Professional Documents

Culture Documents

Process Piping Preheat Temeperatures

Uploaded by

ShreekanthKannathOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Process Piping Preheat Temeperatures

Uploaded by

ShreekanthKannathCopyright:

Available Formats

ASME B31.

3-2014

Fig. 328.5.5 Typical Fabricated Laps

GENERAL NOTE: Laps shall be machined (front and back) or trued after welding. Plate flanges in accordance with para. 304.5 or lap joint

flanges in accordance with ASME B16.5 may be used. Welds may be machined to radius, as in sketch (e), if necessary to match ASME B16.5

lap joint flanges.

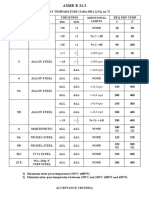

(14) Table 330.1.1 Preheat Temperatures

Base Greater

Metal Material

P-No. Thickness Additional Limits Required Minimum Temperature

[Note (1)] Base Metal Group mm in. [Note (2)] °C °F

1 Carbon steel ≤25 ≤1 %C > 0.30 [Note (3)] 10 50

>25 >1 %C ≤ 0.30 [Note (3)] 10 50

>25 >1 %C > 0.30 [Note (3)] 95 200

3 Alloy steel, Cr ≤ 1⁄2% ≤13 ≤1⁄2 SMTS ≤ 450 MPa (65 ksi) 10 50

>13 >1⁄2 SMTS ≤ 450 MPa (65 ksi) 95 200

All All SMTS > 450 MPa (65 ksi) 95 200

4 Alloy steel, 1⁄2% < Cr ≤ 2% All All None 120 250

5A Alloy steel All All SMTS ≤ 414 MPa (60 ksi) 150 300

All All SMTS > 414 MPa (60 ksi) 200 400

5B Alloy steel All All SMTS ≤ 414 MPa (60 ksi) 150 300

All All SMTS > 414 MPa (60 ksi) 200 400

≤13 ≤1⁄2 %Cr > 6.0 [Note (3)] 200 400

6 Martensitic stainless steel All All None 200 [Note (4)] 400 [Note (4)]

9A Nickel alloy steel All All None 120 250

9B Nickel alloy steel All All None 150 300

10I 27Cr steel All All None 150 [Note (5)] 300 [Note (5)]

15E 9Cr–1Mo–V CSEF steel All All None 200 400

... All other materials ... ... None 10 50

NOTES:

(1) P-Nos. and Group Nos. from BPV Code, Section IX, QW/QB-422.

(2) SMTS p Specified Minimum Tensile Strength.

(3) Composition may be based on ladle or product analysis or in accordance with specification limits.

(4) Maximum interpass temperature 315°C (600°F).

(5) Maintain interpass temperature between 150°C and 230°C (300°F and 450°F).

68

Copyright c 2015 by the American Society of Mechanical Engineers.

No reproduction may be made of this material without written consent of ASME.

You might also like

- Weld Cost CalculationDocument27 pagesWeld Cost Calculation-Abdul Khodir Van Java-100% (7)

- Stainless Steel Grade Composition ChartDocument8 pagesStainless Steel Grade Composition Chart23OtterNo ratings yet

- B31.3 Table 330.1.1 Preheat TempDocument1 pageB31.3 Table 330.1.1 Preheat TempHusam AhmedNo ratings yet

- Ultrasonic Thickness Measurement Procedure for Tank BottomsDocument7 pagesUltrasonic Thickness Measurement Procedure for Tank BottomsShreekanthKannathNo ratings yet

- Ultrasonic Thickness Measurement Procedure for Tank BottomsDocument7 pagesUltrasonic Thickness Measurement Procedure for Tank BottomsShreekanthKannathNo ratings yet

- EN 1563 - Spheroidal Graphite Cast Irons PDFDocument3 pagesEN 1563 - Spheroidal Graphite Cast Irons PDFashishkesharwaniNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Numbering Metals and Alloys in The Unified Numbering System (UNS)Document7 pagesNumbering Metals and Alloys in The Unified Numbering System (UNS)Erick VargasNo ratings yet

- Materials Data for Cyclic Loading: Low-Alloy SteelsFrom EverandMaterials Data for Cyclic Loading: Low-Alloy SteelsRating: 5 out of 5 stars5/5 (2)

- Select Arc Catalogue Part 1Document10 pagesSelect Arc Catalogue Part 1lionheartedNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Pressure Change Measurement Q & ADocument39 pagesPressure Change Measurement Q & AShreekanthKannathNo ratings yet

