Professional Documents

Culture Documents

Refractory/metal interactions and slag formation during high-temperature casting

Uploaded by

josem94Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Refractory/metal interactions and slag formation during high-temperature casting

Uploaded by

josem94Copyright:

Available Formats

KAPILASHRAMI, E., SAHAJWALLA, V., and SEETHARAMAN, S.

Slag formation during high-temperature interactions between SiO2-containing

refractories and iron melts with oxygen. VII International Conference on Molten Slags Fluxes and Salts, The South African Institute of Mining and

Metallurgy, 2004.

Slag formation during high-temperature interactions between

SiO2-containing refractories and iron melts with oxygen

E. KAPILASHRAMI*, V. SAHAJWALLA, and S. SEETHARAMAN*

*Royal Institute of Technology, Stockholm, Sweden

School of Materials Science and Engineering, The University of New South Wales, Australia

Refractory/metal interactions and associated reactions are significant during casting as they can

lead to inclusion formation. High-temperature interactions between aluminosilicate refractories

and molten steel were studied in the present investigation using the sessile drop method. The

changes in the contact angles between molten iron with well-defined oxygen levels and substrates

of silica, mullite (3Al2O32SiO2) as well as commercial refractories were measured in the dynamic

mode. In all cases, the reaction led to slag formation.

The experiments were performed under isothermal conditions at 1823 and 1873 K. A known

and constant oxygen partial pressure was imposed above the iron drop, through appropriate CO-

CO2-Ar mixtures. For all substrates, the contact angles started decreasing due to the lowering of

the surface tension of iron, as oxygen was imposed on to the system. When a critical level of

oxygen was reached, slag started forming at the drop/substrate interface and at this stage, the

contact angle dropped suddenly. Subsequent behaviour of silica and mullite was observed to be

different, with SiO2 showing a non-wetting behaviour. In the case of SiO2 substrate, there were

also deep erosions along the periphery of the drops and there was slag accumulation at the sides of

the metal drop, probably due to Marangoni flow and/or SiO(g) formation. SEM and EDS analysis

of the substrates revealed that the formed slag was fayalite.

The thermodynamic criteria for slag formation and possible mechanisms of the reaction are

discussed in the light of the experiments.

Key words: silica, mullite, fayalite, corundum, slag formation, sessile drop.

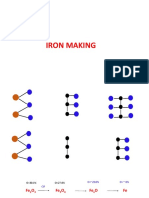

Introduction it is crucial to have an understanding of the

The present work was initiated aiming at an understanding thermodynamics of the reactions occurring between the

of the reactions between silica containing refractories and refractory oxides and iron containing oxygen as well as

liquid iron containing well-defined amounts of oxygen. The with pure iron. As part of the present work, a

work is of relevance to clean steel production, as the thermodynamic study was carried out where the stabilities

refractory erosion products can be sources of non-metallic of the various phases in the system Fe-O-Si were calculated

inclusions in the steel. Erosion of refractories by steel with using thermodynamic data in literature. From this input

slightly higher amounts of oxygen, during the tapping of data, a phase stability diagram, presented in Figure 1, was

LD-furnace and erosion of the refractory runners during constructed. The calculations showed that the two silicates

ingot casting, are the process steps where the present study likely to be formed in this system are orthosilicate and

is of relevance. As the refractories commonly in use are metasilicate. However, at steelmaking temperatures, only

aluminosilicates, the present studies of the reactions the orthosilicate or fayalite in liquid form will be the stable

between oxygen-containing molten iron and SiO2 as well as phase. On the other hand, as the system is cooled down, the

mullite were initiated. metasilicate can precipitate. The constructed phase stability

The reactions between the above-mentioned refractories diagram shows that Fe2SiO4 would be formed if the oxygen

and oxygen-containing iron are characterized by the content in the molten iron exceeded 0.1 wt%. This is likely

formation of molten slag at the interface. The slag to happen during certain steelmaking steps where the

formation seriously affects the mechanisms of the oxygen potential in the slag is high.

refractory reactions and thereby has serious implications on In the case of aluminosilicates, the reactions are a bit

the performance and the life of the refractories. Thus, the more complex. An examination of the phase diagram1 of

present paper aims at an understanding of the implications the system Al 2O 3-SiO 2 reveals the formation of a very

of slag formation for refractory life from a fundamental stable compound, mullite, with the formula 3Al2O32SiO2 as

view point. The studies were carried out in micro scale by well as 2Al2O3SiO2. The reaction and its Gibbs energy of

sessile drop technique, whereby, the reaction was followed formation2 for this compound are as follows:

by visual observation of the drop images dynamically.

