Professional Documents

Culture Documents

MS - 003400 - 01 Rev 29

Uploaded by

Arjun PrajapatiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MS - 003400 - 01 Rev 29

Uploaded by

Arjun PrajapatiCopyright:

Available Formats

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 1 of 22

PROCEDURE FOR MATERIAL PROCESSING AND QUALIFICATION

(WROUGHT AND CAST MATERIALS)

API 6A, PSL 1-4

HANGERS (CRA MATERIALS ONLY),

BODIES, BONNETS, END AND OUTLET CONNECTIONS, AND STEMS

1.0

GENERAL:

This document specifies the processing and qualification requirements for API 6A, product specification level (PSL)

1, 2, 3, and 4 materials for bodies, bonnets, and end and outlet connections, stems, and CRA (i.e., 410 SS, 718,

etc.) hangers. It must be used in conjunction with another Cameron material specification that gives the

requirements for a specific material. When referenced in another material specification, this specification must be

also be complied with.

2.0

MANUFACTURING PRACTICES:

2.1

Wrought Material

All material shall be of pressure vessel quality and shall have a wrought structure throughout. A fully wrought

structure is defined as one that:

1. is free from pipe and harmful segregation (the presence of which would indicate insufficient discard

from the starting ingot).

2. is free from burst, flakes, cracks, seams, laps, or other injurious defects detrimental to the end use of

the part.

3. is free from any open discontinuities (porosity, shrinkage, pipe, etc.) when macroetched or viewed

under a light microscope at 250X.

4. has a homogenous microstructure in any given area. Note: Some banding may be present in heavy

sections. This is normal and will not be cause for rejection unless it can be shown to be detrimental to

the end use of the part.

5. shows no evidence of macrosegregation (ingotism) that may be detrimental to the end use of the part.

6. in the case of carbon, low alloy, and martensitic stainless steels - has isotropic ductility properties within

any given area. Note that this does not require that ductility properties be uniform throughout the entire

cross section. These materials must be capable of meeting the following test unless otherwise agreed

upon with Cameron Metallurgy.

7. If Equivalent Round is 10 or below, then in any given area, the elongation and reduction in area values

of two tensile specimens taken adjacent to and 90 to each other shall satisfy the following:

Elongation (larger value)/Elongation/ (smaller value) < 1.20

Reduction in Area (larger value)/Reduction in Area (smaller value) < 1.20

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 2 of 22

8. If Equivalent Round is greater than 10, then in any given area, the elongation and reduction in area

values of two tensile specimens taken adjacent to and 90 to each other shall satisfy the following:

2.1.1

Elongation (larger value)/Elongation/ (smaller value) < 1.40

Reduction in Area (larger value)/Reduction in Area (smaller value) < 1.40

Hot Work Practice

Material shall be forged ("forged" here refers to any mechanical process that shapes metal at an

elevated temperature utilizing one or more dies, e.g. open/closed die forging, ring rolling, extrusion,

rolling, etc.) according to a written procedure specified by the forging supplier. The minimum

acceptable total hot work ratio from ingot to billet shall be 3 to 1 (except as noted). The total hot work

ratio for hot work practices is defined as the product of the hot work ratio for each hot working

operation, i.e. (hot work ratio of operation #1) X (hot work ratio of operation #2) X (...). The forging

reduction shall be the product of all forging sequences using the original ingot cross section as the

starting point and the final cross section of the billet prior to any closed die work.

Note:

The minimum acceptable hot work ratio is 3 to 1. Hot work shall be sufficient to guarantee a

fully wrought structure as defined above, but in no case less than 3 to 1. Just because a

forging has a hot work ratio exceeding the 3 to 1 minimum does not necessarily mean that

the forging is acceptable. It must have a fully wrought structure as defined in 2.1.

As an alternate to this 3 to 1 ratio requirement, the material supplier may propose other options for

Camerons consideration. If the proposal is acceptable to Cameron Metallurgy, the material supplier

shall perform tests to confirm that a wrought structure throughout is present. Test results shall be

submitted to Cameron Metallurgy for approval. Evaluation of these test results may be used to accept

processing of components forged with similar processes provided that the total hot work of the similar

components is greater than the component process previously evaluated.

Note:

2.1.2

Unless prohibited by the specific material specification, bar stock may be open die forged,

rolled, or extruded.

Micro-cleanliness of Steel Alloys

Forging supplier shall guarantee that production forgings are capable of meeting the following

requirements if tested by Cameron:

Rate the specimen per ASTM E45, Standard Test Method for Determining the Inclusion Level Rating,

Method A.

Type A

Type B

Type C

Type D

Thin/Heavy

2.0/1.5

Thin/Heavy

2.0/1.5

Thin/Heavy

2.0/1.5

Thin/Heavy

2.0/1.5

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

DATE

J. D. Dufour

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

DATE

J. W. Johnson

9 Jan 03

2.2

29

Page 3 of 22

Casting Practices

2.2.1

Casting Quality

All castings shall be of pressure vessel quality. The materials manufacturer shall document foundry

practices which establish limits for sand control, core making, rigging and melting to insure

repeatability in producing castings which meet the requirements of this specification.

2.2.2

Micro-cleanliness of Steel Castings

Casting supplier shall guarantee that steel castings are capable of meeting the following requirements

if tested by Cameron:

Rate the specimen per ASTM E45, Standard Test Method for Determining the Inclusion Level Rating,

Method A.

Type A

Type B

Type C

Type D

2.3

Thin/Heavy

2.0/1.5

Thin/Heavy

2.0/1.5

Thin/Heavy

2.0/1.5

Thin/Heavy

2.0/1.5

Heat Treatment

Sections 2.3.1 through 2.3.6 apply to conventional batch type heat treating. Section 2.3.7 applies to

continuous furnace heat treating.

2.3.1

Heat Treatment Equipment

All heat treatment equipment used for production material and the Qualification Test Coupon (QTC)

shall be qualified. Qualification shall be done in accordance with one of the following:

A. AMS-H-6875, Section 3 (latest edition), including AMS 2750 (latest edition) in accordance with

appropriate furnace class

B. British Standard M54: 1982, Section 5

C. API 6A (latest edition)

D. A written procedure that has been submitted to and approved by Cameron Metallurgy.

2.3.2

Furnace Loading

The material shall be loaded into the heat treatment equipment such that the presence of one part

does not adversely affect the heat treatment response of any other part in the same heat treatment

load. Parts shall be separated for quenching so that there is sufficient space between each part to

provide adequate quench media coverage during to quenching operation.