- Machining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesFrom EverandMachining of Stainless Steels and Super Alloys: Traditional and Nontraditional TechniquesNo ratings yet

- Technical Specification Main WarehouseDocument4 pagesTechnical Specification Main Warehouseadr_kharisma100% (2)

- Welding of Ferritic Creep-Resistant SteelsDocument3 pagesWelding of Ferritic Creep-Resistant Steelssn200709No ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- SKYVILLA SANITARY BOQDocument8 pagesSKYVILLA SANITARY BOQMekdesNo ratings yet

- Chinese Specification For Cast Iron and S. G. IronDocument1 pageChinese Specification For Cast Iron and S. G. IronRahul KhoslaNo ratings yet

- Post Weld Heat Treatment ProcedureDocument20 pagesPost Weld Heat Treatment Proceduresherviny100% (2)

- 51 CR V4Document4 pages51 CR V4armin_kunosic9871No ratings yet

- MS-264 Change Y Jul 06Document17 pagesMS-264 Change Y Jul 06Mike FiorenNo ratings yet

- Sample BQ For WBLFFDocument4 pagesSample BQ For WBLFFUmmi Hanie100% (2)

- Comparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Document7 pagesComparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Erijanio Silva100% (1)

- Welding Filler Metals For Power Plant EngineeringDocument20 pagesWelding Filler Metals For Power Plant EngineeringgogotigNo ratings yet

- Rate Analysis For ShutteringDocument2 pagesRate Analysis For ShutteringSarin100% (2)

- Rtfi Report PDFDocument1 pageRtfi Report PDFShreekanthKannathNo ratings yet

- T° precalentamientoDocument1 pageT° precalentamientoluisNo ratings yet

- 131.4.1-1 Temperaturas de PreaquecimentoDocument1 page131.4.1-1 Temperaturas de PreaquecimentoRodrigo CarneiroNo ratings yet

- Pages From ASME - B31.3 - Ed.201820191106-37149-SjoktkDocument2 pagesPages From ASME - B31.3 - Ed.201820191106-37149-Sjoktksarsan nedumkuzhiNo ratings yet

- ASME B 31.3 preheat temparature tableDocument2 pagesASME B 31.3 preheat temparature tableabdulNo ratings yet

- P Number Table of B31.3Document1 pageP Number Table of B31.3kronos39zeusNo ratings yet

- Rules For Materials and Welding 2021 AmendmentsDocument29 pagesRules For Materials and Welding 2021 AmendmentsSUEZSHIPYARD QCNo ratings yet

- B - Boehler EMK 6 - de - en - 5 PDFDocument1 pageB - Boehler EMK 6 - de - en - 5 PDFburakNo ratings yet

- Duplex Stainless SteelsDocument25 pagesDuplex Stainless Steelspym1506gmail.comNo ratings yet

- 02112015000000B - Boehler FOX DCMS Ti - CeDocument1 page02112015000000B - Boehler FOX DCMS Ti - CeparbinaNo ratings yet

- Data Sheet For BRASS SPECIFICATIONS PDFDocument5 pagesData Sheet For BRASS SPECIFICATIONS PDFvkmsNo ratings yet

- Material Cross Reference TableDocument3 pagesMaterial Cross Reference TableLuis Pol SistiNo ratings yet

- OteluriDocument15 pagesOteluriadyonelNo ratings yet

- Table 330.1.1 Preheat TemperaturesDocument1 pageTable 330.1.1 Preheat TemperaturesFeryadi BuliNo ratings yet

- Applicable Standards: ASTM A792 ASTM A792 EN10215Document14 pagesApplicable Standards: ASTM A792 ASTM A792 EN10215ersinNo ratings yet

- MS-264Document15 pagesMS-264Felipe De la cruzNo ratings yet

- SAW Test Results NSSW NB-250H & Y-80M Flux WireDocument5 pagesSAW Test Results NSSW NB-250H & Y-80M Flux WireEduard Gonzalo Rojas CervantesNo ratings yet

- Chemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateDocument2 pagesChemical Composition of ASTM ASME SA516 Grade 60 70 Steel PlateVarun Malhotra100% (1)

- ASME SA516 Grade 60 70 Steel Plate Properties GuideDocument2 pagesASME SA516 Grade 60 70 Steel Plate Properties GuideIbadurrahman KahfiNo ratings yet

