Professional Documents

Culture Documents

FP-VRC Catalog PDF

FP-VRC Catalog PDF

Uploaded by

frazOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

FP-VRC Catalog PDF

FP-VRC Catalog PDF

Uploaded by

frazCopyright:

Available Formats

FP-VRC

FP-VRC

Four Post Vertical Reciprocating Conveyor

PROFESSIONAL PARKING SOLUTION PROVIDER!

WE PLAN , DESIGN, MANUFACTURE AND INSTALL...

QINGDAO MUTRADE CO., LTD.

FP-VRC

Four Post Vertical Reciprocating Conveyor

Introduction

VRC (Vertical Reciprocating Conveyor) is a

transportation conveyor moving car from one

floor to another, it is a highly customized

product, which could be customized according

to customers different requirements from lifting

height, lifting capacity to platform size!

-FP-VRCis a kind of car or goods lift, and industry

use vertical table lift

-Self-standing and self-support structure

-Hydraulic cylinder + steel chains drive system

-High precision and stable hydraulic drive system

-Automatic shut-off if operator releases the button

switch

-Double chain design for higher safety

-High density chains with longer service lift

-Remote control is optional

-Top quality diamond steel plate

-Hydraulic overloading protection available

General Parts

Double chains Safety Features

2 Hydraulic cylinder

1

1 Double Chain

-High density chains with longer service life

Safety rail

Data Sheet FP-VRC 03 2014 QingDao Mutrade Co,.Ltd.

5

Pallet

3 4

Carriage

Post

2 High precision

-hydraulic drive system

Power pack &

main control panel 3 Limit switch

-To stop the power pack pumping

when the platform reach the floors

Basement 4 Stable

Ramp -145mm thickness platform

5 900mm high safety rail

Qingdao Mutrade Co., Ltd. www.qdmutrade.com Page 1 of 5

Specifications

Model FP-VRC

Lifting capacity 2,000-10,000 kg*can be customized according to your requirement

Lifting height 2,000-13,500mm*can be customized according to your requirement

Platform length 2000mm-6000mm*can be customized according to your requirement

Platform width 2000mm-5000mm*can be customized according to your requirement

Platform material Diamond steel sheet (standard) / 4mm Aluminum steel sheet (optional)

No. of level according to your requirement

Drive mode Hydraulic(cylinder with double steel chains)

Operation button switch (standard) / remote controller (optional)

Power pack 4 kw hydraulic power pump

Lifting speed 4m/min

Safety devices Mechanical anti-falling lock

Finishing Paint spray

Color according to your requirement

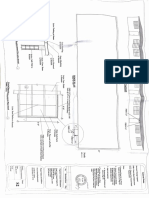

Reference Drawing

QINGDAO MUTRADE CO., LTD. 533 755

TPTP-2

110

TPP-2

326 2120

187

6640

6300

FPSP-4

5000

5000

200

900

1900

FPP-2

200.0

446 446 2300

5000

2500

Main tachnicaI parameters

BDP-3

Lifting weight:5000kg

PFPP-3

Lift Stroke:5000mm

Lifting speed:more than 4000mm/min

Pump pressure:18MPa

2500

VRC

Motor power:4kw

4550

4800

CTT

Drawing above is just a sample, for specific project please contact our sales to confirm exact specifications and

drawing.

