Professional Documents

Culture Documents

HE Material

HE Material

Uploaded by

Jignesh PandyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

HE Material

HE Material

Uploaded by

Jignesh PandyaCopyright:

Available Formats

INTRODUCTION :

AS GIVEN IN NAME THIS IS TO EXCHANGE HEAT FROM ONE MEDIUM TO ANOTHER MEDIUM

BASED ON APPLICATION AND REQUIREMENT HES ARE DESIGNED INDIFFERENT CONFIGURATION.

Type of HEs :

Counter-flow Heat Exchanger

Parallel-flow Heat Exchanger

CLASIFICATION ON HEAT TRANSFER BASIS

DIRECT TRANSFER

1. TUBULAR HEAT EXCHANGERS

CONCENTRIC AND DOUBLE PIPE HES

SHELL AND TUBE HEAT EXCHANGERS

2. PLATE HEAT EXCHANGERS

3. EXTENDED SURFACE HES

STORAGE

DIRECT CONTAT

SHELL AND TUBE HEAT EXCHANGERS ARE MOST COMMONLY USED HES IN

PROCESS INDUSTRY

Fixed tube sheet type

Mostly used for moderate services

Low thermal stresses

Limitations: Shell side cleaning and repair not possible

U- tube type

For high pressure and high temperature services

Tube bundle is removable for cleaning

Limitations: inner tubes cannot be replaced with out removing outer tubes

Floating Head type

Widely used in petroleum industry

Clearance between shell and outer tube limit is larger

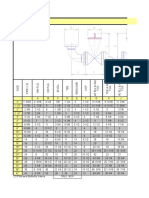

TUBE SHEET :

CRITICAL DIMENSIONS:

THICKNESS

HOLES PITCH

HOLE FINISH :

SMOOTH FINISH

TO AVOIDS DAMAGE ON PIPE OD

ALLOWS EASY INSERTION OF PIPE

BUT, LOW MECHANICAL STREANGTH BETWEEN TUBE AND TUBE

SHEET

GIVES GOOD TIGHTNESS

ROUGH FINISH

GIVES MORE MECHANICAL STREANGTH BETWEEN TUBE AND TUBE SHEET

BUT TUBE OD MAY GET LONGITUDINAL SCRATCHES WHICH MAY LEAD TO

LEAK PATH..

IN GENERAL: LIGHT WALL TUBES NEED MORE SMOOTH FINISH COMPARED

TO HEAVY THICK TUBES.

TUBE SHEET PITCHES : INFLUENCE ON

Lower the pitch More tubes can be accommodate-More Heat Transfer area.

For Small pressure drop large pitch required.

TYPES OF PITCHES:

Triangle

Square

Triangular rotate

Square rotate

CRITICAL: Uniformity in pitch is important, Since it will have impact on

Functionally and also avoids trouble further fabrication activities like tube insertion,

tube to tube sheet expansion and welding.

BAFFLE PLATES:

FUNCTION: 1) DIRECT FLUID FLOW

2) SUPPORT TUBES TO REDUCE FLOW INDUCED VIBRATIONS.

TYPES: 1) HORIZONTAL CUT PATTERN

2) VERCAL CUT PATTERN

3) Up & Down Flow pattern etc.,

CRITICAL ASPECTS TO CHECK:

1) PATTERN

2) PITCH

3)STRAIGHTNESS

4)DEBURRING

5)CLEARANCE BETWEEN SHELL ID AND BAFFLE OD.

6)TUBE TO HOLE CLEARANCE.

7)SPACING BETWEEN BAFFLES

IMPINGEMENT BAFFLE: THESE BAFFLE LOCATED AT INLET TO AVOID

1) SUSPENDED FLOW PARTICLES

2) TO REDUCE IMPACT OF FLOW FORCE ON TUBES

SEALING STRIPS:

TIE RODS & SPACERS:

You might also like

- Heat Exchanger Types and SelectionDocument31 pagesHeat Exchanger Types and Selectionmehul10941No ratings yet

- Heat Exchanger DesignDocument15 pagesHeat Exchanger Designcoldness_13No ratings yet

- Basics of Double Pipe Heat Exchanger (Heat Transfer Slides)Document38 pagesBasics of Double Pipe Heat Exchanger (Heat Transfer Slides)Asad Imran Munawwar100% (2)

