Professional Documents

Culture Documents

Application Guide - Spray Drying PDF

Application Guide - Spray Drying PDF

Uploaded by

ignaciomarinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Guide - Spray Drying PDF

Application Guide - Spray Drying PDF

Uploaded by

ignaciomarinCopyright:

Available Formats

Spray Drying Application Guide

Increase Output in Spray Drying Applications

Improve Production and Product Quality All Year Round

Munters is the world leader in dehumidification

Munters is the largest manufacturer of dehumidifiers in the world. Since developing the first desiccant dehumidifier

in the late 1930s, Munters has continued to innovate in the fields of dehumidification and energy recovery. Our long

history and extensive expertise in dehumidification makes us the premier choice for your dehumidification needs.

he technology of spray drying systems and spray

dryers are widely used in food, pharmaceutical and

industrial applications converting liquid solutions to

powder or granules.

Companies utilizing spray drying technology, prefer the

dry winter climate to the humid summer climate for increased

production and quality. In the winter time, water content in the

air is low which creates optimal operating conditions. In the

summer climate, humid conditions have a greater impact on

production quality, dry time and overall production efficiency.

Additionally, the constantly changing moisture level of outside

air during production can have a negative impact on consistent

quality output.

It is necessary during the spray drying process to stabilize

all parameters of the operation to optimize production and

improve efficiency. Using desiccant dehumidification can

make this possible.

TYPICAL SPRAY DRYING APPLICATIONS

Food

Milk powder, coffee, tea, eggs, cereal, spices, flavorings

Pharmaceutical

Antibiotics, medical ingredients, additives

Industrial

Paint pigments, ceramic materials, catalyst supports

Minimum 20% of the production is lost each year

90

Figure 1: Typical spray dryer

In spray drying applications, it is critical

that moisture is controlled

0

-5

80

-10

70

Humidity Gr/Lb

-20

50

-25

40

-30

30

-35

20

-40

10

-45

-50

January

February

March

April

May

June

July

August

September

October

November December

SPRAY TOWER PROBLEMS

Production rate

varies by season

Production stops

Drying time too long

Lack of flexibility

Inconsistent quality

of the powder

Spray Drying Application Guide

Product scrap

% lost of production

-15

60

By dehumidifying the incoming air, maintaining the same low

moisture content throughout the year is easy. This allows for

stable inlet conditions, enabling consistent quality and increased

performance from the spray drying process. Munters has

developed a range of special high performance dehumidifiers

which enable this to happen. Munters dehumidifiers control

precise moisture content of the incoming air, which provides the

following advantages to the spray drying process:

Consistent production all year. Production is no longer

affected by outside conditions. No more production stops

in the summer due to weather conditions, also eliminating

the need for frequent parameter adjustments.

Consistent quality all year. Having stable dry inlet

conditions means consistent quality.

Less cleaning time. Less product sticking to the wall of the

spray tower.

Fan

Bag

Filter

OUTLET DUCT

FEED

FINES

Feed Screw

Reactivation Air

FRESH AIR

Wet Air

Air

Filter

Fan

Air Heater

DRY/COOLED

PRODUCT

Dry Air

Pre-Cooled Outside Air

FRESH AIR

Air

Filter

Cool / Demist

Reheat

Fan

Figure 2: Munters supplies multiple products for spray drying processes, including indirect gas-fired

heaters, heat exchangers, desiccant air dryers. All of these systems can be used to control the temperature

and humidity of the process air.

Summary

Munters dehumidification can improve the performance of the spray drying

application by providing a low moisture level to the spray dryer all year round.

The moisture in the incoming air to the desiccant is absorbed by the desiccant

rotor. The air coming off the dehumidifier system can be controlled to the desired

moisture content. As the process is exothermic, the temperature difference is

dependent on the amount of moisture removed, but can be up to 120F. This means

the spray dryer has less work to do to achieve its temperature of the entering air into

the chamber. With summer conditions, outdoor air introduces a huge quantity of

water in the spray tower. For example an outdoor air condition of 77F at 61% RH

(85 gr/lb) and an airflow of 50,000 CFM, then 2600 lbs. of water are introduced per

hour into the spray tower.

