Professional Documents

Culture Documents

PSLoss072 Demo

Uploaded by

william robinsonOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PSLoss072 Demo

Uploaded by

william robinsonCopyright:

Available Formats

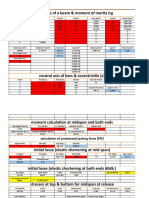

COMPANY NAME Project: Engineer: YP Project #

Date: 6/8/17 0615

PSLoss Subject: Checker: Page:

Copyright 2007 Date:

Rev. 04/04/2007

PRESTRESS LOSSES IN POST-TENSIONING TENDON

Ultimate strength of strand fpu = 270 ksi Units: US

dulus of elasticity of strand Es = 29000 ksi

ross-sectional area of strand 0.217 in

Number of strands in tendon 12

oss-sectional area of tendon 2.604 in

Tendon length 220 ft

urvature Friction Coefficient m = 0.25

Wobble Friction Coefficient K= 0.0002 1/ft

Anchor set DS = 0.375 in

Additional prestress losses DfLT = 20 ksi (long-term and elastic shortening)

Left Pull Right Pull

Stressing ratio FJack/fpu = 0.8 0.8

Stressing order 1 2

Summary of Results

Average stress after seating 187.14 ksi

Final average stress 167.14 ksi

inal average force in tendon 435.23 Kip

Right

Left Pull

Pull

Jacking stress FJack = 216 216 ksi

Jacking force PJack = 562.464 562.464 Kip

Anchor set influence zone Lc = 42.70 42.70 ft

Prestress losses at anchor DF = 34.58 34.58 ksi

Stress at anchor fanchor = 181.42 181.42 ksi

ress at end of inluence zone #VALUE! 198.71 ksi

Elongation before anchor set 16.60 1.19 in

Elongation after anchor set 16.22 0.81 in

Stress ratio at anchorage 0.672

x. stress ratio along tendon 0.736

Prestress, ksi

310

290

270

250

230

210

190

170

150

0Jacking from left

2 end 4 Jacking from right

6 end 8 10

After seating 12

Final After seating on left After seating on right

label points

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Losses Page 1 of 11

250

230

210

COMPANY NAME

190 Project: Engineer: YP Project #

170

Date: 6/8/17 0615

PSLoss Subject: Checker: Page:

150

Copyright 2007 Date:

0Jacking from left

2 end 4 Jacking from right

6 end 8 10

After seating 12

Rev. 04/04/2007

Final After seating on left After seating on right

PRESTRESS

label points LOSSES IN POST-TENSIONING TENDON

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Losses Page 2 of 11

COMPANY NAME Project: Engineer: YP Project #

Date: 6/8/17 0615

PSLoss Subject: Checker: Page:

Copyright 2007 Date:

Rev. 04/04/2007

PRESTRESS LOSSES IN POST-TENSIONING TENDON

Angular Change per Segment

Stress Stress

Distance Horizont Total Distance

Segmen Vertical after after

from left al accumul from left

t Length Profile anchor addition

end Profile ative end

set al losses

ft ft rad rad rad ft ksi ksi

0 0 0.00 181.4 161.4

22 22 0.08317 0.00000 0.0832 22.00 186.8 166.8

40 18 0.17096 0.00000 0.2541 40.00 196.3 176.3

50 10 0.17096 0.00000 0.4251 42.70 198.7 178.7

60 10 0.09141 0.00000 0.5165 50.00 192.3 172.3

110 50 0.09141 0.00000 0.6079 60.00 187.6 167.6

160 50 0.09141 0.00000 0.6993 110.00 181.5 161.5

170 10 0.09141 0.00000 0.7907 110.00 181.5 161.5

180 10 0.17096 0.00000 0.9617 160.00 187.6 167.6

198 18 0.17096 0.00000 1.1326 170.00 192.3 172.3

220 22 0.08317 0.00000 1.2158 177.30 198.7 178.7

180.00 196.3 176.3

198.00 186.8 166.8

220.00 181.4 161.4

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Losses Page 3 of 11

COMPANY NAME Project: Engineer: YP Project #

Date: 6/8/17 0615

PSLoss Subject: Checker: Page:

Copyright 2006 Date:

TENDON PROFILE

2.500

2.000

Elevation, H

1.500

1.000

0.500

0.000

0 50 100 150 200 250

Distance from left end, X

All dimensions are ft Web slope H/V = 0 Angle correction factor = 1.000

Vertical Profile Horizontal Profile

Segment Segme

DX X1 X2 H1 H2 X Radius

type nt type

Sag falling 22 0 22 2 1.083 0

Sag rising 18 22 40 1.083 220 Tangent

Crown rising 10 40 50 3.5

Crown falling 10 50 60 3.5

Sag falling 50 60 110 0.75

Sag rising 50 110 160 0.75

Crown rising 10 160 170 3.5

Crown falling 10 170 180 3.5

Sag falling 18 180 198 1.083

Sag rising 22 198 220 1.083 2

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Profile Page 4 of 11

COMPANY NAME Project: 0 Engineer: YP Project #

Date: 6/8/17

PSLoss Subject: 0 Checker: Page: 1

Copyright 2006 Date:

TENDON VERTICAL PROFILE HORIZONTAL PROFILE

Web slope H/V = 0 Units: ft

Angle correction factor = 1.000

Parabola coefficients

Input Correct

Segme Angle Segme Angle

Point Station Elevatio Elevatio A1 A2 A3 Station Radius

nt type Change nt type Change

n n

Inflection 0 2 2 0

Low Sag 22 1.083 1.083 0.0019 -0.083 2 0.0832 220 Tangent 0.0000

Inflectio Sag 40 ### ### ### ###

High Crown 50 3.5 3.5 ### ### ### ###

Inflectio Crown 60 ### ### ### ###

Low Sag 110 0.75 0.75 ### ### ### ###

Inflectio Sag 160 ### ### ### ###

High Crown 170 3.5 3.5 ### ### ### ###

Inflectio Crown 180 ### ### ### ###

Low Sag 198 1.083 1.083 ### ### ### ###

Inflectio Sag 220 2 2 0.0019 -0.75 75.36 0.0832

COMPANY NAME Project: Engineer: YP Project #

Date: 6/8/17 0615

PSLoss Subject: Checker: Page:

Copyright 2006 Date:

EQUIVALENT POST-TENSIONING LOADS

Steel Area of tendons, Aps = 2.604 in

Construction stage: After anchor set

Right

Left end

End

Elevation of section C.G. : 2.25 2.25 ft

End forces at anchorages

PX - horizontal force (positive left to right)

PY - vertical force (positive is up)

M - moment (negative when clockwise)

PX PY M LA

Kip Kip Kip* ft ft

Left end 470.8 -39.2 117.7 0

Right end -470.8 -39.2 -117.7 220

Equivalent PS loads

1

0.8

0.6

0.4

0.2

0

0 50 100 150 200 250

Equivalent Prestress Load

Vertical Linear Load Horizontal

(positive Up) Dist. from left end Uniform

WA WB LA LB WX

Kip/ft Kip/ft ft ft Kip/ft

1.790 1.843 0.00 22.00 -0.636

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

#VALUE! #VALUE! #VALUE! #VALUE! #VALUE!

1.843 1.790 198.00 220.00 0.636

file: file:///conversion/tmp/scratch/357333951.xls Sheet: EquivalentLoads Page 6 of 11

file: file:///conversion/tmp/scratch/357333951.xls Sheet: EquivalentLoads Page 7 of 11

PSLoss

Copyright 2006

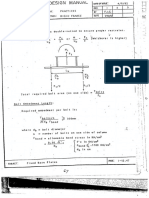

THEORY PRESTRESSING LOSSES DUE TO FRICTION AND ANCHOR SET

FJack Stress before anchor set fx = FJacke-(ma+Kx)

DA Note: stress after anchor

set is symmerical to stress

DF b A before anchor set within Lc.

b

Stress after

Stressing end

Dead end

anchor set

Lc

Ltendon

Fig. 1 Stressing from one end

Stressing from one end

Stress before Stress before

anchor 1 set anchor 2 set

FJack2

Stress after

anchor 2 set

DF2

DF1

Stressing end 2

Stressing end 1

Stress after

anchor 1 set

A1 A2

Ltendon

Fig. 2 Stressing from two ends

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Theory Page 8 of 11

PSLoss

Copyright 2006

Stressing from one end (refer to Fig. 1 above)

fx = FJacke-(ma+Kx) Stress along the tendon at distance 'x' from the stressing end.