Thermodynamic background 3 Al2O3 + 2 SiO2 = 3 Al2O3 2 SiO2 [1]

To understand the nature of the reactions of slag formation, G1o = 18.779 26.953 T J mole 1

SLAG FORMATION DURING HIGH-TEMPERATURE INTERACTIONS 417

At temperatures above the melting point of iron, the silica

part of mullite will react with the metal and form fayalite.

As mentioned previously, the ironmetasilicate being stable

at lower temperatures would not be present in the system.

The Gibbs energy of formation of solid hercynite, FeAl2O4,

is given by the equation2:

1 [3]

Fe + Al2O3 + 2 O2 = FeAl2O4

G3o = 328.349 + 82.044 T J mole 1

The phase stability diagram of the Fe-Al-O system at the

steelmaking temperature has been presented earlier by the

authors. 3. When solid hercynite and liquid fayelite are

formed, there is likely to be a reaction between these two

and they will form a ternary slag that will have a

composition that changes with temperature, according to

Figure 1. The phase stability diagram for the system Fe-O-si the phase diagram FeO-Al2O3-SiO24 presented in Figure 2.

The formation and composition of this slag will not just be

dependent on the thermodynamics of the reactions but also

on the kinetics of the reaction.

As seen, the Gibbs energy of formation is very low and it

is therefore reasonable to assume that this could be a

predominant phase in the runner refractory. The reaction Dynamic investigationexperimental work

between molten iron containing oxygen and mullite could In the present work, the reaction between silica containing

result in the formation of fayalite slag and hercynite substrate and iron drop containing oxygen were

(FeAl2O4) particles. The reaction and the Gibbs energy of investigated on a micro level by means of the Sessile drop

formation2 for fayalite are: technique. The contact angle between the substrates and

2 Fe + O2 + SiO2 = Fe2 SiO4 iron containing varying amounts of oxygen were

[2]

G2o = 518.959 + 116.82 T J mole 1 (T range 1000 1400 K ) investigated in static as well as in dynamic mode. The

Figure 2. Phase diagram of the system FeO-Al2O3-SiO2

418 MOLTEN SLAGS FLUXES AND SALTS

experiments were carried out in purified argon as well as complemented by the image analysis part developed at the

with varying oxygen partial pressures imposed on the Division of Metallurgy, Department of Material Science

system by means of suitable mixtures of CO, CO2 and Ar and Engineering, Royal Institute of Technology, Sweden.

into the system. Details regarding the furnace, the gas

cleaning system as well as the image recording device have

been presented elsewhere56. The change in contact angle

Results and discussions

was followed as a function of time at different The experiments were carried out in purified argon gas as

temperatures. well as with different partial pressures of oxygen, the

The samples were heated up in purified argon gas and the highest partial pressure corresponding to 0.19 wt% O at

appropriate Ar-CO-CO2 gas mixture was then introduced 1823 K and 0.29 wt% O as oxygen dissolved in molten iron

into the system after the attainment of the experimental at 1833 K, i.e. more than required to form fayelite slag

temperature. The X-ray images of the drop along with the according to the thermodynamic analysis.

substrate were taken in the video mode, following the

changes in contact angle with time. The experimental Results with silica substrate

details, the temperatures, gas ratios and their corresponding Images of the drops from the experimental series with the

values of dissolved oxygen in molten iron, are presented in highest oxygen partial pressure and at 1833 K are presented

Table I. At the end of the measurements, the Ar-CO-CO2 in Figure 3. It is seen that the drop flattens as the

gas mixture was replaced by purified argon gas and the atmosphere is changed to the gas mixture with higher

sample was then quenched. The substrate was taken out and oxygen partial pressure confirming, thereby, that the

the cross section was examined by Scanning Electron contact angle decreases due to the introduction of oxygen,

Microscope (SEM) and also through Energy Dispersive which is surface active. An interesting observation in the

Spectroscopy (EDS). Some selected experiments were then present series is that the contact angle exhibits a tendency

repeated in order to confirm the reproducibility of the to increase after reaching a minimum point.

results. A reasonable explanation for the initial decrease in the

The contact angle between the substrates and iron drop contact angle would be due to the increase in the surface

was evaluated by the video film frames obtained using a oxygen concentration by oxygen pick up from the gas

software, developed at the Department of Material Science phase. The oxygen from the surface has to diffuse into the

and Engineering, Carnegie Mellon University, USA, bulk which, perhaps, would account for the plateau region.