Qingdao Mutrade Co., Ltd. www.qdmutrade.com Page 2 of 5

Electric & Hydraulic System

Electric

Code Model Name Specifications Quantity

-KM

FU1 U2 KM CTX2-1201 AC Contactor

L1 24V 1

FU2 V2 M

L2 KA JZ7-44 Intermediate

FU3 W2 ~ 24V 1

L3

PE Relay

AC BK50 Transformer 50VA 380V-24V 1

FU RT18-32X Fuse FU1,FU2,FU3/20A 4

SA SB

FU4/10A

AC 1 2 KA SAO 11Y/Z Electrical Look 1

SB1 SB2 KM1 KA1

SBO 11Y/Z Emergency Stop 1

380V

24V

FU4

Button

KA2 KM1

SB LA-19 Button 2

KM KA VC DC

LH HL2AD11-24V Indicator Light 1

LH

JTE-1081J Alarm Lamp 2

4

KA SQ YBLX-K111

50 Limit switch 1

3

M Y112M-4 Motor 1

OC Solenoid valve 24V 1

Hydraulic System

7

Number Modol Name Quantity Remark

6

1 WU63100 Filter 1

5 2 CBW310 Oil pump 1 Pressure 21MPa

8 3 YF-L10H4 Preasure relief valve 1 31.5MPa

4

4 DFY-L10H2 One -way valve 1

9 5 Pressure mater 1

6 DSG-03-2B2 Electromagnatic 1 24AC

M

-D24-DL directional valve

3

7 Hydraulic cylinder 1

8 KC-03 Flow control valve 1

2

9 Y112M-4 Motor 1 Power 4KW

1

Mechanical System

Chains diagram Lock diagram

Locking latch

Chain Lifting frame

Transmission beam schematic

Cylinder head schematic Chain

Chain

Chain

platfom schematic

Cylinder schematic Locking plate

Column

Locking latch is at the position during maintenance Locking latch is at the position during operation

Locking latch position diagram

Qingdao Mutrade Co., Ltd. www.qdmutrade.com Page 3 of 5

Installation & Maintenance Plan

Installation

(1) Install the automobile lift on a hard concrete foundation which could not vibrate during work.

(2) Install the column bolts in the chassis, and fix the chassis to the ground vertically after installation.

(3) Bolt the transmission beam to the vertical column.

(4) Connect the tray to the lifting beam.

(5) Connect the chains.

(6) Fix the hydraulic station to the back of a vertical column, connect an oil tube, and fill 30# hydraulic oil to the oil tank of

the pump station.

(7) Apply grease to chains and idler pulleys.

Maintenance and Service

(1) Keep clean

Keep this automobile lift clean. Before cleaning, turn power off to assure safety.

(2) Keep the workplace clean. Too much dust will wear the parts and shorten their service life.

(3) Check the chains

Check the chains are in good conditions. In case of chain failure, repair it immediately to prevent an accident.

(4) Maintenance of the hydraulic system

i. Cleaning and oil replacement

After three months use of this automobile lift, clean the hydraulic system and replace 30# hydraulic oil. After that, clean

the hydraulic system and replace 30# hydraulic oil once every six months.

Packaging

Standard packaging:

At MUTRADE, we offer professional steel frame packaging for easy and stable container load. There are 2 types of different

packaging:

1.Packing by single unit(good for retails,

all the parts and structures packaging

separately)

2. Packing by two or more units (good for

big projects, similar parts are packed

together, e.g. all platform parts in 1

package, posts in other packages). It

takes less container space and saves

delivery cost.

Qingdao Mutrade Co., Ltd. www.qdmutrade.com Page 4 of 5

Q&A

1. Is this product can be used indoor or outdoor?

FP-VRC can be installed both indoor and outdoor as long as the site dimensions are enough.

2. What is the surface finishing for this product?

Its paint spray as standard treatment, and optional aluminum steel sheet can be covered above for better water-proof and

looking.

3. What is the power requirements? Is single phase acceptable?

Generally speaking, a 3-phase power supply is a must for our 4Kw motor. If the usage frequency is low (less than one

movement per hour), a single phase power supply can be used, otherwise it may lead to motor burnt out.

4. Can this product still operate if electricity failure happens?

Without electricity the FP-VRC cannot work, so a back-up generator may be needed if electricity failure happens often in

your city.

5. What is the warranty?

Its five years for main structure and one year for moving parts.

6. What is the production time?

Its 30 days after prepayment and final drawing confirmed.