2.3.3

Heat Treatment Instrumentation

2.3.3.1 Only automatic controlling and recording instruments shall be used. Controlling

thermocouples shall be located in the working zone of a furnace.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 4 of 22

2.3.3.2 Heat treatment controlling and recording instrumentation shall possess an accuracy of +1%

of their full scale range and shall be calibrated at least once every three months.

2.3.3.3 Instrumentation used to calibrate the production instruments shall possess an accuracy of +

0.25% of full scale range.

2.3.4

Approved Heat Treatment Time at Temperature Monitoring Methods

There are many methods of monitoring time at temperature which will assure that the requirements of

the Cameron material specification are satisfied. The following methods are the recognized and

approved methods (for batch furnaces only). Any heat treatment certification which requires actual

time or charts shall reference the method utilized. The heat treater shall specify and use an approved

monitoring method. The cross-section of a part is defined as the diameter of the largest sphere that

can be wholly inscribed anywhere within that part.

Note: For PSL 4 body, bonnet, end and outlet connections, and hanger materials, only method C is

acceptable.

Method A - Furnace Temperature Monitoring

This method shall use a thermocouple which monitors the furnace atmosphere temperature. Holding

time shall start after the furnace atmospheric thermocouple reaches the set point temperature.

Holding times shall be as indicated below (see Note):

-

For parts up to and including 10" (25.4 cm) in cross section, hold for a minimum of 1/2 hour/per

inch of heaviest cross section for normalizing, austenitizing, or annealing operations; and a

minimum of 3/4 hour/inch of heaviest cross section for tempering and aging operations. If double

tempering is specified, the first temper cycle shall be for a minimum of 3/4 hour/inch of heaviest

cross section. The second temper for a minimum of 1/2 hour/inch of heaviest cross section.

For parts over 10" (25.4 cm) in cross section, hold for a minimum 1/2 hour/inch of heaviest cross

section for normalizing, austenitizing, or annealing operation; and a minimum of 1 hour/inch of

heaviest cross section for tempering and aging operations. If double tempering is specified, the

first temper shall be for a minimum of one hour/inch of heaviest cross section. The second

temper for a minimum of 1/2 hour/inch of heaviest cross section.

As an alternative for barstock up to and including 10 inches (25.4 cm) in diameter, holding times

at temperature may be selected by the material supplier that are appropriate for his specific heat

treat facilities, the alloy being heat treated, and the cross section of the part; and are consistent

with the required mechanical properties. Holding times, however, must be at least 15

minutes/inch of heaviest cross section for each operation. If this option is selected, material must

be qualified utilizing a full cross section prolongation that remains attached to a production part

throughout heat treatment. All required mechanical test specimens shall be taken with their

longitudinal axes at mid-radius or deeper and with the gage lengths of tensile specimens and the

root of the Charpy V-notch for impact specimens at least 1/4T (where T= heaviest cross section)

from the end of the prolongation.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 5 of 22

Note: It should be noted that some vendors will report on their material test reports (MTRs)

something that is referred to as the time at temperature. This is considered to be the time at which

the entire cross-section of a part is at the specified heat treating cycle temperature (i.e. normalizing,

austenitizing, solution annealing, tempering, etc.). The time at temperature doesnt start until the

entire cross-section of the part has reached equilibrium (or, is at the same temperature). The actual

furnace times may be considerably longer to allow the parts to be heated up to the specified

temperature of the heat treat cycle. The time used shall be sufficient to allow for the complete

transformation of the material depending upon the specific alloy and heat treat cycle selected. It

should also be noted that the time at temperature given on an MTR for certain materials may be

less than the heat up and holding times calculated using the requirements above. However, as long

as the MTR reports a proper time at temperature statement and the material meets the mechanical

property requirements of the material specification, the material is considered to be acceptable. Any

questions in regards to this note should be directed to Cameron Metallurgy.

Method B - Contact Surface Thermocouple

This method shall use a thermocouple in surface contact with the product or a heat sink. The

equivalent round (ER) of the heat sink shall be determined per Figure 1. The ER of the heat sink

shall be greater than or equal to the largest ER of any part in the heat treatment load. The heat sink

shall be made of the same class of material when the components are made of an alloy of the

following classes: carbon steel, alloy steel, stainless steel, titanium base alloys, nickel-copper alloys,

and nickel base alloys. For components which do not meet one of the preceding classes, the heat

sink shall be made from the same alloy as the component. Once the thermocouple reaches

temperature, the part(s) or heat sink shall be held at temperature for the time required by each cycle

stated in the Cameron material specification.

Method C - Heat Sink Thermocouple

This method shall use a thermocouple located such that the temperature sensing tip of the

thermocouple is imbedded within the part or heat sink and is no closer than one inch to any external

or internal surface. The equivalent round (ER) of the heat sink shall be the greater of:

1. The ER as determined using Figure; or,

2. The ER as determined using the thickest cross-section of the largest part.

As an alternative, the largest part in the heat treat load may be used as a heat sink. This option

requires that thermocouple location be specified by Cameron Product Engineering. The heat sink

shall be made of the same class of material when the components are made of an alloy of the

following classes: carbon steel, alloy steel, stainless steel, titanium base alloys, nickel-copper alloys,

and nickel base alloys. For components which do not meet one of the preceding classes, the heat

sink shall be made from the same alloy as the component. The time at temperature required by the

Cameron material specification shall be initiated once the thermocouple comes to temperature.

Other methods of monitoring temperature during heat treatment may be used provided they are first

submitted to and approved by Cameron Metallurgy.

2.3.5

Double Tempering Operations

When a QTC is processed with a double temper operation, the product shall receive a double temper

operation and shall be processed in accordance with time and temperature tolerances specified in

section 3.3.4.2 for each cycle.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

2.3.6

29

Page 6 of 22

Optional Re-tempering

Carbon, low alloy, and martensitic stainless steel parts and QTCs that exceed the maximum

hardness in the applicable material specification after tempering must be re-tempered until the correct

hardness is obtained. Re-tempering shall be done in accordance with one of the following

paragraphs (as applicable).

2.3.6.1 QTC Too Hard - Single Temper Specified

When working to a material specification requiring a single temper and the hardness of the

QTC is too high after tempering, the QTC must be re-tempered. The QTC may be retempered by itself provided that the QTC tempering time at temperature does not exceed that

of the part(s) that it qualifies. Alternatively, the QTC and the part(s) it qualifies may both be

re-tempered. Re-tempering shall consist of one or more additional temper cycles performed

in accordance with the times and temperatures specified for the temper cycle in the material

specification. For PSL 2, 3, and 4, the times and temperatures for the re-temper cycles for the

QTC and part(s) must comply with section 3.3.4 if the QTC and part(s) are re-tempered

separately.

