Professional Documents

Culture Documents

Weldwire Company, Inc. Technical Information

Uploaded by

Andrés Ramírez0 ratings0% found this document useful (0 votes)

3 views1 pageAlloy 117 is a nickel alloy that conforms to AWS A5.11 and ASME SFA A5.11 standards. It has a chemical composition of 0.05-0.15% C, 0.30-2.5% Mn, 5.0% max Fe, 0.03% max P, 0.015% max S, 0.75% max Si, and 0.5% max other elements with the remainder being nickel. Cobalt is 9.0-15.0%, chromium is 21.0-26.0%, molybdenum is 8.0-10.0%, and niobium or tantalum is 1.0% max. Recomm

Original Description:

Datos tecnicos sobre la utilizacion de soldadura para ser utilizada con diferentes materiales base.

Original Title

ENiCrCoMo-1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentAlloy 117 is a nickel alloy that conforms to AWS A5.11 and ASME SFA A5.11 standards. It has a chemical composition of 0.05-0.15% C, 0.30-2.5% Mn, 5.0% max Fe, 0.03% max P, 0.015% max S, 0.75% max Si, and 0.5% max other elements with the remainder being nickel. Cobalt is 9.0-15.0%, chromium is 21.0-26.0%, molybdenum is 8.0-10.0%, and niobium or tantalum is 1.0% max. Recomm

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views1 pageWeldwire Company, Inc. Technical Information

Uploaded by

Andrés RamírezAlloy 117 is a nickel alloy that conforms to AWS A5.11 and ASME SFA A5.11 standards. It has a chemical composition of 0.05-0.15% C, 0.30-2.5% Mn, 5.0% max Fe, 0.03% max P, 0.015% max S, 0.75% max Si, and 0.5% max other elements with the remainder being nickel. Cobalt is 9.0-15.0%, chromium is 21.0-26.0%, molybdenum is 8.0-10.0%, and niobium or tantalum is 1.0% max. Recomm

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

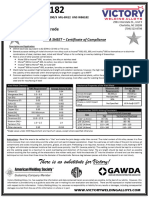

WELDWIRE COMPANY, INC.

Technical Information

Nickel Alloys

Alloy: WWNA117

Class: ENiCrCoMo-1

Alloy 117

Conforms to Certification: AWS A5.11

ASME SFA A5.11

Alloy: ENiCrCoMo-1 (Alloy 117)

Weld Process: Shielded Metal Arc Weld Process (SMAW)

AWS Chemical Composition Requirements

Recommended Weld Parameters

C = 0.05 0.15

Mn = 0.30 2.5

Fe = 5.0 max

P = 0.03 max

S = 0.015 max

Si = 0.75 max

Other = 0.50 max

Diameter of Wire

Cu = 0.50 max

Ni = Remainder

Co = 9.0 15.0

Cr = 21.0 26.0

Cb/Ta = 1.0 max

Mo = 8.0 10.0

Voltage (V)

Amperage (A)

Flat

Vertical and Overhead

3/32 inches (2.4mm)

24 28

70 85

65 75

1/8 inches (3.2mm)

26 30

85 110

80 90

5/32 inches (4.0)

28 32

110 140

100 120

3/16 inches (4.8)

28 32

120 160

110 130

Deposited Chemical Composition % (Typical)

C = 0.06

Fe = 1.52

Cr = 21.7

Ni = Balance

Mn = 0.46

S = 0.005

Mo = 8.70

Si = 0.36

P = 0.011

Co = 12.0

Deposited All Weld Metal Properties % (AW)

Tensile Strength

Yield Strength

Elongation

Application

ENiCrCoMo-1 (NA117) electrode is used for welding of

nickel-chromium-cobalt-molybdenum alloys. It can be used

for overlay cladding when similar alloy is required.

Weld Metal provides optimum strength above 1500F up to

2100F.

