Professional Documents

Culture Documents

Product Sheet SYMAP General Information - Rev - .0 PDF

Product Sheet SYMAP General Information - Rev - .0 PDF

Uploaded by

Keli KeyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Product Sheet SYMAP General Information - Rev - .0 PDF

Product Sheet SYMAP General Information - Rev - .0 PDF

Uploaded by

Keli KeyCopyright:

Available Formats

Product Sheet

SYMAP

Types Y, X, BC General information

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

Product Sheet

Microprocessor-based Protection Relays

SYMAP Product Overview

SYMAP is a flexible microprocessor-based digital protection and control device for use in low,

medium, and high-voltage power systems. Because of its integrated protection functions and humanmachine interface capabilities, it is an efficient and cost-effective solution for all types of

switchgears.With three powerful microprocessors, SYMAP offers complete protection and control

functions for generators, motors (synchronous and asynchronous), transformers, power lines, and

distributions. All protection functions can be activated simultaneously, and there are no limits in using

all of them at the same time.

With SYMAP , five main breaker controls can be activated with all the necessary functions, such as

display, control, and blocking, for optimal breaker management. A small integrated PLC allows

individual interlocks of control commands . For flexibility in commissioning and during use, both digital

and analog outputs can be used to connect the SYMAP control unit to main switchboard controls.

Additionally, a variety of serial interfaces with different kinds of data protocols can be used for

communication between SYMAP units and the central control system.

For diagnostics and monitoring, SYMAP has three microprocessors which supervise each other, and

providing a watchdog system. Important functions are laid out in a double redundancy combination,

operating independently with the second processor. Connected separately, an optional unit for short

circuit protection operates parallel to the SYMAP device and will do so even if the power supply fails.

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

Product Sheet

SYMAP Human Machine Interface

SYMAP is easy to program and operate. A large graphic LCD with optional LED indicators conveys

important data, such as position of all connected breakers, parameter settings, and event history, at

a glance. Graphics and measurement data are displayed side-by-side on the LCD, and the user does

not have to switch between pages.

The programming is built in and is menu-tree driven, making setting parameters an intuitive process.

Beside the option of doing the whole device configuration by application software SYMAP

Parameter Tool (SPT), it is possible to set all available parameters by the keys of the front panel.

Using a laptop offers certain advantages, such as parameter data stored in the laptop can be easily

input into other SYMAP units. Either way, ease of programming is guaranteed and on-site visits by

the manufacturer's engineers during commissioning are not required.

SYMAP provides four hotkeys under the LCD offering access to four groups of values:

-

Meters

Alarm

Process

Breaker Control

The user can press the hotkeys to scroll through pages of information pertaining to these values.

Under the hotkey "Meters," detailed information of electric measurement values, counters for active

and reactive power, and working hours is provided. Byr the hotkey "Alarms," all active alarms, event

stores, and blockings are displayed. Under "Process," all process data, such as synchronization

display, motor thermal indication, and breaker counters, are shown. Under "Breaker Control," up to

five breakers can be accessed and controlled. When programming breaker controls, the user has

access to various layout configurations which are available through a library of graphics maintained

within SYMAP . Programmed blockings remain active when manual control of the breaker is used.

Furthermore, each of the highlighted breakers in the LCD can be controlled by the keys "O" and "I."

For security purpose, access to SYMAP 's parameters and breaker control data of SYMAPis

protected by a code system. The code system offers dual access: by a transponder card or by

password input.

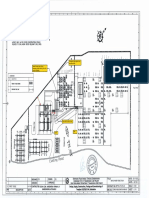

SYMAP Terminal Connections

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

Product Sheet

All connections to SYMAP are made with terminal plugs on the back of the device, allowing the

device to be exchanged easily. The terminal blocks are divided into four groups.

Analog Voltage and Current Measurement

SYMAP provides various analog inputs for voltage and current measuring by conventional potential

transformers (PTs) and current transformers (CTs) at the rear of the device. If terminal plugs for the

CTs are disconnected, the circuits will be linked automatically, thus, there is no disconnection in the

CT circuit loops. A total of 17 analog inputs for current and voltage transformers are used for

protection functions. The following list shows possible connections for CTs and PTs:

-

3 x CT for feeder current

3 x CT for differential current

2 x CT for ground current

3 x PT for feeder voltage

3 x PT for bus bar 1 voltage

3 x PT for bus bar 2 voltage

2 x PT for ground voltage

In case of using combined sensors, SYMAP provides:

