Professional Documents

Culture Documents

Centralign Presentation

Uploaded by

hzq1eCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Centralign Presentation

Uploaded by

hzq1eCopyright:

Available Formats

Laser centerline alignment with

CENTRALIGN

PRUFTECHNIK-WIBREM is part of PRUFTECHNIK group

PRUFTECHNIK-WIBREM Ltd.

51-117 Wrocaw

ul. Paprotna 12A

Konto Bank: BG o/Wrocaw 20302081-2219-2701-11

REGON: 932070401

NIP: 895-16-82-285

Telefon: +48 71 326 20 18

Telefax: +48 71 325 44 39

eMail: info@pruftechnik.com.pl

www.pruftechnik.com

Laser alignment measurement

Laser alignment measurement

with CENTRALIGN

Laser optical alignment

measurement of internal housing

position with respect to outer

housing

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Optical alignment

measurement

Optical method

theodolite (optical

alignment telescope)

Rotating bracket with

optical target

The best accurancy

0.01 mm

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Piano wire method

Steel wire approx.

0.5 mm dia.

Wire sag

Accuracy: 0.10 0.01 mm

Inside micrometer used for

measurement

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Alignment measurement using

dummy shaft

First dummy shaft centered in mediumpressure section

Second dummy shaft centered in LP-1

section

Every of dummy shaft has to be align

separately

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Alignment measurement

using dummy shaft

Inside micrometer used

to measure dummy shaft

position from left, right and

below

Dummy shaft centered

according to rotor position

Time consumption

Dummy shaft sag line

different to the original rotor

sag

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Alignment measurements using

dummy shaft

Dummy shaft center support used

to simulate rotor sag

Dial indicator used to check lateral

position of dummy shaft

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

CENTRALIGN

Laser beam eliminates fixture

sag, tight wires

Wireless data transmission:

no more cumbersome cables

Bore diameters from 100 mm

to over 7 m (4 in. to 23 ft)

Extremely accurate,

repeatable results regardless of

operator

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Large bore bracket: magnetic

knife-edge support at four

outermost support points

Retractable telescopic arms

Rotating sensor head can be

centred or locked in different

angular position

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Universal 5-axis laser

sensors with well

developed brackets

Possibility to apply to

any internal elements

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

CENTRALIGN

Large Bore Bracket

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

CENTRALIGN

Large Bore Bracket

universal for all

measurement situations

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

CENTRALIGN

Laser alignment measurement

on turbines for adjustment of

interial installed parts

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment measurement

with CENTRALIGN

Large bore bracket

Possibility to use the system

for regenerating the borings

surface during modernization and

repair works

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

SWEEP MODE

PRUFTECHNIK-WIBREM Ltd.

MULTIPOINT MODE

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Measurement on diaphragm

and team sealing labyrinth

segments

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Large bore bracket

Possibility to use the system for regenerating

the borings surface during modernization and

repair works

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Alignment big

reaction internal flow

parts

On line correction

included rotor sag line

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Graphic representation of

the vertical and horizontal

measurement values

The front and rear bearing

seals are used as fixed

points

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Result screen 1

Tabular overview of the

measurement values on

turbine elements

The right hand column

shows the vertical presets to

be taken in to account to

alignment

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

Result screen 2

Tabular overview of the

measurement values on

turbine elements

The columns shows the

radius to the laser beam,

calculated vertical minus

horizontal diameter and

mathematical standard

deviation

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment measurement

with CENTRALIGN

Preset Function

To calculate rotor sag

To compensate ovalisation or

deformation of the internal elements

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

[mm]

Laser alignment measurement

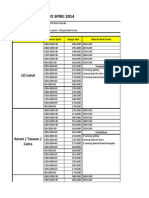

110 MW steam turbine

modernization

5

4

3

2

Theoretical - static sag line

of the rotors

1

0

-1

2.5

7.5

10

12.5

Height before modernization

HP

Bearing

Height before modernization

Height after modernization

PRUFTECHNIK-WIBREM Ltd.

17.5

1

5.64

0.17

22.5

[m]

GEN

2

3.23

0.54

20

Height after modernization

LP

MP

15

3

0.61

0.05

4

0

0

5

0

0

6

0.85

0.04

7

4.03

0.81

CENTRALIGN

Laser alignment measurement

Laser alignment measurement

with CENTRALIGN

Preset Line Function

Preset line function for align

internal parts not to center line

2.251

PRUFTECHNIK-WIBREM Ltd.

1.040

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

110MW BHEL Turbine

modernization

Corrections to the new

rotor line

Preset values and

new-line analysis can be

altered even after

measurement

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment measurement with

CENTRALIGN

On line correction values for

diaphragm and for bearing

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Laser alignment measurement

with CENTRALIGN

Thanks to the laser

technology: new possibility to

carry out the measurement,

correction and aligning

operations simultaneously

PRUFTECHNIK-WIBREM Ltd.

