Professional Documents

Culture Documents

ENiCrFe 2

Uploaded by

briang-2Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ENiCrFe 2

Uploaded by

briang-2Copyright:

Available Formats

WELDWIRE COMPANY, INC.

Technical Information

Nickel Alloys

Alloy: WWAlloy A Conforms to Certification: AWS A5.11

Class: ENiCrFe-2 ASME SFA A5.11

Alloy: ENiCrFe-2 (Alloy A)

Weld Process: Shielded Metal Arc Weld Process (SMAW)

AWS Chemical Composition Requirements Recommended Weld Parameters Amperage (A)

C = 0.10 max Cu = 0.50 max Diameter of Wire Voltage (V) Flat Vertical and Overhead

Mn = 1.0 3.5 Ni = 62.0 min 3/32 inches (2.4mm) 24 28 70 85 65 75

Fe = 12.0 max Co = 0.12 max

P = 0.03 max Cr = 13.0 17.0 1/8 inches (3.2mm) 26 30 85 110 80 90

S = 0.02 max Cb/Ta = 0.5 3.0

5/32 inches (4.0) 28 32 110 140 100 120

Si = 0.75 max Mo = 0.50 2.50

3/16 inches (4.8) 28 32 120 160 110 130

Deposited Chemical Composition % (Typical)

Application

C = 0.04 Mn = 1.75 Si = 0.32

Cr = 15.5 Mo = 1.5 Cb/Ta = 1.25 ENiCrFe-2 (Alloy A) electrodes are used for welding of nickel-

Fe = 8.5 S = 0.006 P = 0.009 chromium-iron alloys to themselves, as well as for dissimilar

Ni = 71.15 welding between various nickel alloys and carbon or stainless

steel. There is a large range of applications from cryogenic

temperature up to 1500F.

Deposited All Weld Metal Properties % (AW)

Tensile Strength 89,000psi

Yield Strength 72,000psi

Elongation 36%

Deposited Charpy-V-Notch Impact Properties %

Not applicable

If additional information is needed Contact Weldwire Company, Inc. 800-523-1266

You might also like

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Metalworking Tig WeldingDocument11 pagesMetalworking Tig WeldingPutra Pratama100% (8)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- ASTM A335 Pipe Specification1 PDFDocument8 pagesASTM A335 Pipe Specification1 PDFRoberto EliasNo ratings yet

- ENiFe CIDocument1 pageENiFe CIakashmalayiNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationAndrés RamírezNo ratings yet

- E309LMo 16Document1 pageE309LMo 16faiz oeNo ratings yet

- Electrodo E347-16Document1 pageElectrodo E347-16Eunilo Valenzuela ZabarburuNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- ERCoCr A - Cobalt 6 Bare WireDocument1 pageERCoCr A - Cobalt 6 Bare Wirekptl6185No ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationchepurthiNo ratings yet

- ER90S-B9 Electrode SpecDocument1 pageER90S-B9 Electrode SpecfaizalzolNo ratings yet

- M El p0.2 2Document3 pagesM El p0.2 2Gopal RamalingamNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationchepurthiNo ratings yet

- ERCUDocument1 pageERCURogério JuniorNo ratings yet

- Pinnacle Alloys E9018-M Code and Specification DataDocument2 pagesPinnacle Alloys E9018-M Code and Specification DataPutra Panca WardhanaNo ratings yet

- ERNiCrCoMo 1Document1 pageERNiCrCoMo 1Vajid MadathilNo ratings yet

- Pinnacle Alloys E8018 C3Document2 pagesPinnacle Alloys E8018 C3Sajeev SivanandanNo ratings yet

- Comparison Welding Wire A5.18-ER70S-3 - A5.18-ER70S-6Document3 pagesComparison Welding Wire A5.18-ER70S-3 - A5.18-ER70S-6QuyetNo ratings yet

- ER70S-2 Mild SteelDocument1 pageER70S-2 Mild SteelNadeemNo ratings yet

- Product Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 75.75: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- ERNiCr 3Document1 pageERNiCr 3Cemal NergizNo ratings yet

- SOW 7018A11 8 SpecSheetDocument2 pagesSOW 7018A11 8 SpecSheetKmi GutierrezNo ratings yet

- Böhler CN 13/4-Mc Hi: Classifi CationsDocument1 pageBöhler CN 13/4-Mc Hi: Classifi CationsBranko FerenčakNo ratings yet

- Product Data Sheet OK 55.00: E 'Manual Metal-Arc Welding' ESAB AB SwedenDocument2 pagesProduct Data Sheet OK 55.00: E 'Manual Metal-Arc Welding' ESAB AB SwedenAzriNo ratings yet