- International Material Grade Comparison TableDocument2 pagesInternational Material Grade Comparison TableS.Hasan MirasadiNo ratings yet

- Sandvik 254 SMO Datasheet for Seamless Tube and PipeDocument9 pagesSandvik 254 SMO Datasheet for Seamless Tube and PipeReadersmoNo ratings yet

- S460MCDocument1 pageS460MCPankaj GuptaNo ratings yet

- Tetra S 316L-G: Technical Data Sheet Cored Welding WireDocument1 pageTetra S 316L-G: Technical Data Sheet Cored Welding WirePeter TvardzíkNo ratings yet

- 34crnimo6: Steel GradeDocument4 pages34crnimo6: Steel GradeAndrea FerrerNo ratings yet

- Sunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcesDocument6 pagesSunny Steel Enterprise LTD.: Collect Steel Pipe and Fitting ResourcessanjeettirkeyNo ratings yet

- SMAW E8015-B8 Electrode for Welding Creep-Resistant SteelsDocument1 pageSMAW E8015-B8 Electrode for Welding Creep-Resistant SteelsIssac GeorgeNo ratings yet

- Product Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Document2 pagesProduct Data Sheet OK 61.30: E 'Manual Metal-Arc Welding'Bayu RahmanNo ratings yet

- ME 205 - 432 - Assignment 1Document9 pagesME 205 - 432 - Assignment 1جعفر السلطانNo ratings yet

- Technical data sheet for rutile flux cored welding wireDocument1 pageTechnical data sheet for rutile flux cored welding wireawNo ratings yet

- MaterialsDocument2 pagesMaterialsSakthi EashwaranNo ratings yet

- Structural Steels: SABS 1431 Technical DataDocument3 pagesStructural Steels: SABS 1431 Technical DataZdravko Vidakovic100% (1)

- FPO22001 ASME Filer Metal Data SheetDocument5 pagesFPO22001 ASME Filer Metal Data Sheetyousab creator2No ratings yet

- Thermanit Chromo 9V SMAW enDocument1 pageThermanit Chromo 9V SMAW ensoft4gsmNo ratings yet

- Chemical Composition of ASTM A516 Grade 70 / ASME SA516 Grade 70Document4 pagesChemical Composition of ASTM A516 Grade 70 / ASME SA516 Grade 70Abdul WahabNo ratings yet

- 34 CR Ni Mo 6Document4 pages34 CR Ni Mo 6InaamNo ratings yet

- Fundamentals of Fabrication WeldingDocument22 pagesFundamentals of Fabrication WeldingKevinNo ratings yet

- CHF101 Flux Wire ComboDocument1 pageCHF101 Flux Wire ComboImmalatulhusnaNo ratings yet

- Steel Grades & Mechanical Properties Specification SheetDocument1 pageSteel Grades & Mechanical Properties Specification SheetKvvPrasadNo ratings yet

- Applications: TYPE: RutileDocument1 pageApplications: TYPE: Rutilesattar12345No ratings yet

- ASTM A514 Grade S: General Product DescriptionDocument2 pagesASTM A514 Grade S: General Product DescriptionAGUSTINNo ratings yet

- Engineering MaterialsDocument16 pagesEngineering MaterialsMohamed EmadNo ratings yet

- Electrodos-Revestidos KiswellDocument116 pagesElectrodos-Revestidos KiswellJoel FloresNo ratings yet

- International standards for aluminium diecasting alloy compositions and propertiesDocument2 pagesInternational standards for aluminium diecasting alloy compositions and propertieszainudinNo ratings yet

- AUTROD 316LSiDocument2 pagesAUTROD 316LSijoao guilhermeNo ratings yet

- Sus904l 158Document1 pageSus904l 158rinthusNo ratings yet

- Steel Pipe and Tubing Specifications GuideDocument2 pagesSteel Pipe and Tubing Specifications GuideShreekanthKannathNo ratings yet

- Types of Coating & Wrapping For Underground PipesDocument9 pagesTypes of Coating & Wrapping For Underground Pipesvijay sharmaNo ratings yet

- 67745048-Weld-Consumable-CalculatorDocument7 pages67745048-Weld-Consumable-CalculatorAlzaki AbdullahNo ratings yet

- Aisi 4130Document2 pagesAisi 4130ShreekanthKannathNo ratings yet

- Preheat Requirements As Per Various Codes-Asme b31.3Document1 pagePreheat Requirements As Per Various Codes-Asme b31.3ShreekanthKannathNo ratings yet

