Professional Documents

Culture Documents

Methyl Tertiary Butyl Ether MTBE Full Report PDF

Methyl Tertiary Butyl Ether MTBE Full Report PDF

Uploaded by

Trà ĐáOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Methyl Tertiary Butyl Ether MTBE Full Report PDF

Methyl Tertiary Butyl Ether MTBE Full Report PDF

Uploaded by

Trà ĐáCopyright:

Available Formats

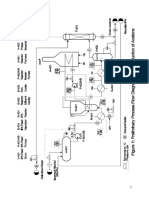

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

MEMBER OF GROUP AND SUPERVISORS

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

ACKNOWLEDGEMENT

First and foremost, thank you to Allah S.W.T for giving us the strength to finish up this

project report. Without Your Willingness we would not be able to complete this project.

It would be impossible to acknowledge adequately all the people who have been

influential, directly or indirectly in forming this project.

We would like to take this opportunity to express our deepest gratitude to our

supervisors, Encik Mohd Imran Bin Zainuddin and Puan Sunita Binti Jobli who has

given us his constant encouragement constructive advises and his patient in

monitoring our progress in this project.

Our appreciation and special thanks goes, Puan Hasnora Binti Jafri, Puan Junaidah

Binti Jai, Encik Aziz Bin Ishak for supplying the valuable information and guidance for

this project.

We greatly indebted to Encik Napis Bin Sudin for his cooperation and willingness to be

interviewed and for provide us with invaluable information and for his resourcefulness

in gathering material.

Special thanks owe to Puan Masni Bt Ahmad for her willingness to be interviewed and

for the painstaking care she has shown in assisting us throughout the project.

We also would like to express our appreciation to the Malaysia Industrial Development

Authority (MIDA), Pusat Informasi Sirim Berhad, Petronas Resource Center, Jabatan

Perangkaan Malaysia and Tiram Kimia Sdn.Bhd. (Kuala Lumpur) for their generous

supply of relevant documents and material needed research.

Last but not least to all my lecturers, family, friends and collegues for their

encouragement and kind support when we need it most.

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

ABSTRACT

The purpose for this MTBE or Methyl tertiary Butyl Ether plant is to produce 300,000

metric tonne/year. MTBE is the simplest and most cost effective oxygenate to produce,

transport and deliver to customers. The additive works by changing the oxygenate /

fuel ratio so that gasoline burns cleaner, reducing exhaust emissions of carbon

monoxide, hydrocarbons, oxides of nitrogen, fine particulates and toxic. Two units will

be considered which are the fluidizations, (Snamprogetti) Unit and the Etherification

Unit. The raw materials used are isobutane, methanol, and water as feedstock. In

addition, two types of catalysts are chromia alumina catalyzed compound in

Snamprogetti Unit, while sulphonic ion exchanged resin catalyzed is used in the MTBE

reactor. A good deal of catalyst has been devoted to improve the activity, selectivity,

and the lifetime of the catalysts.

In the Design Project 2, we emphasize in the individual chemical and mechanical

designs for selected equipments in the plant. The chosen equipments are Catalytic

Cracking Reactor, Multitubular Fixed Bed Reactor, MTBE Distillation Column, LiquidLiquid Extraction Column and Heat Exchanger.

Design Project 2 also includes Process Control, Safety, Economic Evaluation, Process

Integration and as well as Waste Treatment, which are considered as group works.

