Professional Documents

Culture Documents

Bulletin PJD Collector PDF

Bulletin PJD Collector PDF

Uploaded by

mos3ad2006Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bulletin PJD Collector PDF

Bulletin PJD Collector PDF

Uploaded by

mos3ad2006Copyright:

Available Formats

FISHER-KLOSTERMAN

PULSE JET DUST COLLECTORS

A CECO Environmental Company

Standard Features

Solenoid Valve Enclosure

Timer Control

Board

Diaphragm Valve

Top loading bags

Walk-in plenum or top access

door design

Clean Air

Exhaust

Solid state sequential timers

Diaphragm Valve

Access platforms and ladders

Tube Sheet

Flanged inlet and outlet

Manometer

Compressed

Air Supply

Filter Bag

Quick opening access door

in hopper

Filter Housing

L A S S I F I surfaces

ER

PaintedC exterior

on

mild steel units

Venturi

Support legs/structure

Support Cage

Inlet can be hopper entry

or side entry

REFINERY CYCLONES

Dust

Laden Air

Hopper

Material

Discharge

APC

The Fisher-Klosterman FLOWaire Series Pulse Jet Fabric Collector is

designed to be used in a diversity of applications for the collection of

powdered materials and dusts. The Pulse Jet design has been around for

many years and is the workhorse of the dust collection industry. The keys to

successful installations are in proper sizing of the units for the application,

the selection of the filter media, the design and operation of the pulse

cleaning mechanism, and the design of the collector housing itself. At

Fisher-Klosterman, we utilize state-of-the-art design concepts and computer

design programs to optimize sizing and component selection for maximum

cost benefit and performance. We also use experience, which in many cases

is the real key to a successful application.

Guaranteed Gas Cleaning Technologies

PULSE JET DUST COLLECTORS

Typical Applications:

Steel making

Iron foundries

Cement and rock products

Wood industries

Glass making

Industrial boilers

Coal handling

Metal and plastics recycling

Food and pharmaceutical

General industrial

dust collection

Chemical Processing

Design

All standard Fisher-Klosterman FLOWaire dust collector housings are

fabricated of heavy-duty steel, all welded construction, and designed for

internal pressures of +/- 20 inches W.G. (higher design pressures available).

Support structures are designed for the full weight of the collector with all

components plus the anticipated dust load. Wind loads and seismic loads

are calculated and supplied as necessary for the equipment location. A

variety of filter fabrics are available, including pleated spun bonded polyester

filter elements, and are selected based on the application.

Custom designs are readily available to meet customer specifications.

Typical custom features:

Stainless steel and high alloy construction

High pressure or vacuum design (ASME certified with U stamp)

High temperature design and construction

Special sizes or configurations

Special internal or external finishes for food, pharmaceutical,

or chemical applications

Modular construction for field installation or future additions

Explosion venting

Sprinkler or fire suppression systems

Heat tracing

Insulation

Integrated fans

Complete systems

Replacement Parts (for all brands)

Filter bags of all materials and sizes

Cages and venturis

Diaphragm and solenoid valves

Timer boards

Gages

Repair and rebuild services

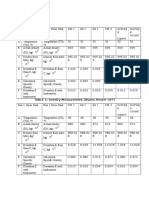

Size Availability

FISHER-KLOSTERMAN

A CECO Environmental Company

822 South 15th Street

Louisville, KY 40210

Phone: 502.572.4000

Fax: 502.572.4025

fki@fkinc.com

www.fisherklosterman.com

Sizes available are virtually unlimited.

From a small unit for a few hundred

cfm, to over one million cfm reverse

air units for foundries and steel mills,

Fisher-Klosterman has a dust collector

to meet your specifications.