The Munters GTR rotor makes the system much more efficient. An outdoor

air condition of 77F at 61% RH (85 gr/lb) passes through the Munters system and

provides process air of 50,000 CFM at 147F and 14 gr/lb. This means only 450 lbs.

of water are introduced per hour to the spray tower a savings of almost 2200 lbs. of

water per hour. In addition over 4,000,000 BTUH is saved because of the higher air

temperature due to the dehumidification process.

With 2200 lbs. of water less per hour

introduced into the tower and a 55% slurry,

a production increase equal to 29

tons of extra powder (product)

can be produced in one summer

day. Munters equipment has been

successfully used in many spray

drying situations worldwide.

GTR Desiccant Rotor

Munters GTR Desiccant Rotor was

designed with the spray drying application

in mind. The GTR Rotor provides

greater grain depression (lower process air

moisture content) than standard desiccant

wheels when exposed to outside air. This

allows for the elimination of pre-cooling.

Another advantage of the GTR

Desiccant Rotor is the higher outlet

temperature (because of the larger

amount of moisture removed), which

can reduce the energy required for process

heating to the high temperatures that spray

dryers require.

With Munters GTR technology,

applications such as spray drying benefit

with a reduction of moisture content while

increasing the process air temperature

resulting in production increases from

1520%.

Installations include:

Nestle

Lesaffre

Sofivo

Aromes de Bretagne

Lactalis Solaipa

Spray Drying Application Guide

Munters is a global leader in

energy efficient air treatment solutions.

Munters manufactures engineered products that can economically control

humidity and temperature, provide energy recovery, and/or utilize direct or

indirect evaporative cooling for comfort, process and environmental protection.

With permanent or temporary solutions, Munters offers a wide variety of

options to meet specific climate, application and budget requirements.

Munters has net sales approaching $1 billion USD with more than 20

manufacturing facilities across the globe and sales offices in over 30 countries.

Munters employs approximately 4,300 people worldwide.

For more information see www.munters.us

Munters Corporation

Tel: (800) 843-5360 E-mail: dhinfo@munters.com www.munters.us

AG0024-00

02/10

You might also like

- TurboTax® Free Edition - Free Tax Filing, Free Taxes Online, Free Tax Return, Free EfileDocument25 pagesTurboTax® Free Edition - Free Tax Filing, Free Taxes Online, Free Tax Return, Free Efilerandy5burton940% (1)

- Herbs by Sebastian DebskiDocument9 pagesHerbs by Sebastian DebskiYakuma HotaruNo ratings yet

- Mercury (Element)Document15 pagesMercury (Element)zidaaanNo ratings yet

- 12 Cooling Load CalculationsDocument61 pages12 Cooling Load Calculationssp su100% (1)

- Borderline Personality Disorder WorksheetsDocument2 pagesBorderline Personality Disorder WorksheetsHaryo WicaksonoNo ratings yet

- Main Idea: Multiple ChoiceDocument1 pageMain Idea: Multiple ChoiceHartonoNo ratings yet

- Multiple AllelesDocument12 pagesMultiple AllelesAmy LalringhluaniNo ratings yet

- Cyclone Separator EfficiencyDocument73 pagesCyclone Separator EfficiencyHassan Faraz100% (1)

- Spray Dryer & Freeze DryerDocument20 pagesSpray Dryer & Freeze DryerHaroon RahimNo ratings yet

- 2010-Lecture 20-Spray Drying - Part I - Introduction and ComponentsDocument30 pages2010-Lecture 20-Spray Drying - Part I - Introduction and ComponentsHeartwin Amaladhas PushpadassNo ratings yet

- Indusdrial Visit in SSP PVT LTD FaridabadDocument16 pagesIndusdrial Visit in SSP PVT LTD FaridabadkedarnathvishwakarmaNo ratings yet

- General FERMENTOR PDFDocument66 pagesGeneral FERMENTOR PDFraghavan89100% (1)

- Aptis G&V Old WB Tests 1,2,3 and AnswersDocument35 pagesAptis G&V Old WB Tests 1,2,3 and AnswersOlivia Marie McardleNo ratings yet

- Two Stage Water Ring Vacuum PumpDocument24 pagesTwo Stage Water Ring Vacuum PumpHassan FarazNo ratings yet

- ECA Granulation TabletingDocument6 pagesECA Granulation Tabletingvaibhav rautNo ratings yet