3 x for feeder current

3 x for feeder voltage

Communication

SYMAP can serve as the main bay controller for the power management system or substation

system. The following list shows the station system items offered by SYMAP:

Remote supervision

Remote control

Remote parameter setting

Central registration of measured and calculated values

Central event logging

Central fault recording, analysis and logging

Plant power management

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

Product Sheet

COMMUNICATION INTERFACES

SYMAP can serve as the main bay controller for the power management system or substation

system. It provides communication ports available with the following interfaces:

RS 232 on the front panel for programming and data output

1 CANBUS 1 (factory protocol)

1 CANBUS 2 for engine

RS422/RS485 port port (Modbus RTU)

iber optic interfaces (Line diff. Protection / SCADA)

PROTOCOLS

CANBUS 1 (factory protocol)

CANBUS 2 (engine control: CATERPILLAR, DEUTZ, MTU, VOLVO, ...)

PROFIBUS DP

MODBUS RTU

IEC60870-5-103

IEC61850

Extended Board (Optional)

An extended board can be connected to SYMAP , providing additional input and output channels.

The extended board is customized to individual client requirements and can be equipped with a

maximum of the following input and output channels:

36 digital inputs

24 relay outputs

8 analog outputs 4...20 mA

21 analog inputs PT 100 / PT 1000 or analog inputs 4...20 mA

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

Product Sheet

SYMAP Recording unit

SYMAP 's recording unit contains up to three separate parts:

1)

2)

3)

Event history,

Detailed protection function history

Event data recorder (optional)

Regardless of power supply, data are to be saved in the non-volatile memory. All data recorded

SYMAP can be transferred and analysed via application software SYMAP Parameter Tool (SPT)

Protection function events, such as activation and eventual intervention

The change of binary inputs and outputs

The control of Local/SCADA

The change of each switching device

ON/OFF commands by central power management system

Any attempt or trail to give a command prohibited by interlocking

Any alarm signal (also from diagnostics)

Data logs for measurement inputs

Event History

SYMAP automatically collects and stores all activated events indicating their number, title,

coming/going status, and time stamp. A maximum of 5,000 events can be stored. In case of overflow,

data overwriting operates according to the first-in-first-out (FIFO) principle.

Detailed Protection Function History

SYMAP automatically collects and stores all activated events referring to protection functions with a

time stamp.

Event number

Event title

Time stamp

Pickup or trip value (with fault phase indication)

Setting value

Trip time

3-line voltage and current pickup, synchronized with the trip event

A maximum of 1,000 protection function events can be stored. In case of overflow, data overwriting

operates according to the first-in-first-out (FIFO).

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

Product Sheet

Data Recorder (Optional)

The data recorder can log 16 analog inputs, 14 digital inputs, and 12 digital outputs. The recorder has

the following settings:

-

Number of samples (6 - 72)

Recording period (5 - 60 sec)

Pre-trigger (0 - 100%)

Trigger event (stop for recorder)

The recording period depends on the set number of samples. The recorder can be set with a pretrigger time to log the faultless period of a fault, too. Stopping the recorder can be triggered either

by an event or by a pre-set time. For easier management and trouble-shooting, event data can be

transferred and analysed via PC or notebook. A serial interface on the SYMAP front panel serves as

a communication port.

Diagnostics and Monitoring

SYMAP has three microprocessors that supervise each other, providing a watchdog system.

Important functions are laid out in a double redundancy combination, operating independently with

the second processor. Connected separately, an optional unit for short circuit protection operates

parallel to the SYMAP device and will do so even if the entire voltage fails. SYMAP provides various

diagnostic and monitoring functions as follows:

-

All memories (ROMs, RAMs, EEPROMs)

All analog reference voltages

Automated test sequences

Control power ON/OFF of SYMAP

Binary input and output for control logic

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

Product Sheet

The following supervising systems are offered by SYMAP :

-

Self-diagnostics of SYMAP

The inputs of analog data (auxiliary circuit)

The status and position of switching device and motor's on-off status

Supervising supply of trip coil

Gas pressure

Temperature inside panel

Each operating life of breaker (hours)

SYMAP Digital Protection Device

There are three type of SYMAP units as follows:

-

SYMAP -Y Essential cost type

SYMAP -X Basic type

SYMAP -BC Basic type expanded to include LED indicators,

www.stuckegroup.com

PS.SYMAP.GI.ENG.REV0

You might also like

- All LCD - LED Panel VoltageDocument4 pagesAll LCD - LED Panel VoltageAndyservo82% (17)