Time and money saving

CENTRALIGN

Laser alignment measurement

Laser alignment

measurement with

CENTRALIGN

110MW BHEL Turbine

modernization

Corrections to the new

rotor line

Preset values and

new-line analysis can be

altered even after

measurement

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

4 Hour Record

Laser-based system measures

high & medium pressure stages

of a turbine in record time

Operators are under immense economic

pressure these days to run plant nonstop and trouble-free, with less and less

time allowed for planned maintenance

outages. On average a turbine needs

overhauling every 5 years and the

alignment in particular is especially timeconsuming, requiring highly skilled

expert attention. A way to cut the

measurement time alone from several

days to just a few hours has again been

demonstrated on a 320 MW Turbine in

Rossano, Calabria.

PRUFTECHNIK-WIBREM Ltd.

CENTRALIGN

Laser alignment measurement

Alignment measurement turbine stages

With original rotor

With dummy shaft

Symmetrical position of

Problem with different

the clearances around the sagging of original rotor

sagging rotor when

and alignment shaft

aligning

Difficult procedures to

A lot time consumption

align dummy shaft to the

during assembly and

rotor center line position

disassembly rotor to the Time consumption during

turbine

montage and making

Dangerous wit rotors

corrections

during input into machine

so often; bearings and

other parts are not

exposed to damage

PRUFTECHNIK-WIBREM Ltd.

With CENTRALIGN

Fast, good reproducibility,

clearly graphic & text

reports

Preset values and fixed

locations - center line

analysis can be altered

even after measurement

Very easy to use

A lot time saving

CENTRALIGN

You might also like

- Mli Selection Guide 2013Document50 pagesMli Selection Guide 2013hzq1eNo ratings yet

- HSE P COW 06 Leak Testing ProcedureDocument19 pagesHSE P COW 06 Leak Testing Procedurehzq1e100% (1)

- Proses PiggingDocument1 pageProses Pigginghzq1eNo ratings yet

- ATDRDocument3 pagesATDRKiran KarthikNo ratings yet

- Commisioning Test ProcedureDocument10 pagesCommisioning Test Procedurehzq1eNo ratings yet

- 04Document1 page04hzq1eNo ratings yet

- Pull AlignDocument4 pagesPull Alignhzq1eNo ratings yet

- COMAP InteliCommunicationGuide February 07 PDFDocument91 pagesCOMAP InteliCommunicationGuide February 07 PDFhzq1eNo ratings yet

- How To Setup and Run RSLogix Emulation (SLC500&Micrologix 1000)Document4 pagesHow To Setup and Run RSLogix Emulation (SLC500&Micrologix 1000)hzq1eNo ratings yet

- Diode Failure Scenarios - Brushless ExciterDocument2 pagesDiode Failure Scenarios - Brushless ExciterTiagoFaleirosNo ratings yet

- Vibration DiagnosticsDocument54 pagesVibration Diagnosticshzq1e100% (1)

- Daily Activity HMI Upgrade TEG 9610-9620 Per November 5,2014Document11 pagesDaily Activity HMI Upgrade TEG 9610-9620 Per November 5,2014hzq1eNo ratings yet

- Conversion FormulasDocument1 pageConversion Formulaslokesc100% (11)

- Vibration Analysis A2130a2 Dual Channel Machinery Health AnalyserDocument12 pagesVibration Analysis A2130a2 Dual Channel Machinery Health Analyserhzq1eNo ratings yet

- Behind The Scene of Why Need Oil AnalysisDocument75 pagesBehind The Scene of Why Need Oil Analysishzq1eNo ratings yet

- Lev AlignDocument4 pagesLev Alignhzq1eNo ratings yet

- Pocket AlignDocument6 pagesPocket Alignhzq1eNo ratings yet

- Vibscanner ManualDocument76 pagesVibscanner Manualhzq1e100% (1)

- Aligneo 2-Page-Flyer Ali-9.110!02!07 GDocument2 pagesAligneo 2-Page-Flyer Ali-9.110!02!07 Ghzq1eNo ratings yet

- Bor AlignDocument4 pagesBor Alignhzq1eNo ratings yet

- Waplab WP 9200Document2 pagesWaplab WP 9200hzq1eNo ratings yet

- Before Applying Power: Standard Start-Up PF70, PF700, PF700VC A and PF700VC BDocument7 pagesBefore Applying Power: Standard Start-Up PF70, PF700, PF700VC A and PF700VC Bhzq1eNo ratings yet

- XM Dyn Vibration Training - Rev3Document38 pagesXM Dyn Vibration Training - Rev3hzq1eNo ratings yet

- Central I GNDocument2 pagesCentral I GNhzq1eNo ratings yet

- Project Handover GuidelinesDocument21 pagesProject Handover GuidelinesAshutosh KumarNo ratings yet

