0% found this document useful (0 votes)

1K views43 pagesThreaded & Riveted Joints

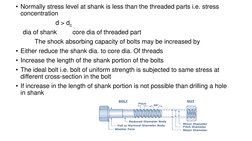

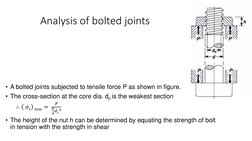

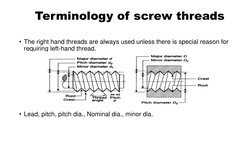

Threaded joints are separable joints held together by bolts and nuts. They are commonly used, making up over 60% of mechanical assemblies. Threaded joints provide advantages like large clamping force, compact construction, and versatility. However, they require holes in parts and can loosen under vibration. Riveted joints are permanent joints that cannot be easily disassembled without damage. They were commonly used before welding and provide reliability and ease of quality checking, but have higher material costs and weight than other joints. Both threaded and riveted joints are analyzed to determine failure loads based on shear strength, tensile strength, and other factors.

Uploaded by

Madhurima BhandariCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views43 pagesThreaded & Riveted Joints

Threaded joints are separable joints held together by bolts and nuts. They are commonly used, making up over 60% of mechanical assemblies. Threaded joints provide advantages like large clamping force, compact construction, and versatility. However, they require holes in parts and can loosen under vibration. Riveted joints are permanent joints that cannot be easily disassembled without damage. They were commonly used before welding and provide reliability and ease of quality checking, but have higher material costs and weight than other joints. Both threaded and riveted joints are analyzed to determine failure loads based on shear strength, tensile strength, and other factors.

Uploaded by

Madhurima BhandariCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

- Threaded Joints: This section covers the definition, advantages, and disadvantages of threaded joints, including classification and material considerations.

- Riveted Joints: Focuses on the characteristics, advantages, variations, and applications of riveted joints in mechanical connections.