- Heat ExchangersDocument43 pagesHeat ExchangersSteve WanNo ratings yet

- Munters Desiccant WheelsDocument8 pagesMunters Desiccant WheelsSerban AlexandraNo ratings yet

- INFORS HT White Paper Continuous CultureDocument6 pagesINFORS HT White Paper Continuous CulturebiocloneNo ratings yet

- Atomisation Technologies Used in - Spray Drying in The Dairy Industry - A ReviewDocument52 pagesAtomisation Technologies Used in - Spray Drying in The Dairy Industry - A ReviewTien Din TranNo ratings yet

- 10.1201 9780429055133 Previewpdf PDFDocument102 pages10.1201 9780429055133 Previewpdf PDFPipee AndreesNo ratings yet

- Spray Dryers Drynetics Brochure 2012 05 en Tcm11 29468Document4 pagesSpray Dryers Drynetics Brochure 2012 05 en Tcm11 29468qaiser khanNo ratings yet

- Agglomeration During Spray Drying Physical and Rehydration Properties of Whole Milk PDFDocument35 pagesAgglomeration During Spray Drying Physical and Rehydration Properties of Whole Milk PDFmarmaduke32No ratings yet

- Instant Coffee 9997 1323 020Document12 pagesInstant Coffee 9997 1323 020banerjeeamlanNo ratings yet

- SYMTEC ADMIX AllProdBrochureDocument20 pagesSYMTEC ADMIX AllProdBrochureRodolfo RuaroNo ratings yet

- 5l Glass FermenterDocument17 pages5l Glass FermenterRobert Jahirzinho Machaca MamaniNo ratings yet

- Features: Shanghai Lapar Control Valve Co., Ltd. Page 1 of 3 Shanghai Xianshun Machinery Co., LTDDocument3 pagesFeatures: Shanghai Lapar Control Valve Co., Ltd. Page 1 of 3 Shanghai Xianshun Machinery Co., LTDUmar MuhammadNo ratings yet

- Spray Dryer ProblemDocument2 pagesSpray Dryer Problemaravind1997murali0% (2)

- NETZSCH Steam Jet Mill S-Jet eDocument20 pagesNETZSCH Steam Jet Mill S-Jet ejojibaNo ratings yet

- Code of Practice FOR Sales and Engineering Process Plants and EquipmentDocument3 pagesCode of Practice FOR Sales and Engineering Process Plants and EquipmentparapencarituhanNo ratings yet

- VTD UrsDocument7 pagesVTD Ursproduksiqa afifarmaNo ratings yet

- A Simple Procedure For Design of A Spray DryerDocument6 pagesA Simple Procedure For Design of A Spray Dryergabriela rahayuNo ratings yet

- 11962-Encapsulated Citric AcidDocument10 pages11962-Encapsulated Citric AcidantiquekNo ratings yet

- Cooling Pipes CalculationDocument2 pagesCooling Pipes CalculationDedi KartiwaNo ratings yet

- ViscosityDocument7 pagesViscositykiran2381No ratings yet

- AlgacultureDocument9 pagesAlgacultureraghavan89No ratings yet

- Pharmaceutical BindersDocument12 pagesPharmaceutical BindersseshuksNo ratings yet

- En Sofraden Blades Mixer Mib-MicDocument4 pagesEn Sofraden Blades Mixer Mib-MicreyesdavidNo ratings yet

- Shell and Tube Heat Exchanger DesignDocument66 pagesShell and Tube Heat Exchanger DesignOmkar SutarNo ratings yet

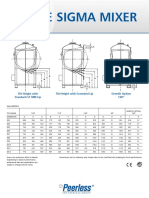

- Sigma MixerDocument2 pagesSigma Mixermmk111No ratings yet

- Instructions Design Laboratory Production Animal Vaccine Cell CultureDocument56 pagesInstructions Design Laboratory Production Animal Vaccine Cell CultureRasu KuttyNo ratings yet

- As 2913-2000 Evaporative Air-Conditioning EquipmentDocument7 pagesAs 2913-2000 Evaporative Air-Conditioning EquipmentSAI Global - APACNo ratings yet