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

CONTENTS

TITLE

PAGE

DECLARATION

II

CERTIFICATION

III

ACKNOWLEDGEMENT

ABSTRACT

VI

LIST OF TABLES

LIST OF FIGURES

LIST OF NOMENCLATURES

REPORT 1

CHAPTER 1 PROCESS BACKGROUND AND INTRODUCTION

1.1 Introduction

1.2 Historical Review of MTBE Production Process

1.2.1 UOP Oleflex Process

1.2.2 Philips Star Process

1.2.3 ABB Lummus Catofin Process

1.2.4 Snmprogetti Yartsingtez FBD Process

1

2

3

3

3

4

CHAPTER 2 PROCESS SELECTION

2.1

2.2

Method Consioderation

Detailed Process Description

2.2.1 Snaprogetti Yarsingtez fbd Process

2.2.2 MTBE Unit

2.2.3 Distillation Column Unit

2.2.4 Liquid-Liquid Extraction Unit

5

7

7

8

8

9

CHAPTER 3 ECONOMIC SURVEY

3.1

3.2

3.3

3.4

Market Survey

3.1.1 World Market

Asia Market

Demand

Production Capacity

10

10

11

11

14

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

3.5

3.6

3.7

Supply

Market Price

3.6.1 Methanol

3.6.2 Isobutane

3.6.3 Catalyst

3.6.4 Conclusion

Economic Analysis

3.7.1 Break Even Analysis

3.7.2 Data Calculation1

14

15

15

16

16

16

17

17

20

CHAPTER 4 PLANT LOCATIONS & SITE SELECTION

4.1

4.2

4.3

4.4

Plant Location

24

General Consideration On the site Selection

24

4.2.1 Location with Respect To Marketing Area 25

4.2.2 Raw Material supply

25

4.2.3 Transport Facilities

25

4.2.4 Availability Of Labor

25

4.2.5 Availability Of Utilities

26

4.2.6 Environmental Impact and Effluent Disposal 26

4.2.7 Local Community Considerations

26

4.2.8 Land (Site Consideration)

26

4.2.9 Political and Strategic Consideration

27

Overview on Prospective Locations

27

4.3.1 Teluk Kalong

28

4.3.2 Tanjung Langsat

28

4.3.3 Bintulu

29

Conclusion

33

CHAPTER 5 ENVIRONMENTAL CONSIDERATION

5.1

5.2

5.3

Introduction

Stack gas

5.2.1 Gas Emission treatment

Wastewater Treatment

5.3.1 Wastewater characteristic

5.3.1a) Priority pollutants

5.3.1b) Organic

5.3.1c) Inorganic

5.3.1d) pH and Alkalinity

5.3.1e) Temperature

5.3.2 Liquid waste treatment

5.3.2a) Equalization treatment

5.3.2b) Solid waste treatment

5.3.3 Waste Minimization

34

35

35

35

35

36

36

37

37

38

38

38

39

41

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

CHAPTER 6 SAFETY CONSIDERATION

6.1

6.2

6.3

Introduction

42

Material Safety Data Sheet

43

6.2.1 Isobutane

43

6.2.1.1 Product Information

43

Physical & Chemical Properties

43

6.2.1.2 Immediate Health Effects

44

6.2.1.3 First Aid Measure

44

6.2.2 N-Butane

44

6.2.2.1 Handling and Storage

45

6.2.3 Methanol

45

6.2.4 MTBE

46

6.2.4.1 Physical State and Appearance46

6.2.4.2 Physical Dangers

46

6.2.4.3 Chemical Dangers

47

6.2.4.4 Inhalation Risks

47

6.2.5 TBA

47

6.2.5.1 Recognition

48

6.2.5.2 Evaluation

48

6.2.5.3 Controls

48

Hazard Identification & Emergency Safety & Health Risk 49

CHAPTER 7 MASS BALANCE

7.1

7.2

7.3

7.4

7.5

7.6

7.7

7.8

7.9

Snamprogetti -Yarsingtez FBD Unit

Separator

Mixer

MTBE Reactor

7.4.1 1st Reaction in rector

7.4.2 2nd Reaction in reactor

7.4.3 3rd Reaction in reactor

7.4.4 Overall reaction

Distillation Column

Liquid Extraction Column

Distillation Column

Overall reaction system; flow diagram

Scales Up Factor

51

53

53

54

55

56

57

58

59

60

61

62

63

CHAPTER 8 ENERGY BALANCES

8.1

8.2

Energy Equation

Energy balance: Sample of calculation

8.2.1 Pump 1

8.2.2 Cooler 1

8.2.3 Separator

8.2.4 MTBE Reactor

8.2.5 Pump 2

64

65

73

75

76

78

79

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

8.2.6

8.2.7

8.2.8

8.2.9

8.2.10

8.2.11

8.2.12

8.2.13

8.2.14

8.2.15

8.2.16

Mixer

Expander 1

Cooler 1

Distillation Column 1

Cooler 2

Pump 3

Extraction Column

Pump 4

Pump 5

Distillation Column 2

Cooler 3

CHAPTER 9 HYSYS

80

81

82

84

86

87

88

89

91

92

93

95

APPENDICES

REPORT 2

CONTENTS

PAGE

CHAPTER 1 CHEMICAL DESIGN AND MECHANICAL DESIGN

SECTION 1 CATALYTIC CRACKING DESIGN

2.2

1.1

Introduction

1.2

Estimation of Cost Diameter of Reactor

1.3

Calculation of TDH Height

1.4

Minimum Fluidization Velocity

1.5

Calculation for Terminal Velocity

1.6

Find the Value Kih

1.7

Find the value Eo

1.8

Calculation of Solid Loading

1.9

Calculation for Holding Time

1.10 Calculation for Pressure Drop

1.11 Determine the Direction and Flowrate

1.12 Design of Cyclone

1.13 Calculation for Mechanical Design

Mechanical Design

2.2.1

Introduction

2.2.2

Design stress

2.2.3

Welded Joint Efficiency

1

3

4

4

5

8

9

10

12

14

15

17

21

58

59

59

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

2.2.4

2.2.5

2.2.6

2.2.7

2.2.7.1

2.2.8

2.2.9

2.2.10

2.2.11

2.2.12

2.2.13

2.2.14

2.2.15

2.2.16

2.2.17

2.2.18

2.2.19

2.2.20

2.2.21

Corrosion allowance

Minimum thickness of cylindrical section of shell

Minimum thickness of domed head

Loading stress

Dead weight load

1.2.7.1

Dead Weight of Vessel

1.2.7.2

Weight of the Tubes

1.2.7.3

Weight of Insulation

1.2.7.4

Weight of Catalyst

1.2.7.5

Total Weight

1.2.7.6

Wind Loading

1.2.7.7

Analysis of Stresses

Dead Weight Stress

Bending Stress

Radial Stress

Check Elastic Stability

Vessel Support

Skirt Thickness

Height of the Skirt

Bending Stress at Base of the Skirt

Bending Stress in the Skirt

Base Ring and Anchor Bolt Design

Compensation for Opening and Branches

Compensation for Other Nozzles

Bolted Flange Joint

2.2.20.1

Type of Flanges Selected

2.2.20.2

Gasket

Flange face

SECTION 3

3.1

3.2

3.3

3.4

59

59

60

61

61

61

62

62

63

63

63

64

65

65

66

67

68

68

69

70

70

71

73

74

74

74

75

75

MTBE DISTILLATION COLUMN

Introduction

Selection f Construction Material

Chemical Design

3.3.1 Determine the Number of Plate

3.3.2 Determination of Number of Plate

3.3.3 Physical Properties

3.3.4 Determination of Column Diameter

3.3.5 Liquid Flow Arrangements

3.3.7 Plate Layout

3.3.8 Entrainment Evaluation

3.3.9 Weeping Rate Evaluation

3.3.13 Number of Holes

3.3.14 Column size

Mechanical Design

3.4.1 Material construction

3.4.2 Vessel Thickness

3.4.3 Heads and closure

3.4.4 Total Column Weight

78

79

79

81

88

89

89

90

91

91

94

95

96

98

98

99

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

3.5

3.4.5 Wind Loads

3.4.6 Stiffness Ring

Vessel Support Design

SECTION 4

4.1

4.2

4.3

5.1

5.2

5.3

DESIGN OF LIQUID-LIQUID EXTRACTION COLUMN

Introduction

Chemical Design

4.2.1 Choice of Solvent

4.2.2 Estimation the Physical Properties

4.2.3 Determination the Number of Stage

4.2.4 Sizing of Sieve Tray

4.2.5 Number of Holes

4.2.6 Column Parameter

4.2.7 Weeping Evaluation

Mechanical Design

4.3.1 Material Construction

4.3.2 Vessel Thickness

4.3.3 Design of Domed Ends

4.3.4 Column Weight

4.3.4.1 Dead Weight of Vessel

4.3.4.2 Weight of Plate

4.3.4.3 Weight of Insulation

4.3.4.4 Total weight

4.3.4.5 Wind Loading

4.3.5 Analysis of Stress

4.3.5. 1 Longitudinal & Circumferential Pressure Stress

4.3.5.2 Dead weight

4.3.5.3 Bending Stress

4.3.5.4 Buckling

4.3.6 Vessel Support Design

4.3.6.1 Skirt Support

4.3.6.2 Base Ring and Anchor

4.3.7 Piping Sizing

SECTION 5

100

100

100

103

104

104

104

105

107

107

107

108

110

111

111

112

112

113

113

113

114

114

115

115

115

115

116

117

117

119

122

HEAT EXCHANGER DESIGN

Introduction

5.1.1 Designing the heater

Chemical Design

5.2.1 Physical Properties of the Stream

5.2.2 The Calculation

5.2.3 Number of Tubes Calculation

5.2.4 Bundle and Shell Diameter

5.2.5 Tube Side Coefficient

5.2.6 Shell Side Coefficient

5.2.7 Overall Heat Transfer Coefficient

5.2.8 Tube Side Pressure Drop

5.2.9 Shell Side pressure Drop

Mechanical Design

5.3.1 Design Pressure

127

129

130

130

131

133

134

135

137

139

140

140

142

142

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

5.3.2

5.3.3

5.3.4

5.3.5

5.3.6

5.3.7

5.3.8

5.39

5.3.10

5.3.11

5.3.12

5.3.13

5.3.14

5.3.15

Design Temperature

Material of Construction

Exchanger Type

Minimum Thickness

Longitudinal Stress

Circumferential Stress

Minimum Thickness of Tube wall

Minimum Thickness of Head and Closure

Minimum Thickness of the Channel Cover

Design Load

Pipe Size Selection for the Nozzle

Standard Flanges

Design Of Saddles

Baffles

142

142

143

143

144

144

144

145

146

147

150

150

152

152

CHAPTER 2 PROCESS CONTROL AND INSTRUMENTATION

2.1

2.2

2.3

Introduction

Objective of control

Control system design sheet

2.3.1 Heat Exchanger

2.3.2 Catalytic cracking fluidized bed reactor

2.3.3 Compressor

2.3.4 Condenser

2.3.5 Separator

2.3.6 Fixed bed reactor

2.3.7 Distillation Column

2.3.8 Liquid -liquid extraction Column

2.3.9 Distillation Column

2.3.10 Mixer

2.3.11 Expander

154

155

156

156

157

158

159

160

161

162

163

164

165

166

CHAPTER 3 SAFETY CONSIDERATION

3.1

3.2

3.3

3.4

Introduction

Hazard and Operability Study

Plant Start Up and Shut Down Procedure

3.3.1 Normal Start Up and Shut Down the Plant

3.3.1.1 Operating Limits

3.3.1.2 Transient Operating and Process Dynamic

3.3.1.3 Added Materials

3.3.1.4 Hot Standby

3.3.1.5 Emergency Shut Down

3.3.2 Start up and Shut down Procedure for the main

Equipment

3.3.2.1 Reactor

3.3.2.2 Distillation Column

3.3.2.3 Liquid-Liquid Extraction Column

3.3.2.4 Heat Exchanger

Emergency Response Plan (ERP)