- Daftar Harga Depo Sprei 2014Document10 pagesDaftar Harga Depo Sprei 2014hzq1eNo ratings yet

- Itawari Cafe & Resto Pasir Ridge at Balikpapan: January FebruaryDocument1 pageItawari Cafe & Resto Pasir Ridge at Balikpapan: January Februaryhzq1eNo ratings yet

- SG90 Tower ProDocument2 pagesSG90 Tower ProZekah VenerosNo ratings yet

- Pre & Post Test Course ## Control System Gas Turbine ##Document5 pagesPre & Post Test Course ## Control System Gas Turbine ##hzq1eNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Kashida Embroidery: KashmirDocument22 pagesKashida Embroidery: KashmirRohit kumarNo ratings yet

- Energy Management Principles and PracticesDocument102 pagesEnergy Management Principles and PracticesConnor ReedNo ratings yet

- Criminal Law Book 2 Titles 1-8Document146 pagesCriminal Law Book 2 Titles 1-8Minato NamikazeNo ratings yet

- Krok1 EngDocument27 pagesKrok1 Engdeekshit dcNo ratings yet

- Brahm Dutt v. UoiDocument3 pagesBrahm Dutt v. Uoiswati mohapatraNo ratings yet

- Key To WORSHIP in SPIRIT and in TRUTHDocument2 pagesKey To WORSHIP in SPIRIT and in TRUTH버니 모지코No ratings yet

- Tristan TateDocument3 pagesTristan Tatecelebritydecks1No ratings yet

- Oils and Lard by Fourier Transform Infrared Spectroscopy. Relationships Between Composition and Frequency of Concrete Bands in The Fingerprint Region.Document6 pagesOils and Lard by Fourier Transform Infrared Spectroscopy. Relationships Between Composition and Frequency of Concrete Bands in The Fingerprint Region.Nong NakaNo ratings yet

- Artificial Neural NetworkDocument16 pagesArtificial Neural NetworkSahil ChopraNo ratings yet

- Unit 4: Modern Biotechnological Processes: Guidelines For Choosing Host-Vector SystemsDocument3 pagesUnit 4: Modern Biotechnological Processes: Guidelines For Choosing Host-Vector SystemsSudarsan CrazyNo ratings yet

- Blue Ocean Strategy: Case Study: Quick DeliveryDocument29 pagesBlue Ocean Strategy: Case Study: Quick DeliveryKathy V. Chua-GrimmeNo ratings yet

- Daily Hora ChartDocument2 pagesDaily Hora ChartkalanemiNo ratings yet

- Gutoiu - 2019 - Demography RomaniaDocument18 pagesGutoiu - 2019 - Demography RomaniaDomnProfessorNo ratings yet

- 9709 w06 Ms 6Document6 pages9709 w06 Ms 6michael hengNo ratings yet

- A Case Study On College Assurance PlanDocument10 pagesA Case Study On College Assurance PlanNikkaK.Ugsod50% (2)

- Tugas Week 6 No 8.23Document5 pagesTugas Week 6 No 8.23Mikael MuhammadNo ratings yet

- Introduction and Assessment of The Renal - Urological SystemDocument182 pagesIntroduction and Assessment of The Renal - Urological SystemValerie Suge-Michieka100% (1)

- Christify LyricsDocument1 pageChristify LyricsJomel GarciaNo ratings yet

- Unit 9Document3 pagesUnit 9LexNo ratings yet

- General ManagementDocument47 pagesGeneral ManagementRohit KerkarNo ratings yet

- Anya Detonnancourt - Student Filmmaker ReflectionsDocument2 pagesAnya Detonnancourt - Student Filmmaker Reflectionsapi-550252062No ratings yet

- Sword Art Online - Unital Ring IV, Vol. 25Document178 pagesSword Art Online - Unital Ring IV, Vol. 257022211485aNo ratings yet

- Contract ManagementDocument26 pagesContract ManagementGK TiwariNo ratings yet

- Meditation Club of RUET Asif EEE 17 PDFDocument2 pagesMeditation Club of RUET Asif EEE 17 PDFShovonNo ratings yet

- Law 431 Course Outline (Aug 22-23)Document3 pagesLaw 431 Course Outline (Aug 22-23)Precious OmphithetseNo ratings yet

- System Design PrimerDocument60 pagesSystem Design PrimerPendyala SrinivasNo ratings yet

- Abella vs. CSCDocument17 pagesAbella vs. CSCRocky Diente SenupeNo ratings yet

- 12 Houses ExplainedDocument3 pages12 Houses ExplainedKoshi EnterprisesNo ratings yet

- Developmental Stages WritingDocument2 pagesDevelopmental Stages WritingEva Wong AlindayuNo ratings yet

- Na'aman, Josiah & The Kingdom of JudahDocument32 pagesNa'aman, Josiah & The Kingdom of JudahKeith HurtNo ratings yet