110,000psi

87,500psi

27%

Deposited Charpy-V-Notch Impact Properties %

Not applicable

If additional information is needed Contact Weldwire Company, Inc. 800-523-1266

You might also like

- Materials Data for Cyclic Loading: Aluminium and Titanium AlloysFrom EverandMaterials Data for Cyclic Loading: Aluminium and Titanium AlloysRating: 1 out of 5 stars1/5 (1)

- ECSDocument58 pagesECSPradeesh Vijayan (v.prathi)No ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- ENiCrFe 2Document1 pageENiCrFe 2briang-2No ratings yet

- ENiFe CIDocument1 pageENiFe CIakashmalayiNo ratings yet

- Electrodo E347-16Document1 pageElectrodo E347-16Eunilo Valenzuela ZabarburuNo ratings yet

- ER90S-B9 Electrode SpecDocument1 pageER90S-B9 Electrode SpecfaizalzolNo ratings yet

- Weldwire Company, Inc. Technical InformationDocument1 pageWeldwire Company, Inc. Technical InformationchepurthiNo ratings yet

- E309LMo 16Document1 pageE309LMo 16faiz oeNo ratings yet

- Common Steel StandardsDocument3 pagesCommon Steel Standardsva3ttnNo ratings yet

- ERCoCr A - Cobalt 6 Bare WireDocument1 pageERCoCr A - Cobalt 6 Bare Wirekptl6185No ratings yet

- TC VerificationDocument33 pagesTC VerificationmaheshNo ratings yet

- Innershield NR - 305: Typical Applications Key FeaturesDocument1 pageInnershield NR - 305: Typical Applications Key FeaturesH_DEBIANENo ratings yet

- 71T-1C Carbon Steel Flux-Cored Wire: Cert # 05-R0925Document1 page71T-1C Carbon Steel Flux-Cored Wire: Cert # 05-R0925kanha15102003100% (1)

- Process Piping Preheat TemeperaturesDocument1 pageProcess Piping Preheat TemeperaturesShreekanthKannathNo ratings yet

- 8015 b8Document1 page8015 b8Issac GeorgeNo ratings yet

- 1N4001 Thru 1N4007: General Purpose Plastic RectifierDocument3 pages1N4001 Thru 1N4007: General Purpose Plastic RectifierDharang ShahNo ratings yet

- ERCUDocument1 pageERCURogério JuniorNo ratings yet

- (TSC) ss32-ss315Document2 pages(TSC) ss32-ss315Gut Besser WasserNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 pageNI-182 Victory ENICRFE-3 Electrode Data SheetgianNo ratings yet

- Perno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Document1 pagePerno A325 HDG 5-8 X 1 3-4 (Ciser+7599055)Alexander Ortiz CarrionNo ratings yet

- Maxfil 42BDocument1 pageMaxfil 42BMurali YNo ratings yet

- Aluminium Diecasting MaterialDocument2 pagesAluminium Diecasting MaterialzainudinNo ratings yet

- 1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 AmperesDocument3 pages1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 AmperesJorge DeganteNo ratings yet

- Filler WeltenDocument5 pagesFiller WeltenEduard Gonzalo Rojas CervantesNo ratings yet

- Astm A514 GR SDocument9 pagesAstm A514 GR SMario GaytanNo ratings yet

- European Steel and Alloy GradesDocument2 pagesEuropean Steel and Alloy Gradesfarshid KarpasandNo ratings yet

- 2 Fcaw-AllDocument51 pages2 Fcaw-AllAhmad ShaheenNo ratings yet

- 6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifierDocument2 pages6A05 THRU 6A10: Axial Silastic Guard Junction Standard RectifiercuickNo ratings yet

- kbl005 PDFDocument3 pageskbl005 PDFdanielliram993No ratings yet

- Heavy Duty Power Relay: Specifications How To Order Coil DataDocument1 pageHeavy Duty Power Relay: Specifications How To Order Coil DataKichu KrishnaNo ratings yet