- Mod1 Nptel Process Exchanger DesignDocument41 pagesMod1 Nptel Process Exchanger DesignAnirudh KaulNo ratings yet

- Heat Exchangers, Strainers and SeperatorsDocument12 pagesHeat Exchangers, Strainers and SeperatorsJaveed A. Khan100% (1)

- Piping NotesDocument11 pagesPiping NotesRavindra S. JivaniNo ratings yet

- Ped CB208 P8 1Document57 pagesPed CB208 P8 1Siddhant SoymonNo ratings yet

- Heat Exchanger FinalDocument35 pagesHeat Exchanger Finalshabirahsan79No ratings yet

- Why A Shell and Tube Heat Exchanger?Document17 pagesWhy A Shell and Tube Heat Exchanger?Avishek KumarNo ratings yet

- Air-Cooled Heat Exchangers Fin-Fan: by M.M.SorourDocument64 pagesAir-Cooled Heat Exchangers Fin-Fan: by M.M.SorourNader GaafarNo ratings yet

- Air Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&AFrom EverandAir Cooled Heat Exchanger Handbook: Fundamentals, Calculations, Design and Q&ANo ratings yet

- Shell and Tube Ref - AnandDocument6 pagesShell and Tube Ref - Anand7761430No ratings yet

- Heat Exchanger Design - ProcessDocument42 pagesHeat Exchanger Design - Processalokbdas100% (1)

- Heat Exchanger PresentationDocument66 pagesHeat Exchanger PresentationMahmoud100% (1)

- Design Procedure For Pressure VesselDocument200 pagesDesign Procedure For Pressure VesselSuryaprakash100% (1)

- SHT ExchangerDocument55 pagesSHT ExchangerCc12 22tNo ratings yet

- Chapter No.6: Design of Heat ExchangerDocument35 pagesChapter No.6: Design of Heat ExchangerGlacier RamkissoonNo ratings yet

- Chemical Design of Heat Exchanger TerdesakDocument22 pagesChemical Design of Heat Exchanger TerdesakNor Ain100% (4)

- Shell and Tube Heat ExchangerDocument112 pagesShell and Tube Heat Exchangerramesh pokhrel100% (3)

- Heat Exchanger - Design CalculationDocument30 pagesHeat Exchanger - Design CalculationdiptyaNo ratings yet

- Piping ComponentsDocument39 pagesPiping Componentsbvenky991100% (1)

- Sthe SSDocument43 pagesSthe SSNathanianNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Heat Exchanger - PPT (Recovered)Document53 pagesHeat Exchanger - PPT (Recovered)Jignesh PandyaNo ratings yet

- Double Pipe Heat ExchangerDocument5 pagesDouble Pipe Heat ExchangerSheb LorenoNo ratings yet

- Plate Type Heat ExchangerDocument28 pagesPlate Type Heat ExchangerJagadeesan Sai100% (1)

- Heat ExchangersDocument8 pagesHeat ExchangersLiyan Fajar GintaraNo ratings yet

- Inspection of Double Tube Sheet Exch - Presentation1Document37 pagesInspection of Double Tube Sheet Exch - Presentation1Asad Bin Ala QatariNo ratings yet

- Din 2605Document3 pagesDin 2605METALBAMENo ratings yet

- PHT Unit-5 (THEORY)Document81 pagesPHT Unit-5 (THEORY)521 Balaji ONo ratings yet

- Presentation On Shell & Tube ExchangerDocument32 pagesPresentation On Shell & Tube Exchangersaurabhmeshram88No ratings yet

- ABC 200 Heat ExchangerDocument200 pagesABC 200 Heat Exchanger전상문100% (2)

- Heat ExchangerDocument6 pagesHeat ExchangeralokbdasNo ratings yet

- Recent Trend in Heat ExchangerDocument9 pagesRecent Trend in Heat Exchangersai100% (1)

- Type of Heat ExchangersDocument46 pagesType of Heat ExchangersguravdrNo ratings yet

- Heat Exchanger SizingDocument6 pagesHeat Exchanger Sizingshoaib705No ratings yet

- Presentation For Shell & Tub Heat ExchangerDocument33 pagesPresentation For Shell & Tub Heat ExchangerHoa Hoang PhuNo ratings yet

- Drop Through The Exchanger, Which Can Result in HigherDocument6 pagesDrop Through The Exchanger, Which Can Result in Higherjoana_vibar100% (1)