167

168

170

171

171

172

172

172

172

172

172

173

174

175

175

10

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

3.5

3.4.1 Emergency Response Procedures

3.4.2 Evacuation Procedures

3.4.3 Fires

3.4.4 Explosion, Line Rupture or Serious Leak

3.4.5 Other Emergencies

Plant Layout

176

176

177

177

177

178

CHAPTER 4 ECONOMIC EVALUATION

4.1

4.2

4.3

4.4

Introduction

Cost Estimation

Profitability Analysis

4.3.1 Discounted Cash flow

4.3.2 Net Present Value

4.3.3 Cumulative Cash flow Diagram

4.3.4 Rate of Return

4.3.5 Sensitivity Analysis

4.3.6 Payback Period

Conclusion

184

187

199

199

202

203

204

205

206

208

CHAPTER 5 PROCESS INTEGRATION AND PINCH TECHNOLOGY

5.1

5.2

5.3

5.4

5.5

Introduction

Pinch Technology

The Problem Table Method

The Heat Exchanger Network

Minimum number of exchangers

209

209

210

214

216

CHAPTER 6 WASTE TREATMENT

6.1

6.2

6.3

6.4

6.5

6.6

Introduction

Wastewater Treatment

Wastewater Treatment Plant Design

Sludge Treatment

Waste Treatment Plant Layout

Absorption tank using granular activated carbon

6.6.1 Analysis of the absorption process

6.6.2 Breakthrough Absorption capacity

220

221

224

229

230

231

232

233

APPENDICES

11

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

LIST OF TABLES OF DESIGN I

TABLE

TITLE

1.1

The Physical and Chemical Properties of MTBE

2.1

The Comparison of the UOP Oleflex, Philips Star

PAGE

2

SP-Isoether FBD Process

3.1

Trade Balance of MTBE in Asia and Pacific

12

3.2

MTBE Balances for Asia and Pacific

13

3.3

Production, Import, Export & Consumption in Europe in

Year 2000

14

3.4

Supplies MTBE Plant in Asia & Pacific

15

3.5

Standard Price for Isobutane

16

3.6

Cost of Producing MTBE 500000 tonne/year

18

3.7

Value in US Dollar Converted to RM

20

3.8

Value in US Dollar Converted to RM per tonne

20

3.9

Data Calculation by using Microsoft Excel in RM

23

4.1

The Comparison of the Potential Site Location

30

4.2

The Comparison of Location in term of Weightage Study

31

4.3

The Electricity Tariffs (Industrial Tariff) for Peninsular

Malaysia and Sarawak

33

12

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

LIST OF TABLES OF DESIGN II

TABLE

TITLE

PAGE

Chapter 1

Section 1

1.1

Calculation for Terminal Velocity in Different Size of dp.

1.2

Correlation of Three Investigators

10

1.3

Data Calculation to Find Solid Loading

12

1.4

Summary of Mechanical Design

40

3.1

The Composition in Feed Stream

80

3.2

The Composition in Top Stream

80

3.3

The Composition in Bottom Stream

80

3.4

The Average Relative Volatility,

3.5

The Non-key Flow of the Top Stream

82

3.6

The Non-key Flow of the Bottom Stream

83

3.7

MTBE Equilibrium Curve

85

3.8

Provisional Plate Design Specification

97

3.9

Summarized Results of Mechanical Design

101

3.10

Design Specification of the Support Skirt

102

4.1

Provisional Plate Design Specification

106

4.2

Summary of the Mechanical Design

118

4.3

Stress Analysis for Liquid-Liquid Extraction Column

119

4.4

Design Specification of the Support Skirt

119

4.5

Piping Sizing for Liquid-liquid Extraction Column

120

Section 3

82

Section 4

Section 5

5.1

Properties of Raw Material (Isobutane and N-butane)

and Steam for (E100)

5.2

5.3

130

Summary of Chemical Design For

Heat Exchanger In Series

141

By taking D = 100 mm, the selected tube nozzle

149

13

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

TABLE

TITLE

PAGE

5.4

By taking D = 500 mm, the selected tube nozzle is:

149

5.5

Standard Flange for Inlet isobutene

150

5.6

Standard Flange for Outlet isobutene

151

5.7

Standard Flange for Inlet Steam

151

5.8

Standard Flange for Outlet Steam

151

5.9

Using Ds = 600mm, the Standard Steel Saddles

for Vessels up to 1.2m

5.10

152

Summary of Mechanical Design For

Heat Exchanger in Series

153

2.1

Parameter at Heat Exchanger

151

2.2

Parameter at Catalytic Cracking Fluidized Bed Reactor

152

2.3

Parameter at Compressor

153

2.4

Parameter at Condenser

154

2.5

Parameter at Separator

154

2.6

Parameter at Fixed Bed Reactor

155

2.7

Parameter at MTBE Distillation Column

156

2.8

Parameter at Liquid-liquid Extraction Column

157

2.9

Parameter at Distillation Column

158

2.10

Parameter at Mixer

159

2.11

Parameter for Expander

160

Important Features in a HAZOP Study

170

4.1

Labor Cost

189

4.2

Estimation Cost of Purchase Equipment

197-198

4.3

Annual Cash flow Before Tax

200

4.4

Annual Cash flow After Tax

201

4.5

Present Worth Value

202

Chapter 2

Chapter 3

3.1

Chapter 4

14

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

4.6

After Tax Cumulative Cash Flow

TABLE

203

TITLE

PAGE

4.7

Present Value (RM) When i = 30% & i = 40%

204

4.8

Future Value (RM) When MARR = 15%

205

4.9

Simple Payback Period

206

4.10

The Interpolation Simple Payback Period

206

4.11

Discounted Payback Period

207

4.12

The Interpolation Discounted Payback Period

207

5.1

Shows the process data for each stream.

210

5.2

Interval Temperature for Tmin = 10oC

211

5.3

Ranked order of interval temperature

212

5.4

Problem Table

213

Chapter 5

Chapter 6

6.1

Parameter Limits for Wastewater and Effluent under the Environmental Quality

Act 1974

6.2

208

Functions of Pumps in the Waste Treatment Plant

215

15

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

LIST OF FIGURES OF DESIGN I

FIGURE

3.1

TITLE

PAGE

MTBEs Role in US Gasoline grew rapidly

Through 1995

10

3.2

World MTBE Demand (1998-2010) Mod Scenario

11

3.3

MTBE supply & Demand Asia and Pacific

13

3.4

Breakeven Analysis Chart Calculated by using Excel

19

5.1

.

Functional Elements in a Solid-Waste Treatment System

40

16

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

LIST OF FIGURES OF DESIGN II

FIGURE

TITLE

PAGE

Chapter 1

Section 1

1.1

Illustration Diagram of the Reactor

1.2

CDRe2 and CD/Re vs. Reynolds Number

Analysis of Stresses

67

3.1

MTBE Distillation Column

78

3.2

McCabe-Thiele Diagram

86

5.1

Heat Exchanger in Series for the Heating Process

129

5.2

Steel Pipe Nozzle

149

5.3

Standard Flange

150

2.1

Control Scheme for the Heat Exchanger

156

2.2

Control Scheme for Catalytic Cracking

Section 2

2.1

Section 3

Section 5

Chapter 2

Fluidized Bed Reactor

157

2.3

Control Scheme for the Compressor

158

2.4

Control Scheme for the Condenser

159

2.5

Control Scheme for the Separator

160

2.6

Control Scheme for the Fixed Bed Reactor

161

2.7

Control Scheme for the MTBE Distillation Column

162

2.8

Control Scheme for the Liquid-liquid Extraction Column

163

2.9

Control Scheme for the Distillation Column

164

2.10

Control Scheme for the Mixer

165

2.11

Control Scheme for the Expander

166

17

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

FIGURE

TITLE

PAGE

Chapter 3

3.1

Methyl tert-Butyl Ether (MTBE) Plant Layout

180

3.2

Methyl tert-Butyl Ether (MTBE) Plant Evacuation Routes

181

3.3

PID before HAZOP

182

3.4

PID after HAZOP

183

Cumulative Cash Flow (RM) Versus Year

203

5.1

Diagrammatically representation of process stream

210

5.2

Intervals and streams

211

5.3

Heat Cascade

212

5.4

Grid for 4 stream problem

213

5.5

Grid for 4 Stream Problem

214

5.6

Proposed Heat Exchanger Network

216

6.1

The Sludge Treatment System

229

6.2

Waste Treatment Plant Layout

231

Chapter 4

4.1

Chapter 5

Chapter6

18

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Ar

Archimedes number

acceleration

settling chamber longitudinal cross-sectional area

dimension

constant

CD

drag coefficient

concentration

system diameter

particle diameter

de

effective fiber diameter

E,

field intensity

cross-sectional area

Pr

Fronde number

gravitational acceleration

height

precipitation constant ,

Cross sectional area of catalytic reactor

Aor

Area of orifice

C Ag

Concentration of gas reactant

CD

Drag coefficient

d Bv

Diameter of bubble in the bed

dp

Particle diameter

Diffusivity

Dt

Diameter of catalytic reactor

Thickness

Activation energy

19

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

FBo

Mass flow of coal to the catalytic reactor

FC

Fixed carbon mass fraction

Hbed

Height of bed

Hh

Height of Catalytic reactor

Joint factor

Reaction rate constant

Reaction rate constant

K eq

Equilibrium constant

Height above the bed

Total no of orifice

No of holes in 1 m2 area

Nor

No of orifice in 1 m2 area

PCO , PH 2 O

Pi

Design stress

Partial pressure

rC , rS -

Rate of reaction

Ideal gas constant

Ret

Reynolds number

Rp

Radius of particle

Total holding time

Temperature

Uo

Superficial gas velocity

Umf

Minimum fluidization velocity

Ut

Terminal velocity

VBed

Volume of bed

WBed

Weight of coal in bed

WC

Total mass of carbon

Conversion factor

Fitting parameter (for this design is 0.21)