- SSPC ChartDocument18 pagesSSPC Chartriskaanf23No ratings yet

- Technical Spec Equipment Food 23-07-2021Document184 pagesTechnical Spec Equipment Food 23-07-2021Subhra AddisNo ratings yet

- GEA Niro Pharmaceutical Spray Dryers: A Unique Union of Proven Technology and Customised SolutionsDocument16 pagesGEA Niro Pharmaceutical Spray Dryers: A Unique Union of Proven Technology and Customised SolutionsBane NikolicNo ratings yet

- Magnetkupplungen, Rührwerksantriebe Für Chemische Reaktoren: BMD Und Cyclone: Absolut Dicht, Sicher Und ZuverlässigDocument8 pagesMagnetkupplungen, Rührwerksantriebe Für Chemische Reaktoren: BMD Und Cyclone: Absolut Dicht, Sicher Und ZuverlässigJohn HaasNo ratings yet

- Hi Shear GranulatorDocument1 pageHi Shear GranulatoreddyteranvacaNo ratings yet

- 3-A Symbol Holders List - October 20, 2010: 3-A Standard Company Name Auth # City Stateorprovinc CountryDocument29 pages3-A Symbol Holders List - October 20, 2010: 3-A Standard Company Name Auth # City Stateorprovinc Countryhugo737977No ratings yet

- 06-449C R.1 PDFDocument27 pages06-449C R.1 PDFKhaqqul YaqinNo ratings yet

- Nano Spray Dryer B-90 - Literature Review and ApplicationsDocument8 pagesNano Spray Dryer B-90 - Literature Review and ApplicationsprinceamitNo ratings yet

- Gea Niro M: MOBILE MINOR™ Spray DryerDocument6 pagesGea Niro M: MOBILE MINOR™ Spray DryerCh Foo0% (1)

- Caustic Recovery Membrane FiltrationDocument9 pagesCaustic Recovery Membrane FiltrationRaghavendra Pratap SinghNo ratings yet

- Final Detailed Fermenter DesignDocument24 pagesFinal Detailed Fermenter DesignRaian Yousuf TanmoyNo ratings yet

- Foaming InstructionDocument25 pagesFoaming InstructionQuang HoangNo ratings yet

- Spray DryingDocument14 pagesSpray Dryingkunalprabhu148No ratings yet

- Fluidized Bed Dryers-Clean RoomDocument4 pagesFluidized Bed Dryers-Clean RoomSaleem Basha100% (1)

- Bio Based Chemical Fermentation Biomass Separation Evaporation Crystallization Drying GeaDocument6 pagesBio Based Chemical Fermentation Biomass Separation Evaporation Crystallization Drying GeaxinlizimuNo ratings yet

- 06-449T R.1 PDFDocument76 pages06-449T R.1 PDFKhaqqul YaqinNo ratings yet

- P180060 TC 00Document18 pagesP180060 TC 00Leon PeterNo ratings yet

- Whey Protein Nitrogen Index A21aDocument6 pagesWhey Protein Nitrogen Index A21aDinesh Kumar BansalNo ratings yet

- 10-Drying of Milk Dairy and Food EngineeringDocument7 pages10-Drying of Milk Dairy and Food Engineeringariyani yanto0% (1)

- GEA Westfalia Separator HYCONDocument1 pageGEA Westfalia Separator HYCONAbdulAbdulNo ratings yet

- Proposal For DDGS DryerDocument15 pagesProposal For DDGS Dryernirmal krisna100% (1)

- Cleaning Principles COP and CIP ProcessDocument62 pagesCleaning Principles COP and CIP ProcessFernando Tellez CordovaNo ratings yet

- Sample Refrigeration UnitDocument29 pagesSample Refrigeration UnitatiqahNo ratings yet

- NETZSCH GlassProcessing CGS eDocument2 pagesNETZSCH GlassProcessing CGS ejojibaNo ratings yet

- 1 - Niro Standard 6.01 PDFDocument10 pages1 - Niro Standard 6.01 PDFJignesh PandyaNo ratings yet

- 5 9 B Cyclone SeparatorsDocument10 pages5 9 B Cyclone SeparatorsYogie S PrabowoNo ratings yet

- Spray DryerDocument2 pagesSpray DryerMuhammad Ali Khan100% (1)