2.3.6.2 QTC Too Hard - Double Temper Specified

When working to a material specification requiring a double temper and the hardness of the

QTC is too high after tempering, the QTC must be re-tempered. The QTC may be retempered by itself provided that the QTC tempering time at temperature does not exceed that

of the part(s) that it qualifies. Alternatively, the QTC and the part(s) it qualifies may both be

re-tempered. Re-tempering shall consist of double tempering again in accordance with the

applicable material specification. For PSL 2, 3, and 4, the times and temperatures for the

double re-temper cycles for the QTC and part(s) must comply with section 3.3.4 if the QTC

and part(s) are re-tempered separately.

2.3.6.3 Part(s) Too Hard - Single Temper Specified

When working to a material specification requiring a single temper and the hardness of the

part(s) is too high after tempering and the hardness of the QTC is acceptable, then just the

part(s) need be re-tempered. Re-tempering shall consist of one or more additional temper

cycles performed in accordance with the times and temperatures specified for the temper

cycle in the applicable material specification. For PSL 2, 3, and 4, the times and

temperatures for the re-temper cycle(s) of the part(s) must comply with section 3.3.4.

2.3.6.4 Part(s) Too Hard - Double Temper Specified

When working to a material specification requiring a double temper and the hardness of the

part(s) is too high and the hardness of the QTC is acceptable, then just the part(s) need be

re-tempered. Re-tempering shall consist of double tempering again in accordance with the

applicable material specification. For PSL 2, 3, and 4, the times and temperatures for the

double re-temper cycle(s) of the part(s) must comply with section 3.3.4.

2.3.7

Continuous Furnace Heat Treatment

For PSL 1-3 applications, continuous furnace heat treatment shall be an acceptable alternative to

conventional batch type heat. Continuous furnaces typically contain several different temperature

zones through which the bar travels. The zone temperatures in the austenitizing furnace are chosen

so as to heat the part to a completely austenitic state in a relatively short time. The part is then spray

quenched before entering the tempering furnace. Zone temperatures in the tempering furnace are

chosen to produce the desired tempering effect, again in a relatively short time. The time spent in the

austenitizing and tempering furnaces depends primarily upon the length of the furnace and the travel

speed. The travel speed varies according to the size of the part. The time in each furnace shall be

sufficient to produce the desired mechanical properties and a microstructure equivalent to that

obtained by a conventional batch type quench and temper heat treatment.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

29

9 Jan 03

Page 7 of 22

For continuous furnace heat treatment, the following parameters shall apply:

A. The minimum part temperature upon exiting the final zone of the austenitizing furnace shall

meet the minimum austenitizing temperature listed in the applicable material specification.

B. The minimum time in the austenitizing furnace shall be 10 minutes.

C. The minimum part temperature upon exiting the final zone of the tempering furnace shall meet

the minimum tempering temperature listed in the applicable material specification.

D. The minimum time in the tempering furnace shall be 10 minutes.

E. The maximum temperature of the quench water prior to quenching shall be 100F (38C).

F. The QTC shall be from the same heat treat batch as the material it represents. For continuous

furnaces, a heat treat batch is defined as a group of bars having the same diameter and from

the same heat run through the furnace sequentially at the same zone temperatures, travel

speed, and other parameters. A minimum of one QTC shall be provided for each heat of

material. In addition, a minimum of one QTC shall be provided for each group of 150 parts from

the same heat. Mechanical property tests shall be conducted on the QTC in accordance with

section 3.4 of this specification except that all specifications shall be taken at the 1/4T location.

In addition to the hardness testing required on the QTC, each part shall be individually

hardness checked with Brinell hardness measurements taken on the surface at each end of the

bar. The hardness measurements shall meet the requirements of the applicable material

specification.

2.4

Weld Repair of Material

2.4.1

PSL 4 Materials: Except for weld overlays, welding is not permitted on any PSL 4 material.

2.4.2

Weld repairs of PSL 3 castings are not permitted without written approval from Cameron Product

Engineering. Weld repairs of wrought material are prohibited.

2.4.3

PSL 3 materials (when approved) and PSLs 1 and 2 castings may be weld repaired provided.

(a) The procedures and welders used are qualified in accordance with ASME Sect. IX (see API

6A).

(b) The filler metal chemistry, hardness and stress relieving temperature meet the requirements of

NACE MR-0175.

(c) The PQR is supported with hardness measurements of the Weld, Base Metal and Heat

Affected Zones (see API 6A).

2.5

NDE Requirements (Weld Repairs)

2.5.1

NDE requirements for forged material (when approved) shall be performed as required by the

Cameron Bill of Materials and the requirements of API 6A.

2.5.2

NDE requirements for PSL 3 castings (when approved) and PSL 1 and 2 castings. NDE shall be

performed as required by the Cameron Bills of Material and the requirements of API 6A. In addition,

the following requirements are mandatory and must be complied with.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 8 of 22

(a) A weld map is required for each casting which details the surface area, configuration and depth

of each weld repair.

(b) A unique number or symbol is required and shall be assigned to each casting, which has been

weld repaired.

(c) A hardness measurement on the weld deposit of one of the weld repairs is required and shall

be made after the final stress relieving operation.

Note:

3.0

The information and test results from the above requirements are to be properly

documented and reported on the Materials Test report.

2.6

Chemical Composition

The chemical composition of the material shall be determined using the latest edition of an appropriate ASTM,

ISO, DIN, or French A Standard or other nationally or internationally recognized standard approved by

Cameron Metallurgy and shall meet the requirements of the specific material specification. Elements (other

than elements used for grain refinement/de-oxidation) not specified in the MS shall not be intentionally added.

Material composition shall be determined on a heat basis (or a re-melt ingot basis for re-melt grade

materials). Any other element not specified and over 0.25% shall be reported. Total amount of residual

elements shall not exceed 1.00%.

2.7

NDE Capabilities

Materials must meet the Quality and NDE requirements as specified by the Cameron Bils of Material.

2.8

Visual Examination and Other Tests

The supplier shall guarantee the material is homogenous and free of all anomalies or deleterious phases

which are detrimental to the mechanical or machining properties of the material or may adversely impact its

corrosion resistance.

2.9

Scale Removal

During the production of any material where excessive surface scale (such as in heavily forged parts) is

produced through oxidization or any other process during either the forging or heat treatment operations, it

must be removed prior to delivery to Cameron. The scale can be removed through any recognized method

(for example air-blast, shot blasting, or grinding). However, it must in no way cause the material to deviate

from the requirements outlined in the Bill of Material or and other reference document.