Fitting parameter (for this design is 0.66)

Gas density

Molar density

Bulk density of catalyst

Particle density

20

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Gas viscosity

Time for complete conversion of reactant particle

Pressure drop

total elutriation rate of particles

Ef

frictional force of particles

Ei

entrainment rate of panicle size i

Ei

elutriation rate of particle size i

Eo

total entrainment rate at bed surface

total elutriation rate of particles

gravitational acceleration constant

gc

gravitational conversion constant, m kg/s2 kg -force

Gi

solids flow rate

height above dense bed surface

Rep

particle Reynolds Number = g (U o U ts ) d p /

Ret

dpU g /

time

Umf

minimum fluidization velocity

Uo

superficial gas velocity

Usi

solid velocity (upward)

Us

single particle terminal velocity of particle size i

weight fraction of bed

Ws

weight of solid particles in verlical pipe having length h

Xi

weight fraction of particle size i in bed

Greek Symbols

voidage in freeboard

21

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

voidage in freeboard for system having only particle size i

solid friciion coefficient

gas density

particle density

22

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

CHAPTER 1

PROCESS BACKGROUND AND INTRODUCTION

1.1

INTRODUCTION

Methyl tertiary butyl ether (MTBE) is produced by reacting isobutene with methanol

over a catalyst bed in the liquid phase under mild temperature and pressure. Isobutene

can be obtained from stream cracker raffinate or by the dehydrogenation of isobutane

from refineries. Ether in general is a compound containing an oxygen atom bonded to

two carbon atoms.

In MTBE one carbon atom is that of a methyl group CH3 and the other is the central

atom of a tertiary butyl group, -C (CH3)). At room temperature, MTBE is a volatile,

flammable, colorless liquid with a distinctive odour. It is miscible with water but at high

concentrations it will form an air-vapour explosive mixture above the water, which can

ignite by sparks or contact with hot surfaces.

MTBE has good blending properties and about 95% of its output is used in gasoline as

an octane booster and an oxygenate (providing oxygen for cleaner combustion and

reduced carbon monoxide emissions). It is also used to produce pure isobutene from

C4 streams by reversing its formation reaction. It is a good solvent and extractant.

Table 1.1: The Physical and chemical properties of MTBE

23

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Chemical formula

Molecular structure

Oxygen content

Physical state (at normal

C5H12O

(CH3)4CO

18.2 wt%

Colorless liquid

temperature and pressure)

Boiling point

Melting point

Flash point

Autoignition temperature

Flammable limits in air

Relative density

Vapour pressure

Reactive index

Color

Water solubility

55.2oC

-108.6 oC

30 oC

425 oC

1.5 8.5%

0.7405g/ml at 20 oC

245 mm Hg at 25 oC

1.3690 at oC

Colorless

42000mg/l at 25 oC (<10% in

water, miscible with ethanol and

1.2

Partition coefficient n-

diethyl ether)

1.06

octanol/water (log10)

Henrys Law Constant

65.4 Pa/m3/mol

HISTORICAL REVIEW OF MTBE PRODUCTION PROCESS

The MTBE plants actually consist of six units: Isomerization Unit (including

deisobutanizer), Dehydrogenation Unit, MTBE Unit, Methanol Recovery Unit,

Oxygenate Removal Unit and Olefin Saturation Unit. A common offsite utility system

will be incorporated to distribute the required utilities to each unit. There are four

method of producing MTBE implemented under license as the following:

1. UOP-Oleflex Process

2. Phillips STAR Process

3. ABB Lummus Catofin Process

4. Snamprogetti-Yarsingtez FBD (SP-Isoether) Process.

1.2.1

UOP-Oleflex Process

24

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

The UOP-Oleflex process uses multiple side-by-side, radial flow, moving-bed reactors

connected in series. Preheated feed and interstage heaters supply the heat of reaction.

The reaction is carried out over platinum supported on alumina, under near isothermal

conditions. The catalyst system employs UOP's Continuous Catalyst Regeneration

(CCR) technology. The bed of catalyst slowly flows concurrently with the reactants and

is removed from the last reactor and regenerated in a separate section. The

reconditioned catalyst is then returned to the top of the first reactor.

processes

involved

are

the

deisobutenization,

the

isomerisation

The typical

and

the

dehydrogenation process that has been commercial in Malaysia.

1.2.2

Philips Star Process

The second one is the Philips Steam Active Reforming (STAR) Process. The Phillips

Steam Active Reforming (STAR) Process uses a noble metal-promoted zinc aluminate

spinel catalyst in a fixed-bed reactor. The reaction is carried out with steam in tubes

that are packed with catalyst and located in a furnace. The catalyst is a solid,

particulate noble metal. Steam is added to the hydrocarbon feed to provide heat to the

endothermic reaction, to suppress coke formation, and to increase the equilibrium

conversion by lowering partial pressures of hydrogen and propane.

1.2.3

ABB Lummus Catofin Process

The ABB Lummus Catofin Process uses a relatively inexpensive and durable

chromium oxidealumina as catalyst. This catalyst can be easily and rapidly

regenerated under severe conditions without loss in activity. Dehydrogenation is

carried out in the gas phase over fixed beds. Because the catalyst cokes up rapidly,

five reactors are typically used. Two are on stream, while two are being regenerated

and one is being purged. The reactors are cycled between the reaction and the

reheat/regeneration modes, and the thermal inertia of the catalyst controls the cycle

time, which is typically less than 10 minutes. The chromium catalyst is reduced from

Cr6+ to Cr3+ during the dehydrogenation cycle. The raw materials used to produce

MTBE by using this method are butanes, hydrogen and as well as recycled isobutene

from the system itself. In this process, there is an isostripper column, which separates

the heavies, and the light ends from which then could produce MTBE.

25

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

1.2.4

Snamprogetti-Yartsingtez FBD (SP-Isoether)

The Snamprogetti-Yarsingtez SP-Isoether (FBD) Process uses a chromium catalyst in

equipment, which is the fluidized bed that resembles conventional fluidized catalytic

cracking technology used in the oil refinery. The catalyst is recirculated from the

reactor to the regeneration section on a 3060-min cycle. The process operates under

low pressure and has a low-pressure drop and uniform temperature profile.

Snamprogetti has been presenting and marketing their hydrogenation technology,

ISOETHER 100, since 1997. This process is to be used to convert MTBE units by

utilizing Snamprogettis MTBE Water Cooled Tubular Reactor Technology. In this SPIsoether Process, the products are MTBE and isooctagenas (iso octane gas). In this

SP-Isoether Process the catalyst used in the isoetherification reactor is the same as

those other typical processes, which is Platinum. (Please refer Appendix A Figure

1.3).

Four method processes of the MTBE above are favorable among the

petrochemical firms.

CHAPTER 2

PROCESS SELECTION

26

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Suitable process, which is gives a lot of profit and less problem is an important in order

to determinant for the success of a plant. This chapter will briefly discuss the best

process selected based on a few criteria. It covers general consideration, detailed

consideration for process selection and conclusion on the process selection.

2.1

METHOD CONSIDERATION.

From the processes mentioned earlier, there are many ways to produce MTBE. It is

essential to choose the best method that will be used to produce MTBE. The selection

of the method must consider the safety of the plant, minimum waste or by product

generated, efficient and economical. Snamprogetti-Yarsingtez SP- Isoether FBD

process will be chosen as the method to produce MTBE. More detailed reasons for the

selection of this process are: High conversion (greater than 98 %) with few by-products

compared to other process. From the economy aspect,Snamprogetti-Yarsingtez FBD

Process can reduce the cost of setting up the plant as it can be implied in any of typical

MTBE-produced plant, known as Financial Safety Net.(When an MTBE plant faces an

oversupplied MTBE market, Isoether makes it possible to switch production from

MTBE to a superior Alkylate.). As for the safety aspects of the plant, as the

Snamprogetti-Yarsingtez FBD is a safe process as it just use the fluidize bed to the

process of producing MTBE. The process operates under low pressure and has a lowpressure drop and this means that the fluidized bed is physically not harmful to anyone.