FJack Jacking stress at anchor

a Accumulative angle change from stressing end to 'x'

m Curvature Friction Coefficient

K Wobble Friction Coefficient

DL = A/Es Strand elongation during stressing operations.

Es Strand modulus of elasticity

A Area below the graph of 'stress before anchor set' and above the line of zero

stress (yellow colored area on Fig. 1)

DS = DA/Es Anchor set

DA Area below graph 'stress before anchor set' and above graph 'stress after

anchor set' (shaded area on Fig. 1)

Lc Length of stress conversion zone.

DF Prestress losses at anchor

Stressing from two ends (refer to Fig. 2 above)

Compute stresses at second pull before and after anchor set independently

from first pull. The resulting stress is the maximum of stresses due to first

and second pulls (red line on Fig. 2)

DL2 = A2/Es Elongations during second pull

A2 Area below graph 'stress before anchor 2 set' and above graph 'stress after

anchor 1 set' (orange shaded area on Fig. 2).

Angle change within a parabolic segment of tendon

y = aX+bX+c Parabolic equation of tendon

a1 = atan[(2aX1+b)/sin(b)] Start angle adjusted for web slope

v/sin(b) b

a2 = atan[(2aX2+b)/sin(b)] End angle adjusted for web slope

Da = abs(a2-a1) Angle change within a parabolic segment

v

a, b, c Parabolic coefficients

X1, X2 Start and End stations of parabolic segment

b = atan(v/h) Web slope angle to horizon h

Combining tendon angular changes in vertical and horizontal planes

Da Total angular change within a segment

Dav, Dah Angular change in ortogonal planes

cos(Da)=cos(Dav)*cos(Dah)

Equivalent beam loads due to post-tensioning

The explanatory paper on this subject was presented at 2002 GT STRUDL

user group conference. It's available on GATECH website at

http://www.gtstrudl.gatech.edu/

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Theory Page 9 of 11

PSLoss

Copyright 2006

Follow 'Technical Papers' then scroll down to 2002 "Analysis of Post-

Tensioned Continuous Span Bridges" by Abhijit Naik & Jay A. Quioque,

California Department of Transportation. Download 7MB powerpoint

presentation.

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Theory Page 10 of 11

PSLoss

Copyright 2006

INSTRUCTIONS FOR USING PSLoss SPREADSHEET

Spreadsheet functionality:

Computes friction and anchor set losses in prestressing tendon

Computes tendon elongations

Developes tendon vertical and horizontal profiles

Calculates equivalent beam loads due to post-tensioning

Capabilities:

Pulling from one or both ends

Multiple angle changes in three-dimensional tendon profile

SI and US measurement systems

US and international codes

Instruction for data input

All input cells in the spreadsheet are formatted as a blue text on yellow background 4.35

The custom toolbar menu provides the following functions:

Calculate ! Performs iterative calculations necessary to compute prestress losses

Tendon Profile Activates 'Tendon Profile' worksheet

PT Losses Activates 'Losses' worksheet

Equivalent Loads Activates 'Equivalent Post-Tensioning Loads' worksheet

Theory/Help Activates current worksheet

Design Units Toggles US and SI units

Disclaimer Displays PSLoss disclaimer

PSLoss Step by Step

1. Open 'Tendon Profile' worksheet (use menu Tendon Profile - Edit or click on 'Profile' tab below).

2. Establish tendon vertical profile built out of parabolic or tangent segments. Provides location of

tangent and radial segments of horizontal profile.

