Professional Documents

Culture Documents

QA and QC PDF

QA and QC PDF

Uploaded by

Vinod YbOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

QA and QC PDF

QA and QC PDF

Uploaded by

Vinod YbCopyright:

Available Formats

When it comes to quality, people sometimes disagree...

Quality Control

and Quality Assurance:

Defining the Roles and Responsibilities

of the Contractors QC and the Owners QA

By Alison B. Kaelin, Corporate Quality Assurance Manager, KTA-Tator, Inc., Pittsburgh, PA, USA

E very painting project begins with the expectation that the result will be a painted structure

that will be protected for a minimum period of time. Owners rely on tools such as the spec-

ifications, contractor certification, quality control, and quality assurance inspection to verify that the work is per-

formed as specified. While many projects require quality control and/or quality assurance inspections, few specifi-

cations, if any, differentiate between the two or provide guidance on the responsibilities of each.

After discussing the difference between the functions of quality control and quality assurance, this article

reviews the SSPC certification program requirements, other recognized industry standards, and transportation

specifications that establish minimum standards of practice for quality control and quality assurance. It concludes

with recommendations for maximizing the benefits of both quality control and quality assurance.

Evolution of QC and QA in the Coatings Industry

When the coatings inspection industry began to evolve in the 1970s, there was little distinction between the roles

of QC and QA. Most early coating inspection was performed as a response to the inspection parameters established

in the nuclear power industry and ANSI/ASME N45.2.6, Qualification of Inspection, Examination and Testing

Personnel for Construction Phase of Nuclear Power Plants, and ANSI N101.4, Quality Assurance for Protective

Coatings Applied to Nuclear Facilities. These standards defined the qualifications of coatings inspectors and inspec-

tion tasks that were required during installation or maintenance of nuclear power facilities. ANSI N45.2.6 specifi-

cally applied to third-party inspectors retained by the owner to perform hold point inspection of contractor activi-

ties. As coating inspection expanded beyond nuclear power into industries like transportation and water storage

and supply, most owners continued to rely on third-party inspection to verify that contractor activities were per-

58 JPCL / April 2005 / PCE www.paintsquare.com

formed according to the specification. responsible for every aspect of the pro- Control of W ork:

In the 1990s and 2000s, with the ject from the equipment and materials, A Critical Difference

increased recognition of the International and experience and training of person- Only the contractors QC person has the

Organization for Standardization (ISO), nel, to the quality of the final product. authority to direct the contractors

American Society of Quality (ASQ), and QC is a full-time requirement and has employees or production operations.

other certifying organizations, more own- responsibilities for every aspect of the When a contractor is required to retain a

ers, consultants, and contractors started surface preparation and painting third-party QC representative, that per-

moving to the concept of a total quality process. QA can be full- or part-time, or son is not a direct employee of the con-

system with a clear division between QC, performed at specific stages (e.g., follow- tractor and may not have the authority to

conducted by the contractor, and QA, ing surface preparation) of the project to direct the contractors workers or ensure

conducted by the owner or a third-party verify the adequacy of the contractors that they correct their work when need-

owners representatives. Owners began QC. When the owner does not perform ed. Similarly, limitations may be found

to recognize that while third-party QA or provides limited QA inspection, when the owner requires the coating

inspection was still necessary, it was not half of the total quality management manufacturers technical representative to

intended to replace the contractors QC. process is lost. perform QC functions: there is no con-

Unfortunately, this awareness has not Both QC and QA are necessary to ver- tractual relationship; observations may

always been been transferred to the ify specification compliance and quality not be free of bias; conflicts between the

specifications as particular QC require- work, but an owner (or third-party manufacturer and contractor may result;

ments. The result is that QA personnel inspector) performing QA on a project and neither QC nor QA is provided.

still perform the primary role of inspect- does not relieve the contractor of the But when the owners staff performs

ing and accepting the work. When the responsibility of performing QC. QA (with direct staff), the owner has a

roles of QC and QA personnel are not contractual relationship with the contrac-

defined, a critical component of a total

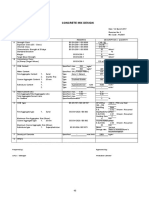

quality system is lost, and conflict can TABLE 1 Division of QC and QA Hold Point Inspections

arise between QA and contractor per-

Hold Point Inspection Quality Quality

sonnel. But when the QC and QA per-

Control Assurance

sonnel perform their respective tasks

Ambient conditions (pre-preparation) TD TD

during coating system installation, the

Pre-surface preparation conditions (welds, rust, edges, etc.) VO VO

end product improves.

Pre-surface preparation conditions (grease, dust, etc.) and/or SP 1 V V

Surface preparation equipment operation and abrasive size/type VD/TP RD/VO/TP

QA vs. QC:

Abrasive cleanliness TP RP/TP

Whats the Difference, Anyway?

Compressed air cleanliness TD RD/TP

Quality Control is performing the neces-

Soluble salt contamination TO RO/TP

sary observations, testing, and documen-

Soluble salt remediation VO VO

tation to verify that the work performed

Ambient conditions (pre-mixing and application) TD TD

meets or exceeds the minimum stan-

Mixing and materials (batch nos., pot life, thinner, etc.) VO RO/TP

dards established by the project specifi-

Application equipment operation (pressures, agitation, type, etc.) VD/TP RD/VD/TP

cations or contract. QC is the contractors

Compressed air cleanliness (spray application) TD RD/TP

responsibility.

