Professional Documents

Culture Documents

Tool Life

Uploaded by

trimohitOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Tool Life

Uploaded by

trimohitCopyright:

Available Formats

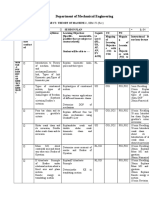

Tool Life

Three common modes of tool failures:

1).Fracture failure: this mode of failure occurs when the cutting

force at the tool point becomes excessive, causing it to fail

suddenly by brittle fracture.

2). Temperature failure: this failure occurs when the cutting

temperature is too high for the tool material, causing the material

at the tool point to soften, which leads to plastic deformation and

loss of the sharp edge.

3). Gradual wear: gradual wearing of the cutting edge causes loss

of tool shape, reduction in cutting efficiency, accelerated wear, and

final tool failure in a manner similar to a temperature failure.

Note: Modes 1) and 2) result in premature (or unexpected) loss of the cutting tool, therefore, it is

undesirable tool failure.

Tool Wear

Abrasion: this is a mechanical wearing action

due to hard particles in the work material

gouging and removing small portions of the

tool.

Location: both on rake and flank faces.

Adhesion: as the cutting chip flows across the

tool under high temperature and high pressure,

small particles of the tool are "welded" to the

chip surface and taken away.

Location: mostly on the rake face.

Diffusion: is a process in which an exchange

of atoms takes place across a close contact at

the tool-chip boundary between two materials.

Location: on the rake face.

Tool Life

Tool life is defined as the length of cutting time that the

tool can be used.

1) Rapid initial wear;

2) Steady-state wear;

1.Failure-state wear.

Taylor Tool Life Equation

v Tn = C

where v = cutting speed, ft/min (m/min), T = tool life; and n and C are parameters

whose values depend on feed, depth of cut, work materials, tool material, and tool

life criterion used.

Tool life criteria in production

1.Complete failure of the cutting edge;

2.Chips becomes ribbony, stingy, and difficult to dispose of;

3.Degradation of the surface finish on the work;

4.Cumulative cutting time or workpiece count.

Tool Materials

Required Properties for better wear resistance

Toughness: the capacity of a material to absorb energy

without failing.

Hot hardness: the ability to retain its hardness at

high temperatures.

Plain carbon and low-alloy tool steels;

High-speed steel;

Cast cobalt alloys;

Cemented carbides, coated carbides;

Ceramics;

Cubic boron nitride;

Synthetic diamonds and nature diamonds.

Cutting Fluids

A cutting fluid is any liquid or gas that is applied directly to the machining operation

to improve cutting performance.

Functions: 1). Reduce cutting temperature;

2). Reduce friction at tool-chip and tool-work;

3). Reduce cutting forces;

4). Improve dimensional stability of the part;

5). Improve surface finish.

Types of Cutting Fluids

1.Coolant-type: mostly water-based solutions;

2.Lubricants: usually oil-based fluids.

You might also like

- Session Plan TOM I 4 3Document5 pagesSession Plan TOM I 4 3trimohitNo ratings yet

- 132018defaulter Div B 2017-18 Even - B4Document1 page132018defaulter Div B 2017-18 Even - B4trimohitNo ratings yet

- Laser Beam MachiningDocument25 pagesLaser Beam MachiningtrimohitNo ratings yet

- University of MumbaiDocument20 pagesUniversity of MumbaitrimohitNo ratings yet

- Unit Content From Syllabus No. and Date Conducted: Module - I: Fundame Ntal OF Kinetics AND Kinemati CDocument4 pagesUnit Content From Syllabus No. and Date Conducted: Module - I: Fundame Ntal OF Kinetics AND Kinemati CtrimohitNo ratings yet

- GATE 2018 Admit Card S1: Examination CentreDocument1 pageGATE 2018 Admit Card S1: Examination CentretrimohitNo ratings yet

- 6th Sem Div A - Attendance ListDocument3 pages6th Sem Div A - Attendance ListtrimohitNo ratings yet

- b1 211 Ankit MohiteDocument1 pageb1 211 Ankit MohitetrimohitNo ratings yet

- Ex-Servicemen Contributory Health Scheme (Echs) Employment NoticeDocument1 pageEx-Servicemen Contributory Health Scheme (Echs) Employment NoticetrimohitNo ratings yet

- Finite Element Analysis of A Euler Bernoulli Beam: Calculations of Natural Frequencies With MatlabDocument6 pagesFinite Element Analysis of A Euler Bernoulli Beam: Calculations of Natural Frequencies With MatlabtrimohitNo ratings yet