3. On the worksheet 'Losses' enter required stressing data and click command 'Calculate !'

4. Print file.

file: file:///conversion/tmp/scratch/357333951.xls Sheet: Theory Page 11 of 11

You might also like

- m1340008 Dark FutureDocument220 pagesm1340008 Dark Futurejkj1176100% (1)

- Circular Section Crack Width Under Pure TensionDocument1 pageCircular Section Crack Width Under Pure TensionAbinash ModakNo ratings yet

- Bridge Abutment DesignDocument15 pagesBridge Abutment DesignPRAVEEN NAUTIYALNo ratings yet

- Chapter 10 Design of Prestressed 761661594169023Document15 pagesChapter 10 Design of Prestressed 761661594169023Puzzle ArtsNo ratings yet

- Bridge Slab DesignDocument9 pagesBridge Slab DesignCapacitacion TecnicaNo ratings yet

- Irc 112 2020 in Midas Civil For Bridge DesignDocument20 pagesIrc 112 2020 in Midas Civil For Bridge Designpinakin nikashNo ratings yet

- Solid Slab Bridges: Advantages, Disadvantages and PrinciplesDocument10 pagesSolid Slab Bridges: Advantages, Disadvantages and PrinciplesAmbrishNo ratings yet

- Cable Supported Bridges: Concept and DesignFrom EverandCable Supported Bridges: Concept and DesignRating: 5 out of 5 stars5/5 (1)

- AASHTO - Prestressed Beams AASHTO ExamplesDocument29 pagesAASHTO - Prestressed Beams AASHTO ExamplesAli ÖztürkNo ratings yet

- Composite Bridge Steel Girder Design in BSDocument131 pagesComposite Bridge Steel Girder Design in BSSANDIPNo ratings yet

- Design of PSC Box Girder BridgeDocument19 pagesDesign of PSC Box Girder BridgeStructural Spreadsheets100% (1)

- Confinement DesignDocument405 pagesConfinement DesignJAcc COncepcionNo ratings yet

- Lisa-Operation Manual: Installation and Operation Instructions (Part B)Document41 pagesLisa-Operation Manual: Installation and Operation Instructions (Part B)majdNo ratings yet

- Plate Girder Design ExampleDocument14 pagesPlate Girder Design ExampleWaleed KhalidNo ratings yet

- Padds Users GuideDocument481 pagesPadds Users GuideAndrew M. Ng'ang'a100% (1)

- Pharmacology SamplexDocument12 pagesPharmacology SamplexLiezel Dejumo BartolataNo ratings yet

- Slender Piers Design FIP 96Document17 pagesSlender Piers Design FIP 96Marco BourdonNo ratings yet

- T Girder Bridge Deck Diaphragm-20 MDocument14 pagesT Girder Bridge Deck Diaphragm-20 MAmitabha DebNo ratings yet

- References Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)Document10 pagesReferences Calculations Bridge Abutment Curtain Wall Analysis and Design (Bs 5400)WycliffeNo ratings yet

- Crackwidth Calculation Spreadsheet (Restricted Version)Document11 pagesCrackwidth Calculation Spreadsheet (Restricted Version)Nicholas ThompsonNo ratings yet

- Super T StandardsDocument16 pagesSuper T Standardschithirai10No ratings yet

- Foundation PDFDocument23 pagesFoundation PDFNisarga KeshavmurthyNo ratings yet

- Composite Beam DesignDocument33 pagesComposite Beam DesignihpeterNo ratings yet

- ACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Document5 pagesACI 318M-11 RC Beam Ledge Design - v0.04 - 2020-07-23Vietanh PhungNo ratings yet

- Bridge PierDocument9 pagesBridge PierJeevan BishtNo ratings yet

- Integral BridgesDocument12 pagesIntegral Bridgessoniafaisal100% (1)

- ISolutions Lifecycle Cost ToolDocument8 pagesISolutions Lifecycle Cost ToolpchakkrapaniNo ratings yet

- Appendix 02 Elastomeric Bearing Calculation ReportDocument8 pagesAppendix 02 Elastomeric Bearing Calculation ReportYasela100% (1)

- Neutral Axis of A Beam & Moment of Inertia IcgDocument8 pagesNeutral Axis of A Beam & Moment of Inertia Icgassaad006No ratings yet

- Prestree Bridge Design 20200316 PDFDocument47 pagesPrestree Bridge Design 20200316 PDFsantosh yevvariNo ratings yet