As for the temperature, it operates under uniform temperature profile. As the

temperature is not high, this means that the process is not as dangerous as other hightemperature-operated process. But, precautions should be taken seriously all the time,

as we do not know when an accident could happen even in the safest place. As for the

waste by using the Snamprogetti-Yarsingtez FBD Process, the product of the process

is only MTBE and other effluent and as well as flue gas which are not harmful to the

environment.

Table 1.1 The comparison of the UOP-Oleflex, Philips Star, ABB Lummus Catofin and

Snamprogetti- Yartsingtez SP-Isoether FBD process.

27

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Method and

UOP-Oleflex

STAR Philip

ABB Lummus

Snamprogetti-

Consideration

Process

process

Process

Yarsingtez FBD

Investment cost

Investment cost

Lower capital

process

Reduce the cost

is very modest

were evaluated

investment

of setting up the

Economic

for 700 BPSD

plant as it can be

Consideration

(650tonne/day)

implied in any of

feed capacity

typical MTBE-

Efficiency

97-99%

98%

99 .99%

produced

Greater than 98%

1. Higher per

1. The Stabilized

1.CD Tech

1.Environmental

pass

Product Is Near

Efficiently Uses

Friendly

conversion and

Equilibrium

The Heat

2.Financial

at least 1-2%

Mixture Of

Released By An

Safety Net.

higher catalyst

Isobutane.

Exothermic

(When an MTBE

selectivity as a

2.The Light-End

Reaction.

plant faces an

result of lowest

Yield Fr. Cracker

2.Conducting 2

oversupplied

operating

Is Less Than 1

Unit Operations

MTBE market,

pressure and

Wt% Butane

In 1 Equipment

Isoether makes it

temperature.

Feed

(Isobutylene

Selectivity)

Advantages

possible to switch

2. No catalyst

production from

losses.

MTBE to a

superior Alkylate.)

Disadvantages

1. Less

1. Much heat is

1. The Reaction

1. Not widely

efficiencies

needed as

Must Take Place

practiced in

furnace is used.

In The Liquid

industry, as it

Phase Catalyst

needs thorough

Must Remain

research to

Completely

implement it.

Wetted.

2.The Reaction

Cannot Be Overly

28

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Endothermic

2.2.1

DETAILED PROCESS DESCRIPTION

2.2.2

Snamprogetti-Yartsingtez SP-Isoether (FBD) Process

The Snamprogetti-Yarsingtez SP-Isoether (FBD) Process uses a chromium catalyst in

equipment, which is the fluidized bed that resembles conventional fluidized catalytic

cracking technology used in the oil refinery with 65% isobutane (i-C4H10) conversion to

produce isobutene.

Dehydrogenation reaction that occur in this process:

iC4H10

iC4H8 + H2

The main feature of this process is that the catalyst filled annuli are connected in such a way

that small, discrete amounts of catalyst can be withdrawn from the bottom of a reactor,

and sent to the top of the reactor. Catalyst withdrawn from the bottom of the reactor is

sent to a separate regeneration section for regeneration prior to being sent to the top of

the reactor. The catalyst is recirculated from the reactor to the regeneration section on

a 3060-min cycle. The reactor and regeneration sections are totally independent of

each other. The regeneration section can be stopped, even for several days, without

interrupting the dehydrogenation process in the reactor section. The vaporized

isobutane is fed along with fresh catalyst to the first, called reactor, and the spent

catalyst is separated from the products and sent to the regenerator, where air (O 2) is

added to oxidize the carbon. The reactor cracks the isobutane and forms coke on the

catalyst. Then in the regenerator the coke is burned off and the catalyst is sent back

into the reactor. The magic of this process is that the reactor-regenerator combination

solves both the heat management and coking problems simultaneously. Burning off the

coke is strongly exothermic, and this reaction in the regenerator supplies the heat

(carried with the hot regenerated catalyst particles) for the endothermic cracking

reactions in the reactor.

The process operates under low pressure and has a low-pressure drop and

uniform temperature profile. Products that have been produced from this unit are

29

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

isobutene. Isobutene available in the C4 stream from the Snamprogetti-Yarsintez FBD

unit will be combining with methanol, which is sourced from the Sabah Gas Industries

methanol plant in Labuan to produce, fuel-grade MTBE with a high-octane value in the

MTBE unit.

2.2.3

MTBE Unit

The MTBE unit includes two sections such as the main reaction section and the

finishing reaction. In the main reaction section, 98% conversions of isobutene occurs

mainly in the main reactor which are designed to provide the mechanical ands thermal

conditions required by the expanded catalyst bid technology.

Reactions occur in this unit are:

1.

iC4H8 (isobutene) + CH3OH (methanol)

2.

CH3OH + CH3OH

(CH3)2O + H2O (DME)

3.

iC4H8 + H2O

C4H10O (TBA)

C5H12O (MTBE)

The reactor is operated in an up-flow direction with an external liquid recycle to

remove the heat of reaction and to control the expansion of the catalyst bed. This

selective reaction of methanol with isobutene is conducted in liquid phase at moderate

temperature on an ion exchange resin type catalyst. The expansion of the catalyst bed

in the reactor is ensured by pump around circulation loop with a cooling water cooler to

control the reactor feed temperature to remove the heat of reaction. Resin traps on top

of each reactor to trap resin in case of carryover with the liquid. In the finishing reactor

section, isobutene final conversion is achieved in a catalytic column where reaction

and distillation are performed simultaneously.

2.2.4

Distillation Column Unit

30

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

This column includes a separation column yielding MTBE product at the bottom and

(isobutene, isobutene, normal butane, water and DME) with methanol entrained by

azeotropy at the top. The reaction section bed is contained in the upper part of this

column. An excess of methanol is maintained corresponding to the amount leaving the

tower in the azeotrope. The required methanol is passed through guard beds and

filtered prior to being charged to the catalytic column to achieve final conversion.

Bottom MTBE product and the other by-product such as TBA, DME is sent to rundown

tanks under level control after cooling in feed/bottom exchanger and trim cooler.

The overhead of the column is condensed in the air-cooled condenser under

pressure control. One part of the liquid is sent to the column as reflux and the other

part to the liquid-liquid extraction unit after cooling.

2.2.5

Liquid-Liquid Extraction Unit

In this unit methanol will extract from the isobutene, isobutene, normal butane to

produce C4 raffinate from the overhead of the column and at the bottom, methanol and

water are produced. C4 raffinate from this unit we decided to sell to the Korea.

CHAPTER 3

ECONOMIC SURVEY

31

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

3.1 MARKET SURVEY

3.1.1

World Market

The MTBE market has been in strong continuous growth since 1992. For instance, the

1998 world consumption was approximately 19.5 million tonnes, about double that of

1992, representing an annual growth rate of about 12%. Present trends indicate a mild

growth in 2000, up to 20 million tonnes, with US consumption slightly declining and

other parts of the world growing (EEA 2000). The MTBEs role in U.S. gasoline grew

rapidly through 1995 given away in figure 3.1.

Figure 3.1 MTBEs role in U.S. gasoline grew rapidly through 1995

(Sources: Local Issues, Global Implications)

3.2 ASIA MARKET

Most Asia countries such as South Korea, Japan, Hong Kong, Taiwan, China, Malaysia,

Singapore, Philippines and Thailand, have already phased lead out of their gasoline pool

and are replacing it with oxygenates such as MTBE. Due to MTBEs relative ease in

blending into gasoline, easy transportation and storage, as well as relatively cheap and

abundant supply, MTBE is the most widly use oxygenate in Asia.

However, the use of MTBE in gasoline blending is not mandatory for countries

like South Korea and Thailand. South Korea, for instance, requires a 1.3% - 2.3%

32

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

oxygenate content in gasoline during the winter, compared to a minimum of 0.5% for

the summer. In other Asian Countries, MTBE is mainly use as an octane booster to

replace lead. (source: features mtbe asias.html).

3.3 DEMAND

World demand of MTBE mod scenario is about 4.1 mil ton per annum consumption in

US West Coast at stake due to the legislation from 1998 to 2010. It has as an impact

on 80% of PETRONAS MTBE exports to the US. This mod scenario is representing in

figure 3.2.

