.inmeetvinayak2007No ratings yet

- PROFIS Anchor 2.1.4: WWW - Hilti.atDocument5 pagesPROFIS Anchor 2.1.4: WWW - Hilti.atfrog15No ratings yet

- Beam End Connection ReportDocument6 pagesBeam End Connection ReportHibri HalimNo ratings yet

- Machine RoomDocument6 pagesMachine RoomRonnie De Joya AguirreNo ratings yet

- 1 Input Data: Profis Anchor 2.4.6Document6 pages1 Input Data: Profis Anchor 2.4.6Naresh KumarNo ratings yet

- PROFIS Anchor 2.0.7: WWW - Hilti.usDocument5 pagesPROFIS Anchor 2.0.7: WWW - Hilti.usadelhelmiNo ratings yet

- PES Hilti M10 HSA ReportDocument4 pagesPES Hilti M10 HSA ReportCollin NguNo ratings yet

- B3L01 - Detail 1Document7 pagesB3L01 - Detail 1vikramjain66No ratings yet

- PROFIS Anchor 2.2.0: WWW - Hilti.deDocument6 pagesPROFIS Anchor 2.2.0: WWW - Hilti.deCollin NguNo ratings yet

- PROFIS Anchor 2.0.7Document4 pagesPROFIS Anchor 2.0.7Miky CastenNo ratings yet

- Pipe Rack Hilti Bolt CalculationsDocument6 pagesPipe Rack Hilti Bolt CalculationsAnonymous MAQrYFQDzVNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- SAMPLE HILTI SolutionDocument6 pagesSAMPLE HILTI SolutionJester AbucayNo ratings yet

- PES Hilti M10 HSA Report RunnerDocument4 pagesPES Hilti M10 HSA Report RunnerCollin NguNo ratings yet

- Profis Rebar ReportDocument5 pagesProfis Rebar ReportSowmya MajumderNo ratings yet

- 1 Input Data: WWW - Hilti.inDocument5 pages1 Input Data: WWW - Hilti.inpudumaiNo ratings yet

- 1 Input Data: Profis Anchor 2.5.2Document5 pages1 Input Data: Profis Anchor 2.5.2jasekan.dcNo ratings yet

- Rowad Debugging MachineDocument6 pagesRowad Debugging MachineRonnie De Joya AguirreNo ratings yet

- 1 Input Data: Profis Anchor 2.2.4Document6 pages1 Input Data: Profis Anchor 2.2.4Safiueddin A. SafiueddinNo ratings yet

- Hilti AnchorsDocument58 pagesHilti AnchorsPaulSwinbankNo ratings yet

- Connection d01 1Document6 pagesConnection d01 1Win ThanNo ratings yet

- 1 Input Data: WWW - HiltiDocument5 pages1 Input Data: WWW - HiltiCibotaru MihaiNo ratings yet

- Kempinski Hilti Rc-ODocument6 pagesKempinski Hilti Rc-OsobhiNo ratings yet

- Hilti - Profis Anchor Design Report 594Document5 pagesHilti - Profis Anchor Design Report 594Madhu GuptaNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- Anchor Design - Hilti (HP)Document6 pagesAnchor Design - Hilti (HP)Harikrishnan PNo ratings yet

- PROFIS Anchor 2.4.6: WWW - Hilti.luDocument6 pagesPROFIS Anchor 2.4.6: WWW - Hilti.luMashudi AliNo ratings yet

- Flupec Catalog Etansari Translatie PDFDocument446 pagesFlupec Catalog Etansari Translatie PDFRadu VasileNo ratings yet

- 250x16 Shs Column Base - Pa2123Document5 pages250x16 Shs Column Base - Pa2123ihpeterNo ratings yet

- Anchor Bolt PDFDocument7 pagesAnchor Bolt PDFRonnie Albert MonteroNo ratings yet

- Shaft B, Hb1 Kempinski 11-1-17.pa2Document7 pagesShaft B, Hb1 Kempinski 11-1-17.pa2sobhiNo ratings yet

- Base CHS X 10tDocument7 pagesBase CHS X 10tCollin NguNo ratings yet

- Hilti Connection ReportDocument7 pagesHilti Connection ReportFrancisco BonillaNo ratings yet

- WIT-PE 500 Design Manual RBDocument24 pagesWIT-PE 500 Design Manual RBMadusha TisseraNo ratings yet

- HILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsDocument21 pagesHILTI HIT HY200 Injection Adhesive: Quality Management ApprovalsGeorge KaridisNo ratings yet

