Professional Documents

Culture Documents

3

Uploaded by

Riaz ahmedCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3

Uploaded by

Riaz ahmedCopyright:

Available Formats

RTR specialist certification

1. Introduction

RTR/GRP piping systems have many important

advantages over steel piping, including

corrosion resistance, long life-time, low

maintenance, etc. During its life-time RTR/GRP

piping seldom shows any failures. The failures

which do occur are mostly in the

commissioning phase. It is no surprise, then,

that end-users and contractors seek to

overcome this hurdle.

Middle east

also covered laminated, flanged and adhesive

bonded joints.

3. Course content

The course content was in compliance with

the DNV requirements for Inspector of

RTR/GRP pipe systems. The following topics

were addressed in the course

Failures can usually be attributed to the

installers, particularly on account of a lack of

proper knowledge regarding RTR/GRP

procedures and a lack of skills and experience.

A group of end-users, pipe manufacturers and

contractors decided to tackle this problem,

and jointly with DNV drew up a competence

profile for every RTR/GRP specialist working in

the field.

The requirements set out in the competence

profiles are demanding, but the overall aim is

simple: a reduction of installation failures.

.

2. Example: inspector

The first Middle East inspectors training and

exam for RTR/GRP pipe systems was recently

conducted. The 15 candidates were all

employees of a large Middle Eastern oil

company with several years of general

inspectors experience. The main focus was on

high pressure threaded joints. The course,

given by Mr. Shadab (Future Pipe Industries),

instruction

Safety, handling, transportation and

storage procedures to be followed during

installation.

Basics of fiberglass pipe and connections,

such as threaded, adhesively bonded

(TB/TS) and lamination.

Best techniques to be followed while

assembling connections and the dos and

donts of site installation and site

hydrotesting.

Understanding

of

executing

recommendations from pipe system

design.

The acceptance / rejection criteria (Quality

Control) for pipe and fittings.

Basic repair and corrective techniques,

mainly for threaded line pipe.

RTR specialist certification

Middle east

4. Theoretical exam

The theoretical exam was administered under

supervision of DNV. The available time was 60

minutes for open and multiple choice

questions and 2.5 hours for a theoretical case.

5. Practical exam

The practical assessment took about 8 to 10

hours. The candidates had to make up a socalled threaded high pressure joint, exactly

according to the FPI procedure. This joint was

subsequently hydrotested at 3000 Psi (all

joints proved leak-tight).

The second assignment was for each

candidate to individually manage a crew (= the

other candidates) for a real assembly of an 8

30 ft length pipe. During the assessment many

mistakes were made deliberately, while the

candidates had to report their findings and

devise solutions.

sample investigation by inspectors

6. DNV Certification

DNV has drawn up competence profiles for

professionals working on RTR/GRP pipe

systems, in close cooperation with renowned

stakeholders.

The DNV Certification programme contains

the competence profiles for bonder,

spoolbuilder, pipe fitter, supervisor and

inspector.

6.1. Bonder

A Bonder is a skilled worker, specialised in

jointing RTR/GRP pipes, whose competences

are certified in respect of one or more

different types of joints (e.g. laminated joints ,

adhesive joints, threaded joints, O-rings,

locking keys etc.)

full scale assembly

Finally, the candidates had to examine 3

random samples with errors and to report

their findings in writing. Complete in line with

a welding inspectors exam.

6.2. Spool builder

A spool builder is a certified bonder who is

additionally certified to assemble the RTR/GRP

RTR specialist certification

Middle east

spools and fabricate RTR/GRP (mitered) Tees

and mitered Elbows

6.3. Pipe fitter

A Pipe fitter is certified to lay out, assemble,

build, maintain and repair piping systems.

6.4. Supervisor

A certified supervisor monitors and carries

responsibility for the execution of the work

done by the bonders, spool builders and pipe

fitters.

6.5. Inspector

A certified inspector independently monitors

the installation of RTR/GRP piping systems. He

controls and verifies that bonders, spool

builders, pipefitters, supervisors and other

personnel have performed in compliance with

the job specifications..

7. Training

The candidates are trained by (local) training

institutes to achieve the competence

requirements, up to the desired certification

level.

These institutes can be listed on the DNV

website for RTR/GRP pipe systems. To

accommodate potential clients searching for

recognised training institutes, DNV can

provide trainers and training institutes with

workshops for RTR/GRP-examination.

adhesive bonded joint, Bondstrand/Amiantit

8. Overall certification process

The certification schemes may require prior

training qualifications as a condition for

admission to or application for the

examination phase.