Wet film thickness TO RO/TP

Quality Assurance is an audit process

Stripe coat, caulking, intercoat cleanliness, etc. VO RO/VO

to verify that the quality of work per-

Dry film thickness TO TO

formed is what was inspected and

Visual appearance (runs, drips, sags, etc.) VO VO

reported by the contractors QC. QA is

Repairs VO VO

conducted by the owner or by a third

Legend

party inspector on the owners behalf.

Frequency of Verification Type of Verification

QA may include reviewing QC documen-

D = Daily V = Visual

tation, observation of QC testing or actu-

O = Occurrence-based T = Testing

al testing on a spot or periodic basis.

P = Periodic R = Review of QC report or testing

Basically, then, the contractor is fully

www.paintsquare.com JPCL / April 2005 / PCE 59

tor, and therefore can exert control QA inspector accepts the work and the Qualifications of Contractors Who

through the contract (or by withholding contractor proceeds to the next step of Apply Thermal Spray (Metallizing) for

payment or stopping work) when opera- the painting process. It is often helpful, if Corrosion Protection to Steel and

tions or conditions are non-conforming. not necessary, to have the QC inspector Concrete Surfaces. QP 6 requires QP 1

Third-party QA subcontracted to the and the foreman present during the QA or QP 3 certification, also.

owner does not have a contractual rela- observations so that any deficiencies can Each standard above identifies mini-

tionship with the contractor; therefore, be identified and confirmed by all par- mum requirements for quality control

the third-party QA inspector typically ties. This also allows the QC inspector personnel, programs, inspections, and

can only document the non-conformance and the foreman to clearly identify areas documentation. The following provides a

of the contractors operations and advise requiring rework to the laborers and brief review by key topic. While the spe-

the contractor or the owner. If the con- reduces production delays. cific QC duties are not well defined in

tractor fails to correct the non-confor- The QA observations may include a the SSPC-QP standards, the supporting

mance, the owner must decide whether review of the contractors QC tests or documentation required by the respec-

to stop work, withhold payment, accept documentation and duplicate inspection tive standards sometimes provides addi-

the non-conformance or take other or testing of certain hold points (e.g., dry tional insight on the requirements for the

action. film thickness measurements) to verify contractors QC.

But whoever performs QA must be that the contractors reported results Minimum QC Qualifications: Under QP

careful not to direct or unduly interrupt reflect the quality of the work. 1 and QP 3, the QC supervisor is respon-

contractor operations due to potential When results of QC and QA inspec- sible for oversight of the QC inspectors.

contract issues regarding control of the tion differ, the QA observations typically The QC supervisor is required to have

work and costs related to work stop- supersede those of the QC. The resolu- three to five years of experience and for-

pages. tion of differing QC and QA observa- mal training. The QC inspector is to have

tions should be defined in the project a minimum of two years of experience

Sequence of QC and QA specification or agreed upon by all stake- and formal training for QP 1; however,

The specific duties of QC and the QA holders in the pre-job meeting. QP 3 allows the QC inspector to substi-

personnel will vary from project to pro- tute in-house training for formal training.

ject. The coating inspection process typi- SSPCs Approach to QC and QA QP 8 requires the QC manager and QC

cally dictates that after certain activities SSPC: The Society for Protective inspectors to have two years of experi-

(e.g., surface preparation), work should be Coatings (SSPC) has established four ence, 8 hours of general QC training, and

inspected, rework performed as neces- qualification procedures (QP) for con- 16 hours of concrete training. QP 6

sary, and the surfaces accepted by QC tractors that include minimum require- refers to the thermal spray supervisor

and QA staff before the contractor can ments for QC. (TSS) and thermal spray inspector (TSI)

move on to the next step of the project. SSPC-QP-1, Standard Procedure for rather than QC. It requires the TSS to

These specific inspection items are typi- Evaluating Qualifications of Painting have minimum of two years of experi-

cally referred to as hold points (Table 1). Contractors (Field Application to ence and qualification under internal

Generally, the QC inspection of each Complex Structures), establishes specif- programs. The TSI must be internally

hold point should occur first, and any ic requirements for the qualifications and qualified to perform thermal spray

non-conforming items identified should duties of the contractors QC personnel inspections.

be corrected, re-inspected and accepted on field coating application projects. There is no established curriculum,

by the QC inspector. The QA inspection Three other standards have similar duration, or evaluation of knowledge or

should only occur after the work (hold requirements: QP 3, Standard practical testing required under the QP 1

point) has been inspected and accepted Procedure for Evaluating Qualifications and QP 3 standards. Refresher training

by the QC inspector. The QA inspector of Shop Painting Applicators; QP 8, is not required by any QP standards.

should then verify that the work that Standard Procedure for Evaluating the Written Procedures/Quality Manuals:

the QC inspector accepted meets the Qualifications of Contracting Firms that QP 1 requires the contractor to have

requirements of the specification. If the Install Polymer Coatings and Surfacings written procedures to ensure that major

QA inspector identifies non-conforming on Concrete and Other Cementitious operations (surface preparation; primer,

items, they should be repaired and re- Substrates; and QP 6, Standard intermediate, and top coat applications)

inspected by the QC inspector before the Procedure for Evaluating the are inspected. It suggests that these pro-

60 JPCL / April 2005 / PCE www.paintsquare.com

cedures are components of a QC QC Inspection Hold Points: QP 1 does Documentation/Report: QP 1 does not