QUALIFICATION TESTING:

3.1

General

The properties exhibited by the Qualification Test Coupon (QTC) shall represent the properties of the thermal

response of the material comprising the production parts it qualifies. Depending upon the hardenability of a

given material, the QTC results may not always correspond with the properties of the actual components at all

locations throughout their cross-section. A single QTC may be used to represent the impact and/or tensile

properties of the part(s) produced from the same heat provided it satisfies the requirements of this

specification.

For batch heat treatment only: When the QTC is a trepanned core or prolongation removed from a production

part or a sacrificial production part, the QTC may only qualify production parts having the same or smaller ER.

The QTC shall only qualify material and parts produced from the same heat.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

29

9 Jan 03

Page 9 of 22

For material heat treatment in a continuous furnace: The QTC shall consist of a sacrificial production part or

a prolongation removed from a production part. The sacrificial production part or prolongation QTC shall only

qualify production parts having identical size and shape. The QTC shall only qualify material and parts

produced from the same heat and heat treat lot.

3.2

Equivalent Round (ER)

3.2.1

Selection

The size of a QTC for a part shall be determined using the following equivalent round (ER) methods.

3.2.2

ER Methods

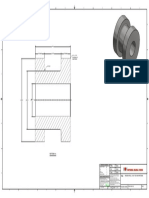

Figure 1 illustrates the basic models for determining the ER. The ER of a part shall be determined

using the actual dimensions of the part in the "as heat treated" condition. Figure 2 shows examples

of how prolongations are determined on several product configurations to meet the ER requirements.

The ER of a studded type part shall be determined by using T equal to the thickness of the thickest

flange that can be bolted to that part. ER determination of studded, non-studded or flange parts shall

be in accordance with Figure 1 methods for complex shaped parts.

When a prolongation is used, it shall remain integrally attached during all heat treatment operations

except post weld heat treatment, stress relief, and any re-tempering or re-aging that may be required.

For tubular components, bar stock, mill shapes and other raw material with a uniform cross section,

the prolongation shall have the same cross section as that raw material. For a production part with a

complex shape or varying cross section, the prolongation need not be an extension of the largest

cross section of the part. However, the extension shall meet or exceed the minimum equivalent

round (ER) required for a separate QTC.

3.2.3

Maximum ER QTC Size Requirement

The ER of the QTC, as determined using Figure 1, shall be equal or greater than maximum

ER of the part which it qualifies, except as follows:

3.2.3.1 For PSL 1 and 2

3.2.3.1.1 Forgings

Size required NOT to exceed 2-1/2 inches (63 mm) ER.

3.2.3.1.2 Castings

Size required NOT to exceed size shown in ASTM A703 (latest revision).

3.2.3.2

3.3

For PSL 3 and 4

Size required NOT to exceed 5 inches (125 mm) ER.

QTC Processing

3.3.1

Melting Practices

In no case shall the QTC be processed using a melting practice(s) cleaner than that of the material it

qualifies (e.g. a QTC made from a remelt grade or vacuum degassed material may not qualify

material from the same primary melt which has not experienced the identical melting practice). For

PSL 1, 2, and 3, remelt grade material removed from a single remelt ingot may be used to qualify

other remelt grade material which is from the same primary melt; no additional alloying shall be

performed on these individual remelt

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 10 of 22

3.3.2

Hot Working Practices (Wrought Materials Only)

Hot working ratios on the QTC shall be equal to or less than those used in processing the part(s) the

QTC qualifies. The total hot work ratio for the QTC shall not exceed the total hot work ratio of the

part(s) the QTC qualifies.

3.3.3

Casting Practices (Cast Materials Only)

The QTC shall be made using the same foundry practices that were used on the part(s) it qualifies.

3.3.4

QTC Heat Treating

3.3.4.1 Equipment Qualification

All heat treatment operations shall be performed utilizing equipment qualified in accordance

with 2.3.1.

3.3.4.2 Methods

The QTC shall experience heat treatment per Section 2.3 and the Cameron material

specification. The QTC shall be heat treated in a production furnace that is routinely used to

produce production parts having an equivalent round equal or greater than the QTC. The

method of monitoring QTC heat treatment may be different than that utilized for the parts if

the Cameron material specification heat treatment and Section 2.3 of this specification are

satisfied.

PSL 2, 3 and 4 Requirements

When the QTC is not heat treated as part of the same heat treatment load as the part(s) it

qualifies, the austenitizing, solutionizing or age hardening (as applicable) temperatures for

the QTC shall be within 25F (14C) of those for the part(s). The tempering temperature for

the parts shall be no lower than 25F (14C) below that of the QTC. The upper limit shall be

no higher than permitted by the heat treat procedure for that material.

If the QTC is heat treated separately from the part(s) it qualifies, the time at temperature of

the QTC shall not exceed the time at temperature of the part(s) for each heat treatment cycle

and must be within the tolerances specified in the applicable material specification.

3.3.5

3.4

QTC Welding

Welding on QTC is not allowed except for attachment type welds.

QTC Tensile and Impact Testing

3.4.1

Methods

Charpy V-notch impact and tensile testing shall be performed in accordance with ASTM A370 (latest

revision). A minimum of one tensile and one set of three impact specimens shall be taken. Out of the

set of three impact specimens, not more than one specimen shall fall below the required minimum

average and shall never be less than two-thirds of the minimum average.

3.4.2

Specimen Size

Standard size 0.500 inch diameter tensile specimens shall be used unless the physical configuration

of the QTC prevents their use. Then, the standard sub-size specimens in ASTM A370 (latest revision)

may be used. Standard size impact specimens 10 mm X 10 mm in cross section shall be used,

except where there is insufficient material, in which case the next smaller standard size specimen

obtainable shall be used. Sub-size specimens shall not be used for PSL 4 material.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 11 of 22

3.4.2.1 Sub-size Impact Specimens (PSL 1, 2, and 3 only)

When sub-sized specimens are used, the Charpy V-notch impacts shall be equal to that of

the 10 mm x 10 mm specimens multiplied by the appropriate adjustment factor tested in

Table 1.