7. What is the shipping size? Is LCL acceptable, or it must be FCL?

As FP-VRC is a fully customized product, the shipping size depends on the specifications you need.

As there are some electrical parts and hydraulic parts, and the packages for components are in different shapes, LCL cannot

be used. 20 feet or 40 feet container is necessary as per the lifting height.

Reference Pictures

Qingdao Mutrade Co., Ltd. Tel : +86 532 5557 9606/608 Add: Room205, BuiLding A, #63 Haier Road, Page 5 of 5

Website:www.qdmutrade.com Fax: +86 532 5557 9607 Laoshan District, Qingdao, China 266100

You might also like

- DE712 Spec Sheet 02 2018Document5 pagesDE712 Spec Sheet 02 2018Zeus ChillopaNo ratings yet

- LDocument5 pagesLKatherine NaveaNo ratings yet

- Assignment 6 - Rapid Miner PDFDocument3 pagesAssignment 6 - Rapid Miner PDFAkriti JaiswalNo ratings yet

- Electric Mining Shovel - DC Drive Product OverviewDocument5 pagesElectric Mining Shovel - DC Drive Product OverviewLeandro Jaimes AlvaradoNo ratings yet

- Strapping Machines 2Document8 pagesStrapping Machines 2312653653No ratings yet

- Hydro Park 1123 PrintDocument14 pagesHydro Park 1123 PrintKamen RNo ratings yet

- Hydra Rig HR 660 Coiled Tubing Injector Data SheetDocument2 pagesHydra Rig HR 660 Coiled Tubing Injector Data SheetЭльмирNo ratings yet

- Hydra Rig HR 680 Coiled Tubing Injector Data SheetDocument2 pagesHydra Rig HR 680 Coiled Tubing Injector Data SheetDowell Josp RalhNo ratings yet

- Demag PDFDocument40 pagesDemag PDFclaudinei alves fonsecaNo ratings yet

- DX220AF: Construction EquipmentDocument10 pagesDX220AF: Construction EquipmentBolivar LemaNo ratings yet

- Khodiyar Engineering CatlogeDocument12 pagesKhodiyar Engineering Catlogemanoj_doshi_1No ratings yet

- CatalogueDocument2 pagesCatalogueganesh_d2k6No ratings yet

- Oleo Buffer Stop Hydraulic FrictionDocument2 pagesOleo Buffer Stop Hydraulic FrictionShahryarNo ratings yet

- xs-5487-1 2800xpc DC BroDocument5 pagesxs-5487-1 2800xpc DC BrojohnNo ratings yet

- Demag CraneDocument12 pagesDemag Cranesaleh.sajjadyNo ratings yet

- Walking SystemDocument2 pagesWalking SystemLuis Eduardo Ferro CotesNo ratings yet

- JAB LKW LeafletDocument9 pagesJAB LKW LeafletDSNo ratings yet

- Planeta Rapk: RAPK Aluminium Gantry Crane Can Be UsedDocument2 pagesPlaneta Rapk: RAPK Aluminium Gantry Crane Can Be UsedGURUMOORTHY PNo ratings yet

- Catalog - Conveyor Systems OverviewDocument16 pagesCatalog - Conveyor Systems Overviewleomariano21No ratings yet

- Epiroc FR T45Document5 pagesEpiroc FR T45RAFTAMA JAYA ABADINo ratings yet

- OM Industries: "Material Handling Equipment Manufacturer"Document12 pagesOM Industries: "Material Handling Equipment Manufacturer"krupesh patelNo ratings yet

- Engineered Conveyor Pulleys: Power Transmission ComponentsDocument2 pagesEngineered Conveyor Pulleys: Power Transmission ComponentsHà NguyễnNo ratings yet

- Wormgaer Winches MC-L and MC-HDocument2 pagesWormgaer Winches MC-L and MC-Handy131078No ratings yet

- Resources PDF 342606091Document4 pagesResources PDF 342606091Praveen MNo ratings yet