Further decrease in the contact angle is indicative of the

attainment of the equilibrium oxygen concentration at the

Table I

metal-substrate interface and the progress of the reaction.

Experimental sequences and their conditions At this point, the drop would also have reached the

equilibrium oxygen content with respect to the gas phase

Experimental CO/CO2 Targeted Corresponding Temperature

and enough oxygen will be present in the system for

series ratio PO2 Pa ppm O (K) fayalite slag to form. There is a likelihood of a thin fayalite

layer formation between the substrate and the drop, which

A - < 10-14 - 1823.1873 would arrest the reaction. At this stage, the contact angle

B 0.28/0.42 1.510-2 2900 1873 measured would, most probably, be between the iron drop

B 0.28/0.42 1.510-2 1960 1823

with oxygen potential equal to that of the gas phase and the

C 0.42/0.28 3.010-3 871 1823

D 0.56/0.14 9.910-4 327 1823

thin slag film on the silica substrate. This, evidently, is the

fayalite slag formed by the following reaction:

1 second 10 seconds 20 seconds

36 seconds 38 seconds 52 seconds

Figure 3. X-ray images of the sessile-drop at 1833 K at different time interval as an oxygen partial pressure of

1.510-2 Pa was imposed at zero time

SLAG FORMATION DURING HIGH-TEMPERATURE INTERACTIONS 419

2 Fe( l ) + 2 O( Fe, l ) + SiO2 ( s ) = Fe2 SiO4 ( l ) [4] of SiO gas. These reactions would be dampened as the slag

layer was formed around the bottom of the metal drop.

Beyond this point, the iron drop showed a tendency to Another plausible explanation is that the erosion is caused

move from its original position. This behaviour is likely to by Marangoni flow in the melt induced by differential

be due to the imbalance in the forces acting on the drop. A surface tension due to concentration gradients.

similar phenomenon was observed by the present authors in

the case of the dynamic contact angle measurements Results with Mullite Substrate

between liquid iron and alumina substrate3. The results observed in the case of mullite, viz. the

The SEM micrograph of the reacted drop with the immediate decrease in contact angle with the introduction

substrate after the experiment at 1833 K is presented in of the gas mixture with high oxygen potentials, the

Figure 4. The insert in the Figure shows the location of the somewhat steady state when oxygen diffuses from the

field of vision vis--vis the iron drop. The low contact angle surface of the drop to the bulk and then the final slow drop

between the drop and the substrate is quite evident in this in the contact angle were similar to those of silica substrate.

Figure. It is also seen that a thick product layer is formed by However, the slag formed during the reaction between

the side of the drop as mentioned earlier. The atomic ratio mullite and molten iron would be different from the silica

of iron to silicon in this layer, obtained by Electron system. The thermodynamic analysis shows that when

Dispersion Spectroscopy (EDS) was close to 2, confirming mullite and iron containing some amounts of oxygen starts

that this phase was indeed the fayalite slag. The figure, on reacting, fayalite and hercynite will be formed. According

higher magnification, showed clearly the formation of to the ternary phase diagram presented in Figure 2, the

dendrites in the slag. These were found to be pure SiO2 by mullite, fayalite and hercynite will start to dissolve into

EDS analysis. The SEM micrographs of the drops at other each other and form a slag. The composition path of the

oxygen partial pressures and temperatures were found to be slag will go towards mullite and an intermediate phase, iron

quite similar, the amount of slag decreasing with decreasing cordierite could be formed. At the experimental

oxygen partial pressure. temperature, the ternary slag would consist of FeO-Al2O3-

In some of the experiments, there was a preferential SiO2, the final composition being marked as x in Figure 2.

corrosion observed along the periphery of the drop. This If the reactions are allowed to continue, this slag will be in

may be caused by the formation and evaporation of SiO, equilibrium with mullite and corundum. This is in

either due to direct decomposition of SiO2 substrate at the agreement with the results of the SEM-EDS analyses.

low oxygen potentials prevailing in the gas phase or the However, due to the kinetics of the reactions, there could

reaction between silicon dissolved in the liquid metal and still be particles of iron cordierite and hercynite as the

SiO2 substrate, both the reactions leading to the formation reactions may not reach equilibrium. The composition of

the slag would also change during cooling and low

temperature phases could precipitate and this makes the

EDS analysis of the slag very complicated and difficult.

