Professional Documents

Culture Documents

4stepstosuccessformaintenancesupervisors 12800174832736 Phpapp01 PDF

4stepstosuccessformaintenancesupervisors 12800174832736 Phpapp01 PDF

Uploaded by

RadivojJovanovOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4stepstosuccessformaintenancesupervisors 12800174832736 Phpapp01 PDF

4stepstosuccessformaintenancesupervisors 12800174832736 Phpapp01 PDF

Uploaded by

RadivojJovanovCopyright:

Available Formats

4 Steps to Success

for

Maintenance Supervisors

Presented by: Ricky Smith, CMRP

July 8, 2010

Copyright 2010 GPAllied

Maintenance Supervisors are the people who

make the largest impact on reliability in most

organizations and if trained and empowered

effectively they will far exceed managements

expectations

Ricky Smith, former Maintenance Supervisor

Copyright 2010 GPAllied

What is Maintenance?

To Maintain an Asset

Keep in existing condition

Keep, preserve, protect

Copyright 2010 GPAllied

Potential Failures Where to Detect them?

Copyright 2010 GPAllied

Our Goal

Copyright 2010 GPAllied

Failure Modes Driven Strategy

What is a Failure Mode?

How something fails

Most work should come from prevention or

prediction of specific failure modes

Example: Part Bearing

Failure Mode Wear

Cause Lack of Lubrication

Prevention Effective Lubrication

Copyright 2010 GPAllied

Step Number 1 PM Evaluation

Evaluate a sampling of your PMs

1. Review each PM with a few of your maintenance

staff

2. Sort the PMs

Stack 1 PM adds no value

Stack 2 PM adds value but give to ops

Stack 3 PdM will address this PM earlier and more effectively

Stack 4 PM needs to be re-written

Stack 5 PM is good

3. Identify the number of labor hours identified in each

stack how many labor hours did you save?

Copyright 2010 GPAllied

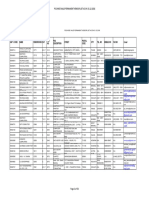

Example of a PM Evaluation

PM Task Action Man-Hours

# of Tasks % of Tasks

Recommendation Represented

Non-Value Added

1,640 8.2% 6,661

(Delete)

Reassign to Operator

1,380 6.9% 5,605

Care

Reassign to Lube

2,856 14.3% 11,600

Route

Replace with PdM 6,437 32.2% 28,222

Re-Engineer 5,200 26.0% 26,221

No Modifications

2,487 10.4% 8,987

Required

Totals 20,000 100.0% 87,297

Copyright 2010 GPAllied

Work Flow of Planning and Scheduling

Failure Mode Driven Strategy

Proactive Work

Work W.O. Close

PM/PdM Planning Scheduling FRACAS

Execution Out

Proactive Work

Copyright 2010 GPAllied

Step Number 2 Work Order Information

Rules which are not optional

1. Work Orders for all work

2. Work Order Codes must be accurate

3. How do youWork

make this

Flow happenand Scheduling

of Planning

Proactive Work

Work W.O. Close

PM/PdM Planning Scheduling FRACAS

Execution Out

Proactive Work

Copyright 2010 GPAllied

Work Order Close Out

If you need a training guide send me an email

at rsmith@gpallied.com

Copyright 2010 GPAllied

Work Order Close Out Who Cares?

Copyright 2010 GPAllied

Do you and your crew know where you are?

Copyright 2010 GPAllied

Common Failure Threads

Develop a Process which delivers the Report

you want.

Dominant Failure Pattern

Copyright 2010 GPAllied

Mean Time Between Failure

Copyright 2010 GPAllied

Culture: Defining Roles and Responsibilities

Maintenance Maintenance Maintenance Maintenance Reliability PdM

Tasks Supervisors Planner Technician Manager Engineer Technician

Inputting Failure A I R C C

Data -

CMMS/EAM

Work Order R C R A R R

Close Out

Validating C I C A R C

Failure Data and

Codes

QA of Failure I C A R C

Data Input

Analyze Failure R I C R A/R R

Reports

Making I I I A R C

Maintenance

Strategy

Adjustments

Responsibility the Doer

Accountable the Buck stops here

Consulted in the Loop

Informed kept in the picture

Copyright 2010 GPAllied

Step Number 3 Change your Culture

Culture Change is not easy

How do you change your culture?

One step at a time

Copyright 2010 GPAllied

The significant problems we face cannot be

solved with the same level of thinking we were

at when we created them.

- Albert Einstein

Copyright 2010 GPAllied

Re-invent Yourself

Lead by Example

Know yourself and seek self improvement

Go to training

Failure Modes Driven Strategy

Planning and Scheduling

Leadership 101

Treat everyone equally (like you want to be treated)

Be Technically and Tactically Proficient

Work as a partner with Production

Talk to Operators

Take the Lead and Empower your Employees

Copyright 2010 GPAllied

Change your Maintenance Staff

Copyright 2010 GPAllied

Empowerment

Copyright 2010 GPAllied

Empowerment

400

350

300

250

200 PM

EM

150

100

50

0

June July Aug Sept Nov Dec

Copyright 2010 GPAllied

Give them the GPS and let them Drive Some

Copyright 2010 GPAllied

70-80 % of equipment failures are Self-Induced

Putting hydraulic fluid into a reservoir without

filtering it

Welding on equipment without grounding

properly

Running Equipment to Failure when it is not

part of your maintenance strategy

Aligning couplings without using a laser

Improperly lubricating electric motors

Not using a torque wrench

Not Following Known Best Practices

Procedures

PM

CM / Repair

Lubrication

Copyright 2010 GPAllied

Causes of Variation

Lack of an effective PM Program

Lack of a repeatable repairs with

specifications

Lubrication issues, lack of lubrication,

contamination, etc.