- Greenhouse Humidity Control SolutionDocument25 pagesGreenhouse Humidity Control SolutionArthur GostickNo ratings yet

- Thermophysical Properties of Seawater DWT 16 354 2010Document28 pagesThermophysical Properties of Seawater DWT 16 354 2010Hassan FarazNo ratings yet

- Mba Iii Semester Time Table (2017 - 2019) - (HR and Operation)Document1 pageMba Iii Semester Time Table (2017 - 2019) - (HR and Operation)santoshNo ratings yet

- Brochure Técnico - e-GS SeriesDocument12 pagesBrochure Técnico - e-GS SeriesAdrian CordovaNo ratings yet

- Imran Et Al 2022 Development Molecular Docking and in Silico Adme Evaluation of Selective Alr2 Inhibitors For TheDocument12 pagesImran Et Al 2022 Development Molecular Docking and in Silico Adme Evaluation of Selective Alr2 Inhibitors For TheBudi AbutNo ratings yet

- Novel Surgical Approach To AcalvariaDocument2 pagesNovel Surgical Approach To AcalvariaKezia Rachellea MustakimNo ratings yet

- Product Catalogue: PSC CorporationDocument53 pagesProduct Catalogue: PSC Corporationphuhai haizaNo ratings yet

- 2D Heat Transfer TutorialDocument180 pages2D Heat Transfer Tutorialsanojk_2000No ratings yet

- Avaliação 1 Ano 3 Trimestre CDocument3 pagesAvaliação 1 Ano 3 Trimestre CLígia ArrudaNo ratings yet

- Aquadry La-Rla EngDocument2 pagesAquadry La-Rla EngtamanogNo ratings yet

- Alnjm Pre Qualification 2022Document85 pagesAlnjm Pre Qualification 2022Anas SalamaNo ratings yet

- Schemes of Service For Clinical Officers (SMK)Document45 pagesSchemes of Service For Clinical Officers (SMK)branchardmushabeNo ratings yet

- 2017-Conte and Azmera IJARR 5 579-587Document9 pages2017-Conte and Azmera IJARR 5 579-587Pellegrino ConteNo ratings yet

- Death Penalty 1Document4 pagesDeath Penalty 1Samantha SantiagoNo ratings yet

- Pluggable Connection System picoMAX 60295981Document92 pagesPluggable Connection System picoMAX 60295981Cudritescu VictorNo ratings yet

- Battery - Containing Product Information Data Sheet: Lithium-Ion and Lithium-Ion Polymer BatteryDocument4 pagesBattery - Containing Product Information Data Sheet: Lithium-Ion and Lithium-Ion Polymer BatteryJoão Pedro AlmeidaNo ratings yet

- 0016 KJ Emails PDFDocument255 pages0016 KJ Emails PDFNickMillerNo ratings yet

- h17 - Cognos ROI Case Study - Trillium Health CenterDocument5 pagesh17 - Cognos ROI Case Study - Trillium Health CenterMike__RobertsNo ratings yet

- Pe 022-3 - 87Document20 pagesPe 022-3 - 87Radu NanuNo ratings yet

- Full Download Ebook Ebook PDF Marketing 4th Edition Australia by David Waller PDFDocument41 pagesFull Download Ebook Ebook PDF Marketing 4th Edition Australia by David Waller PDFbrenda.richardson73098% (46)

- HFRR Humidity Controlled Cabinet: Fuels and Lubricants Test EquipmentDocument19 pagesHFRR Humidity Controlled Cabinet: Fuels and Lubricants Test EquipmentWilliams MedinaNo ratings yet

- Chronic PeriodontitisDocument14 pagesChronic PeriodontitisNami RajpootNo ratings yet

- Hubungan Tungau Debu Rumah Terhadap Angka Kejadian Rinitis Alergi Yang Berobat Di Poli THT Rsud Bangli TAHUN 2019Document12 pagesHubungan Tungau Debu Rumah Terhadap Angka Kejadian Rinitis Alergi Yang Berobat Di Poli THT Rsud Bangli TAHUN 2019RiskaaNo ratings yet

- A4 Case Study Design 5 2Document7 pagesA4 Case Study Design 5 2Bautista JunNo ratings yet

- Hot Water Test ProceduresDocument18 pagesHot Water Test Procedures3piNo ratings yet