TABLE 1

Adjustment Factors for Sub-Sized

Charpy V-Notch Specimens

Specimen

Dimension (mm)

10 x 7.5

10 x 5.0

10 x 2.5

3.4.3

Adjustment

Factor

0.833

0.667

0.333

Tensile and Impact Results

3.4.3.1 Acceptance Criteria

Tensile and impact test results must meet the requirements of the material specification

specified on the Cameron Bills of Material. In addition, the fractured test specimens shall be

visually examined (up to 10X maximum) for the following:

Tensile Specimens: Tensile test specimens must break within the gage length marks. There

shall be no evidence of inclusions or hydrogen damage (fish eyes, flakes, etc.) on the fracture

faces. Secondary cracking (defined here as cracks initiating and growing on the surface of

the gage section of the specimen that are not associated with the main fracture faces) is

cause for rejection.

Impact Specimens: Fracture must have originated at the tip of the V-notch. There shall be no

evidence of inclusions or hydrogen damage (fish eyes, flakes, etc.) on the fracture faces.

3.4.3.2 Retest

If the results of a tensile test do not satisfy the applicable mechanical property requirements,

two additional tensile tests may be performed. Retest specimens shall be removed from the

same location within the same QTC with no additional heat treatment. The results of each of

these tensile tests shall satisfy the material specification requirements.

If a Charpy V-notch test fails to meet the applicable mechanical property requirements, retest

of three additional specimens, removed from the same location within the same QTC with no

additional heat treatment, shall be made. Each impact specimen shall exhibit an impact

value equal to or exceeding the required minimum average.

3.4.4

QTC Test Specimen Location

When tensile and/or impact test specimens are required, they shall be removed from the same QTC

after the final QTC treatment cycle. Tensile and impact specimens shall be removed from the QTC

such that their longitudinal centerline axis is wholly within the center core 1/4T envelope for a solid

QTC or within 1/8 inch of the midthickness of the thickest section of a hollow QTC. Test specimens

shall be removed from the QTC such that the tensile specimen gage length and Charpy V-notch root

are at least 1/4T from the ends of the QTC.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 12 of 22

For QTCs larger than the size specified in 3.2.3, the test specimens need not be removed from a

location farther from the QTC surface than would be required if the specified QTC size were used.

When a sacrificial production part is used as a QTC, the impact and/or tensile test specimens shall be

removed from a section of the part meeting the size requirements for a QTC for that production part

as defined in 3.2.3.

3.5

3.6

4.0

QTC Hardness Testing

3.5.1

General

A minimum of one Brinell or Rockwell test shall be performed on the QTC after final heat treatment.

The QTC(s) heat treatment cycles prior to hardness testing shall be the very same heat treatment

cycles experienced by the tensile and impact test specimens.

3.5.2

Methods

Hardness testing shall be performed in accordance with procedures specified in ASTM E10 (latest

revision), ASTM E18 (latest revision) or ASTM E110 (latest revision).

3.5.3

QTC Hardness Acceptance Criteria

The QTC shall have the same hardness acceptance criteria as the product it represents as specified

in the applicable material specification.

Hardness Testing (Product)

Hardness testing of the product shall be done in accordance with the applicable material specification. Brinell

testing, if used, shall be performed in accordance with ASTM E10 (latest revision). Rockwell testing, if used,

shall be performed in accordance with ASTM E18 (latest revision). Portable Brinell testing, if used, shall be

performed in accordance with ASTM E110 (latest revision).

FIRST ARTICLE CASTING (CAST MATERIAL ONLY):

The foundry shall produce a first article casting and submit it to Cameron for approval prior to casting the production

parts as described below. A first article casting is required under the following circumstances.

4.1

Implementation of First Article

A first article casting is required when any of the following conditions apply.

4.1.1

New pattern.

4.1.2

Transfer of pattern from another foundry.

4.1.3

Engineering design change that will affect a critical dimension or the integrity of the casting.

4.1.4

Changes in any of the following foundry processes, subsequent to first article approval, in which case

Cameron shall be notified.

4.1.4.1 Gating system.

4.1.4.2 Risering and/or padding.

4.1.4.3 Chilling, external chills only. Internal chills are prohibited, except with specific written

agreement with the purchaser.)

4.1.4.4 Molding or core making methods, such as a change from green sand to no-bake.

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

4.1.5

4.2

29

Page 13 of 22

Upon Identification of a Recurring Defect in a Production Casting

At Cameron's discretion, the first production run of castings may be considered the sample. In this

instance, one of the castings shall be selected at random to be processed as the first article casting.

Submittal of First Article

4.2.1 Sample castings shall be delivered to Cameron. All inspection documentation shall be with the sample

casting when delivered. All sample castings shall be clearly marked with a large "S" or the word

"sample".

4.2.2 Subsequent runs of castings shall not be made until Cameron has approved a first article casting or

waived, in writing, all or part of the described first article casting inspection. Final acceptance is

dependent on the first article passing a hydrostatic pressure test if required by Cameron.

4.3

Heat Treatment

The first article casting shall be heat treated in the same condition (machined or unmachined) as the

production castings.

4.4

Repair Welding

Repair welding on the first article castings is not allowed unless approved in writing by Cameron. The sample

casting shall meet all of the required acceptance criteria prior to casting production parts. Cosmetic grinding

to remove defects is permitted.

4.5

First Article Inspection

The material supplier is responsible for performing the following inspections on first article castings before

submitting them to Cameron. The results of these inspections must accompany the first article castings.

Cameron may reconfirm any or all of these inspection requirements to assure that the casting is in

compliance.

4.5.1

Dimensions

The first article casting shall be dimensionally inspected to the applicable Cameron drawing. Any

dimensions out of drawing specification shall be submitted to Cameron for approval.

4.5.2

Material Specification Requirements

The heat treatment, chemical composition, and mechanical properties of the first article casting shall

meet the requirements of this specification.

4.5.3

Visual Inspection

4.5.3.1 All surfaces of first article castings shall be visually inspected per MSS-SP-55 (latest edition),

"Steel Castings for Valves, Flanges, and Fittings and Other Piping Components".

4.5.3.2 The reference photographs in MSS-SP-55 shall be used to evaluate the acceptability of

castings.

Type 1 - none acceptable

Type 2-12 - A and B are acceptable, all others are unacceptable.

4.5.4

Magnetic Particle Inspection

4.5.4.1 All surfaces of first article castings shall be magnetic particle inspected per ASTM E709

(latest edition).

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

29

9 Jan 03

Page 14 of 22

4.5.4.2 Only those indications with major dimensions greater than 1/16 inch shall be considered

relevant. Inherent indications not associated with a surface rupture (i.e. magnetic permeability

variations, non-metallic stringers...) are considered non-relevant. If indications are believed to

be non-relevant, they shall be examined by liquid penetrant surface NDE methods, or

removed and reinspected to prove their non-relevancy.