- Design of Elastomeric Bearing Based On IRC 083-2-1987Document4 pagesDesign of Elastomeric Bearing Based On IRC 083-2-1987Babita SharmaNo ratings yet

- Crack Width CheckDocument2 pagesCrack Width CheckJitendra SinghNo ratings yet

- Box Girder - Bridge - Sci PDFDocument58 pagesBox Girder - Bridge - Sci PDFTarun Kant GoyalNo ratings yet

- Extended-Design and Analysis of A Network Arch BridgeDocument10 pagesExtended-Design and Analysis of A Network Arch BridgehansNo ratings yet

- 24-Design and Construction Techniques of Daning River BridgeDocument6 pages24-Design and Construction Techniques of Daning River Bridgeatac101No ratings yet

- Transverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFDocument15 pagesTransverse Post-Tensioning Design and Detailing of Precast Prestressed Concrete Adjacent-Box-Girder Bridges PDFSanti CheewabantherngNo ratings yet

- Composite Steel Beam - Hogging - ULS To AS5100.6 (Corrected 2016-08-02)Document18 pagesComposite Steel Beam - Hogging - ULS To AS5100.6 (Corrected 2016-08-02)Sharyn Polley100% (1)

- RCC BoxDocument85 pagesRCC Boxabhijeet sahuNo ratings yet

- How To Use A MicroscopeDocument12 pagesHow To Use A MicroscopeTommy LeungNo ratings yet

- Bridge Abutment DesignDocument14 pagesBridge Abutment Designmdemonpl0% (1)

- PSC Girder-25m R0Document148 pagesPSC Girder-25m R0infra120100% (1)

- Cable Geometry and PT Losses1Document4 pagesCable Geometry and PT Losses1Loziardo KuncayoNo ratings yet

- mIDAS Civil 2020 v11 UPDATES PDFDocument27 pagesmIDAS Civil 2020 v11 UPDATES PDFani4576No ratings yet

- The Design of Hazard Analysis Critical Control Point (HACCP) Plan For Biscuit PlantDocument7 pagesThe Design of Hazard Analysis Critical Control Point (HACCP) Plan For Biscuit Plantttk_maniNo ratings yet

- Inverted T Bent Cap Design ExampleDocument88 pagesInverted T Bent Cap Design ExampletedfdfeNo ratings yet

- BA42 Intergral BridgesDocument27 pagesBA42 Intergral BridgesBridgy mcbridgeNo ratings yet

- Hmmer Head Pier DesignDocument24 pagesHmmer Head Pier DesignabadittadesseNo ratings yet

- Study On The Behavior of Box Girder BridgeDocument96 pagesStudy On The Behavior of Box Girder BridgeIsaac Farfan OtondoNo ratings yet

- M - IMP - Prestressed Hollow Core Design To Bs8110Document295 pagesM - IMP - Prestressed Hollow Core Design To Bs8110Ramon GutierrezNo ratings yet

- Design of Pile Cap (Pramod)Document159 pagesDesign of Pile Cap (Pramod)Lavender HoneyNo ratings yet

- RM E Balanced Cantilever AASHTODocument95 pagesRM E Balanced Cantilever AASHTOTran Tien Dung100% (1)

- Technology and The Transformation of Performance - Chris Salter PDFDocument49 pagesTechnology and The Transformation of Performance - Chris Salter PDFFelipe Merker Castellani100% (1)

- 2001: A Space Odyssey - Film AnalysisDocument4 pages2001: A Space Odyssey - Film AnalysisSummerNo ratings yet

- Determination of Design Moments in Bridges Constructed by Balanced Cantilever MethodDocument10 pagesDetermination of Design Moments in Bridges Constructed by Balanced Cantilever MethodalbsteinporNo ratings yet

- IRS Seismic Code 2017 PDFDocument39 pagesIRS Seismic Code 2017 PDFvigneshrajamanickamNo ratings yet

- Fatigue Provision in IRS Girder Vs InternationalDocument27 pagesFatigue Provision in IRS Girder Vs Internationalpant_tcNo ratings yet

- Prestress Continuous Box Girder DesignDocument26 pagesPrestress Continuous Box Girder Designdulanbackup1No ratings yet