During the examination phase, a certification

candidate will have to demonstrate his/her

knowledge, skills and performance in a

theoretical and practical exam. The exam

pieces will be tested according to specific

DNV-criteria. More information about the

personnel certification of RTR/GRP can be

found on this page.

9. General test criteria for exam pieces

All joints/connections have to pass a hydro

test.

Test spools must pass a hydro test, using a

2.5 times higher pressure than the design

pressure for over one hour.

For high-pressure joints, specific test

protocols are available.

The performance of the tests is supervised by

a DNV-authorised examiner, using control

equipment compliant with DNV specifications.

RTR specialist certification

10. Examination details

DNV enforces and monitors the quality and

independence of all DNV-licensed examination

organisations and authorised examiners.

The examinations are supervised by a DNVauthorised examiner using control equipment

compliant with DNV specifications.

During the theoretical and practical exams,

the DNV examination regulations apply.

10.1. For Bonder:

Theoretical test: (multiple-choice) questions.

Available time: 60 minutes.

Practical test: the candidate must produce a

joint in accordance with the desired

certification level and range.

Middle east

must make a report about his own exam

spool

must make a report about a prepared

exam spool.

10.3. For pipe fitter:

Theoretical test: (multiple-choice) questions

and 1 extra case in addition to the

examination for a spool builder

Practical test: the candidate must produce a

joint in accordance with the desired

certification level and range, including making

calculations based on manufacturing literature

and listing the tools needed. In addition, the

candidate must calculate and perform a hydro

test.

11. Examination and test facilities

laminated joint, Bondstrand/Amiantit, SA

10.2. For spool builder:

Theoretical test: (multiple-choice) questions.

Available time: 60 minutes.

Practical test: the candidate

must produce a joint in accordance with

the desired certification level and range,

including making calculations based on

manufacturing literature and listing the

tools needed.

DNV has licensed local independent

examination organisations to organise

certification exams and tests, and has

authorised local examiners to supervise these

examinations and tests. Although the exams

and tests are strictly independent of any

particular training institute, they can be

efficiently organised and scheduled in

cooperation with local training institutes.

12. Certification decision

All exam and test results will be assessed for

each candidate by DNV, preceding the

certification decision by the Manager

Personnel Certification of DNV. Once a

positive certification decision has been taken,

a DNV Competence Certificate will be issued

to the successful candidate.

RTR specialist certification

Middle east

certificate holder is required to take and pass

the recertification exam, similar to the

conditions of the initial exam.

aftermaths

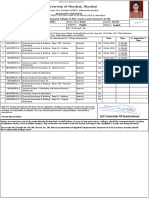

13. DNV Certificate of Competence

The DNV certificate of competence for

RTR/GRP field specialists states the following

essential information:

Name, initials and picture of the certificate

holder

Date of certification and expiry date

Place of the exam

Any specific norms or classes

Range of certification

Diameter of the RTR/GRP pipe by test and

certified diameter range

Design pressure and certified range

Manufacturers

rules/specification

if

applicable

Other information, if applicable

DNV Certification rules

All certificates of competence for RTR/GRP

field specialists have a validity period of two

years. Every six months, both the certificate

holders and the employer/contractor shall

validate the work experience of the certificate

holder within his certification range. At the

end of the two-year validity period, the

All certificate holders are expected to perform

in

compliance

with

their

certified

competences and certification conditions.

Complaints received by DNV concerning

incompetence on the part of the certificate

holder may lead to sanctions for the

certificate holder.

The DNV certification committee for GRP,

comprising renowned stakeholders from

across the world, advises DNV on the

maintenance of the competence profiles and

certification rules, taking into account market

developments, technological developments,

products and assembly developments, and

their own valuable experiences. The DNV

examination committee for RTR/GRP will

approve and monitor the examination

methods and evaluate the validity of the

exams through statistical analyses.