4.5.4.3 The acceptance criteria are as follows:

4.5.5

No relevant indication with a major dimension equal to or greater than 3/16 inch.

No more than ten relevant indications in any continuous 6 square inch area.

Four or more relevant indications in a line separated by less than 1/16 inch (edge to

edge) are unacceptable.

No relevant indications in the pressure contact sealing surfaces.

Radiographic Inspection

4.5.5.1 As far as practical, the entire volume of each first article casting shall be radiographed after

heat treatment for mechanical properties in accordance with ASTM E94 (latest edition) to a

minimum sensitivity of 2%.

4.5.5.2 Radiographs shall be evaluated using the latest editions of ASTM Standard Reference

Radiographs E186, E280 and E446.

4.5.5.3 Maximum allowable defect classification is as follows:

Type Defect

A

B

C

D

E

F

G

5.0

Maximum Defect Class

2

2

2 (All Types)

None Acceptable

None Acceptable

None Acceptable

None Acceptable

FORGING VENDOR PROCEDURES:

Forging vendors shall have written procedures controlling the following areas. These procedures must be made

available to Cameron for review during an onsite audit.

5.1

Billet/Ingot Supplier Qualification

5.1.1

The forging vendor shall have a procedure in place for qualifying billet/ingot suppliers that is based

upon both a quality assurance and a technical evaluation. An acceptable quality program, such as

an ISO accreditation is not sufficient by itself to satisfy this requirement. There must be

documented evidence that a billet/ingot supplier has the technical know-how and the necessary

procedures and equipment in place to consistently produce acceptable product. Technical approval

of a billet/ingot supplier may be done using one or more of the following methods:

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

5.1.2

29

Page 15 of 22

An onsite technical audit

Receipt inspection that includes NDE, chemistry check, macroetch, etc. on a sample basis.

A first article cut up evaluation

Successful experience over a period of time. Documentation must include tests/inspections that

were performed on either the starting material or finished forgings.

The forging vendor is responsible for insuring that a billet/ingot supplier has an acceptable quality

program, and has procedures addressing the following:

Chemistry control (including chemistry balance or aim)

Melting practice

Pouring practice and type of ingot mold

Hot work practice (method of forging, amount of reduction, forging temperature, etc.)

Cooling rate and method after forging

Cropping the billet

Inspection and acceptance criteria (cleanliness requirements, limitations on porosity or

inclusions, grain size, secondary phases, microstructure, macrostructure, etc. as applicable)

Hydrogen control. In carbon, low alloy, and martensitic stainless steels (410, F6NM, etc.)

hydrogen must be controlled to 2 ppm maximum.

5.2

Receiving inspection and material clearance of billet/ingot

5.3

Chemistry verification

5.4

Hot work requirements (how is the minimum reduction of area during forging determined in order to produce a

fully wrought structure for a given forging)

5.5

Forging sequence, temperature

5.6

Cooling after forging

5.7

Heat treating (if applicable)

5.8

Hardness testing

5.9

Nondestructive testing (if applicable)

5.10 Mechanical testing

5.11 Macrostructure and microstructure control (as applicable)

5.12 Quality control including inspection and acceptance criteria

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

6.0

29

Page 16 of 22

CERTIFICATION REQUIREMENTS:

The actual certification requirements are dependent on the API 6A product Specification Level (PSL). Whenever "if

applicable" appears below, verify that the operation/test is required by the material specification - if it is, then

certification is required.

Note: For duplex and super duplex stainless steel materials, the results for the ASTM G48 corrosion testing, ferrite

content determination, and metallographic examination shall also be reported in the certification

requirements for all PSL levels.

6.1

PSL 1 and 2 Certification

Certification of Compliance - Certification shall include certification to the requirements of the material

specification and the heat treat requirements. The MS and revision shall be included on certifications.

P.O. Number

Part Number and Revision

Material Description - Certification shall include description of the material (configuration, size) and

quantity.

Material Heat number

Material Chemistry - Certifications shall include actual chemistry per heat or re-melt ingot.

QTC Description - Certifications shall include the configuration and size of the QTC.

QTC Hardness - Certifications shall include the actual hardness of the QTC after final heat-treating and

prior to cutting the tensile and impact specimens.

QTC Tensile Test Results (If applicable) - Certifications shall include ultimate tensile, yield, elongation

and reduction in area. It is required that the tensile specimen size be included only if the specimens were

other than standard 0.500" Dia. with 2" gage length.

QTC Impact Test Results (If applicable) - When impact testing is required, certification shall include

impact test results for each specimen and include the orientation (if other than longitudinal) and test

temperature. It is required that the impact specimen size be included only if the specimens were other

than standard 10mm X 10mm.

NDE Records (PSL 1)

NDE personnel qualification records

NDE Records (PSL 2)

NDE personnel qualification records

Surface NDE records

Weld volumetric NDE records (If applicable)

Repair weld NDE records (If applicable)

Hardness Test Record of Parts (if applicable)

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

29

9 Jan 03

6.2

Page 17 of 22

PSL 3 Certification

Certification of Compliance - Certification shall include certification to the requirements of the material

specification and the heat treat requirements. The MS and revision shall be included on certifications.

P. O. Number

Part Number and Revision

Material Description - Certifications shall include material description, configuration, size and quantity.

Material Heat Number

Material Chemistry - Certification shall include actual chemistry per heat or remelt ingot.

Actual Hot Work Ratio

Material Heat Treatment - Certifications shall include actual temperatures and times at temperature for

each heat treat cycle, quench media type and temperature monitoring method.

Heat Treat Lot Identification - Certification to include heat-treat load identification. If serialization

marking of material is employed instead of heat treat load, certifications shall indicate the serial numbers

included in each heat treat load.

QTC Description - Certifications shall include the configuration and size of the QTC.

QTC Heat treatment - Certifications shall include actual temperatures and times at temperature for the

QTC heat treat cycle, quench media type, and temperature-monitoring method.

QTC Hardness - Certifications shall include the actual hardness of the QTC after final heat-treating and

prior to cutting the tensile and impact specimens.

QTC Tensile Test Results - Certifications shall include ultimate tensile, yield, elongation and reduction in

area. It is required that the tensile specimen size be included only of the specimens were other than

standard 0.500" dia. with 2" gage length.

QTC Impact Results - Certifications shall include impact test results for each specimen and include the

orientation (if other than longitudinal) and test results. It is required that the impact specimen size be

included only if the specimens were other than standard 10mm X 10mm.

NDE Records

- NDE personnel qualification records.