- 1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 AmperesDocument2 pages1N5400 THRU 1N5408: Reverse Voltage - 50 To 1000 Volts Forward Current - 3.0 Amperesjsalinas78No ratings yet

- ER4043Document1 pageER4043Luis Fidel Ramírez LópezNo ratings yet

- Common Abbreviations in The Valve IndustryDocument10 pagesCommon Abbreviations in The Valve IndustryNath BoyapatiNo ratings yet

- T° PrecalentamientoDocument1 pageT° PrecalentamientoluisNo ratings yet

- ERNiCrCoMo 1Document1 pageERNiCrCoMo 1Vajid MadathilNo ratings yet

- Section 2 - Nichia Welding ConsumableDocument9 pagesSection 2 - Nichia Welding ConsumableLodyNo ratings yet

- Bavaria en BA-TIG 309LSiDocument1 pageBavaria en BA-TIG 309LSicocoNo ratings yet

- SF 71MCDocument1 pageSF 71MCGESTION Y CONTROL DE PROYECTOS IngeminNo ratings yet

- 0.75 in Hex Plug A105 3000-6000 HT Ca 1397Document2 pages0.75 in Hex Plug A105 3000-6000 HT Ca 1397JORGE BAENANo ratings yet

- Material Tech SpecsDocument8 pagesMaterial Tech SpecsSachin JawaleNo ratings yet

- Comparison Welding Wire A5.18-ER70S-3 - A5.18-ER70S-6Document3 pagesComparison Welding Wire A5.18-ER70S-3 - A5.18-ER70S-6QuyetNo ratings yet

- ASTM A537 Class 1: General Product DescriptionDocument2 pagesASTM A537 Class 1: General Product Descriptionfelipercaliariyahoo.com.brNo ratings yet

- 70ksi Grade MIG Solid Wire: Code DataDocument2 pages70ksi Grade MIG Solid Wire: Code Datarahman2007No ratings yet

- Isolating Joint General Data SheetDocument1 pageIsolating Joint General Data SheetGerardo GonzálezNo ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- AWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Document2 pagesAWS A5.20 E71T-1C BS EN ISO 17632-T42 2 P C 1 H10 Jis Z3313 Yfw-C50Dr CSA W48-01 E491T-1-H8 GB/T 10045 E501T-1Andre Brama AlvariNo ratings yet

- Welding Book Revised 2012 07 14Document15 pagesWelding Book Revised 2012 07 14surya1960No ratings yet

- Pin Description Features: Dual Enhancement Mode MOSFET (N-And P-Channel)Document14 pagesPin Description Features: Dual Enhancement Mode MOSFET (N-And P-Channel)javierrincon800No ratings yet

- 000 - Informe de Pruebas G1Document8 pages000 - Informe de Pruebas G1Darwin SilvaNo ratings yet

- Miniature Power Relays: Specifications How To Order Coil DataDocument1 pageMiniature Power Relays: Specifications How To Order Coil DataFenil JaiyawalaNo ratings yet

- SuperArc L 50NDocument1 pageSuperArc L 50NH_DEBIANENo ratings yet

- 110 Filarc 76SDocument1 page110 Filarc 76SAzriNo ratings yet

- Alloy 5556 Weld Data Sheet: Typical ApplicationsDocument2 pagesAlloy 5556 Weld Data Sheet: Typical Applicationsvishal bailurNo ratings yet

- AO3401Document5 pagesAO3401Yonatan RivadeneyraNo ratings yet

- Bavaria en BA-TIG 310Document1 pageBavaria en BA-TIG 310cocoNo ratings yet

- WELDING ESAB Welding Handbook XA00106720 - Pipeline Catalogue (Ebook, 66 Pages)Document66 pagesWELDING ESAB Welding Handbook XA00106720 - Pipeline Catalogue (Ebook, 66 Pages)Denny SyamsuddinNo ratings yet

- 0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611Document2 pages0.75 in Sockolet 36-2 X 3-4 6m BW X SW HT Ca0611JORGE BAENANo ratings yet