- 8015 b8Document1 page8015 b8Issac GeorgeNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- ESAB ENiCiFe-3Document1 pageESAB ENiCiFe-3Sadhasivam VeluNo ratings yet

- Product Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument3 pagesProduct Data Sheet OK 76.18: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenKARLNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- Ok 347 AutrodDocument2 pagesOk 347 Autrodjoao guilhermeNo ratings yet

- Pinnacle Alloys E11018 MDocument2 pagesPinnacle Alloys E11018 MMoch_adiganjarNo ratings yet

- Pinnacle Alloys E7018 E7018 1Document2 pagesPinnacle Alloys E7018 E7018 1BerniIrleNo ratings yet

- Thermocouple: Common SpecificationsDocument6 pagesThermocouple: Common Specificationsmertel_26No ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationdfmolinaNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- SS 316 (0.5 FN) : Stainless Steel ElectrodeDocument1 pageSS 316 (0.5 FN) : Stainless Steel Electrodeflasher_for_nokiaNo ratings yet

- L1 12783 en Thermanit 25 09 CuT 1SC6A00G 3394780 ENDocument1 pageL1 12783 en Thermanit 25 09 CuT 1SC6A00G 3394780 ENcycsi02No ratings yet

- B Boehler Aws E316l 17 Se en 5a Mds PDFDocument1 pageB Boehler Aws E316l 17 Se en 5a Mds PDFInaamNo ratings yet

- SF 71MCDocument1 pageSF 71MCGESTION Y CONTROL DE PROYECTOS IngeminNo ratings yet

- Boehler CN 13 4-MC FDocument1 pageBoehler CN 13 4-MC FFilipe CordeiroNo ratings yet

- Product Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 67.55: E 'Manual Metal-Arc Welding'rajNo ratings yet

- Pinnacle Alloys E8018-B6 Code and Specification DataDocument2 pagesPinnacle Alloys E8018-B6 Code and Specification DataMurad AlmoudiNo ratings yet

- Pinnacle Alloys E6013Document2 pagesPinnacle Alloys E6013rahulNo ratings yet

- Supratherm E7018Document1 pageSupratherm E7018yskushwah16No ratings yet

- 213 Ok 64 30Document1 page213 Ok 64 30Mohd AnsariNo ratings yet

- ASTM A335 Pipe Specification1Document8 pagesASTM A335 Pipe Specification1Rupam BaruahNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- Thermanit GE-316L PDFDocument1 pageThermanit GE-316L PDFsmpoe017No ratings yet

- UTP 6222 MoDocument1 pageUTP 6222 ModantegimenezNo ratings yet

- Product Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB SwedenDocument2 pagesProduct Data Sheet OK 74.78: E 'Manual Metal-Arc Welding' ESAB Perstorp AB Swedentungau87No ratings yet

- Shielded Metal Arc WeldingDocument0 pagesShielded Metal Arc WeldingMohd AnsariNo ratings yet

- Thermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicDocument1 pageThermanit Nimo 100: Stick Electrode, Low-Alloyed, BasicbrayanNo ratings yet

- Bavaria en BA-TIG 310Document1 pageBavaria en BA-TIG 310cocoNo ratings yet

- Lincolnweld 888 & LA-85Document2 pagesLincolnweld 888 & LA-85Pablo PazNo ratings yet

- CERTILAS EN Edition2023 320Document1 pageCERTILAS EN Edition2023 320Alireza KhodabandehNo ratings yet

- Prequalified WPS Requirement ASTM D1.1Document1 pagePrequalified WPS Requirement ASTM D1.1briang-2No ratings yet

- AWS D1.1 Visual Inspection Acceptance CriteriaDocument1 pageAWS D1.1 Visual Inspection Acceptance Criteriabriang-286% (7)

- SA 387 Grade 91 Class 2Document4 pagesSA 387 Grade 91 Class 2briang-2No ratings yet

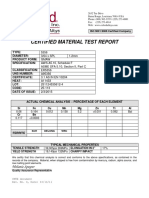

- Certified Material Test Report: Melanie SpeyrerDocument1 pageCertified Material Test Report: Melanie Speyrerbriang-2No ratings yet

- American Welding Society 8669 NW 36 Street, #130 Miami, FL 33166-6672Document1 pageAmerican Welding Society 8669 NW 36 Street, #130 Miami, FL 33166-6672briang-2No ratings yet

- Weld Parameters Data SheetDocument1 pageWeld Parameters Data SheetshwayeNo ratings yet