- 111031Document21 pages111031setiawanayNo ratings yet

- Hegenscheidt RRE CatalogueDocument32 pagesHegenscheidt RRE Catalogueperrimeisonensalou001No ratings yet

- Electric Mining Shovel - DC Drive Product OverviewDocument5 pagesElectric Mining Shovel - DC Drive Product OverviewmohanNo ratings yet

- Product DirectoryDocument8 pagesProduct DirectoryĐăng Điệp NguyễnNo ratings yet

- Brosura Statii Sortare Gama MDocument7 pagesBrosura Statii Sortare Gama MBora TinaNo ratings yet

- RackerDocument1 pageRackerDavid MayNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)Hendra HalimNo ratings yet

- Demag DMR (Brochure)Document20 pagesDemag DMR (Brochure)MadhaneNo ratings yet

- SPL 1000Document4 pagesSPL 1000Lúcio MartinsNo ratings yet

- TRB - 8 Pages - GBDocument5 pagesTRB - 8 Pages - GBСергей ЧетвериковNo ratings yet

- Automatic Guided Vehicle Systems (AGVS) : Unit Load Carrier VehiclesDocument8 pagesAutomatic Guided Vehicle Systems (AGVS) : Unit Load Carrier VehiclesMohit ComputerNo ratings yet

- The Industry's Most Innovative Solution To Big Rough Terrain Cranes Maneuverability and Transportability!Document8 pagesThe Industry's Most Innovative Solution To Big Rough Terrain Cranes Maneuverability and Transportability!eduardoNo ratings yet

- Link Belt Crawler Cranes Spec dfd279Document82 pagesLink Belt Crawler Cranes Spec dfd279Lorena ReyesNo ratings yet

- 9407 GB Telescopic GantriesDocument12 pages9407 GB Telescopic GantriesSebastian VelasquezNo ratings yet

- Equipment Placement - Product Catalog - CompressedDocument12 pagesEquipment Placement - Product Catalog - CompressedisbrediputraNo ratings yet

- Rolling 412 Standard enDocument2 pagesRolling 412 Standard enMAMI RAKOTOMAHANINANo ratings yet

- FlexiROC T35 & T40Document5 pagesFlexiROC T35 & T40Kemal MalicbegovicNo ratings yet

- 克隆伯格Kronenburg Appendix Crashtender Brochure Range 2013Document2 pages克隆伯格Kronenburg Appendix Crashtender Brochure Range 2013GinoGuanNo ratings yet

- Industry-Port Goodyear-7-2020Document13 pagesIndustry-Port Goodyear-7-2020Percy Robert Olaechea ZunigaNo ratings yet

- Gantry Crane Brochure Website 2Document40 pagesGantry Crane Brochure Website 2Thein MaungNo ratings yet

- SPS 12500 Stiff Boom Crane: Ideal Lifting Solution For 2 & 3 Axle TrucksDocument4 pagesSPS 12500 Stiff Boom Crane: Ideal Lifting Solution For 2 & 3 Axle Trucksanon_485665212No ratings yet

- WARMAN - Q-Series Axial Flow Pumps-EN-2015 - PREVIEWDocument8 pagesWARMAN - Q-Series Axial Flow Pumps-EN-2015 - PREVIEWmicheldenijs84No ratings yet

- L GH Catalog PullingDocument60 pagesL GH Catalog PullingLuis LuperdiNo ratings yet

- Rotary Motions RR-Heavy DutyDocument8 pagesRotary Motions RR-Heavy DutyLucas Vinícius CostaNo ratings yet

- National 800D PDFDocument16 pagesNational 800D PDFmarisol ibarraNo ratings yet

- NDMBrochureDocument16 pagesNDMBrochurepnsanatNo ratings yet

- Demag Chain Hoist NewDocument40 pagesDemag Chain Hoist Newparahu ariefNo ratings yet