- Surface NDE records

- Weld volumetric NDE records (If applicable)

- Repair weld NDE records (If applicable)

- Volumetric NDE records (except valve-bore sealing mechanisms)

Hardness Test Record of Parts (if applicable)

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

6.3

29

Page 18 of 22

PSL 4 Certification

Certification of Compliance - Certifications shall include certification to the requirements of the material

specification and the heat treat requirements. The MS and revision shall be included on the certifications.

P.O. Number

Part Number and Revision

Material Description - Certifications shall include material description, configuration, size and quantity.

Material Heat Number

Material Melting Practice

Material Chemistry - Certifications shall include actual chemistry per heat or re-melt ingot.

Actual Hot Work Ratio

Material Heat Treatment - Certifications shall include actual temperatures and times at temperature for

each heat treat cycle, quench media type and temperature monitoring method.

Heat Treat Charts - Actual heat treat charts shall be provided identified with heat treat load and cycle.

Heat Treatment Lot Identification - Certifications to include heat-treat load identification. If serialization

marking of material is employed instead of heat treat load, certifications shall indicate the serial numbers

included in each heat treat load.

QTC Description - Certifications shall include the configuration and size of the QTC.

QTC Heat Treatment - Certifications shall include actual temperatures and times at temperature for the

QTC heat treat cycle, quench media type, temperature-monitoring method.

QTC Hardness - Certification shall include the actual hardness of the QTC after final heat-treating and

prior to cutting the tensile and impact specimens.

QTC Tensile Test Result's - Certifications shall include ultimate tensile, yield, elongation and reduction

in area. It is required that the tensile specimen size be included only if the specimens were other than

standard .500" dia. with 2" gage length.

QTC Impact Test Results - Certifications shall include impact test results for each specimen and include

the orientation (if other than longitudinal) and test temperature. It is required that the impact specimen

size be the standard 10mm x 10mm.

NDE Records

- NDE personnel qualification records.

- Surface NDE records

- Weld volumetric NDE records (If applicable)

- Repair weld NDE records (If applicable)

- Volumetric NDE records (except valve-bore sealing mechanisms)

Hardness Test Record of Parts (if applicable)

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

DATE

J. D. Dufour

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

DATE

J. W. Johnson

9 Jan 03

29

Page 19 of 22

FIGURE 1

METHOD OF CALCULATING EQUIVALENT ROUND

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

J. D. Dufour

DATE

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 20 of 22

FIGURE 1 (CONTINUED)

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

DATE

J. D. Dufour

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

DATE

J. W. Johnson

29

9 Jan 03

Page 21 of 22

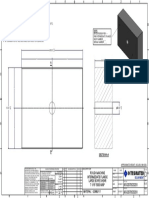

FIGURE 2

EXAMPLE ER CALCULATIONS FOR PROLONGATIONS

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

PROPERTY OF

DRAWN BY:

DATE

J. D. Dufour

REVISION

MS-003400-01

9 Jan 03

APPROVED BY:

J. W. Johnson

DATE

9 Jan 03

29

Page 22 of 22

FIGURE 2

(Continued)

Last Revision Date & Name: 21 Apr 16, K. S. Johnson

This document contains confidential and trade secret information which is the sole property of CAMERON, a division of CAMERON INTERNATIONAL CORPORATION. Receipt or possession does not

convey any right to loan, sell or otherwise disclose said information. Reproduction or use of said information for any purpose other than that for which it is intended may not be made without written

permission from CAMERON. This document is to be returned to CAMERON upon request and in all events upon completion of the use for which it is intended.

CAM-2174 C

June 5, 2008

You might also like

- Failure Analysis of Cracked Reformer Tubes Reveals Thermal Shock CauseDocument6 pagesFailure Analysis of Cracked Reformer Tubes Reveals Thermal Shock CauseOwais MalikNo ratings yet

- Fastener FailuresDocument3 pagesFastener FailuresWylliam Diel WagnerNo ratings yet

- Metallurgical Failure Analysis-IDocument30 pagesMetallurgical Failure Analysis-ISaurabh SinghNo ratings yet

- SMS Casting BreakoutsDocument20 pagesSMS Casting BreakoutsShubham KaushikNo ratings yet

- Flare Tip FailureDocument4 pagesFlare Tip FailuremohammadazraiNo ratings yet

- PREN Number Effect On AlloyDocument6 pagesPREN Number Effect On AlloyVed JoshiNo ratings yet

- Metalography and Microstructures of Stainless Steels and Maraging SteelsDocument32 pagesMetalography and Microstructures of Stainless Steels and Maraging SteelsChaguy VergaraNo ratings yet

- History of Stainless SteelDocument65 pagesHistory of Stainless SteelMayank100% (1)

- Martensite and The Control of Retained AusteniteDocument6 pagesMartensite and The Control of Retained AusteniteMarcoTulioFonsecaNo ratings yet

- GBA's Guide to Selecting Flare Tip MaterialsDocument2 pagesGBA's Guide to Selecting Flare Tip MaterialsDpto SSO SimbioNo ratings yet

- Common Causes of Premature Failure of MN SteelDocument3 pagesCommon Causes of Premature Failure of MN Steeldrackensohn100% (1)

- Deformation Behavior of The Surface Defects of Low Carbon Steel in Wire Rod RollingDocument6 pagesDeformation Behavior of The Surface Defects of Low Carbon Steel in Wire Rod RollingAvinash KumarNo ratings yet

- CH 3 PDFDocument20 pagesCH 3 PDFHassaan SajidNo ratings yet

- LIBRO3Document43 pagesLIBRO3Camilo LacoutureNo ratings yet

- SS 310 Temperature Limit AlternativesDocument3 pagesSS 310 Temperature Limit AlternativesyogacruiseNo ratings yet

- Amp16304p036 PDFDocument3 pagesAmp16304p036 PDFMarius Alin LupașcuNo ratings yet

- MCM AllDocument7 pagesMCM AllPalanisamy RajaNo ratings yet

- AISI 430 Ferritic Stainless Steel MicrostuctureDocument7 pagesAISI 430 Ferritic Stainless Steel MicrostuctureAid Farhan MaarofNo ratings yet

- Piercing of Low-Carbon SteelDocument3 pagesPiercing of Low-Carbon SteelRicardo PaceNo ratings yet

- Corrosion of SS in Nitric Acid ServiceDocument23 pagesCorrosion of SS in Nitric Acid ServiceAdriaan de Witt100% (1)

- SPECIFICATION FOR SOLID SURFACING WELDING RODSDocument23 pagesSPECIFICATION FOR SOLID SURFACING WELDING RODSDmitriyNo ratings yet