Manual. QP 3 simply requires the QC not define the specific hold points for define the information that must be doc-

to have relevant inspection standards. QC. However, the SSPC-QP 1 Annual umented in QC. The SSPC-QP 1 Annual

QP 8 specifically details standard operat- Internal Audit Report/Checklist for Internal Audit Report/Checklist, specifi-

ing procedures that must be included in SSPC Certified Contractors (Rev 02/04) cally requires that daily QC reports be

the contractors QC manual. QP 6 indicates that hold point inspections are prepared to include information such as

requires the contractor to have formal to be conducted during each major oper- compressed air cleanliness, dry film

written procedures for performing and ation: pre-cleaning, surface preparation, thickness, air temperature, humidity,

documenting inspections. primer, intermediate coat, topcoat appli- dew point, surface temperature, abrasive

Authority of the QC/Management: cation, and cure. cleanliness, degree of cleanliness

QP 1 requires written authority for the QP 3 defines hold points for receipt of achieved, surface profile, batch numbers

QC inspectors to report directly to items to be coated, inspection of repaired of paint and thinner used, and mixing

management and have to have authori- and coated items, storage of repaired and according to specification.

ty to stop work for non-conformances. coated items, surface preparation, stor- QP 3 provides a similar list; however,

QP 3 is similar but requires evidence age of coating materials, handling, repair, it adds wet film thickness and the type

that the QC inspector reports directly labeling, and handling and shipment, and amount of thinner used. QP 6 and

to management, not to a production- among others. QP 8 do not define the information to be

related supervisor or manager. QP 8 QP 8 requires hold point inspections recorded other than references to the

and QP 6 do not define the authority of based upon the detailed requirements of QP program requirements.

the QC. QP 6 requires the TSS to be on- the QC plan. QP 6 requires hold point SSPC has indicated that it will review

site and involved in material and equip- inspection for major operations defined all QP procedures and auditing discrep-

ment decisions. in the written procedures. ancies for resolution in 2005.

Other Organizations that Define QC and QA Responsibilities

NACE inspection and inspection activities related to applicator certification

The NACE International Coating Inspection Program (CIP) began cer- include the following:

tifying coatings inspectors over 20 years ago. The CIP establishes D 4227-99, Standard Practice for Qualification of Coating

three levels of certification for individual coatings inspectors (regard- Applicators for Application of Coatings to Concrete Surfaces;

less of whether they perform QC or QA). D 6237-98, Standard Guide for Painting Inspectors (Concrete and

The NACE training provides a comprehensive review of the obser- Masonry Substrates);

vations, tests and examinations that may be performed by a coating D 4228-99, Standard Practice for Qualification of Coating

inspector during the coating process but does not define them rela- Applicators for Application of Coatings to Steel Surfaces;

tive to QC and QA. The student manual for Session 1 (7/1/98), The D 3276-00, Standard Guide for Painting Inspectors (Metal

Coating Inspectors Checklist, indicates inspection tasks ranging Substrates);

from pre-surface preparation to coating application. D 5161-04, Standard Guide for Specifying Inspection

Requirements for Coating and Lining Work (Metal Substrates); and

ANSI/ASME D 4537, Establishing Procedures to Qualify and Certify Personnel

ANSI/ASME N45.2.6, Qualification of Inspection, Examination and Performing Coating Work Inspection in Nuclear Facilities.

Testing Personnel for Construction Phase of Nuclear Power Plants,

establishes criteria for companies to internally certify individual coat- Painting and Decorating Contractors of America (PDCA)

ings inspectors through experience, education, and testing as Level PDCA has three specifications that address inspection:

I, II, or III coating inspectors. The SSPC-QP 5 standard adopted the P2-92, Third Party Inspection Qualification and Responsibilities;

levels used by ANSI/ASME N45.2.6. PDCA P4, 94, Responsibilities for Inspection and Acceptance of

Surfaces Prior to Painting and Decorating; and

ASTM International PDCA P8-00, Owners Responsibility for Maintenance of Paints

ASTM International has several standards that discuss coating and/or Coatings.

inspectors and responsibilities but without differentiating between None of the PDCA documents address the specific division of QC

QC and QA. ASTM standards discussing inspector responsibilities or and QA responsibilities.

www.paintsquare.com JPCL / April 2005 / PCE 61

Transportation Agencies Addressing QC and QA

New Quality Standard from SSPC

A review was conducted of the standard speci- As shown below, 24 of the over 50 standard

Supplements the QC Standard

fications for over 50 transportation authorities specifications reviewed (approximately 50%)

as listed in the Federal Highway Administration contained QC requirements or required QP 1 SSPC has prepared SSPC-QS 1,

(FHWA) state transportation websites. certification. Fourteen of the 24 specifications Standard Procedure for Evaluating a

Specifications were examined for either QC or relied solely on QP 1 certification. Three of the Quality Standard of Contractors That

QA requirements relative to personnel train- states required the contractor to complete Apply Protective Coatings and Linings,

ing/experience, written procedure/quality con- owner-developed QC forms to document QC for the 2005 SSPC Volume 2, Systems

trol manuals, management, inspection hold inspection of specified hold points. Five of the and Specifications. It provides a supple-

points, and documentation requirements. standard specifications addressed QA require- mental standard (QS 1) for use by own-

Where QP 1 certification was required by the ments. One state required QA to complete an ers that require a higher level of QC on

specification, it was assumed that the mini- owner-developed form. QA requirements are projects than is addressed in the QP

mum QP 1 requirements for the above topics often handled on a per contract basis rather standards. This standard must be speci-