- N&V 2012-01Document84 pagesN&V 2012-01Eugene Lisovy100% (4)

- Fiac Airblok 10-30Document60 pagesFiac Airblok 10-30Keli Key67% (3)

- Flyer SYMAP-BC, BCG, X, XG, Y PDFDocument11 pagesFlyer SYMAP-BC, BCG, X, XG, Y PDFxvehicleNo ratings yet

- 7SJ61 63Document104 pages7SJ61 63Mahasan Ahmad0% (1)

- Ankit Sharma PTSDocument37 pagesAnkit Sharma PTSankitsharma14101990100% (1)

- SM6 BrocDocument12 pagesSM6 Brocsubidubi99No ratings yet

- Protection & Control Sepam 1000 PCRED399039ENDocument73 pagesProtection & Control Sepam 1000 PCRED399039ENmikearkellNo ratings yet

- Dkg-317 Manual and Remote Start Unit: DescriptionDocument2 pagesDkg-317 Manual and Remote Start Unit: DescriptionThao Nguyen XuanNo ratings yet

- Genset AMF Controller DKG-309Document2 pagesGenset AMF Controller DKG-309SAMEERNo ratings yet

- 6-Channel Monitor: Rev. GDocument23 pages6-Channel Monitor: Rev. GJavier BushNo ratings yet

- Dkg-309J Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-309J Automatic Mains Failure Unit With J1939 Interface: DescriptionThao Nguyen XuanNo ratings yet

- DE 3000 BrochureDocument4 pagesDE 3000 BrochureJerNo ratings yet

- 3G3 Variador de FrecuenciaDocument12 pages3G3 Variador de Frecuenciabrand10No ratings yet

- 1 Intro, S1, MaintDocument35 pages1 Intro, S1, MaintOsman AhmedNo ratings yet

- Data Sheet PDFDocument13 pagesData Sheet PDFFabio JuniorNo ratings yet

- DKG-109J Automatic Mains Failure Unit: Canbus VersionDocument2 pagesDKG-109J Automatic Mains Failure Unit: Canbus VersionNazmin ZulbadliNo ratings yet

- Programmable Scheme Logic: Disturbance RecordsDocument1 pageProgrammable Scheme Logic: Disturbance RecordskarthikNo ratings yet

- Dst4601px Dichron Eng Rev 1Document4 pagesDst4601px Dichron Eng Rev 1Mohand Oubélaid Ait HammouNo ratings yet

- Protective Relays and Trip UnitsDocument23 pagesProtective Relays and Trip UnitsMancamiaicuruNo ratings yet

- Flyer BlueLine Rev-05 enDocument8 pagesFlyer BlueLine Rev-05 enajaysapruNo ratings yet

- Relay 543 - 545 ManualDocument70 pagesRelay 543 - 545 ManualVenkatesh Rao100% (2)

- Siemens Pac3200 4200Document12 pagesSiemens Pac3200 4200Anonymous Y6Mrs88No ratings yet

- REM 543 Motor Protection Relay: ApplicationDocument24 pagesREM 543 Motor Protection Relay: ApplicationPrateek SinghNo ratings yet

- Sicam PDocument16 pagesSicam PFlo Mirca100% (1)

- Intelilite NT Mrs19 Leaflet 07-2010 S2leilnt19Document2 pagesIntelilite NT Mrs19 Leaflet 07-2010 S2leilnt19balajiboss005No ratings yet

- World of Industrial Applications Brochure 2011-02 CPCEIDAPDocument44 pagesWorld of Industrial Applications Brochure 2011-02 CPCEIDAPMarcelo Palacios SantanaNo ratings yet

- Machine Terminals REM 543 REM 545: Product GuideDocument70 pagesMachine Terminals REM 543 REM 545: Product Guidemad_sam282729No ratings yet

- 743CBDocument16 pages743CBTenza Zangetsu MaetNo ratings yet

- Altronic de 3000Document93 pagesAltronic de 3000Mohammad AliNo ratings yet

- Over View On Section MillDocument137 pagesOver View On Section MillMustafa Mahmoud AwwadNo ratings yet

- 327 DatatakomDocument2 pages327 DatatakomNorman RuizNo ratings yet

- Siemens Sipart DR19 ControllersDocument18 pagesSiemens Sipart DR19 Controllersdaniel builesNo ratings yet