- Heat ExchangerDocument9 pagesHeat ExchangerChrissa Villaflores GanitNo ratings yet

- Document 1Document4 pagesDocument 1SAMARTHNo ratings yet

- Details of Engineering Design and Selection of Heat ExchangerDocument25 pagesDetails of Engineering Design and Selection of Heat ExchangerthejusNo ratings yet

- Sop PPT2Document16 pagesSop PPT2Anusha SinghNo ratings yet

- Designing AND Optimization OF A Shell and Tube Heat ExchangerDocument8 pagesDesigning AND Optimization OF A Shell and Tube Heat ExchangerAyush SinghNo ratings yet

- Baffles Types and GeometryDocument16 pagesBaffles Types and GeometryPaul Arokiam SNo ratings yet

- Heat Transfer MidtermDocument29 pagesHeat Transfer MidtermIvan Jeremy AbilaNo ratings yet

- Project PPT of Heat ExchangerDocument18 pagesProject PPT of Heat ExchangerGaurav Thakkar50% (2)

- HTED Shell and Tube H.ex. 2020Document68 pagesHTED Shell and Tube H.ex. 2020Vinesh KumarNo ratings yet

- Part.a.classification of Heat ExchangersDocument11 pagesPart.a.classification of Heat ExchangersAhmed GadNo ratings yet

- Figure 1: Schematic of A Shell-and-Tube Heat ExchangerDocument7 pagesFigure 1: Schematic of A Shell-and-Tube Heat ExchangerSarthak RautNo ratings yet

- Heat Exchanger Types and SelectionDocument4 pagesHeat Exchanger Types and Selection12mchc07No ratings yet

- Classification According To Construction FeaturesDocument30 pagesClassification According To Construction FeaturesImraan KhanNo ratings yet

- Raj Khare (181113044) Chemical Engineering, 7 Sem PED-II Assignment - 1Document10 pagesRaj Khare (181113044) Chemical Engineering, 7 Sem PED-II Assignment - 1A KhapreNo ratings yet

- Heat ExchangerDocument22 pagesHeat ExchangerYashwant SinghNo ratings yet

- PED Ch2Document30 pagesPED Ch2Shubham KumarNo ratings yet

- What Are The Types of Heat ExchangersDocument9 pagesWhat Are The Types of Heat Exchangersjr gajelesNo ratings yet

- Helical Baffle Design in Shell and Tube Type Heat Exchanger With CFD AnalysisDocument6 pagesHelical Baffle Design in Shell and Tube Type Heat Exchanger With CFD AnalysispriyabNo ratings yet

- Shell and Tube Heat ExchangersDocument16 pagesShell and Tube Heat Exchangersmohamad ltefNo ratings yet

- TEMA Terminology:: o o o o oDocument5 pagesTEMA Terminology:: o o o o oNathanianNo ratings yet

- DR. Mohammed A.kassem: Design Shell and Tube HEX Air Cooler HEXDocument105 pagesDR. Mohammed A.kassem: Design Shell and Tube HEX Air Cooler HEXعمر محمد عبدالرحمن عليNo ratings yet

- 4.4. Shell-And-Tube Heat Exchangers 2022Document29 pages4.4. Shell-And-Tube Heat Exchangers 2022ziphatheesona242No ratings yet

- L&T Valves - PpsDocument1 pageL&T Valves - PpsJignesh PandyaNo ratings yet

- RDocument161 pagesRJignesh PandyaNo ratings yet

- Plug Valves PDFDocument23 pagesPlug Valves PDFJignesh PandyaNo ratings yet

- MSS SP-69 Selection and Application PDFDocument20 pagesMSS SP-69 Selection and Application PDFJignesh PandyaNo ratings yet

- Trunnion Mounted Ball ValveDocument20 pagesTrunnion Mounted Ball ValveJignesh PandyaNo ratings yet

- MSS SP-61 Pressure Testing of Steel Values PDFDocument8 pagesMSS SP-61 Pressure Testing of Steel Values PDFJignesh PandyaNo ratings yet

- Piping Valve Flange DimensionsDocument252 pagesPiping Valve Flange DimensionschadNo ratings yet

- Thu Jun 07 07:52:00 2001Document40 pagesThu Jun 07 07:52:00 2001Jignesh PandyaNo ratings yet