(i.e., training/experience) were invoked. than through standard specifications.

fied in addition to the applicable QP stan-

Owner / Specifying Agency Training / Written Authority &/or Inspection Documentation dard. QS 1 sets out minimum QC qualifi-

Experience Procedures / Management Hold Points or Report cations; requires implementation of a

Quality Manuals of QC

quality system rather than a QC manual;

Ministry of Transportation and YES YES YES YES YES

calls for documentation of training of

Highways (Canada) (Owner Form)

managerial staff and demonstrated man-

Delaware River Port Authority QP1 QP1 NO YES YES

agement review of fieldwork and QC

Illinois DOT YES YES YES YES YES

documentation; recommends that the

(Owner Form)

contractor provide a project-specific

Ohio DOT YES NO NO YES YES

work plan defining the inspections, refer-

(Owner Form)

ence standards, and documentation; and

Nebraska Department of Roads YES NO NO YES YES

requires that results of all inspections

Maine DOT QP1 YES NO NO YES

and tests be recorded in a written report.

Rhode Island DOT QP1 QP1 NO NO QP1

QS 1 also introduces requirements

Connecticut DOT QP1 QP1 NO NO QP1

that are not included in the QP stan-

Massachusetts DOT QP1 QP1 NO NO QP1

dards for contractors, including an annu-

New Jersey Highway Authority QP1 QP1 NO NO QP1

al written review of the QC manual by

NJ/NY Port Authority QP1 QP1 NO NO QP1

the QC manager; periodic internal

New York City DOT QP1 QP1 NO NO QP1

review of QC documentation by the QC

New York City Transit Authority QP1 QP1 NO NO QP1

manager; and a policy to address the

New York State DOT QP1 QP1 NO NO QP1

investigation, auditing, and resolution of

New York State Thruway QP1 QP1 NO NO QP1

client complaints.

New York TBTA QP1 QP1 NO NO QP1

Ohio Turnpike Commission QP1 QP1 NO NO QP1

SSPC Qualification Procedures

Oklahoma DOT QP1 QP1 NO NO QP1

for Quality Assurance

Texas DOT QP1 QP1 NO NO QP1

SSPC has one QP applicable to QA:

Utah DOT QP1 QP1 NO NO QP1

SSPC-QP 5, Standard Procedure for

Alabama DOT NO NO YES NO YES

Evaluating Qualifications of Coating and

Alaska DOT NO NO NO YES YES

Lining Inspection Companies. The SSPC-

Maryland SHA QP1 YES NO YES YES

QP 5 program establishes a certification

Indiana DOT QP1 YES YES YES NO

for inspection companies whose focus is

Delaware River Port Authority NO NO NO YES NO

the industrial coating and lining industry.

Illinois DOT NO NO NO YES YES

It evaluates an inspection companys abil-

Maine DOT NO NO NO YES NO

ity to provide consistent quality inspec-

Oregon DOT NO NO NO YES NO

tion of coatings and linings for its clients

Alaska DOT YES NO NO YES NO

(typically third-party QA). Like the por-

Note: If QP 1 is specified, training and QC manual are assumed. tions of the SSPC-QP certifications relat-

62 JPCL / April 2005 / PCE www.paintsquare.com

ed to QC, QP 5 provides minimum contractor QP programs, such as internal and contractors labor. However, once a

requirements for quality assurance per- audits, internal review of QA reports, contractor has been selected, the con-

sonnel, programs, inspections and docu- and resolution of client complaints. tractor typically dictates the schedule,

mentation. The new QS 1 incorporates number of work crews, work areas, and

many QP 5 requirements. Staffing of QC and QA Personnel working hours. The QA staffing plan

Minimum QA Qualifications: QP 5 The contractors schedule, number of should be carefully evaluated against the

requires the company to employ a total work crews or locations, the QCs other contractors actual schedule to see if ade-

quality manager (TQM) who reports responsibilities, and adequate staffing for quate QA staff is available.

directly to management. The TQM must QC and QA can also have a significant Another potential problem with QA

have at least 10 years of experience and impact on QC and QA work. staffing is that with shrinking painting

be an SSPC PCS or NACE-Certified Under the SSPC certification require- budgets, often QA time on-site is limited

Coating Inspector or must hold a BS ments, while the contractor is required by the project budget. QA may be limit-

degree in corrosion science or engineer- to provide a QC representative, there is ed to an eight-hour workday, while actu-

ing. Inspectors employed by a QP 5-certi- no guidance on the number of QC per- al contractor operations occur for 12 to

fied company are divided into three lev- sonnel or QC time necessary to achieve 14 hours per day during peak periods.

els of responsibility, based primarily adequate quality control. For projects As most of the coating work is per-

upon experience and education. In addi- involving multiple structures or loca- formed at the end of the day, a QA

tion to coating inspection training, QP 5 tions, or multiple crews, it is unlikely inspector may not be on-site during the

requires QA inspectors to undergo that a single QC inspector could perform mixing and application of the coating. A

annual vision testing and a coating the necessary observations, testing, and reasonable rule of thumb is that the QC

inspection refresher training. documentation to verify that all the and QA should be present for the com-

Written Procedures/Quality Manuals: work was performed as required by the plete workday or week.