2008 07/08

CLASSIFIER

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Homax Texture Gun 4610Document3 pagesHomax Texture Gun 4610dpberry100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Waterproofing GuideDocument62 pagesWaterproofing Guidejvansen67% (3)

- Databook Ch2-Ammonia PDFDocument32 pagesDatabook Ch2-Ammonia PDFjmjaravNo ratings yet

- Calidades Carbon-Grafito SCHUNKDocument2 pagesCalidades Carbon-Grafito SCHUNKcpchectorhNo ratings yet

- Subsea Engg Guide For InspectionDocument0 pagesSubsea Engg Guide For Inspectionkoib789100% (1)

- Sysmex Application Note Yeast Control ViabilityDocument6 pagesSysmex Application Note Yeast Control ViabilityNRL CMC100% (1)

- FAQ HEPAs and ULPAs Technical Bulletin - Parte2Document1 pageFAQ HEPAs and ULPAs Technical Bulletin - Parte2Nicolás VargasNo ratings yet

- Fruit BatteryDocument2 pagesFruit BatteryeyydaNo ratings yet

- Result: TABLE 1: Density Measurement (Water, Heater OFF)Document6 pagesResult: TABLE 1: Density Measurement (Water, Heater OFF)Zulfitri ZulkarnainNo ratings yet

- Practice Problems - StoichiometryDocument2 pagesPractice Problems - StoichiometryAriel Raye RicaNo ratings yet

- Hot Dip Galvanizing Design ConsiderationsDocument22 pagesHot Dip Galvanizing Design Considerationsabhi_akNo ratings yet

- Sandeep SeminarsDocument16 pagesSandeep SeminarsSandeep Mishra100% (1)

- Diesel Fuel Injection PumpsDocument10 pagesDiesel Fuel Injection PumpsRsjBugtong100% (1)

- Isolation and Characterization of CarbohydratesDocument4 pagesIsolation and Characterization of CarbohydratesJearweine FormaranNo ratings yet

- Atomic Spectroscopy and Atomic Absorption SpectrosDocument80 pagesAtomic Spectroscopy and Atomic Absorption SpectrosMuhammad Mustafa IjazNo ratings yet

- Ultraspin Oily WaterDocument3 pagesUltraspin Oily WaterAnonymous QSfDsVxjZNo ratings yet

- Cerabeads InformationDocument3 pagesCerabeads InformationDimitar PartenovNo ratings yet

- 00029487Document12 pages00029487Régis OngolloNo ratings yet

- Reference ElectrodeDocument3 pagesReference ElectrodesiapakahdirikuNo ratings yet

- Top Plant - Kajang Waste-to-Energy Plant, Semenyih, MalaysiaDocument3 pagesTop Plant - Kajang Waste-to-Energy Plant, Semenyih, MalaysiaPeter Varun DsouzaNo ratings yet

- Dental CleanserDocument7 pagesDental CleanserwahyuhidayattNo ratings yet

- LPI - Company Profile - 2022Document4 pagesLPI - Company Profile - 2022Chrisneil DelosreyesNo ratings yet

- Quantitative Determination of Acid Phosphatase (ACP)Document2 pagesQuantitative Determination of Acid Phosphatase (ACP)Ulises Benítez HernándezNo ratings yet

- UAV WingDocument5 pagesUAV WingSUNDARAMAHALINGAM ANo ratings yet

- Bohler Welding Selection GuideDocument32 pagesBohler Welding Selection GuideEh OngNo ratings yet

- Stepan Formulation 926Document2 pagesStepan Formulation 926Moaz SiddigNo ratings yet

- Densities of Various Materials As Per ASCE-10Document8 pagesDensities of Various Materials As Per ASCE-10irfanquadriNo ratings yet

- Floor Deck CatalogDocument184 pagesFloor Deck CatalogLester SonzaNo ratings yet

- PVPS Life CycleDocument105 pagesPVPS Life CyclepabloNo ratings yet

- Research On The Character and Degumming Process of Different Parts of Ramie FiberDocument11 pagesResearch On The Character and Degumming Process of Different Parts of Ramie FiberhawNo ratings yet