The SEM micrograph of the reacted drop with the

substrate after the experiment at 1823 K and the highest

partial pressure of oxygen is presented in Figure 5. Once

again, the insert in the figure shows the location of the field

of vision vis--vis the iron drop. It is seen that the drop has

reacted with the substrate and has also sunk into it. It is also

seen that a molten phase has been formed and that there are

free particles in this phase. The slag phase, in the figure

entrapped by the molten iron, was magnified and examined

Iron drop

Figure 4. Photomicrograph of a section of the reacted drop and Figure 5. Photomicrograph of a section of the reacted drop and

the silica substrate after the sessile-drop experiments at 1833 and the mullite substrata after the sessile-drop experiments at 1823

oxygen partial pressure, PO2 = 1.510-2 Pa and oxygen partial pressure, PO2 = 1.510-2 Pa

420 MOLTEN SLAGS FLUXES AND SALTS

SE, 255 Tetra, 255 Oka, 255

AlKa, 18 SiKa, 6 FeKa, 19

Figure 6. EDS mapping of the slag formed during reaction between mullite substrate and molten iron containing oxygen

through EDS mapping and the result is presented in Summary

Figure 6. It is seen that the slag mainly consist of alumina, The present work was focused on studying the slag

silica and iron oxide. The particles are found to be alumina

formation phenomenon during the reactions between

particles and at the periphery of these particles there is a

oxygen-containing molten iron and aluminosilicate lining

layer containing aluminium, oxygen and iron. This layer

was found to be hercynite. The EDS mapping also shows materials by means of X-ray sessile drop method. In the

that the composition of the slag varies. case of silica or mullite refractories, the reactions resulted

The present experimental work also showed that other in the formation of a slag. With silica substrate, the slag

factors, besides the composition of the substrate, will have was found to be fayalite (2FeOSiO2). In the case of mullite,

an impact on the reaction mechanism. Factors like the slag phase formed contained alumina. The slag

inhomogeneity, surface roughness and amounts of pores formation led to non-wetting conditions and the movement

will also be of importance. The analysis of the porous of the iron drop. Preferential corrosion of the silica

mullite substrate, revealed that, along with the surface refractory due to possible SiO evaporation or Marangoni

reaction with the substrate, reactions were taking place convection was also observed in the present study. The

downwards into the substrate, which could escalate the slag factors that influence the corrosion of lining materials, apart

formation and corrosion of refractories. from the chemical reactions, were oxygen content in the

The present work is of great importance for the steel metal, porosity and surface roughness of the refractories.

industry, especially for the steel plants targeting the The present studies are expected to lead to the development

production of clean steel. The results show that the of new generation refractories, which are resistant to

composition of the refractory plays a great role in corrosion chemical attack by molten steel, thereby leading to lesser

of the furnace linings resulting in slag formation which, in contamination of the steel produced by non-metallic

turn, can result in the formation of non-metallic inclusion in inclusions.

the steel matrix. The present work shows that silica, even

though chemically bonded strongly in mullite, reacts with

molten iron that contains some amounts of oxygen and Acknowledgements

form a slag. The formation of a thin, dense, non-wetting Part of the work was carried out at in the University of New

hercynite layer between molten iron containing oxygen and South Wales, Australia. Financial supports for travel to

alumina substrates shows a protective influence of the Australia from Brinell Centre, KTH and Axel Hultgrens

presence of higher alumina contents in the lining material, Trust are gratefully acknowledged.

leading to less reaction with steel and thereby resulting in

fewer non-metallic inclusions. A distinct possibility to

increase the life of the furnace linings is to coat them with a

References

non-wetting layer, for example, hercynite. This layer would 1. BOWEN, N.L. and GREIG, J.W. J. Am. Soc., 1924, 7,

act as a barrier between the refractory and the metal and it p. 242.

would prevent further reactions with the refractory. Of

course, the economic gain in clean steel with these changes 2. BARIN, I. Thermodynamical Data of Pure

should be compared to the higher cost of refractory Substances, Part I and II, VCH, 1993.