- Job Offer Letter Sample 7Document2 pagesJob Offer Letter Sample 7trimohitNo ratings yet

- Sudo Getweb 1018 Sudo hplj1018Document2 pagesSudo Getweb 1018 Sudo hplj1018trimohitNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Repair WeldingDocument33 pagesRepair WeldingAkhilesh Kumar100% (1)

- Maintenance Practice2Document2 pagesMaintenance Practice2Handy SetiantoNo ratings yet

- AWS - The Everyday Pocket Handbook For Visual Inspection of AWS D1.1 Structural Welding Codes Fabrication and Welding Requirements PDFDocument37 pagesAWS - The Everyday Pocket Handbook For Visual Inspection of AWS D1.1 Structural Welding Codes Fabrication and Welding Requirements PDFEvangelos Mathas100% (1)

- Alok Tools India Final PDFDocument96 pagesAlok Tools India Final PDFmahendrasinhNo ratings yet

- Machinery's Handbook 27th EditionDocument10 pagesMachinery's Handbook 27th EditionOmkar Kshirsagar0% (1)

- ASTM A355 Steel Bars - Alloys For NitridingDocument2 pagesASTM A355 Steel Bars - Alloys For Nitridingnse mcxNo ratings yet

- Metal Cutting and Machine Tools: 1 Lecture: IntroductionDocument43 pagesMetal Cutting and Machine Tools: 1 Lecture: IntroductionSrimanthula SrikanthNo ratings yet

- Foredom SR ManualDocument16 pagesForedom SR ManualFernando Lopez LagoNo ratings yet

- Hot Rolled SlittingDocument4 pagesHot Rolled SlittingVikas SinghNo ratings yet

- NIKO Ball ScrewsDocument33 pagesNIKO Ball ScrewsAndrey RossiNo ratings yet

- Setup Sheet Report: Doosan Lynx 220LMYDocument10 pagesSetup Sheet Report: Doosan Lynx 220LMYMiguel Angel MartinezNo ratings yet

- Japanese Steel StandardsDocument3 pagesJapanese Steel StandardsmirekwaznyNo ratings yet

- Hardinge Catalog 2351Document48 pagesHardinge Catalog 2351JoeGriffNo ratings yet

- Slips & Parts: Cavin TBDocument8 pagesSlips & Parts: Cavin TBmantilla7No ratings yet

- Job Sheet CamDocument5 pagesJob Sheet Cam44Vincentius Alexander ChristianNo ratings yet

- Fracture Testing According EN 9017Document3 pagesFracture Testing According EN 9017Anil100% (1)

- Screw Thread Calculations - Roy MechDocument6 pagesScrew Thread Calculations - Roy Mechangelo collaNo ratings yet

- Aluminium Wheel RepairDocument26 pagesAluminium Wheel RepairAndrew MatsovkinNo ratings yet

- Hex Key ChartDocument1 pageHex Key Charter lopNo ratings yet

- BORIDE Engineered AbrasivesDocument78 pagesBORIDE Engineered Abrasivesalexandr_sorokin_3100% (1)

- Mini La The Users GuideDocument9 pagesMini La The Users GuidepedjaNo ratings yet

- Machine Shop Elements: Answer ADocument32 pagesMachine Shop Elements: Answer ATatsNo ratings yet

- Bector Group of CompaniesDocument13 pagesBector Group of CompaniesBECTOR GROUP OF COMPANIESNo ratings yet

- Microcut Catalog MC77-14Document140 pagesMicrocut Catalog MC77-14batman2054No ratings yet

- Unit-4 Advanced Machining ProcessesDocument61 pagesUnit-4 Advanced Machining ProcessesHarshalPatilNo ratings yet

- Aws D3.5-93PV PDFDocument8 pagesAws D3.5-93PV PDFwalter091011No ratings yet

- WWW Instructables Com Id DIY Self Balancing One Wheel Vehicle PDFDocument17 pagesWWW Instructables Com Id DIY Self Balancing One Wheel Vehicle PDFHeretic HarmoniesNo ratings yet

- Bomba Fristam Modelo FZXDocument3 pagesBomba Fristam Modelo FZXElizandro TorresNo ratings yet

- University of The East College of Engineering: Plate No. 2 Rolling MillDocument17 pagesUniversity of The East College of Engineering: Plate No. 2 Rolling MillJOHNEDERSON PABLONo ratings yet

- All RDSO Bow String Girder of Span 60-72 MDocument9 pagesAll RDSO Bow String Girder of Span 60-72 MAjay Sinha60% (5)