How to request for certification

(Middle East)

Dana A. Al Dossary MD

Real Vision Technical Services

Tel.: +966-3-895-7001/2 Ext. 100

dana@realvisionts.com

www.realvisionts.com

note :

GRP=Glass Reinforced Plastic

RTR=Reinforced Thermohard Resin

GRP=RTR

RTR specialist certification

Middle east

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5795)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Ul555 555S 702 PDFDocument2 pagesUl555 555S 702 PDFRiaz ahmed100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- UNSW Letter ID3308016 K2C 20090701 163501Document7 pagesUNSW Letter ID3308016 K2C 20090701 163501amizal13No ratings yet

- Using Writing Assessment Criteria and Preparing Students For The Writing Tasks Jan 2018 FINAL-Davide GreeneDocument27 pagesUsing Writing Assessment Criteria and Preparing Students For The Writing Tasks Jan 2018 FINAL-Davide GreeneLe Hoang LinhNo ratings yet

- Fire Damper and Fire Smoke Damper PDFDocument26 pagesFire Damper and Fire Smoke Damper PDFRiaz ahmedNo ratings yet

- Namat CPVCDocument3 pagesNamat CPVCRiaz ahmedNo ratings yet

- Aramco-GI Instruciton Manual PDFDocument12 pagesAramco-GI Instruciton Manual PDFRiaz ahmed100% (2)

- Formative and Summative AssessmentDocument4 pagesFormative and Summative AssessmentPaola Fernanda Montenegro100% (1)

- Parts of SpeechDocument30 pagesParts of SpeechNizam ZamNo ratings yet

- 4 The Rationale of Deficit Measurement EspañolDocument42 pages4 The Rationale of Deficit Measurement EspañolManuel VillagranNo ratings yet

- Child and Adolescent Development Free Elect. 3: Code: E001Document10 pagesChild and Adolescent Development Free Elect. 3: Code: E001MykaNo ratings yet

- My ApplicationDocument4 pagesMy ApplicationHisham SyedNo ratings yet

- Intro To Ed TestingDocument10 pagesIntro To Ed Testingapi-288919230No ratings yet

- Notification Indian Coast Guard Navik GD 02 2019Document7 pagesNotification Indian Coast Guard Navik GD 02 2019Aman OjhaNo ratings yet

- Certified Renewable Energy Project DeveloperDocument7 pagesCertified Renewable Energy Project DeveloperosvaldoNo ratings yet

- Cambridge International Advanced Subsidiary and Advanced LevelDocument4 pagesCambridge International Advanced Subsidiary and Advanced LevelDeepNo ratings yet

- Research TitleDocument1 pageResearch TitleMharaTootNo ratings yet

- Course Outline - Behavior in Organizations 2020-21 - SSDocument8 pagesCourse Outline - Behavior in Organizations 2020-21 - SSHarshad SavantNo ratings yet

- PHI-250 Syllabus 2021 v. 3Document10 pagesPHI-250 Syllabus 2021 v. 3Tariq NassorNo ratings yet

- Certificate of Completion: Haseeb Tariq KhanDocument1 pageCertificate of Completion: Haseeb Tariq Khanhaseeb tNo ratings yet

- Education System ArubaDocument32 pagesEducation System Arubagus ediNo ratings yet

- Ntse Practice SheetDocument4 pagesNtse Practice Sheetrs149100% (1)

- Common P.G. Entrance Test-2021 (CPET-2021) : Higher Education Department Govt of OdishaDocument2 pagesCommon P.G. Entrance Test-2021 (CPET-2021) : Higher Education Department Govt of OdishaRohan kumar DashNo ratings yet

- Lepper Corpus IyengarDocument13 pagesLepper Corpus IyengarPaulina NiedziałekNo ratings yet

- Bethlehem University Faculty of Business AdministrationDocument5 pagesBethlehem University Faculty of Business AdministrationMarcel Al SelwadiNo ratings yet

- Reaction PaperDocument34 pagesReaction PaperHarriane Mae GonzalesNo ratings yet

- Final Exam Mat093 Sep 2013 N Nov 2013Document8 pagesFinal Exam Mat093 Sep 2013 N Nov 2013Syahir HamidonNo ratings yet

- Facultad de Ciencias QuímicasDocument3 pagesFacultad de Ciencias QuímicasFer AvilaNo ratings yet

- (PDF) Quasi-Experimental Research Designs. Available FromDocument1 page(PDF) Quasi-Experimental Research Designs. Available FromBETSY LITERALNo ratings yet

- Take Home ExamDocument3 pagesTake Home ExamChristine JerosoNo ratings yet

- Soft Skills Needs AssessmentDocument6 pagesSoft Skills Needs Assessmentapi-601533359No ratings yet

- HT 164 20 17 B Com 2013016401610566Document1 pageHT 164 20 17 B Com 2013016401610566THE INDIAN FOOTBALL GUYNo ratings yet

- Lomagundi College: Sixth Form Prospectus 2018Document17 pagesLomagundi College: Sixth Form Prospectus 2018asprillaNo ratings yet

- Review and Post AssessmentDocument9 pagesReview and Post AssessmentFaizan KhanNo ratings yet