production. 3. KAPILASHRAMI, E., JAKOBSON, A., LAHIRI,

SLAG FORMATION DURING HIGH-TEMPERATURE INTERACTIONS 421

A.K., and SEETHARAMAN S. Studies of the A.W., and SEETHARAMAN, S. Investigation of the

Wetting Characteristics of Liquid Iron on Dense reactions between oxygen-containing iron and SiO2

Alumina by X-Ray Sessile Drop Technique. Metall. substrate by X-ray sessile drop technique. Accepted

Mater. Trans. B, vol. 34B, 2003. pp. 193199. for publication in Metall. Mater. Trans. B 2003

4. LEVIN, E.M., ROBBINS, C.R., and MCMURDIE, 6. KAPILASHRAMI, E., SAHAJWALLA, V., and

H.F. Phase Diagrams for Ceramists, Reser, M.K (ed.). SEETHARAMAN, S. Investigation of the wetting

Ohio, The American Ceramic Society, 1964, p. 696. characteristics of liquid iron on mullite by sessile drop

5. KAPILASHRAMI, E., LAHIRI, A.K., CRAMB, technique, to be published.

422 MOLTEN SLAGS FLUXES AND SALTS

You might also like

- Decomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingsDocument9 pagesDecomposition and Reaction of Thermal-Formed Alumina in Aluminum Alloy CastingskarthikkandaNo ratings yet

- 10.1016@S0921 50939800573 5Document9 pages10.1016@S0921 50939800573 5Kannan RamarajNo ratings yet

- Laboratory Procedures For Mining Pelletizing Characterization of Iron Ore ConcentrationDocument9 pagesLaboratory Procedures For Mining Pelletizing Characterization of Iron Ore ConcentrationgeodasNo ratings yet

- Ajst 5 1 25 31Document7 pagesAjst 5 1 25 31Satadal GhoraiNo ratings yet

- Microstructural of Second Phases in Ascast and Homogenized Aluminum AlloyDocument7 pagesMicrostructural of Second Phases in Ascast and Homogenized Aluminum AlloyHamed NobariNo ratings yet

- 2014-Li - Oxidation of Fe-Si Alloys in CO2-H2O AtmospheresDocument6 pages2014-Li - Oxidation of Fe-Si Alloys in CO2-H2O AtmospheresDavid Hernández EscobarNo ratings yet

- 799 YazawaDocument10 pages799 YazawaGiorgio CroseNo ratings yet

- Slag Metal Reactions in Binary CaF2-Metal Ozide Welding FluxesDocument4 pagesSlag Metal Reactions in Binary CaF2-Metal Ozide Welding FluxesBurag HamparyanNo ratings yet

- Lecture 7 Inclusions and Pinhole Formation in DIDocument33 pagesLecture 7 Inclusions and Pinhole Formation in DILuis Arturo RamirezNo ratings yet

- 59 - Isijint 2018 613Document8 pages59 - Isijint 2018 613Satadal GhoraiNo ratings yet

- Role of Magnetism in The Formation of A ShortRange OrderDocument12 pagesRole of Magnetism in The Formation of A ShortRange OrderJoão Vitor FardinNo ratings yet

- Effect of Quenching Temperature On Local Ordering in Al85Ni5Co2Y8 Metallic Glass.Document7 pagesEffect of Quenching Temperature On Local Ordering in Al85Ni5Co2Y8 Metallic Glass.Kibria ShabbirNo ratings yet

- Aiche-33-01Catalyst Poisoning6Document17 pagesAiche-33-01Catalyst Poisoning6Hsein WangNo ratings yet

- Particle Size Effects On The Thermal Behavior of Hematite.Document7 pagesParticle Size Effects On The Thermal Behavior of Hematite.田旭No ratings yet

- P2219Document2 pagesP2219KundanNo ratings yet

- 2002-Yanagihara - Microscopic Features in The Transition From External To Internal OxidationDocument16 pages2002-Yanagihara - Microscopic Features in The Transition From External To Internal OxidationDavid Hernández EscobarNo ratings yet

- Zircon DissosiationDocument2 pagesZircon DissosiationChris BothaNo ratings yet

- PhaseequilibriaofFeOx SiO2 Al2O3slagsystemat1200CandpO2of108.6atmDocument13 pagesPhaseequilibriaofFeOx SiO2 Al2O3slagsystemat1200CandpO2of108.6atmmarcelo_ivnNo ratings yet