- GRR 100Document16 pagesGRR 100Basim Al-AttarNo ratings yet

- 09 # Flexible Motor ControlDocument4 pages09 # Flexible Motor ControlRaj ChavanNo ratings yet

- MPR 6 Instruction Manual SolconDocument26 pagesMPR 6 Instruction Manual Solconcchung147554No ratings yet

- Mark VieDocument4 pagesMark VieWalid Bahi100% (1)

- Numerical Generator Protection Reg216 Reg216 ClassicDocument52 pagesNumerical Generator Protection Reg216 Reg216 ClassicRaviteja NowduruNo ratings yet

- Control Systems Product GUIDE - Ing PDFDocument2 pagesControl Systems Product GUIDE - Ing PDFtecnigenelecNo ratings yet

- 1 Megabit (128 K X 8-Bit) CMOS 5.0 Volt-Only, Uniform Sector Flash MemoryDocument31 pages1 Megabit (128 K X 8-Bit) CMOS 5.0 Volt-Only, Uniform Sector Flash MemoryJavier BendekNo ratings yet

- ControlDocument5 pagesControlamerquipNo ratings yet

- Industrial Security System Using Microcontroller Regulated Power SupplyDocument6 pagesIndustrial Security System Using Microcontroller Regulated Power Supplynaveenraj111No ratings yet

- ABB Unitrol 6800 Brochure PDFDocument12 pagesABB Unitrol 6800 Brochure PDFhvhung165No ratings yet

- Katalog SIMEAS P enDocument9 pagesKatalog SIMEAS P eniwan.satyaNo ratings yet

- PLC IntroductionDocument18 pagesPLC IntroductionVictorNo ratings yet

- InteliATS NT DatasheetDocument4 pagesInteliATS NT DatasheetasuhuaneNo ratings yet

- CMG-5TD Manual Rev BDocument73 pagesCMG-5TD Manual Rev BGianfrancoJuarezNo ratings yet

- InteliCompact NT Datasheet 2011-11 CPLEICNTDocument6 pagesInteliCompact NT Datasheet 2011-11 CPLEICNTThao Nguyen XuanNo ratings yet

- DATAKOM DKG109 DatasheetDocument2 pagesDATAKOM DKG109 DatasheetWilliam FlorezNo ratings yet

- Dkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionDocument2 pagesDkg-547 Automatic Mains Failure Unit With J1939 Interface: DescriptionabotalebNo ratings yet

- Data Sheet r11Document15 pagesData Sheet r11Roberto Carlos Alvarez VidalNo ratings yet

- SCADAFlex Distributed Control System SPECDocument2 pagesSCADAFlex Distributed Control System SPECnaveedfndNo ratings yet

- 3 7Document2 pages3 7JoshSancho9No ratings yet

- Erl Scada BrochureDocument12 pagesErl Scada BrochureBehzadNo ratings yet

- PLC Scada IndustrialDocument36 pagesPLC Scada IndustrialAnmolNo ratings yet

- Preliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960From EverandPreliminary Specifications: Programmed Data Processor Model Three (PDP-3) October, 1960No ratings yet

- PLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.From EverandPLC: Programmable Logic Controller – Arktika.: EXPERIMENTAL PRODUCT BASED ON CPLD.No ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Vdocuments - MX - Iet600 Training Rev 02 PDFDocument24 pagesVdocuments - MX - Iet600 Training Rev 02 PDFKeli KeyNo ratings yet

- XP Embedded Boot Options JonesDocument66 pagesXP Embedded Boot Options JonesKeli KeyNo ratings yet

- Get 20048Document17 pagesGet 20048Keli KeyNo ratings yet

- Gek 106310ahDocument1,052 pagesGek 106310ahKeli KeyNo ratings yet

- The IEC 61499 Standard. Concepts and R&D ResourcesDocument78 pagesThe IEC 61499 Standard. Concepts and R&D ResourcesKeli KeyNo ratings yet

- SRV02-Series Ball & Beam: Student HandoutDocument13 pagesSRV02-Series Ball & Beam: Student HandoutKeli KeyNo ratings yet

- NEW Owners Manual RITTIUM 7 Metalsheet VersionDocument24 pagesNEW Owners Manual RITTIUM 7 Metalsheet VersionKeli KeyNo ratings yet

- CyBro Components PosterDocument1 pageCyBro Components PosterKeli KeyNo ratings yet