Figure 3.2: World MTBE demand (1998-2010) mod scenario

(Sources: Petronass Library Kuala Lumpur City Center (KLCC)

U.S. demand is about 250,000b/d, dominates MTBE consumption. Most MTBE

is used to comply with mandated oxygen content rules for gasoline supplied to either

RFG or wintertime carbon monoxide areas. A small amount may be utilized for octane

enhancement.

In Europe, MTBE demand is estimated about 60,000 b/d. MTBE use in Europe

is essentially confined to Octane enhancement, and about 6,000 b/d is exported to the

United States. Eastern Europe currently consumed about 10,000 b/d of MTBE.

In Asia, demand for MTBE in this region is expected to grow at much more

rapid rate than elsewhere in the world. The rate will taper off late in decade from about

12% per year to about 8% by the turn of the century, since the early rapid growth has

33

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

been fed by the lead phase down which should be nearly complete by 2000. Throughout

the period, the region will be a net importer of MTBE, mostly obtained from the Middle

East. The trade balance of MTBE in Asia and Pacific is expected to be in table 3.1.

(Sources: MTBE annual Report)

Table 3.1 Trade Balance of MTBE in Asia and Pacific

(Sources: MTBE annual Report)

Capacities listed are the average available during the year. Details for 1995 and 1999

of MTBE Balance for Asia and Pacific are shown in table 3.2. These data are also

shown graphically in figure 3.3 which indicate for MTBE supply and demand Asia and

Pacific. (Sources: MTBE annual Report)

Table 3.2: MTBE Balance for Asia and Pacific

(Sources: MTBE annual Report)

34

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

MTBE supply and demand

Asia and Pacific

Figure 3.3: MTBE supply and demand Asia and Pacific

(Sources: MTBE annual Report)

Demand for MTBE expected to be marginally firmer in the near future as Asian

Countries such as Indonesia and India are working totally phase out lead from their

gasoline pool. Supply on other hand is expected to remain abundant, as Asia is able to

produce about 3 million Mt/yr of MTBE for its Captive consumption. In addition to this,

Asia attracts a regular supply of about 500,000 ton/yr of MTBE from Middle Eastern

and Europe sources.(Reference: features mtbe asias.html).

35

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

3.4 PRODUCTION CAPACITY

Commercial production of MTBE started in Europe in 1973 and in the US in 1979. Total

worldwide production capacity in 1998 was 23.5 million tones and the actual production

was 18 million tones

The annual production volume of MTBE in the year 2000 in the Europe was

2,844,000 tons. About 129,000 tonnes was imported and about 479 000 tonnes were

exported outside the Europe in the year 2000 ((Dewitt & Company Inc. 2002). The

majority of the exported volume (> 83%) was exported to USA and Canada. The

majority of exported volume (> 80%) was transported as non-blended MTBE and

minority as a component of petrol (blended). The annual consumption of MTBE within

the Europe was hence 2,495,000 tons in the year 2000 (see table below). For the future

no substantial increase in MTBE usage is expected. (Dewitt & Company Inc. 2002).

Table 3.3: Production, import, export and consumption in Europe in year 2000

(tonnes/year) souces: (Dewitt & Company Inc. 2002).

Production

2 844 000

Import into Europe

129 000

Export outside Europe

479 000

Consumption

2 495 000

The world's MTBE industry today is operating at about 80% of capacity. The US

is by far the largest market, having about 43% of the production capacity but

consuming 63% of total global output. On stability, the Middle East is the swing

producer, exporting more than 50,000 bbl/day to the US and elsewhere.

3.5

SUPPLY

DeWitts Company estimates for local production of MTBE a summarized in table 3.4.

Most of plants unit are refinery-based units taking isobutylene from FCCU units, or as

Raffinate I from olefins plants. Since olefin plants in the region a mostly naphthabased, they produce significant quantities of C4 olefins for this purpose. There is one

butane-based plant in Malaysia. Table 3.4 also shown for MTBE plants suppliers to

Asia and Pacific.

36

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Table 3.4 Suppliers MTBE plant in Asia and Pacific

(Sources: MTBE annual Report)

3.6 MARKET PRICE

3.6.1

Methanol

Price of methanol, as feedstock in Asia is $240 - $280 /ton. While in Europe, the prices

is $265 - $270 / ton free on board (fob) Rotterdam. In U.S. the price of methanol is 76

cts 77cts/ gal in fob.

Global Methanol demand is expected to increase to 3.5 % per year over the

next 5 years, compared to 1.0% - 1.5% growth in 2002 and 2003. Those lower growth

rates are attributable to the phase-out of Methyl tert-butyl ether (MTBE) as oxygenate

in gasoline in California, and slower economic growth in China caused by SARS.

Methanol growth in China is forecast at 7% - 8.5% per year, fueled by formaldehyde

and acetic acid demand. (Chemicals Week)

3.6.2

Isobutane

Standard price for isobutene is stated by followed:

37

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Table 3.5 : Standard price for isobutane

Grade

Purity

Grade 4.0

99.99%

Grade 3.0

99.9%

Instrument

99.5%

3.6.3

Cylinder Size

LP30

LP15

LP05

LP01

1/2 Ton

LP30

LP15

LP05

LP01

1 Ton

LP30

LP15

LP05

LP01

Volume

lbs

117

60

23

6

490

117

60

23

6

490

117

60

23

6

Price per Cylinder

RM900.00

RM600.00

RM370.00

RM200.00

RM1225.00

RM380.00

RM240.00

RM170.00

RM100.00

RM890.00

RM293.00

RM185.00

RM100.00

RM75.00

Catalyst

Price of Chromia catalyst Compound USD60 000/Rottedam (Rdam) from the existing

plant. (En Mohd. Napis, from MTBE plant, Gebeng )

3.6.4

Conclusion

Our company will import the methanol and isobutane as feedstock, from Petronas

Malaysia and United State (US) respectively. Methanol feedstock will be supplied from

Gurun, Kedah production capacity of 66,000 ton/year. For the second feedstock,

isobutane (instrument grade) will be supplied by Chevron Phillips Chemical Company

LP, 10001 Six Pines Drive, The Woodlands, Texas, US by shipping method.

MTBE is suitable as a gasoline additive which simultaneously increases the

octane rating of the fuel and adds oxygen which promotes cleaner burning. When used

in place of lead-based octane enhancers, dual environmental benefits are realized, a

reduction in atmospheric lead concentrations and reduced emissions of carbon

monoxide and other smog forming chemicals. Since the 1970s, the worldwide

38

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

consumption of MTBE has increased significantly and many new facilities have been

constructed to support the growing market (Kirschner, 1996; Riddle, 1996).

MTBE production will increase in future in Asia, Asia Pacific, Middle East and

Europe even though MTBE is banned in California but not in the entire nation of the

United States.

3.7

ECONOMIC ANALYSIS

An economic analysis used to smooth the progress of based on existing plant. This

analysis is important to ensure that the chemical plants converge and the economics is

satisfactory before the plant operate. All the data taken from MTBE Annual 1994,

DeWitt & Company

Incorporated, 16800 Greenpoint Park, Suite 120 N, Houston,

Texas, that given by Petronas Library, KLCC.

3.7.1

Break-Even Analysis

When chemical engineers determine outlay for any type commercial process, they

want these costs to be enough accuracy to provide reliable decision. To accomplish

this, they must have a complete understanding of the many factors that can affect

costs. Break-even analysis is important to ensure that the plant can give profit before

the plant can run.

The objective of break even analysis is to find the point, in dollars or in ringgits

and units, at which costs equal revenues. This point is the break even point. Break

even analysis requires an estimation of fixed costs, variable costs and revenue.

Fixed costs are costs that continue even if no units are produced. Examples

include depreciation, taxes, debt, and mortgage payments. Variable costs are those

that vary with the volume units produced. The major components of variable costs are

labor and materials. However, others cost, such as the portion of the utilities that varies

with volume, are also variable cost. The different between selling price and variable

cost is contribution. Only when total contribution exceeds total fixed cost will there be

profit.

39

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Another element in break-even analysis is the revenue function. From the

graph, revenue begins at the origin and proceeds upward to the right, increasing by

selling price of each unit. Where the revenue function crosses the total cost line (the

sum of fixed and variable costs), is the break even point, with a profit corridor to the

right and a loss corridors to the left.