- Role and Effects of Slag Components in ESR ProcessesDocument14 pagesRole and Effects of Slag Components in ESR ProcessesKestrel MgNo ratings yet

- Cast Iron Microstructures Explained by Oxide BifilmsDocument16 pagesCast Iron Microstructures Explained by Oxide BifilmsJustin DixonNo ratings yet

- Pigarev 2013 Structure and Properties of The SlaDocument6 pagesPigarev 2013 Structure and Properties of The SlaSonedi LeonNo ratings yet

- ASM Heat Treating Society (Aluminum and Its Alloys)Document6 pagesASM Heat Treating Society (Aluminum and Its Alloys)Finney JacobNo ratings yet

- Fluxes For Electroslag Refining: Dr. Satadal GhoraiDocument21 pagesFluxes For Electroslag Refining: Dr. Satadal GhoraiGarry's GamingNo ratings yet

- Evaluating Slag-Metal Deoxidation Equilibrium in Secondary SteelmakingDocument6 pagesEvaluating Slag-Metal Deoxidation Equilibrium in Secondary SteelmakingThayeni Ávila da PazNo ratings yet

- Paper Decarburization in Spring SteelDocument7 pagesPaper Decarburization in Spring SteelMauricio RodriguezNo ratings yet

- Fundamentals of Solidification in Aluminum Castings: Geoffrey K. SigworthDocument14 pagesFundamentals of Solidification in Aluminum Castings: Geoffrey K. SigworthMohmal AhmedNo ratings yet

- InTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsDocument19 pagesInTech-Chemical and Physical Properties of Fluxes For Saw of Low Carbon SteelsSiap SiapNo ratings yet

- Tortorelli1992 - Behavior of Iron Aluminides in OxidizingDocument5 pagesTortorelli1992 - Behavior of Iron Aluminides in OxidizinguristerinNo ratings yet

- Journal of Alloys and Compounds: N. Bayat, T. Carlberg, M. CieslarDocument6 pagesJournal of Alloys and Compounds: N. Bayat, T. Carlberg, M. CieslarMARIA CAMILA VIERA BALLESTEROSNo ratings yet

- Aluminium - Iron - SiliconDocument51 pagesAluminium - Iron - SiliconAnonymous HzbpFGY80No ratings yet

- Prescott1992 The Oxidation of Iron-Aluminum AlloysDocument15 pagesPrescott1992 The Oxidation of Iron-Aluminum AlloysuristerinNo ratings yet

- Microstructure and Mechanical Properties of Spray Deposited Hypoeutectic Al-Si AlloyDocument4 pagesMicrostructure and Mechanical Properties of Spray Deposited Hypoeutectic Al-Si AlloySantosh GoudarNo ratings yet

- How BaSO4 concentration affects interfacial reactions of high-alumina refractories with Al-alloysDocument11 pagesHow BaSO4 concentration affects interfacial reactions of high-alumina refractories with Al-alloysTania Zefanya Suranikarina WayNo ratings yet

- Al-Si-Cu-Mg Alloy PDFDocument18 pagesAl-Si-Cu-Mg Alloy PDFRocio LopezNo ratings yet

- Producing Magnesia from SeawaterDocument11 pagesProducing Magnesia from Seawaterwakasensei99No ratings yet

- Thermodynamic study of the effect of nickel additions in galvanizing zinc bathsDocument10 pagesThermodynamic study of the effect of nickel additions in galvanizing zinc bathsAkash PatelNo ratings yet

- Herrmann2003 - Def at High TemperaturesDocument10 pagesHerrmann2003 - Def at High TemperaturesuristerinNo ratings yet

- Precipitation Process in Fe-Ni-Al-based AlloysDocument24 pagesPrecipitation Process in Fe-Ni-Al-based AlloysdinambrosNo ratings yet

- Lower Temperature Formation of Alumina Thin Films Through Sol-Gel Route Al2o3 RiazDocument8 pagesLower Temperature Formation of Alumina Thin Films Through Sol-Gel Route Al2o3 RiazEero IiskolaNo ratings yet

- Effectsof Different Barium Compoundsonthe CorrosionDocument14 pagesEffectsof Different Barium Compoundsonthe CorrosionDavid KehindeNo ratings yet

- Pettit2011 Article HotCorrosionOfMetalsAndAlloysDocument21 pagesPettit2011 Article HotCorrosionOfMetalsAndAlloysmanishtubNo ratings yet