- Crane Dimension: Technical SpecificationDocument1 pageCrane Dimension: Technical Specificationilham firmansyahNo ratings yet

- Linearlift EATP EnglDocument2 pagesLinearlift EATP EnglMarius SauciucNo ratings yet

- Belt Conveyor BrochureDocument5 pagesBelt Conveyor BrochureMostafa Farahani100% (1)

- Electric Reach Truck 48 Volt 1400 / 1600 KG 2800 / 3200 LbsDocument8 pagesElectric Reach Truck 48 Volt 1400 / 1600 KG 2800 / 3200 LbsThanh Ngoc0% (1)

- 244 Hydraulic ActuatorsDocument3 pages244 Hydraulic ActuatorsjmezapNo ratings yet

- Conolift: Marine Hydraulic EquipmentDocument24 pagesConolift: Marine Hydraulic EquipmentRoberto Omar Morante VillarrealNo ratings yet

- MC 100 Cargador de ExplosivosDocument8 pagesMC 100 Cargador de ExplosivosWiwa Hernandez Donoso100% (1)

- Oleo Buffer Stop Fixed HydraulicDocument2 pagesOleo Buffer Stop Fixed HydraulicShahryarNo ratings yet

- Wyma Lift Roller Sizer May - 2013Document4 pagesWyma Lift Roller Sizer May - 2013Marcelo CamargoNo ratings yet

- Some Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentFrom EverandSome Aspects of Hydraulics in Mechanical Handling and Mobile EquipmentRating: 3.5 out of 5 stars3.5/5 (2)

- San Francisco Bikeway Network Map: LegendDocument1 pageSan Francisco Bikeway Network Map: LegendfrazNo ratings yet

- DIY eGPU Experiences - Page 419 - NotebookReview PDFDocument17 pagesDIY eGPU Experiences - Page 419 - NotebookReview PDFfrazNo ratings yet

- Pearl Thompson - WikipediaDocument3 pagesPearl Thompson - WikipediafrazNo ratings yet

- Dick Clark - WikipediaDocument13 pagesDick Clark - WikipediafrazNo ratings yet

- Pink Moon - WikipediaDocument8 pagesPink Moon - WikipediafrazNo ratings yet

- Handprint - RedDocument16 pagesHandprint - RedfrazNo ratings yet

- Handprint - YellowDocument17 pagesHandprint - YellowfrazNo ratings yet

- Orange: Key To The Paint RatingsDocument6 pagesOrange: Key To The Paint RatingsfrazNo ratings yet

- Orange: Key To The Paint RatingsDocument6 pagesOrange: Key To The Paint RatingsfrazNo ratings yet

- Handprint - The Complete PaletteDocument9 pagesHandprint - The Complete PalettefrazNo ratings yet

- Owner'S Manual Owner'S Manual: Designed in Southern California byDocument8 pagesOwner'S Manual Owner'S Manual: Designed in Southern California byfrazNo ratings yet

- Homemade Pork Tocino Recipe - Recipe Ni JuanDocument5 pagesHomemade Pork Tocino Recipe - Recipe Ni JuanfrazNo ratings yet

- I Get Around - WikipediaDocument5 pagesI Get Around - WikipediafrazNo ratings yet

- OTIS FreightElevators PDFDocument1 pageOTIS FreightElevators PDFfrazNo ratings yet

- Infinity Pool - WikipediaDocument2 pagesInfinity Pool - WikipediafrazNo ratings yet

- Little Saint Nick - WikipediaDocument2 pagesLittle Saint Nick - WikipediafrazNo ratings yet

- Icici PoDocument5 pagesIcici Potanujchopra1No ratings yet

- "A Generation of Leadership and Excellence" Curriculum VitaeDocument3 pages"A Generation of Leadership and Excellence" Curriculum Vitaebabs23No ratings yet

- YAMAHA MG C Models DatasheetDocument2 pagesYAMAHA MG C Models DatasheetZoliValyiNo ratings yet