Operator Error

Use of wrong tool to make repair

Bearing heater

Use of wrong specification

Torque values

Copyright 2010 GPAllied

Variation is your enemy

Copyright 2010 GPAllied

Step Number 4 Utilize Effective Work Procedures

Repeatable process

Capture knowledge

Train new employees

Reduce / eliminate self induced failures

Copyright 2010 GPAllied

What are Work Procedures?

Preventive Maintenance

Corrective Maintenance

Operator Care

Lubrication

Copyright 2010 GPAllied

Effective Procedure Execution

Copyright 2010 GPAllied

Our Goal

Copyright 2010 GPAllied

Effective Work Procedures

What is required to ensure you have a

repeatable process?

Step by Step Procedures

Specifications / Standards

Required Parts

Potential Parts

Special Tools (Core Drill)

Special Equipment (60 JLG Lift)

Craft and Number of Each Craft

Special Permits

Copyright 2010 GPAllied

Who writes the procedures?

Copyright 2010 GPAllied

Excellence is a Habit

- Aristotle, 330 BC

Copyright 2010 GPAllied

4 Steps to Success for Maintenance Supervisors

Step 1 Perform a sample PM Evaluation

(free up staff)

Step 2 Ensure Effective Work Order Information

(know what is killing you)

Step 3 Change your Culture

(change the way you and your staff think)

Step 4 - Utilize Effective Work Procedures

(reduce variation)

Copyright 2010 GPAllied

If you want copies of the slides send me a

request

If you want copies of the Tool Box Training

Sessions send me a request

Questions

rsmith@gpallied.com

Lets Make a Difference

Copyright 2010 GPAllied

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5811)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Integration Functional Design TemplateDocument4 pagesIntegration Functional Design TemplateherandevakiNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Thrush S2R R-1340 Maintenence ManualDocument227 pagesThrush S2R R-1340 Maintenence Manualarizonaflyer1_732976100% (1)

- GlaxoSmithKline-Computer System Validation GuidelineDocument104 pagesGlaxoSmithKline-Computer System Validation GuidelineAtifKhan92% (13)

- Ducato 290 Handbook 05-15Document387 pagesDucato 290 Handbook 05-15Darko SelenicNo ratings yet

- Annexure W - Commissioning Management PlanDocument38 pagesAnnexure W - Commissioning Management Plansimbamike100% (3)

- Fs Pp07 Badi MFBF Mf42nDocument5 pagesFs Pp07 Badi MFBF Mf42nAnonymous UsBZYFAGBNo ratings yet

- Upload A CSV Excel File or Text File in SAP CRM WebUIDocument13 pagesUpload A CSV Excel File or Text File in SAP CRM WebUIMohinder SureshNo ratings yet

- PlexConnect Edition 44Document45 pagesPlexConnect Edition 44Kool LeisureNo ratings yet

- 3 Swot Analysis WorksheetDocument5 pages3 Swot Analysis Worksheetapi-720147459No ratings yet

- Ar08 PDFDocument240 pagesAr08 PDFSaikat DawanNo ratings yet

- Just in Time Jit Back FlushDocument16 pagesJust in Time Jit Back FlushSunsong31No ratings yet

- Components CatalougeDocument338 pagesComponents CatalougeTarek AbulailNo ratings yet

- Major Project Key Decision PointsDocument7 pagesMajor Project Key Decision PointssiklebNo ratings yet

- Daftar PustakaDocument3 pagesDaftar Pustakawahyu raharjoNo ratings yet

- ABB 68300746 SheetDocument3 pagesABB 68300746 SheetSukhendu MaityNo ratings yet

- System Modeling: Existing and Planned System ModelsDocument5 pagesSystem Modeling: Existing and Planned System ModelsMaricar SucalditoNo ratings yet

- Aidan Singh ReportDocument25 pagesAidan Singh ReportGolyanShubhamNo ratings yet

- Internal Dispatch Clearance ChecklistDocument54 pagesInternal Dispatch Clearance ChecklistMahesh2101No ratings yet

- Draft Survey - Procedures and Calculation - Marine Surveyor InformationDocument4 pagesDraft Survey - Procedures and Calculation - Marine Surveyor Informationstamatis0% (1)

- FT-11.05 - 01 - CASAPPA - Bomba de Engranajes - PLP30Document12 pagesFT-11.05 - 01 - CASAPPA - Bomba de Engranajes - PLP30Carlos Augusto Navarro BurgosNo ratings yet

- Terex Digger Derrick Operators Manual 7Document16 pagesTerex Digger Derrick Operators Manual 7Israel SotoNo ratings yet

- ET UserGuideDocument354 pagesET UserGuideNanda Ganesh KumarNo ratings yet

- Miqdad CVDocument1 pageMiqdad CVZaigham AliNo ratings yet

- PSG Wise Permanent Vendor List 31-12-2016Document58 pagesPSG Wise Permanent Vendor List 31-12-2016kumarneerajNo ratings yet

- Unit 1soaDocument19 pagesUnit 1soaABIRAMI100% (1)

- Conbextra EP 0211Document4 pagesConbextra EP 0211didonkimurayahooNo ratings yet

- OPI Company-Profile LowresDocument19 pagesOPI Company-Profile LowresMustafamobilyaprojeNo ratings yet

- CV Fanji Aby SahputraDocument3 pagesCV Fanji Aby SahputraReddy herly PriyatnaNo ratings yet

- SixsigDocument90 pagesSixsigHokuto No KenNo ratings yet

- DILG Memo - Circular 2012423 8a32c95747Document4 pagesDILG Memo - Circular 2012423 8a32c95747marie_magsilaNo ratings yet