- Developments in High Temperature Corrosion Protection CoatingsDocument9 pagesDevelopments in High Temperature Corrosion Protection CoatingsRecep Vatansever100% (1)

- Duplex Stainless Steel 329 Round Bars ManufacturerDocument2 pagesDuplex Stainless Steel 329 Round Bars Manufacturertien100% (1)

- S&B Industrial Minerals Moulding Sand Defect GuideDocument1 pageS&B Industrial Minerals Moulding Sand Defect Guideleh antNo ratings yet

- Feeding Risering For Steel Casting Design PDFDocument10 pagesFeeding Risering For Steel Casting Design PDFHusen TaufiqNo ratings yet

- Chemical Machining Processes For Aircraft Parts Manufacturing (May 2019)Document105 pagesChemical Machining Processes For Aircraft Parts Manufacturing (May 2019)Luis Gustavo PachecoNo ratings yet

- 18 Ni (250) MaragingDocument68 pages18 Ni (250) MaragingsunsirNo ratings yet

- Master ThesisDocument61 pagesMaster ThesisManoj K NaikadeNo ratings yet

- Team Pipe RepairDocument24 pagesTeam Pipe RepairDavid Rios CruzNo ratings yet

- Gaseous NitridingDocument139 pagesGaseous NitridingPaulo OliveiraNo ratings yet

- Cast MaterialsDocument20 pagesCast MaterialsLoru GomezNo ratings yet

- Aws WJ 202009Document78 pagesAws WJ 202009Fernando Emmanuel BenitezNo ratings yet

- Evolution of Quench Factor Analysis - A ReviewDocument22 pagesEvolution of Quench Factor Analysis - A Reviewluigi_mazzucco100% (1)

- GMAW of Creep Resistant SteelsDocument5 pagesGMAW of Creep Resistant SteelsJustin Morse100% (1)

- Gray Cast Iron-1Document18 pagesGray Cast Iron-1ManicharanNo ratings yet

- Effect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIDocument6 pagesEffect of Cooling Rate On Microstructure and Mechanical Properties of Gray Cast Iron - IsIgiokniessNo ratings yet

- Engineering Failure Analysis of Low Carbon Steels in Deep DrawingDocument7 pagesEngineering Failure Analysis of Low Carbon Steels in Deep DrawingPaul RosiahNo ratings yet

- Gas Atmosphere Heat Treatment PDFDocument59 pagesGas Atmosphere Heat Treatment PDFsmani170No ratings yet

- Data Sheet AluminaDocument10 pagesData Sheet AluminaXin EnNo ratings yet

- Stainless Steel 410Document2 pagesStainless Steel 410Suriyachai NiamsornNo ratings yet

- Electroplating Handbook GuideDocument13 pagesElectroplating Handbook GuideAbeerNo ratings yet

- Forgingforging ProcessDocument13 pagesForgingforging Processpatel ketanNo ratings yet

- A Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaDocument8 pagesA Review - Weight Loss Studies On The Corrosion Behavior of Some Metals in Various MediaRonald GarciaNo ratings yet

- STD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXDocument2 pagesSTD-INSP-0125 IGC Phases Practice - A - (ASTM A923) DUPLEXAkshay KalraNo ratings yet

- Reverted austenite causes fastener corrosionDocument3 pagesReverted austenite causes fastener corrosionmp87_ingNo ratings yet

- The effect of annealing on aluminum clad steel sheet propertiesDocument6 pagesThe effect of annealing on aluminum clad steel sheet propertiesRina OktapianiNo ratings yet

- Determining Decarburization and Carburization in Hardened and Tempered Threaded Steel Bolts, Screws and StudsDocument4 pagesDetermining Decarburization and Carburization in Hardened and Tempered Threaded Steel Bolts, Screws and StudscristianNo ratings yet

- Measurement of Decarburization PDFDocument6 pagesMeasurement of Decarburization PDFnayefamkNo ratings yet

- Bitumastic 300 MDocument2 pagesBitumastic 300 MANIBALLOPEZVEGA100% (1)

- Filter NotesDocument46 pagesFilter Notestanzil10100% (1)

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Laser WeldingDocument11 pagesLaser WeldingnkalaiNo ratings yet

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Adiabatic Shear Localization: Frontiers and AdvancesFrom EverandAdiabatic Shear Localization: Frontiers and AdvancesBradley DoddNo ratings yet

- The Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaFrom EverandThe Physical Metallurgy of Fracture: Fourth International Conference on Fracture, June 1977, University of Waterloo, CanadaD M R TaplinNo ratings yet

- Advances in Research on the Strength and Fracture of Materials: An OverviewFrom EverandAdvances in Research on the Strength and Fracture of Materials: An OverviewD M R TaplinNo ratings yet

- Friction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysFrom EverandFriction Stir Welding of 2XXX Aluminum Alloys including Al-Li AlloysNo ratings yet

- Metal matrix composites: Processing and InterfacesFrom EverandMetal matrix composites: Processing and InterfacesR EverettNo ratings yet

- Stub Shaft Forging: ATKP362340/ATKP302958Document1 pageStub Shaft Forging: ATKP362340/ATKP302958Arjun PrajapatiNo ratings yet

- Righton LTD Stainless Steel 3S144 394Document1 pageRighton LTD Stainless Steel 3S144 394Arjun PrajapatiNo ratings yet

- Specification For Plates and Forgings PDFDocument2 pagesSpecification For Plates and Forgings PDFArjun PrajapatiNo ratings yet

- Packing ProcedureDocument24 pagesPacking ProcedureArjun PrajapatiNo ratings yet

- ATKP362341 Revb1 111116Document1 pageATKP362341 Revb1 111116Arjun PrajapatiNo ratings yet

- ATKP362339 Revb1 111116 PDFDocument1 pageATKP362339 Revb1 111116 PDFArjun PrajapatiNo ratings yet

- Anov DWG 201Document1 pageAnov DWG 201Arjun PrajapatiNo ratings yet

- Integrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWPDocument1 pageIntegrated: Rough Machine Intermediate Flange Large Bore Shear 7 1/16"-5000 MWPArjun PrajapatiNo ratings yet

- BU Motors and Generators: Prepared Separate Part List Title ScaleDocument1 pageBU Motors and Generators: Prepared Separate Part List Title ScaleArjun PrajapatiNo ratings yet

- QS MS 117Document5 pagesQS MS 117Arjun PrajapatiNo ratings yet

- ATKP362339 Revb1 111116Document1 pageATKP362339 Revb1 111116Arjun PrajapatiNo ratings yet