- Fascia Repair DetailsDocument2 pagesFascia Repair DetailsPatricia TicseNo ratings yet

- Compulsory To All Branch 14Phdrm: Research MethodologyDocument6 pagesCompulsory To All Branch 14Phdrm: Research MethodologyAmbica AnnavarapuNo ratings yet

- User Home Folders - SambaWikiDocument7 pagesUser Home Folders - SambaWikiedwinNo ratings yet

- First DemandDocument1 pageFirst Demandbodyofagod1108No ratings yet

- Service Manual: SS-DR4/DR7AV/XB500Document2 pagesService Manual: SS-DR4/DR7AV/XB500DakhNo ratings yet

- Audit of Fleet ManagementDocument17 pagesAudit of Fleet Managementhatemhendawi74No ratings yet

- Systems TheoryDocument5 pagesSystems TheoryGaoudam NatarajanNo ratings yet

- The MailboxesDocument4 pagesThe MailboxesDayanaNo ratings yet

- B.ingg Minat AjisDocument4 pagesB.ingg Minat Ajistoniibu87No ratings yet

- Creating A Painting RubricDocument1 pageCreating A Painting Rubricapi-376050083No ratings yet

- Blue Ocean BrainDocument2 pagesBlue Ocean BrainJeffrey LodenNo ratings yet

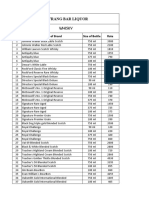

- Hotel Navrang Liquor NON-1Document6 pagesHotel Navrang Liquor NON-1gourav.damadeNo ratings yet

- Cleft Lip PalateDocument37 pagesCleft Lip PalateMuhammad Hamid Muktashim100% (1)

- Ancient Echoes PDFDocument18 pagesAncient Echoes PDFDick DansleyNo ratings yet

- Introduction To Mental RetardaDocument6 pagesIntroduction To Mental RetardadrumeshozaNo ratings yet

- Parental Leave Will CostDocument284 pagesParental Leave Will CostHòa HuỳnhNo ratings yet

- Absorption II. Abstrip-Packed - ColumnsDocument58 pagesAbsorption II. Abstrip-Packed - ColumnsAnonymous wCDPbgMLJNo ratings yet

- United States District Court Order To Show CauseDocument2 pagesUnited States District Court Order To Show CauseAndre Duke CoulterNo ratings yet

- Building For Future LTD.: Project:Sajeda OrchidDocument2 pagesBuilding For Future LTD.: Project:Sajeda OrchidhelalNo ratings yet

- Top 10 Tricks For Delphi and C++Builder VCL Database Developers by Cary JensenDocument25 pagesTop 10 Tricks For Delphi and C++Builder VCL Database Developers by Cary JensenIP ManNo ratings yet

- KL University, Vaddeswaram, Dept. of ECE, Signal Analysis (15 ES 2002) Lesson-1b Fundamentals of SignalsDocument16 pagesKL University, Vaddeswaram, Dept. of ECE, Signal Analysis (15 ES 2002) Lesson-1b Fundamentals of SignalsramsastryNo ratings yet

- Chapter 4 Capacitance PDFDocument12 pagesChapter 4 Capacitance PDFRessyl Mae PantiloNo ratings yet

- Prof Ed 1Document26 pagesProf Ed 1Jenelyn GafateNo ratings yet

- Na C2 O4Document5 pagesNa C2 O4Fernando AriantoNo ratings yet

- Silo - Tips - Employee Welfare in Singareni Collieries Company Limited A StudyDocument125 pagesSilo - Tips - Employee Welfare in Singareni Collieries Company Limited A StudyDivya Darshini SaravananNo ratings yet

- Eating Your Lover's Otherness: Cahiers de Recherches Médiévales Et HumanistesDocument21 pagesEating Your Lover's Otherness: Cahiers de Recherches Médiévales Et HumanistesMariam MüllerNo ratings yet