QP 5 requires participants to develop a project specification or the respective QP When QA staffing is inadequate, the

complete quality system that addresses: standard. If the QC inspector is perform- ability to observe all operations is com-

quality policy and management com- ing additional duties (e.g., acting as the promised. In the absence of effective QC,

mitments; competent person or assisting in produc- valuable QA time is lost performing ini-

organizational, management structure, tion operations), his or her ability to ade- tial inspections.

and reporting relationships; quately perform QC is further compro-

procedures for performing coating mised. None of the QP requirements pre- Separating QC and QA

inspections and tests; vent the QC from performing other func- Responsibilities

references to inspection equipment, cal- tions. Qualifications: QC qualifications appear

ibration, maintenance, and measurement Where there is inadequate QC cover- to be inconsistently defined in most of

standards; and age of the key hold points, the QA the documents researched. Since QC has

internal audit procedures and schedule. inspector may be the only one perform- the primary responsibility for the quality

The program must be reviewed annu- ing observations and testing. This results of the end product, QC personnel should

ally and documented by a written report in the loss of the primary component have a minimum level of experience and

to management. (quality control) of the total quality man- formal training to perform and document

Management of QA: QP 5 requires the agement system. It can also lead to con- the implementation of the QC process.

TQM to audit the QA inspection staff frontation between the contractor and Consideration should be given to requir-

and oversee the implementation of the the QA inspector when non-confor- ing QC personnel to document proficien-

quality system. In addition, QP 5 mances are observed and the QC inspec- cy in coating inspection through formal

requires participants to train auditors tor was not involved in the initial inspec- certification or successful completion of

and audit the implementation of the tion and correction of the work. a specific curriculum.

quality system. Inadequate QA staffing can also result When SSPC-QP 1 is specified, the

QP 5 does not define QA hold points in inadequate quality auditing of the QC. experience and training of the proposed

or documentation requirements, but The level of QA inspection and the num- QC should be verified.

states that they are dictated by contract. ber of assigned staff are typically estab- Procedures: Similar to the above, the con-

QP 5 places several additional require- lished by the owner based on an engi- tractor should be required to follow writ-

ments on QA that are not included in neers estimate of the project schedule ten QC procedures and maintain docu-

www.paintsquare.com JPCL / April 2005 / PCE 63

mentation for recording the QC observa- Conclusion Benefits can include avoiding duplication

tions. Most specifications reviewed did Only by establishing clear qualifications, of documentation and inspection, reduc-

not specify submission of QA proce- responsibilities, and documentation ing conflicts among the contractor,

dures. Documentation was required for requirements for both QC and QA on a owner, and third party QA; real or per-

most QA inspections. given project will all parties to a protec- ceived under- or over-inspection; and

Hold Points: This article suggests that the tive coatings project benefit fully from a most importantly, long-lasting protec-

QC has full-time responsibility for all total quality management process. tion of the structure or asset.

phases of the project. Further, given the

contractors control of the equipment,

personnel, material, and processes, they

must, through QC, be responsible for test- Recommendations

ing of its operation and adequacy. QA is We all can improve our understanding of the functions of quality assurance and quality control.

typically specified at critical hold points Owners, for example, should evaluate and revise current standard specifications, special

and for periodic verification that the QC provisions, and contracts (i.e., contractor and owner or third-party inspection) to clearly define

is being implemented. An appropriate the responsibilities of QC and QA personnel.

division of hold points between QC and Owners also should require adequate QC coverage based on projected schedules or mini-

QA is delineated in Table 1 on p. 59. mum QC coverage by crew, structure, location, or working hours.

Appropriate division of hold point And owners should require QC personnel to meet minimum standards of training and expe-

inspections of the QC and QA personnel rience, provide QC procedures, and maintain documentation that will be used to verify the

should result in the ultimate responsibili- quality of the final product.

ty for quality being that of the contrac- Furthermore, when specifying SSPC or similar certifications, owners should require the

tors, and should allow QA inspectors to contractor to provide evidence of QC personnel qualifications and training, necessary QC

fulfill their role as an audit function, equipment, QC procedures, and the type of documentation to be completed by the QC inspec-

rather than as the sole entity responsible tor. QS 1 should be required in addition to QP certifications.

for the quality of a coatings project. Owners also should develop QC forms or require the QC to use industry-recognized forms.

Similarly, owners should develop QA forms for use by internal QA or third party QA.

Finally, owners should evaluate QA coverage based on the contractors proposed work plan,

number of crews, locations, or working hours.

Alison B. Kaelin is the Contractors must recognize that QC is the first step in the total quality process and that

KTA corporate quality adequate employee training, experience, and adherence to QC procedures and documentation

assurance manager are crucial. In addition, contractors should provide for adequate level of QC in the project esti-

and former manager mate and bids.

of the KTA Third-party inspection agencies need to clarify in advance with owners and contractors the

Environmental Health

sequence of QC and QA inspections, how to resolve conflicts, and how to communicate non-

and Safety Group. She

conforming conditions.

holds a BE in civil and

Third-party inspectors also must verify whether the scope of the inspection is quality con-

environmental engi-

neering from Vanderbilt University and is a trol or quality assurance. They must clarify QA inspection hold points versus QC responsibili-

NACE-certified coatings inspector. Ms. ties.