- Hollow Core Concrete DetailingManualDocument41 pagesHollow Core Concrete DetailingManualJevgenijsKolupajevs100% (2)

- Cable Transit Brochure W4310 (22.10.15) PDFDocument28 pagesCable Transit Brochure W4310 (22.10.15) PDFgoomar6No ratings yet

- Anchor Presentation Hilti 2011 PDFDocument8 pagesAnchor Presentation Hilti 2011 PDFNelsonDay100% (1)

- Hilti Hit Re 500 With Hit V HasDocument16 pagesHilti Hit Re 500 With Hit V HaslaurentiubnNo ratings yet

- X BT Brochure en W3987Document68 pagesX BT Brochure en W3987Paul RobbinsNo ratings yet

- Anclaje Quimico HILTIDocument84 pagesAnclaje Quimico HILTIWuceirNo ratings yet

- 4597 AAB SC 07 Addendum 2 R0v0 78Document1 page4597 AAB SC 07 Addendum 2 R0v0 78danieldumapitNo ratings yet

- Topcor Belco: Welding Procedure Specification (WPS)Document9 pagesTopcor Belco: Welding Procedure Specification (WPS)Madhan RamamoorthyNo ratings yet

- Main Steel ConnectionsDocument40 pagesMain Steel ConnectionsIndrayadi AbdillahNo ratings yet

- Chumbador HiltDocument14 pagesChumbador HiltSamanta FigueredoNo ratings yet

- Bollhoff Armstrong HeliCoilDocument28 pagesBollhoff Armstrong HeliCoilAce Industrial Supplies100% (1)

- Hilti Calc For RC StumpDocument15 pagesHilti Calc For RC StumpSantosoNo ratings yet

- Hilti Hit Re 500 Cu Has Hit-V His-N 1Document36 pagesHilti Hit Re 500 Cu Has Hit-V His-N 1Sorin RaduNo ratings yet

- Hilti Monitor - Pa2Document2 pagesHilti Monitor - Pa2Asaru DeenNo ratings yet

- Hollow CoreDocument41 pagesHollow Corepaulo_arrieiroNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Spot Welding Interview Success: An Introduction to Spot WeldingFrom EverandSpot Welding Interview Success: An Introduction to Spot WeldingNo ratings yet

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- F2150RA Xhe-Dynamic - F2150RAL Xhe-DynamicDocument16 pagesF2150RA Xhe-Dynamic - F2150RAL Xhe-DynamicCollin NguNo ratings yet

- AxiTrader Setup GuideDocument10 pagesAxiTrader Setup GuideCollin NguNo ratings yet

- tb0006 PDFDocument12 pagestb0006 PDFCollin NguNo ratings yet

- 3urgxfwv &dofxodwru: +RPH $Erxw8V 3urgxfwv &Dvh6Wxglhv, Qgxvwu//Lqnv 'Rzqordgv) $4V 1Hzv 6xssruw 5Htxhvw%Urfkxuh &Rqwdfw8VDocument2 pages3urgxfwv &dofxodwru: +RPH $Erxw8V 3urgxfwv &Dvh6Wxglhv, Qgxvwu//Lqnv 'Rzqordgv) $4V 1Hzv 6xssruw 5Htxhvw%Urfkxuh &Rqwdfw8VCollin NguNo ratings yet

- Bolt and Weld Capacities - BS5950Document1 pageBolt and Weld Capacities - BS5950Helena DomičićNo ratings yet

- Authorisation Letter v2Document1 pageAuthorisation Letter v2Collin NguNo ratings yet

- Example1 Timber DesignDocument3 pagesExample1 Timber DesignCollin NguNo ratings yet

- PES Hilti M10 HSA ReportDocument4 pagesPES Hilti M10 HSA ReportCollin NguNo ratings yet

- Canopy Height Size Uplift Downwards Moment Shear No + 1.2M Sq. M KN KN KNM KNDocument1 pageCanopy Height Size Uplift Downwards Moment Shear No + 1.2M Sq. M KN KN KNM KNCollin NguNo ratings yet

- PES Hilti M10 HSA Report RunnerDocument4 pagesPES Hilti M10 HSA Report RunnerCollin NguNo ratings yet

- 1 Input Data: Profis Anchor 2.6.0Document2 pages1 Input Data: Profis Anchor 2.6.0Collin NguNo ratings yet

- Base 2 - CHS139.7x5thk: 8 Installation DataDocument1 pageBase 2 - CHS139.7x5thk: 8 Installation DataCollin NguNo ratings yet