- 9 Ball and BeamDocument15 pages9 Ball and BeamshaheerdurraniNo ratings yet

- Relay ProtectionDocument1 pageRelay ProtectionKeli KeyNo ratings yet

- Precision-M4600 Service Manual En-UsDocument142 pagesPrecision-M4600 Service Manual En-UsKeli KeyNo ratings yet

- NRJED312404EN Internal Pages PrintDocument105 pagesNRJED312404EN Internal Pages PrintKeli KeyNo ratings yet

- DSP - Nov 19 Q&a PDFDocument17 pagesDSP - Nov 19 Q&a PDFAnonymous yO7rcec6vuNo ratings yet

- DNSD 339 FDocument2 pagesDNSD 339 FrajeshdaveNo ratings yet

- Keystation 49: 49-Key Mobile USB MIDI ControllerDocument1 pageKeystation 49: 49-Key Mobile USB MIDI ControllerAlf MegsonNo ratings yet

- Communication BooksDocument7 pagesCommunication BooksKishore CkNo ratings yet

- Digital Audio TheoryDocument5 pagesDigital Audio Theorymws_97No ratings yet

- Switchyard Fence Drawing DetailsDocument2 pagesSwitchyard Fence Drawing DetailsSagun KatuwalNo ratings yet

- 7UM62 Installation Instr 02Document6 pages7UM62 Installation Instr 02Eduardo Garcia PNo ratings yet

- Prepaid Insurance CalculatorDocument7 pagesPrepaid Insurance Calculatorpradhan13No ratings yet

- DX DiagDocument11 pagesDX DiagzelijeNo ratings yet

- FinalDocument28 pagesFinalSupriya GPNo ratings yet

- Lab 7 v2Document9 pagesLab 7 v2ali basitNo ratings yet

- Ti Slma002 Power PadDocument45 pagesTi Slma002 Power Padjcristhian_1No ratings yet

- Fisher RS1060 RS1080Document28 pagesFisher RS1060 RS1080Cco BogdanNo ratings yet

- Hochspannungstastköpfe High Voltage Probes: TT-HVP 15HfDocument1 pageHochspannungstastköpfe High Voltage Probes: TT-HVP 15HfCucu CatalinNo ratings yet

- Tuning of Power System StabilizerDocument31 pagesTuning of Power System StabilizerRajesh PrasadNo ratings yet

- Type SCA50: Automation / StandardDocument5 pagesType SCA50: Automation / StandardPaulo PauladaNo ratings yet

- Ch35 Manual enDocument2 pagesCh35 Manual enStewart ChimkomolaNo ratings yet

- Pci & Pci-E Sephiroth Kwon Grma 2009-05-26.Document32 pagesPci & Pci-E Sephiroth Kwon Grma 2009-05-26.Flaviano Costa SilvaNo ratings yet

- Graphic Recorder - GR200 SeriesDocument4 pagesGraphic Recorder - GR200 Seriesrolando ojedaNo ratings yet

- DigitalMatrix CatalogDocument24 pagesDigitalMatrix CatalogNarcis PatrascuNo ratings yet

- 2.1m New RRZZHHTTS4-65B-R8N Product SpecificationsDocument6 pages2.1m New RRZZHHTTS4-65B-R8N Product SpecificationsConor RyanNo ratings yet

- Extra: Battery Chargers and Expansion ModulesDocument2 pagesExtra: Battery Chargers and Expansion Modulessammy muisyoNo ratings yet

- Using The Serial Peripheral Interface (SPI) Module On 68HC (9) 08 MicrocontrollersDocument8 pagesUsing The Serial Peripheral Interface (SPI) Module On 68HC (9) 08 MicrocontrollersJackson Dias RochaNo ratings yet

- Spurious Emissions Are Emissions, Which Are Caused by Unwanted TransmitterDocument3 pagesSpurious Emissions Are Emissions, Which Are Caused by Unwanted TransmitterAnuj ThakurNo ratings yet

- Agilent PN 8590-10 Obtaining Analog Spectrum Analyzer Characteristics With A Digital DisplayDocument3 pagesAgilent PN 8590-10 Obtaining Analog Spectrum Analyzer Characteristics With A Digital Displayporchop58No ratings yet

- Parallel Installation Guide: 4KVA/5KVADocument6 pagesParallel Installation Guide: 4KVA/5KVAAlberto GanelaNo ratings yet

- Chaitanya Cadence TutorialDocument98 pagesChaitanya Cadence TutorialSaravanan NsNo ratings yet

- Power InverterDocument11 pagesPower Inverterriz2010No ratings yet