Kaelin also has 17 years of public health Trade organizations, such as SSPC, NACE, PDCA, and ASTM, should evaluate the appropri-

and environmental experience. She chaired ate qualifications/experience, inspection, and documentations specific to QC and QA in their

the SSPC Task Group C.5.3 on standards. Such organizations should also consider annual retraining, minimum training cur-

Environmental Monitoring Strategies and riculum or training hours, or certifications for QC personnel.

the Dust Collection Committee, and is a SSPC should evaluate its certification programs for consistency among the different QP

principal instructor of SSPCs C-3 Certified standards. Consideration should be given to defining minimum training requirements for QC

Supervisor/Competent Person for Industrial and management of the QC process similar to the approach used for QP 5-certified inspection

Deleading Projects. Ms. Kaelin has present-

companies. Some of the actions planned for this year appear to indicate that SSPC is moving

ed and published over 15 articles on envi-

in this direction.

ronmental protection, worker health and

FHWA//AASHTO should consider developing master guidelines and specifications relative to

safety, and other topics related to the coat -

ings industry. the QC and QA on transportation projects.

64 JPCL / April 2005 / PCE www.paintsquare.com

You might also like

- Expediting ProcedureDocument16 pagesExpediting Procedurekbldam94% (17)

- Epoxy Bonding Agent For Segmental ConstructionDocument10 pagesEpoxy Bonding Agent For Segmental ConstructionAkash YadavNo ratings yet

- Measuring & Removing Moisture in ConcreteDocument6 pagesMeasuring & Removing Moisture in Concretedantranz100% (1)

- Micrasil TDSDocument2 pagesMicrasil TDSAmmarNo ratings yet

- Antiwashout Admixtures For Underwater ConcreteDocument2 pagesAntiwashout Admixtures For Underwater Concretemanil_5No ratings yet

- Student Registration Invoice (Complete) : University of GuyanaDocument1 pageStudent Registration Invoice (Complete) : University of GuyanaOneil Prettyboyswagg LeitchNo ratings yet

- Parc de La Villette Rem KoolhaasDocument7 pagesParc de La Villette Rem KoolhaasAnonymous Psi9GaNo ratings yet

- MaxDEA Pro 6 Manual PDFDocument126 pagesMaxDEA Pro 6 Manual PDFkokoh kabul kabulNo ratings yet

- Northwind DatabaseDocument9 pagesNorthwind DatabaseAdi AdiNo ratings yet

- The Specification The Weak Link in Concr PDFDocument9 pagesThe Specification The Weak Link in Concr PDFJorge Cordoba100% (1)

- BS 8204 BondingDocument1 pageBS 8204 BondingNicola BeechNo ratings yet

- PDS Simacover Tar Epoxy 3404-00Document4 pagesPDS Simacover Tar Epoxy 3404-00Aulia RahmahNo ratings yet

- Hot - Weather Creaton 2Document7 pagesHot - Weather Creaton 2Pankaj PriyadarshiNo ratings yet

- RMCDocument2 pagesRMCraju_mantripragadaNo ratings yet

- Concrete Mix Design Optimized ApproachDocument8 pagesConcrete Mix Design Optimized ApproachHerman MwakoiNo ratings yet

- Mix DesignDocument29 pagesMix Designshahhassa9No ratings yet

- Concrete Specification - enDocument43 pagesConcrete Specification - ennguyencongoanhNo ratings yet

- Effect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteDocument26 pagesEffect of Restraint, Volume Change, and Reinforcement On Cracking of Mass ConcreteDIDIER ANGEL LOPEZ RINCONNo ratings yet

- Transgulf Catalogue PDFDocument52 pagesTransgulf Catalogue PDFHusainNo ratings yet

- Carbonation TestDocument2 pagesCarbonation TestShashank TiwariNo ratings yet

- Technical Data Sheet: Stolevell Thinplast FinishDocument3 pagesTechnical Data Sheet: Stolevell Thinplast FinishAnthony Al Lakiss0% (1)

- TDS - Sonoshield ParkcoatDocument2 pagesTDS - Sonoshield ParkcoatVenkata RaoNo ratings yet

- Chloride Content of Fresh ConcreteDocument4 pagesChloride Content of Fresh ConcreteAlan KirbyNo ratings yet

- Concrete in Hot Weather Conditions-Challanges - Precautions: Dr. S. Vijaya Mohan RaoDocument6 pagesConcrete in Hot Weather Conditions-Challanges - Precautions: Dr. S. Vijaya Mohan RaoHussain ElarabiNo ratings yet

- Monitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewDocument8 pagesMonitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewAmit Sharma IPS AcademyNo ratings yet

- Carbonation Test: 1. ObjectiveDocument1 pageCarbonation Test: 1. ObjectiveSubramanyam VangaraNo ratings yet

- Core Strength Variation of In-Place Concrete - tcm77-1305833Document3 pagesCore Strength Variation of In-Place Concrete - tcm77-1305833usama anterNo ratings yet

- Bridge PaintingDocument25 pagesBridge PaintingKalesan Gopalakrishnan GNo ratings yet

- TDS Fosroc Polyurea WH 200 IndiaDocument4 pagesTDS Fosroc Polyurea WH 200 Indiaprem prakash mishraNo ratings yet

- Factory Produced Mortar For Internal PlasteringDocument4 pagesFactory Produced Mortar For Internal PlasteringJonathan Wang HSNo ratings yet

- Portland Cement Plastering IFC PDFDocument12 pagesPortland Cement Plastering IFC PDFTEC PlantNo ratings yet

- Non Destructive Testing of ConcreteDocument6 pagesNon Destructive Testing of ConcreteAatifNo ratings yet

- Checklist For Concrete WorkdDocument12 pagesChecklist For Concrete WorkdJawad NaderiNo ratings yet