Table 3.6: Cost of producing MTBE 500,000 ton/year

(Sources: DeWitt & Company Incorporated, Annual Report)

Table 3.6 showed that the cost of production of MTBE based on existing plant

producing 500,000 ton/year. From table 3.6, given data, break-even analysis can be

calculated to know the break-even point figure. Figure below indicate that break-even

chart, where it has been calculated by using excel that shown in table 3.8 and based

on the data given from table 3.6.

40

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Figure 3.4 : Break even analysis chart calculated by using excel.

From the break even chart figure above, the value of break-even point at the

existing capacity of 500,000 ton/year is 185,629.85 tons in units and RM

244,679,817.14 in Ringgit Malaysia (RM). This value indicates the minimum units and

values needed to be sold. The given capacity of 500,000 tons/year can give profit to

the company. The margin of safety (MOS) calculated from the graph, which is

314,370.15 tons and RM414,373,182.86. Margin of safety (MOS) in percentage of

sales is 62.87%. The sale is allowed to drop about 62.87% before the company will

incurred a loss.

In other word, at selling 300,000 tons/year capacity will also give profit to our

company. The margin of safety from the graph for 300,000 ton/year calculated is

114,370.15 tons and RM150,751,982.86. The margin of safety (MOS) as percentage of

sales is 38.12%. The sale is allowed to drop about 38.12% before the company will

incurred a loss. All the data calculation is shown in the next section.

41

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

3.7.2

Data Calculation

All the data based on 500,000 tons/year producing MTBE from existing plant.

Table 3.7 Values in USD converted to RM

(Sources: Data collected from table 3.6)

Total revenue, TR

Total variable cost, TVC

Total fixed cost, TFC

RM 659,053,000.00

RM 504,754,000.00

RM 57,285,000.00

Total Revenue (TR), MTBE (500,000 ton),

TR

= Quantity of MTBE X Price of MTBE

= QMTBE X PMTBE

= 500,000 tons X USD346.87 X 3.8

= RM 659,053,000

Total cost

TC

= total fixed cost + total variable cost

= TFC + TVC

Where,

Total fixed cost

= 500,000 ton X USD30.13 X 3.8

= RM 57,285,000.00

Total variable cost

= 500,000 ton X USD (226.4 + 39.26) X 3.8

= RM 504,754,000.00

Total cost, TC

= RM57,285,000.00 + RM 504,754,000.00

= RM 562,039,000.00

Tables 3.7 represent cost per unit ton converted into Ringgit Malaysia (RM), taking

datas directly from the table 3.6.

Table 3.8 Values in USD converted to RM per ton

(Sources: Data collected from table 3.6)

Revenue (RM) per ton

RM1,318.00

Variable cost (RM) per ton

RM 1,009.51

Fixed cost (RM) per ton

RM114.57

Break-even point in ton can be calculated based on formula equation, which given by

follow:

42

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Break-even point, BEP (tons)

= Total Fixed cost

Contribution/ton

where,

Contribution/ton

= revenue / ton - variable cost / ton

BEP (tons) =

______RM 57,285,000.00_____

(RM1, 318.00 - RM 1,009.51)

185,629.85 tons (the minimum capacity)

Next, Break-even point in RM can be calculated based on formula equation, which

given by follow:

BEP (RM)

Break-even point, BEP (tons) X revenue / ton

185,629.85 tons X RM1, 318.00

RM 244,679,817.14

Beside that, margin of safety and percentage of sale can be calculated as follows:

For 500,000 ton/year production,

Margin of safety (MOS) in units = Budgeted sale (units) - BEP (units)

= 500,000 tons - 185,629.85 tons

= 314,370.15 tons

Margin of safety (MOS) in RM = Budgeted sale (RM) - BEP (RM)

= RM 659,053,000.00 - RM 244,679,817.14

= RM 414,373,182.86

Margin of safety (MOS) as percentage of sales = MOS (RM) x 100%

Sales(RM)

= RM 414,373,182.86 x 100%

RM 659,053,000

= 62.87%

43

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

For 300,000 ton/year production,

Margin of safety (MOS) in units = Budgeted sale (units) - BEP (units)

= 300,000 tons - 185,629.85 tons

=

114,370.15 tons

Margin of safety (MOS) in RM = Budgeted sale (RM) - BEP (RM)

= RM 395,431,800 - RM 244,679,817.14

= RM 150,751,982.86

Margin of safety (MOS) as percentage of sales = MOS (RM) x 100%

Sales(RM)

= RM150,751,982.86 x 100%

RM 395,431,800

= 38.12%

Table 3.9 shown that the calculation of break-even point by using excel.

Table 3.9: Data calculation by using excel in RM

(Sources: Data taking from table 3.7)

44

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

CAPACITY

TFC1

57,285,000.00

10000

57,285,000.00

20000

TVC1

0

TR1

TC1

57,285,000.00

10,095,080.00

13,181,060

67,380,080.00

57,285,000.00

20,190,160.00

26,362,120

77,475,160.00

40000

57,285,000.00

40,380,320.00

52,724,240

97,665,320.00

60000

57,285,000.00

60,570,480.00

79,086,360

117,855,480.00

80000

57,285,000.00

80,760,640.00

105,448,480

138,045,640.00

100000

57,285,000.00

100,950,800.00

131,810,600

158,235,800.00

120000

57,285,000.00

121,140,960.00

158,172,720

178,425,960.00

140000

57,285,000.00

141,331,120.00

184,534,840

198,616,120.00

160000

57,285,000.00

161,521,280.00

210,896,960

218,806,280.00

180000

57,285,000.00

181,711,440.00

237,259,080

238,996,440.00

200000

57,285,000.00

201,901,600.00

263,621,200

259,186,600.00

220000

57,285,000.00

222,091,760.00

289,983,320

279,376,760.00

240000

57,285,000.00

242,281,920.00

316,345,440

299,566,920.00

260000

57,285,000.00

262,472,080.00

342,707,560

319,757,080.00

280000

57,285,000.00

282,662,240.00

369,069,680

339,947,240.00

300000

57,285,000.00

302,852,400.00

395,431,800

360,137,400.00

320000

57,285,000.00

323,042,560.00

421,793,920

380,327,560.00

340000

57,285,000.00

343,232,720.00

448,156,040

400,517,720.00

360000

57,285,000.00

363,422,880.00

474,518,160

420,707,880.00

380000

57,285,000.00

383,613,040.00

500,880,280

440,898,040.00

400000

57,285,000.00

403,803,200.00

527,242,400

461,088,200.00

420000

57,285,000.00

423,993,360.00

553,604,520

481,278,360.00

440000

57,285,000.00

444,183,520.00

579,966,640

501,468,520.00

460000

57,285,000.00

464,373,680.00

606,328,760

521,658,680.00

480000

57,285,000.00

484,563,840.00

632,690,880

541,848,840.00

500000

57,285,000.00

504,754,000.00

659,053,000

562,039,000.00

CHAPTER 4

45

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

PLANT LOCATIONS AND SITE SELECTION

4.1

PLANT LOCATION

The location of the plant can have a crucial effect on the profitability of a project and the

scope for future expansion. Many factors must be considered when selecting a suitable

site. A good location is required to optimise the production of the plant. It is important to

know that, not all Malaysian industrial park caters the need of a chemical plant. Also not

all industrial park allows the building of chemical plants. Our industrial parks are divided

into categories such as: 1. Light industrial

2. Medium industrial

3. Heavy industrial

4. General industrial

5. Hi-tech industrial

4.2

GENERAL CONSIDERATION ON THE SITE SELECTION

All the information about plant locations are based on the data gathered from the

Malaysian Industrial Development Authority (MIDA). And we refer detail information on

important factors that need to be considered in the site selection. In the process of

selecting the location, we did some evaluation. Among the principle factors considered

are:

4.2.1

Location With Respect To Marketing Area

For materil that are produced in bulk quantities, such as cement, fertilizer, raw material

of petrochemical product, where the cost of product per tone is relatively low and the

cost of transport a significant fraction of the sales price, the plant must located close to

the primary market. This consideration will be less important for low volume production,

high priced products; such as pharmaceuticals, plastisizer and etc. in an international

46

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

market, there may be an advantage to be gained by locating the plant within an area

with preferential tariff agreement.

4.2.2

Raw Material Supply

The availability and price of suitable raw materials will often determine the site location.