- Effect of Heat Treatment and Alloying Elements On Precipitation and Surface Behavior of Co-Cr-Mo ALLOYSDocument5 pagesEffect of Heat Treatment and Alloying Elements On Precipitation and Surface Behavior of Co-Cr-Mo ALLOYSAl AlNo ratings yet

- Iron Making PPT Notes 2Document49 pagesIron Making PPT Notes 2SHUBHAM VERMANo ratings yet

- Effect of Saltoxide Interaction On The Process of Aluminum RecyclingDocument5 pagesEffect of Saltoxide Interaction On The Process of Aluminum RecyclingPaula BrazueloNo ratings yet

- Heat Treatment of CastingDocument15 pagesHeat Treatment of CastingjmmshahNo ratings yet

- Materials Chemistry and PhysicsDocument11 pagesMaterials Chemistry and PhysicsAbraham Becerra AranedaNo ratings yet

- Effect of Caf On Interfacial Phenomena of High Alumina Refractories With Al AlloyDocument10 pagesEffect of Caf On Interfacial Phenomena of High Alumina Refractories With Al Alloyretnadiah354No ratings yet

- Marina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. KuvshinovDocument15 pagesMarina A. Ermakova, Dmitry Yu. Ermakov, Andrey L. Chuvilin, and Gennady G. Kuvshinovjocy1989No ratings yet

- Corrosion Science: Yuantian Li, Ping Zhang, Jinyong Zhang, Zheng Chen, Baolong ShenDocument11 pagesCorrosion Science: Yuantian Li, Ping Zhang, Jinyong Zhang, Zheng Chen, Baolong ShenPei Yu ChenNo ratings yet

- Thermal Evolution of Metakaolin Geopolymers Part 1 - Physical Evolution PDFDocument15 pagesThermal Evolution of Metakaolin Geopolymers Part 1 - Physical Evolution PDFLenia LuciaNo ratings yet

- Controlof Shapeof Faceted Crystals Solidifiedin Cast AlloysDocument16 pagesControlof Shapeof Faceted Crystals Solidifiedin Cast AlloysirmaNo ratings yet

- SlagDocument7 pagesSlagOUSSAMA BEN OMARNo ratings yet

- Stability of Minels in Ring Reaneral Thchemical Approach (Earth Surface Processes, Vol. 1, Issue 1) (1976)Document8 pagesStability of Minels in Ring Reaneral Thchemical Approach (Earth Surface Processes, Vol. 1, Issue 1) (1976)Anonymous FigYuONxuuNo ratings yet

- Zr02 Application in CatalysisDocument19 pagesZr02 Application in CatalysisSantiago FerraezNo ratings yet

- Ullmans EncylopaediaDocument14 pagesUllmans EncylopaediaKnowchemNo ratings yet

- s11663-019-01711-z (2)Document10 pagess11663-019-01711-z (2)amannigam19940914No ratings yet

- Effect of Microalloying With Silicon On High Temperature Oxidation Resistance of Novel Refractory High-Entropy Alloy Ta-Mo-Cr-Ti-AlDocument23 pagesEffect of Microalloying With Silicon On High Temperature Oxidation Resistance of Novel Refractory High-Entropy Alloy Ta-Mo-Cr-Ti-AlDattatreya PatiNo ratings yet

- Deep Earth: Physics and Chemistry of the Lower Mantle and CoreFrom EverandDeep Earth: Physics and Chemistry of the Lower Mantle and CoreHidenori TerasakiNo ratings yet

- Hydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseFrom EverandHydrogen in Steel: Effect of Hydrogen on Iron and Steel During Production, Fabrication, and UseNo ratings yet

- Cembinder 8 TDSDocument1 pageCembinder 8 TDSkbkshanakaNo ratings yet

- Alternation of Traditional Cement Mortars Using Fly Ash-Based Geopolymer Mortars Modified by SlagDocument35 pagesAlternation of Traditional Cement Mortars Using Fly Ash-Based Geopolymer Mortars Modified by SlagMJundiNo ratings yet

- Caña de Azucar-1-Conceptos Generales - Silicon in Sugarcane Availability in Soil, Fertilization, and UptakeDocument11 pagesCaña de Azucar-1-Conceptos Generales - Silicon in Sugarcane Availability in Soil, Fertilization, and Uptakeviviana erazoNo ratings yet

