Professional Documents

Culture Documents

345 KW Motor Speci

Uploaded by

DharmenderSinghChoudhary0 ratings0% found this document useful (0 votes)

28 views4 pagessdfsdfsa

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentsdfsdfsa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

28 views4 pages345 KW Motor Speci

Uploaded by

DharmenderSinghChoudharysdfsdfsa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

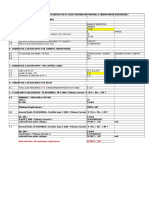

TECHNICAL BID

ANNEXURE-I

(Note: Bidder has to confirm their acceptance in given sheet and for technical evaluation, this Annexure

to be submitted in Technical bid (Packet 1) in e-Tender)

NAME OF BIDDER:

Tem | Bidder] Deviation if

sn Code | Confirmation | Any, Separate

Short Text ase put 4° | Deviation list in

No And | (Please put | ote should

ty | confirmation) | be submitted

speed

; SOnsse 13, Proa: 50 be

eaters, STD/BTD,

RCF requirement.

‘Ambient air temp.

A Ref. value 40 dog.c

8 System condition

1) | Normal voltage 3.3kv, 3 phase

2) | Frequency SOHz 300089

3) | system variations Voltaget/-10% 526

1 © Agree

frequency +/-5% tno |" eed

«Disagreed

c Specification

Totally Enclosed Tube

Ventilated High Voltage

Squirre! cage

1) | type induction motor

2) | Location Outdoor

3) | protection/trame IP 55 / 450 Ma/ TETV

4) | Duty continuous

Horizontal foot

5) | Mounting mounted

6) [Kw 350 Kw/ 460 Hp

7) | speed 1500 RPM

8) [Voltage 3300 volts

Page 7 of 40

9) | Phase 3

high efficiency

(Min 94 % at Full load

40) | efficiency and 92% at $0 % Load)

Class-F with rise limit to

11) | insulation Class-B

WK2/6D2 of Motor suitable for

12) | Blower 800 KGF-M? Fan G D2

13) [ Direction of rotation _| bi-directional

DOL through cireuit

14) | Method of starting breaker

Suitability of motor

415) | to driven equipment

Thermal with stand

16) | time Ith sec Hot/cold

17) | staring time

No.of. Starts/hour at | Hot start(2)/

18) | 100% cold start(3)

1) Separate TB along

with glands shall

be

provided for main

power cable (

single glanding

type of proper

size) . Neutral

point, space

heater detector.

TB should be

weatherproof

15) | Terminal boxes construction,

2) The leads of the motor

shall be taken out 3 nos on

either side in phase

segregated way. Suitable for

3.3KV,150 MVA rating

copper shorting link shall be

provided for the star point.

3) The motor leads

to terminal box

shall be fibre glass

insulated suitable

for 3.3 kv

Page 8 of 40

4) The main power cable

terminal box shall be

onleft side viewed

from NDE of the

motor.

20)

Anti condensation

heaters

‘The motor should be

provided with anti

condensation heaters of 240

volt AC supply and shall

remain ON when motor is

not in service. The heaters

lead should be brought out

as separate TB

21)

Bearing

1) Motor shall be

provided with grease

lubricated bearings.

2)Bearings housing

should be provided with a

nipple & drain plug for

greasing the bearing during

normal running .Bearing

should be of the properly

insulated so that the bearing

is not affected by induced

shaft voltage.

22)

Accessories

1) 6 nos. pf Platinum

resistance type wdg temp.

detectors, BTD each for DE

& NDE

2)Lifting arrangement-lifting

eye bolts shall be provided

on the motor body.

3) Two earthing terminals

shall be provided outside of

the enclosure

4)Three sets of manuals

shall be provided

Page 9 of 40

23)

Other features

1) The motor shall be

painted

with one coat of acid/alkali

resistance paint. One coat of

anti rust paint & two coats

of suitable corrosion

resistance epoxy paint,

2)Dimensional drawing is of

existing motor

24)

Tests

Routine/heat run tests.

‘The motor shall be tested

for all routine tests at

manufacturers shop as per

relevant standards. All

above tests shall be carried

out in presence of M/S RCF

representative

25)

Delivery Period

6 Months

26)

Guarantee

18 Months from the

Date of Supply

Mandatory

Page 10 of 40

You might also like

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- PCR049 MGDS 2 30 0001Document19 pagesPCR049 MGDS 2 30 0001DharmenderSinghChoudhary0% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- S&B Engineers and Constructors, Ltd. Texas Registration Number F-1581Document1 pageS&B Engineers and Constructors, Ltd. Texas Registration Number F-1581DharmenderSinghChoudharyNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- Iec 60865 & Ieee 605Document13 pagesIec 60865 & Ieee 605DharmenderSinghChoudhary100% (2)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- CT Sizing For MalawiDocument2 pagesCT Sizing For MalawiDharmenderSinghChoudhary100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5806)

- Battery Sizing 110VDocument17 pagesBattery Sizing 110VDharmenderSinghChoudhary100% (1)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- CT Sizing For MalawiDocument2 pagesCT Sizing For MalawiDharmenderSinghChoudharyNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- PCR049 MGDS 2 17 0001Document11 pagesPCR049 MGDS 2 17 0001DharmenderSinghChoudharyNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- SIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2Document3 pagesSIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2DharmenderSinghChoudharyNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Cable Sizing For Main Cable - DBDocument8 pagesCable Sizing For Main Cable - DBDharmenderSinghChoudharyNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- SIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2Document3 pagesSIP5 7UT82-85-86-87 V07.00 Manual C016-6 En2DharmenderSinghChoudharyNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (589)

- Qatar Design Consortium, W.L.L: Weekly Time SheetDocument1 pageQatar Design Consortium, W.L.L: Weekly Time SheetDharmenderSinghChoudharyNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Comments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseDocument2 pagesComments Resolution Sheet (CRS) : No. QP Comments Contractor ResponseDharmenderSinghChoudharyNo ratings yet

- Data Sheet of Local Control StationsDocument4 pagesData Sheet of Local Control StationsDharmenderSinghChoudharyNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Indian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093Document2 pagesIndian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093DharmenderSinghChoudharyNo ratings yet

- Indian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093Document1 pageIndian Oil Corporation Limited Guwahati Refinery: NIT NO: GC16ITT093DharmenderSinghChoudharyNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- ChatLog ETAP 14 Online Demo 2016-04-13 13 - 14Document2 pagesChatLog ETAP 14 Online Demo 2016-04-13 13 - 14DharmenderSinghChoudharyNo ratings yet

- Providing Manpower Assistance & Supervision For Instrumentation DepartmentDocument5 pagesProviding Manpower Assistance & Supervision For Instrumentation DepartmentDharmenderSinghChoudharyNo ratings yet

- ChatLog CYMGRD - Earthing System Design Demo 2016-04-12 16 - 16Document1 pageChatLog CYMGRD - Earthing System Design Demo 2016-04-12 16 - 16DharmenderSinghChoudharyNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- Tender Acceptance FormatDocument1 pageTender Acceptance FormatDharmenderSinghChoudharyNo ratings yet

- Cover Page Tender 1631Document244 pagesCover Page Tender 1631DharmenderSinghChoudharyNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Dos - ElectricalDocument4 pagesDos - ElectricalDharmenderSinghChoudharyNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)