- Specifying Concrete For Durability Cif Dec 05Document9 pagesSpecifying Concrete For Durability Cif Dec 05Veio MacieiraNo ratings yet

- Carbonation TestDocument1 pageCarbonation TestMiguel Ivan Acosta MondragonNo ratings yet

- Conrete Mix Design ACI and JSCE Example. (20+33 Mpa)Document8 pagesConrete Mix Design ACI and JSCE Example. (20+33 Mpa)nirmaljoshi100% (1)

- Anti CarbonationDocument4 pagesAnti Carbonationraja qammarNo ratings yet

- 7-SCC C60 Mix Design MDC 2Document1 page7-SCC C60 Mix Design MDC 2Kelly JuarezNo ratings yet

- 00 Concrete Construction Troubleshooting TipsDocument20 pages00 Concrete Construction Troubleshooting TipsSue JinsueNo ratings yet

- Post Cast Strip PDFDocument2 pagesPost Cast Strip PDFKwoshaba PidsonNo ratings yet

- Approval of - Concurewb309-As Concrete Curing CompoundDocument4 pagesApproval of - Concurewb309-As Concrete Curing Compoundsalman tariqNo ratings yet

- 134 - As Struck Finishes PDFDocument2 pages134 - As Struck Finishes PDFJonathan KeoughNo ratings yet

- Concrete Technology Notes 2Document10 pagesConcrete Technology Notes 2Munir HalimzaiNo ratings yet

- Fosroc Catalogue 2011Document112 pagesFosroc Catalogue 2011Bahtiar AntanaNo ratings yet

- MS-2 Asphalt Film ThicknessDocument5 pagesMS-2 Asphalt Film ThicknessSinan İcikNo ratings yet

- NEVILLE, AITCIN (1998) - High Performance Concrete - An OverviewDocument7 pagesNEVILLE, AITCIN (1998) - High Performance Concrete - An OverviewKimberley HollandNo ratings yet

- Concrete Mix Design RC5001Document1 pageConcrete Mix Design RC5001shahrilzainul77No ratings yet

- A1-80-2 External Wall Tiling - 1 PDFDocument15 pagesA1-80-2 External Wall Tiling - 1 PDFZYWNo ratings yet

- MasterSeal 550Document38 pagesMasterSeal 550Ahmad ElghazolyNo ratings yet

- Control Tests For ConcreteDocument30 pagesControl Tests For ConcreteBia Mughal100% (1)

- 04 - TDS Meyco FlowcableDocument3 pages04 - TDS Meyco FlowcablebossbobNo ratings yet

- Concrete Discharge Time (ASCC)Document1 pageConcrete Discharge Time (ASCC)V. ManilalNo ratings yet

- Critical Chloride Content in ConcreteDocument8 pagesCritical Chloride Content in ConcreteChatchai ManathamsombatNo ratings yet

- CIP33-High Strenght ConcreteDocument2 pagesCIP33-High Strenght Concrete7774R105No ratings yet

- Study On The Durability of Surface Coating Materials For Concrete StructuresDocument12 pagesStudy On The Durability of Surface Coating Materials For Concrete StructuresagustinussetNo ratings yet

- Surface Preparation Repair May 2020Document6 pagesSurface Preparation Repair May 2020Mel AnieNo ratings yet

- Concrete Scaling - A Critical ReviewDocument41 pagesConcrete Scaling - A Critical ReviewsatpalNo ratings yet

- Chloride Migration Test: NORDTEST METHOD (NT BUILD 492 Approved 1999-11)Document8 pagesChloride Migration Test: NORDTEST METHOD (NT BUILD 492 Approved 1999-11)Sreenath Menon K100% (1)

- Cement Mortar PlasterDocument5 pagesCement Mortar PlasterMani Appa100% (1)

- Concrete TestsDocument2 pagesConcrete TestsdaraweereNo ratings yet

- Recron 3S GuideDocument11 pagesRecron 3S GuideJay BhayaniNo ratings yet

- Causes of Defects in Concrete StructuresDocument3 pagesCauses of Defects in Concrete StructuresSyed Mohd MehdiNo ratings yet

- Qc&qa AbkDocument22 pagesQc&qa Abkdosetiadi100% (1)

- QAQC Questions & AnswersDocument5 pagesQAQC Questions & Answersnafis2uNo ratings yet

- SSPC InspectionplanDocument28 pagesSSPC Inspectionplanffds100% (3)

- Book of Best PracticesDocument117 pagesBook of Best PracticesMoeen Khan Risaldar100% (2)

- 181 - DE0521 Paint Standard Rev81Document5 pages181 - DE0521 Paint Standard Rev81Moeen Khan RisaldarNo ratings yet

- Polythane PDocument2 pagesPolythane PMoeen Khan RisaldarNo ratings yet

- BIG - Employment Application Form (HR-RS-02)Document5 pagesBIG - Employment Application Form (HR-RS-02)Moeen Khan RisaldarNo ratings yet

- Syllabus TPDocument2 pagesSyllabus TPMoeen Khan RisaldarNo ratings yet

- Aspen Help Session: Flash Distillation: Smith@suntan - Eng.usf - EduDocument6 pagesAspen Help Session: Flash Distillation: Smith@suntan - Eng.usf - EduMoeen Khan RisaldarNo ratings yet

- Corrosion Under Insulation White Paper PDFDocument4 pagesCorrosion Under Insulation White Paper PDFMoeen Khan Risaldar100% (1)