- Boron - : The BouncerDocument3 pagesBoron - : The BouncerACU PLUNGERNo ratings yet

- Non-cement binder using industrial byproductsDocument9 pagesNon-cement binder using industrial byproductsAINA SAMNo ratings yet

- 3 Binders For Refractory CastablesDocument10 pages3 Binders For Refractory CastablesAditya BhordeNo ratings yet

- EPITHERMAL GOLD DEPOSITS-AdUDocument193 pagesEPITHERMAL GOLD DEPOSITS-AdUMuhammad Nasuhi100% (24)

- Silicosis: SeminarDocument11 pagesSilicosis: SeminarFelipe Barbosa CordeiroNo ratings yet

- Phase Composition of Bauxite-Based Refractory CastablesDocument8 pagesPhase Composition of Bauxite-Based Refractory CastablesDick ManNo ratings yet

- BBC 16W Leg Rock DrillDocument132 pagesBBC 16W Leg Rock DrillMiguel Eleazar Marin ArosNo ratings yet

- Petrographic Examination of Hardened Concrete: Standard Practice ForDocument14 pagesPetrographic Examination of Hardened Concrete: Standard Practice ForHéctor Armando Valderrama BaqueroNo ratings yet

- NMA Fact Sheet 40 Minerals and UsesDocument6 pagesNMA Fact Sheet 40 Minerals and UsesKemal FatahNo ratings yet

- Pharmaceutical Containers ClosuresDocument13 pagesPharmaceutical Containers ClosuresFilipNo ratings yet

- Chapter # 03Document68 pagesChapter # 03mc170202750 Alishba WazahatNo ratings yet

- Recent Technology of Coke Oven Refractories: Technical ReportDocument8 pagesRecent Technology of Coke Oven Refractories: Technical ReportAmit Kumar DasNo ratings yet

- Formation of Soil: Byers, Charles E. Kellogg, M. S. Anderson, James ThoriDocument31 pagesFormation of Soil: Byers, Charles E. Kellogg, M. S. Anderson, James ThoriVishal BabuNo ratings yet

- Silica LiteratureDocument2 pagesSilica Literatureyousria.ahmed46No ratings yet

- Residual Stress and Laser-Induced Damage of Ion-Beam SputteredDocument4 pagesResidual Stress and Laser-Induced Damage of Ion-Beam Sputtered夕何No ratings yet

- CLS Aipmt 16 17 XI Che Study Package 3 SET 2 Chapter 11Document21 pagesCLS Aipmt 16 17 XI Che Study Package 3 SET 2 Chapter 11kalloli100% (1)

- Silica: For Water and Seawater Silicomolybdate/Heteropoly Blue MethodDocument1 pageSilica: For Water and Seawater Silicomolybdate/Heteropoly Blue Methodhakim1702No ratings yet

- Study of Combined Effect of Polypropylene Fibres and Raw Rice Husk To Enhance Insulation Property of Concrete at Elevated TemperatureDocument9 pagesStudy of Combined Effect of Polypropylene Fibres and Raw Rice Husk To Enhance Insulation Property of Concrete at Elevated TemperatureIJRASETPublicationsNo ratings yet

- Chapter - Furnaces and RefractoriesDocument36 pagesChapter - Furnaces and Refractorieshasan_waqar2004No ratings yet

- Non MetalsDocument34 pagesNon MetalsDigvijay Patil100% (2)

- Glaze ForwardDocument24 pagesGlaze Forwardaonegodman100% (2)

- Refractory: CMC APAC, Fall 2014, Michael Kapphahn EPT-TTDocument44 pagesRefractory: CMC APAC, Fall 2014, Michael Kapphahn EPT-TTSamnang HangNo ratings yet

- Disadvantages of Glass RecyclingDocument1 pageDisadvantages of Glass RecyclingJenny ValderramaNo ratings yet

- Fiveland AnnbjørgDocument131 pagesFiveland AnnbjørgAli AliievNo ratings yet

- Combination Tanning Based on Tara and Sodium MetasilicateDocument96 pagesCombination Tanning Based on Tara and Sodium MetasilicatesamiNo ratings yet

- Relation Between Density & Compressive Strength of Foamed ConcreteDocument22 pagesRelation Between Density & Compressive Strength of Foamed Concretekinley dorjeeNo ratings yet

- What Is Silica FumeDocument2 pagesWhat Is Silica FumeAmmarNo ratings yet