0% found this document useful (0 votes)

1K views12 pagesTubular Chain Conveyors: Installation and Loop Arrangements

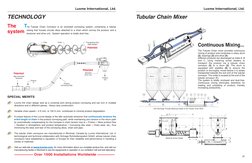

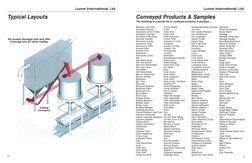

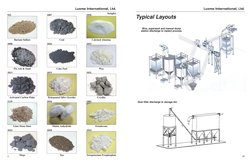

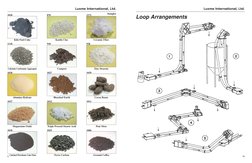

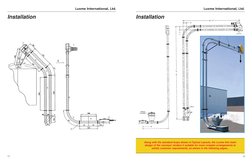

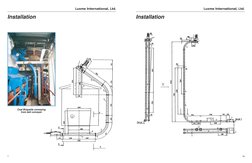

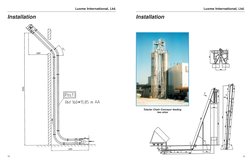

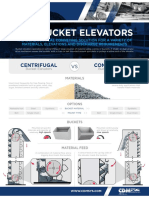

This document provides information about Luxme International Ltd., a manufacturer of tubular chain conveyors and related equipment. It includes a schematic showing 12 products they manufacture, including tubular chain conveyors in various configurations, mixers, feeders, and detectors. Sample applications and layouts are shown, along with over 100 examples of materials that can be conveyed. Installation photos depict complex arrangements of the conveyors.

Uploaded by

Ivo KovachevCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views12 pagesTubular Chain Conveyors: Installation and Loop Arrangements

This document provides information about Luxme International Ltd., a manufacturer of tubular chain conveyors and related equipment. It includes a schematic showing 12 products they manufacture, including tubular chain conveyors in various configurations, mixers, feeders, and detectors. Sample applications and layouts are shown, along with over 100 examples of materials that can be conveyed. Installation photos depict complex arrangements of the conveyors.

Uploaded by

Ivo KovachevCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Technology Overview

- Typical Layouts and Conveyed Products

- Loop Arrangements

- Installation Guidelines