- Base CHS X 10tDocument7 pagesBase CHS X 10tCollin NguNo ratings yet

- Base 1 - CHS139.7x10thk: 8 Installation DataDocument1 pageBase 1 - CHS139.7x10thk: 8 Installation DataCollin NguNo ratings yet

- MetallurgyDocument2 pagesMetallurgygjabyNo ratings yet

- ANDRE BAKKER Dartmouth CollegeDocument36 pagesANDRE BAKKER Dartmouth CollegeCarlos Alberto Dutra Fraga FilhoNo ratings yet

- A001en PDFDocument30 pagesA001en PDFnthongNo ratings yet

- Arc Detection in Electro-Discharge MachiningDocument16 pagesArc Detection in Electro-Discharge MachiningMitu Leonard-GabrielNo ratings yet

- ASTM 253 ZincatoDocument7 pagesASTM 253 Zincatoasistente calidadNo ratings yet

- Buckling Instability of StructuresDocument17 pagesBuckling Instability of StructuresPeter IyereNo ratings yet

- CU Poster Draft PresentationDocument1 pageCU Poster Draft PresentationSoikotNo ratings yet

- Solutions To 7.012 Problem Set 1Document4 pagesSolutions To 7.012 Problem Set 1attiqueNo ratings yet

- Experiment 1: Purification of Benzoic Acid Data and Results: Crude Benzoic Acid Purified Benzoic Acid Mass AppearanceDocument2 pagesExperiment 1: Purification of Benzoic Acid Data and Results: Crude Benzoic Acid Purified Benzoic Acid Mass AppearanceLarry OngNo ratings yet

- Matter (Science Form 1 - Short Notes)Document1 pageMatter (Science Form 1 - Short Notes)jrpyroNo ratings yet

- E1935-97 Cal & Measure CT DensityDocument5 pagesE1935-97 Cal & Measure CT DensitysanthakumarNo ratings yet

- 1213sem1 Me3122Document14 pages1213sem1 Me3122Nian Wee Wu0% (2)

- Steps To Design A CulvertDocument18 pagesSteps To Design A CulvertOliver Brown67% (9)

- Wopq Asme Section IxDocument2 pagesWopq Asme Section IxkanchanabalajiNo ratings yet

- Sulfadiazine OralDocument1 pageSulfadiazine OralMariatul KiptiahNo ratings yet

- ErDocument27 pagesErAsif UllahNo ratings yet

- Atomic and Molecular Physics - NET-JRFDocument25 pagesAtomic and Molecular Physics - NET-JRFLineesh100% (1)

- Comment On A General Property of Radionuclides: P. L. Airey, C. J. HowardDocument2 pagesComment On A General Property of Radionuclides: P. L. Airey, C. J. HowardBranislavaTenjovicNo ratings yet

- Lab Manual (March-July 2018)Document37 pagesLab Manual (March-July 2018)haikalNo ratings yet

- Problem Set 3-Chapter 6 - Failure Theories-Selected ProblemsDocument22 pagesProblem Set 3-Chapter 6 - Failure Theories-Selected ProblemsIsmail DoğanNo ratings yet

- Laidler 5Document116 pagesLaidler 5Teresa Cano100% (1)

- Pemilihan Sistem Cadcam Dalam Industri Manufaktur Studi Kasus Brake DrumDocument5 pagesPemilihan Sistem Cadcam Dalam Industri Manufaktur Studi Kasus Brake DrumnanangNo ratings yet

- Diagram MeDocument22 pagesDiagram MeAkira SaidNo ratings yet

- Glass and Brittle Plastics RegisterDocument3 pagesGlass and Brittle Plastics RegisterAdnan Meghani100% (3)

- Review in Clinical MicrosDocument103 pagesReview in Clinical MicrosSyvelmarie Tinte100% (1)

- IEEE Guide For Thermal Resistivity Measurements of Soils and Backfill MaterialsDocument33 pagesIEEE Guide For Thermal Resistivity Measurements of Soils and Backfill MaterialsMarcos Serrão93% (27)

- Introduction and Review: Organic Chemistry, 5Document28 pagesIntroduction and Review: Organic Chemistry, 5anu MalikNo ratings yet

- FPS Errata 07-15Document39 pagesFPS Errata 07-15William Lopez AyalaNo ratings yet

- Rohs Material Confirmation CertificateDocument2 pagesRohs Material Confirmation Certificateimtiyaz aliNo ratings yet

- Synthesis of Asprin Lab ReportDocument3 pagesSynthesis of Asprin Lab ReportRachelleNo ratings yet