- B.Tech. Chemical Engineering: Name: Roll NoDocument1 pageB.Tech. Chemical Engineering: Name: Roll NoMoeen Khan RisaldarNo ratings yet

- Aspen Help Session: Flash Distillation: Smith@suntan - Eng.usf - EduDocument6 pagesAspen Help Session: Flash Distillation: Smith@suntan - Eng.usf - EduMoeen Khan RisaldarNo ratings yet

- SSPC Painting Manual: SSPC: The Society For Protective Coatings 40 24th Street, 6th Floor Pittsburgh, PA 15222Document6 pagesSSPC Painting Manual: SSPC: The Society For Protective Coatings 40 24th Street, 6th Floor Pittsburgh, PA 15222Moeen Khan RisaldarNo ratings yet

- Ne335 Macro Lab1Document17 pagesNe335 Macro Lab1Moeen Khan RisaldarNo ratings yet

- 03 - 120803 Hot Melt Extrusion With BASF Pharma PolymersDocument201 pages03 - 120803 Hot Melt Extrusion With BASF Pharma PolymersMoeen Khan Risaldar100% (1)

- CTEB 101 INGE R ET 5ada026 0+inglésDocument43 pagesCTEB 101 INGE R ET 5ada026 0+inglésMoeen Khan RisaldarNo ratings yet

- Membrane Ultrafiltration ScriptDocument10 pagesMembrane Ultrafiltration ScriptMoeen Khan RisaldarNo ratings yet

- Praveen Balaji.RDocument3 pagesPraveen Balaji.RPraveen Balaji RamachandranNo ratings yet

- QGL-CE-009 Design Guidelines For Road PavementDocument10 pagesQGL-CE-009 Design Guidelines For Road PavementMedhat ElhagrasyNo ratings yet

- Instructions To Suppliers For Providing Equipment, Spare Parts and Operating Materials Data For New Equipment Purchased For or by Saudi AramcoDocument3 pagesInstructions To Suppliers For Providing Equipment, Spare Parts and Operating Materials Data For New Equipment Purchased For or by Saudi Aramcoarulselvan22No ratings yet

- Chapter 3 Fyp AziziDocument3 pagesChapter 3 Fyp AziziAmir AlistyNo ratings yet

- Dorneich Files 2015 08 WorkingVandJ-SQC 2015-08-24Document413 pagesDorneich Files 2015 08 WorkingVandJ-SQC 2015-08-24ainun endarwatiNo ratings yet

- Project EngineerDocument6 pagesProject Engineerapi-78713833No ratings yet

- Atlantic Computer: A Bundle of Pricing Options Group 4Document16 pagesAtlantic Computer: A Bundle of Pricing Options Group 4Rohan Aggarwal100% (1)

- 240-95401790 Reference Project Lifecycle Model StandardDocument25 pages240-95401790 Reference Project Lifecycle Model StandardsiphoNo ratings yet

- Renewable and Sustainable Energy Reviews: Yao Zhang, Wei Chen, Weijun GaoDocument11 pagesRenewable and Sustainable Energy Reviews: Yao Zhang, Wei Chen, Weijun Gaobtganyo6028No ratings yet

- Coursera NBBXS6GSGBBCDocument63 pagesCoursera NBBXS6GSGBBCAlejandra Jackeline MartinezNo ratings yet

- Incoloy 800 / Alloy 800 / UNS N08800 / DIN 1.4876Document3 pagesIncoloy 800 / Alloy 800 / UNS N08800 / DIN 1.4876SamkitNo ratings yet

- Project Manager - Mineral Processing Plants - Job at Extraordinary Futures in MpumalangaDocument2 pagesProject Manager - Mineral Processing Plants - Job at Extraordinary Futures in MpumalangaOwm Close CorporationNo ratings yet

- Information Technology at IKEADocument10 pagesInformation Technology at IKEAOranoot WangsukNo ratings yet

- FMCDocument2 pagesFMCRajkumarNo ratings yet

- Standard Sap ReportsDocument22 pagesStandard Sap ReportsGaurav Harimitter100% (1)

- Chicago Pneumatic Breakers Brochure (US)Document12 pagesChicago Pneumatic Breakers Brochure (US)Sumit BhasinNo ratings yet

- The Development of A Paraffin Based Experimental Hybrid Sounding Rocket UCLADocument14 pagesThe Development of A Paraffin Based Experimental Hybrid Sounding Rocket UCLAmcbooth3100% (1)

- 700-0096-00 EOSR Handbook Rev 16Document32 pages700-0096-00 EOSR Handbook Rev 16Jaya JayavardhanNo ratings yet

- TOP225Document5 pagesTOP225johndavsg8022No ratings yet

- Why It Is Important To Consider "Fiori Design Guidelines" To Develop SAP Fiori Apps?Document2 pagesWhy It Is Important To Consider "Fiori Design Guidelines" To Develop SAP Fiori Apps?shyamvs2002No ratings yet

- Gill Battery VRLA Service ManualDocument48 pagesGill Battery VRLA Service ManualtheoNo ratings yet

- Exercises Operational ERD - Without - SolutionDocument9 pagesExercises Operational ERD - Without - SolutionRihabNo ratings yet

- 150 5320 17a PDFDocument4 pages150 5320 17a PDFarti100% (1)

- Series 300 API Filter PressDocument39 pagesSeries 300 API Filter Pressjuli_radNo ratings yet

- Sunrise Software Fortek Case StudyDocument4 pagesSunrise Software Fortek Case Studycsteer5026No ratings yet