Plant producing bulk chemicals are best located close to the source of the major raw

material, where this is also close to the marketing area.

4.2.3

Transport Facilities

The transport of materials and products to and from the plant will be an overriding

consideration in site selection. If practicable, a site that we are consider that close to at

least two major forms of transport: road, rail, waterway or a sea port. Road transport

being increasing used, and is suitable for local distribution from central warehouse. Rail

transport will be cheaper for the long distance transport of bulk chemicals

.

Air transport is convenient and efficient for the movement of personnel and

essential equipment and supplies and the proximity of the site to a major airport also

considered.

4.2.4

Availability of Labour

Labour that will be needed for construction of the plant and its operation. Skilled

construction workers will usually be brought in from outside the site area, but there

should be an adequate pool of unskilled labour available locally and labour suitable for

training to operate the plant. Skill tradesman will be needed for plant maintenance.

Local trade union customs and restrictive practices will have to be considered when

assessing the availability and suitability of the local labour for requirement and training

.

4.2.5

Availability of Utilities

47

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Chemical processes invariably require large quantities of water for cooling and general

process used and the plant must be located near a source of water of suitable quality.

Process water may be drawn from a river, wells or purchased from a local authority.

At some site, the cooling water required can be taken from a river or lake or

from the sea; at other locations cooling towers will be needed.

Electrical power will be needed at all sites. Electrochemical processes that

required large quantities of power: for example, aluminium smelters need to be located

close to a cheap source of power. A competitively priced fuel must be available onsite

for steam and power generation.

4.2.6

Environmental Impact and Effluent Disposal

All industrial processes produce waste products and full consideration must be given to

the difficulties and cost of their disposal. The disposal of toxic and harmful effluents will

be covered by local regulations and the appropriate authorities must be consulted

during the initial site survey to determine the standards that must be met.

An environmental impact assessment should be made for each new project or

major modification of addition to an existing process.

4.2.7

Local Community Considerations

The proposed plant must fit in with and be acceptable to the local community. Full

consideration must be given to the safe location of the plant so that it does not impose

a significant additional risk to the community.

On a new side, the local community must be able to provide adequate facilities

for the plant personnel: schools, banks, housing and recreational and cultural facilities.

4.2.8

Land (site consideration)

48

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Sufficient suitable land must be available for the proposed plant for future expansion.

The land should ideally be flat, well drained suitable load-bearing characteristics. A full

site evaluation should be made to determine the need for piling or other special

foundations.

4.2.9

Political and Strategic Considerations

Capital grants, tax concessions and other inducements are often given by government

to direct new investment to preferred locations such as areas of high unemployment.

The availability of such grants can be the overriding factor in site selection.

4.3 OVERVIEW ON PROSPECTIVE LOCATIONS

Our process is a petrochemical base process; therefore we choose to locate our plant in a

petrochemical complex. The reason is quite simple; a petrochemical complex could

simplify the formation and the maintenance of a chemical plant. It could also cut the daily

operation cost and saving us the hassle of transportation.

In Malaysia there are only three such places, known as the Integrated

Petrochemical Complexes. These complexes are situated in each of the site below:

1. Telok Kalong Industrial Park.

2. Tanjung Langsat Industrial Park.

3. Bintulu Industrial Park.

Other than the above factors, the capacity of plant was also taken into consideration in

determining the suitability of site. Plant capacity will determine how big the space required

to build the plant and the storage area and also the mode of transportation to be use.

The manufacture of MTBE is classified as a petrochemical project. Several

locations of industrial area particular at Teluk Kalong Industrial Area in Terengganu,

Tanjung Langsat Industrial Area in Johor and Bintulu Industrial Area, Sarawak that we are

refer for location.

49

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

4.3.1

Teluk Kalong

Teluk Kalong Industrial Estate located 9.6 km from Kemaman. Total area available

167.46 hectares. The price of land in ranges RM 0.46 to RM 4.18 per Feet Square.

This area is proposed for petrochemical and heavy industry petrochemical.

The Electricity is generated at the following station. Total generation capacity is

900 MW. Local consumption is less than 1/3. No major breakdown, low frequency of

interruption. Water most plentiful with surplus capacity. Water supply capacity at

various treatment plants total 331000-meter cube per day, with planned upgrading for

additional requirement. Kenyir Lake with 39000 hectares of water with 134 metre

average depth, make Terengganu a potential export of water middle East. Water

supply is in Bukit Shah. Water tariffs (industrial) are RM1.15 metre cube. The raw

materials supplier of isobutene is availability from Chevron Philips Chemical Company

LP, United State and methanol is availability from Petronas Malaysia, Labuan.

1.

Airport facilities

Terengganu major industrial locations are serve by 3 airports

- Kuantan

- Kerteh

- Kuala Teregganu

2.

4.3.2

Kuala Teregganu

Port Facilities

Kemaman Port, Kerteh Port and Kuantan Port

Tanjung Langsat Industrial Park

Tanjung Langsat is designed as hub for heavy/medium industries with all the

necessary infrastructure and service facilities. 91.43 km distance from Johor Baharu.

The infrastructure works such as the Pasir Gudang Segamat Highway. Sungai

Johore Bridge and dedicated Port in Tanjung Langsat. Tanjung Langsat Industrial

Complex is a sprawling area just a stones through from Pasir Gudang Industrial Area.

A total hectare still available is 1,085.95. Selling price is RM8 to RM22 square feet. In

term of seaport two seaports are currently being constructed at Tanjung Pelepas,

50

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

located 40 km west of Johore Baharu city and Tanjung Langsat located 10 km east of

the Johore Port. Tenaga Nasianal Berhad (TNB) provides electricity.

Two airports in the 50km radius. There is the Sultan Ismail International Airport

(common known locally as Senai Airport) in Johore Baharu and the Changi

International Airport in Singapore. The Sultan Ismail International Airport, which is

located about 30km to the north west of JB city, is currently being expended and

upgrades to become the regional airport for southern peninsular Malaysia.

4.3.3

Bintulu

The distance from nearest town is 224.29 km from Sibu. Type of industries is light and

medium petrochemical. Area available is 77 hectares. Selling price RM2.5 to RM10 per

feet square. Electricity supplies by Sarawak Electricity Supply Cooperation (SESCO).

Airport facilities - Bintulu Airport

Port Facilities - Bintulu Port

51

PRODUCTION OF 300,000 METRIC TON OF MTBE PER YEAR

Table 4.1 The Comparison of The Potential Site Location:

Teluk Kalong

Industrial Park

Tanjung Langsat

Industrial Park

Bintulu Industrial

Park

9.6 km from Kemaman

91.43 km from Johor

Baharu

224.29 km from Sibu

Types of

Industry

Isobutane from US and

methanol from Labuan

Petrochemical and heavy

industry

Isobutane from US and

methanol from Labuan

Petrochemical light and

medium

Isobutane from US and

methanol from Labuan

Petrochemical light and

medium

Area Available

167.46 hectares

1085.98 hectares

77 hectares

RM 0.46 - 4.18

RM 8.00 - 22.00

RM 2.50 - 10.00

Electricity

Supply

Tenaga National Berhad

Tenaga National Berhad

Sarawak Electrycity

Supply Cooperation

(SESCO)

Water Supply

Bukit Shah Water

Treatment

Road Facilities

Kuala TerengganuKuantan-Kuala LumpurKuala Terengganu-KertehTeluk Kalong-KuantanKuala Lumpur

Distance from

the nearest town

Raw Material

Land Price

2

(RM/ft )

Airport Facilities

Port Facilities

Water Tariffs

3

(RM/m )

Kuala Terengganu Airport

Kerteh Airport

Kemaman Port,

Kerteh Port

Kuantan Port

RM 1.15

Syarikat Air Johor and

Logi Air Sg. Layang

Syarikat Air Sarawak

North-South Highway

from Bukit Kayu Hitam to

Singapore-

Major Road : Bintulu Sibu and Bintulu - Miri

Senai International

Airport

Bintulu Airport

Pasir Gudang Port

Bintulu Port

RM 1.68 (0-20 m 3)

RM2.24 (more than

20 m 3)

RM 0.95 (0 -25 m 3)

RM1.20 (more than

25 m 3)

(Source: MIDA)

A few proposed plant sites were narrowed down based on the above factors (table 4.2).