- Skew Bridges Calculation MethodsDocument9 pagesSkew Bridges Calculation MethodsIsidro P. BuquironNo ratings yet

- Analysis of Displacement of A Concrete Barrier OnDocument9 pagesAnalysis of Displacement of A Concrete Barrier OnDyah Nimas Ayu SekartiNo ratings yet

- Equivalent Udl For IRC Live LoadsDocument14 pagesEquivalent Udl For IRC Live LoadsHanamantrao Khasnis100% (1)

- Seismic Design of Bridges Example 8Document36 pagesSeismic Design of Bridges Example 8Mike2322No ratings yet

- Bursting Reinforcement Calculation - 19T15Document1 pageBursting Reinforcement Calculation - 19T15Saibal SahaNo ratings yet

- Bridge TempDocument36 pagesBridge TempmitnathNo ratings yet

- IRC 22-2015 Ammendment (Jul-17)Document4 pagesIRC 22-2015 Ammendment (Jul-17)avisek_basu100% (1)

- Box Girder BridgesDocument20 pagesBox Girder Bridgesfaraday99No ratings yet

- Pre-Stressed Concrete PDFDocument75 pagesPre-Stressed Concrete PDFUmer WaheedNo ratings yet

- ACI 350-06 & ACI224R-01 Rec Sec Flexural Crack Width Control Rev00 07-Sep-2013Document7 pagesACI 350-06 & ACI224R-01 Rec Sec Flexural Crack Width Control Rev00 07-Sep-2013Muhammad Imran ZafarNo ratings yet

- Shear StudsDocument3 pagesShear StudsrahuljoagNo ratings yet

- 7.TDI FCR Data 7.0 23 PPF NL80 BTC Rev.7Document1 page7.TDI FCR Data 7.0 23 PPF NL80 BTC Rev.7javier monteroNo ratings yet

- 17.TDI FCR Data 9.625 47 PPF L80 BTC Rev.7Document1 page17.TDI FCR Data 9.625 47 PPF L80 BTC Rev.7javier monteroNo ratings yet

- Member'S Data Form (MDF) : Membership CategoryDocument4 pagesMember'S Data Form (MDF) : Membership CategoryuiopNo ratings yet

- Career Framework BookletDocument15 pagesCareer Framework Bookletwilliam robinsonNo ratings yet

- Bearing Capacity of Unstiffened WebsDocument15 pagesBearing Capacity of Unstiffened Webswilliam robinsonNo ratings yet

- Bridge 1 - Abut Design - 11x5 Rows Pile - With Future Ramp - v7Document64 pagesBridge 1 - Abut Design - 11x5 Rows Pile - With Future Ramp - v7william robinsonNo ratings yet

- SPM Manual CalcsDocument4 pagesSPM Manual Calcswilliam robinsonNo ratings yet

- Pds Microstran LTR en LRDocument2 pagesPds Microstran LTR en LRanhhungvoleNo ratings yet

- Closedproperties PDFDocument1 pageClosedproperties PDFwilliam robinsonNo ratings yet

- B04 Plan Fire MainDocument1 pageB04 Plan Fire Mainwilliam robinsonNo ratings yet

- Masonry Design Fo Disproportionate CollapseDocument12 pagesMasonry Design Fo Disproportionate Collapseterror_ro533No ratings yet

- CDocument1 pageCwilliam robinsonNo ratings yet

- CDocument1 pageCwilliam robinsonNo ratings yet

- CDocument1 pageCwilliam robinsonNo ratings yet

- Design of Segmental Bridges For Thermal GradientDocument18 pagesDesign of Segmental Bridges For Thermal GradientRAIMUNDO SUHERDINNo ratings yet

- Monitoring WellDocument1 pageMonitoring Wellwilliam robinsonNo ratings yet

- App Form UMID 2013Document2 pagesApp Form UMID 2013Адриан Убежище МоленьоNo ratings yet

- Design of Concrete TanksDocument198 pagesDesign of Concrete Tankssuman33100% (1)

- Integral Bridges (A Fundamental Approach To The Time Temperature Loading Problems) - Goerge L EnglandDocument145 pagesIntegral Bridges (A Fundamental Approach To The Time Temperature Loading Problems) - Goerge L England20108750% (2)