- Preheat An Essential VariableDocument3 pagesPreheat An Essential VariableShreekanthKannathNo ratings yet

- Selecting the Right Dry-Type TransformerDocument2 pagesSelecting the Right Dry-Type Transformerbhargavram1987No ratings yet

- Elec StdsDocument13 pagesElec Stdskarim karimNo ratings yet

- Voltage TransformerDocument8 pagesVoltage TransformerDaniel ReyesNo ratings yet

- Asme Sections ListDocument1 pageAsme Sections ListShreekanthKannathNo ratings yet

- How To Read Welding GaugesDocument6 pagesHow To Read Welding GaugesSaira ShahNo ratings yet

- Process Piping, Pressure Vessels, Tanks, and Boiler Welding StandardsDocument2 pagesProcess Piping, Pressure Vessels, Tanks, and Boiler Welding StandardsShreekanthKannathNo ratings yet

- Proposal ResearchDocument2 pagesProposal ResearchLouie Jay BallenasNo ratings yet

- Concrete Aggregates: Factors Influencing PerformanceDocument70 pagesConcrete Aggregates: Factors Influencing PerformanceJames McguireNo ratings yet

- Summary of Mix Design Details 11Document1 pageSummary of Mix Design Details 11Mohd.irfanNo ratings yet

- (Xaydung360.Vn) 01 BoQ Interial Works The NASSIMDocument27 pages(Xaydung360.Vn) 01 BoQ Interial Works The NASSIMChâu TúNo ratings yet

- STAMPING Journal - May June 2021Document4 pagesSTAMPING Journal - May June 2021waqar mansoorNo ratings yet

- Material Composition Analysis ReportDocument28 pagesMaterial Composition Analysis ReportBinay ChaudharyNo ratings yet

- Typical BomDocument40 pagesTypical BomVWSSI Technical TeamNo ratings yet

- 12/1/2014 Powder MetallurgyDocument29 pages12/1/2014 Powder Metallurgysofyan sam0% (2)

- Berat Jenis BesiDocument16 pagesBerat Jenis BesiRezza Octova GochirNo ratings yet

- Calculation Chek - CorrectionDocument37 pagesCalculation Chek - Correctiondebashish sarkarNo ratings yet

- Pipe Support StandardDocument32 pagesPipe Support StandardHema Nandh100% (1)

- Interpipe CatalogDocument3 pagesInterpipe CatalogUmmes AhmedNo ratings yet

- Iso 4435 en PDFDocument11 pagesIso 4435 en PDFMarwaNo ratings yet

- Construction English 101810Document29 pagesConstruction English 101810mlamourNo ratings yet

- D2 Tool Steel - Heat Treatment Process PDFDocument3 pagesD2 Tool Steel - Heat Treatment Process PDFGayathriRajasekaranNo ratings yet

- Edco Incinerator Plant 2: Refractory Lining at IncineraterDocument1 pageEdco Incinerator Plant 2: Refractory Lining at IncineraterNic RicNo ratings yet

- Detail of Floor Drain Detail of Floor Cleanout Vent Thru Roof DetailDocument1 pageDetail of Floor Drain Detail of Floor Cleanout Vent Thru Roof DetailLhewiz BrionesNo ratings yet

- Stress Corrosion Cracking Susceptibility of A Super Duplex ValveDocument15 pagesStress Corrosion Cracking Susceptibility of A Super Duplex ValveMubeenNo ratings yet

- Concrete Masonry Unit Test ReportsDocument2 pagesConcrete Masonry Unit Test Reportsaristeo garzonNo ratings yet

- All in Aggregate M-45 (PQC) : For The Contractor For The Engineer / ConsultantDocument5 pagesAll in Aggregate M-45 (PQC) : For The Contractor For The Engineer / ConsultantImran KhanNo ratings yet

- Smart City Ecological Park BOQDocument21 pagesSmart City Ecological Park BOQJalal TamboliNo ratings yet

- Sika Viscocrete 3115n Pds enDocument3 pagesSika Viscocrete 3115n Pds entantriNo ratings yet

- 5.method Statement Shuttering and Form WorkDocument4 pages5.method Statement Shuttering and Form Workشاز إياس100% (1)

- Material Science & Metallurgy 2131904: Heat Treatment ProcessesDocument47 pagesMaterial Science & Metallurgy 2131904: Heat Treatment ProcessesNyanda MadiliNo ratings yet