- Embedment Length PDFDocument1 pageEmbedment Length PDFwilliam robinsonNo ratings yet

- Ret Walls-MCN PDFDocument15 pagesRet Walls-MCN PDFDivyadristiNo ratings yet

- Embedment LengthDocument1 pageEmbedment Lengthwilliam robinsonNo ratings yet

- Plastic Versus Elastic Design of Steel StructuresDocument10 pagesPlastic Versus Elastic Design of Steel StructureskalpanaadhiNo ratings yet

- Glossary of Post-Tensioning Terms, April 2007Document20 pagesGlossary of Post-Tensioning Terms, April 2007william robinsonNo ratings yet

- Reinforced Concrete Design FILEDocument42 pagesReinforced Concrete Design FILEJude Maala Onanad100% (1)

- Keywords and Quality ContentDocument4 pagesKeywords and Quality Contentwilliam robinsonNo ratings yet

- Datasheet Continental ccp800 PDFDocument2 pagesDatasheet Continental ccp800 PDFKarni Aerospace Inc.No ratings yet

- Galleria MellonellaDocument6 pagesGalleria MellonellaJustin GarciaNo ratings yet

- Dumpy LevelDocument8 pagesDumpy LevelKhiel YumulNo ratings yet

- MonkayoDocument12 pagesMonkayoJabezNo ratings yet

- Mua prc007 en - 12042009Document73 pagesMua prc007 en - 12042009sachinsaklani23No ratings yet

- Zener Diodes and Transient Voltage Suppressors Quarter 3, 1998 SG274 - D Rev 16Document8 pagesZener Diodes and Transient Voltage Suppressors Quarter 3, 1998 SG274 - D Rev 16Imraan RamdjanNo ratings yet

- Lab4 F15 Si DiodeDocument15 pagesLab4 F15 Si DiodeJohn MarkNo ratings yet

- CU50 Service ManualDocument30 pagesCU50 Service ManualjhalmarckNo ratings yet

- Hydraulic and Irrigation EnggDocument9 pagesHydraulic and Irrigation EnggUmar Farooq 175-17 CNo ratings yet

- Obturator / Orthodontic Courses by Indian Dental AcademyDocument97 pagesObturator / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- Vray MaterialsDocument206 pagesVray MaterialsDodeptrai BkNo ratings yet

- Tutoria Radio MobileDocument11 pagesTutoria Radio MobileGanti Nama Aja LahNo ratings yet

- 2006 Conference On IEEE 1588 - TutorialDocument57 pages2006 Conference On IEEE 1588 - TutorialliolioskNo ratings yet

- Zeroing Neural Networks, An Introduction To, A Survey Of, and Predictive Computations For Time-Varying Matrix ProblemsDocument24 pagesZeroing Neural Networks, An Introduction To, A Survey Of, and Predictive Computations For Time-Varying Matrix ProblemsgoatcockNo ratings yet

- CalaDocument13 pagesCalaMorris KwangwareNo ratings yet

- Lab 6 - Wide Flange BeamDocument4 pagesLab 6 - Wide Flange BeamJanithNo ratings yet

- 3152NDocument20 pages3152NRogelioNo ratings yet

- Laporan Hasil Praktik Bahasa Inggris Dengan Tamu Asing Di Pantai KutaDocument12 pagesLaporan Hasil Praktik Bahasa Inggris Dengan Tamu Asing Di Pantai KutaEnal MegantaraNo ratings yet

- OLIVE VIEW HOSPITAL-San Fernando Earthquake 1971 PDFDocument5 pagesOLIVE VIEW HOSPITAL-San Fernando Earthquake 1971 PDFZakir UllahNo ratings yet

- Spare Parts: LKH Centrifugal PumpDocument20 pagesSpare Parts: LKH Centrifugal PumpService CTANo ratings yet

- Hot Vibrating Gases Under The Electron Spotlight: Gas MoleculesDocument2 pagesHot Vibrating Gases Under The Electron Spotlight: Gas MoleculesRonaldo PaxDeorumNo ratings yet