Professional Documents

Culture Documents

Elliott Centrifugal Compressor

Uploaded by

ionutlaur860 ratings0% found this document useful (0 votes)

258 views2 pagesElliott Centrifugal Compressor

Copyright

© © All Rights Reserved

Available Formats

XLSX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentElliott Centrifugal Compressor

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

258 views2 pagesElliott Centrifugal Compressor

Uploaded by

ionutlaur86Elliott Centrifugal Compressor

Copyright:

© All Rights Reserved

Available Formats

Download as XLSX, PDF, TXT or read online from Scribd

You are on page 1of 2

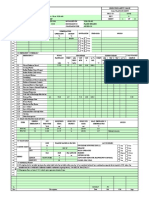

CENTRIFUGAL COMPRESSOR CALCULATION BY THE "N" METHOD

(EXTENSIVE USE OF THE POLYTROPIC EXPONENT, "N")

NOTE: -----> If the gas is pure, begin with STEP 2 Bulbuceni

bara

Inlet temperature F 68

Inlet pressure (psia) 217.5 15

Discharge pressure (psia) 638 44 Nm3/h kmoli/h

Inlet mixture flow rate (kmol/hour) 11247 Qinlet 252083 11247 = 6613 cfm

STEP 1 Gas Mixture properties

1 2 3 4 5 6 7 8 9 10 11

Gas Mol % Mols/Hr Mol wt. Mixture Weight% Tc Pc 1 x 6 1x7 Mcp 1 x 10

mixture each gas Mol% x 11246.68 (Table 1) Mol wt. [(4:44,24)]x100 (Table 1) (Table 1) (Table 1)

CO2 0.0022 25 44.01 0.10 0.22 548 1073 1.2 2.4 8.71 0.02

N2 (nitrogen) 0.0007 8 28.02 0.02 0.04 228 492 0.2 0.3 6.96 0.00

Methane 0.994 11179 16.04 15.94 36.04 344 673 341.9 669.0 8.38 8.33

Ethane 0.0014 16 30.07 0.04 0.10 550 708 0.8 1.0 12.13 0.02

Propane 0.00069 8 44.09 0.03 0.07 666 617 0.5 0.4 16.82 0.01

i-Butane 0.0002 2 58.12 0.01 0.03 735 529 0.1 0.1 22.1 0.00

n-Butane 0.0001 1 58.12 0.01 0.01 766 551 0.1 0.1 22.83 0.00

i-Pentane 0.0001 1 72.15 0.01 0.02 830 483 0.1 0.0 27.59 0.00

n-Pentane 0.0001 1 72.15 0.01 0.02 847 489 0.1 0.0 28.27 0.00

Hexane 0.0001 1 86.17 0.01 0.02 915 440 0.1 0.0 33.87 0.00

C7+ 0.0002 2 100.2 0.02 0.05 973 397 0.2 0.1 39.52 0.01

H2O 0 0 18.02 0.00 0.00 1166 3208 0.0 0.0 7.98 0.00

0.99979

TOTAL MIXTURE : 11244 16.19 345.2 673.5 8.406

k Mixture = 1.310

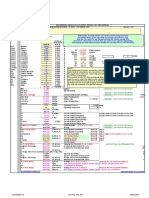

STEP 2 STEP 3

Calculate inlet flow (Q1): From Table 2 we can select the compressor frame which include: 110M

Weight flow (w) 3035 lb./min - The available number of stages 6

Pr1= 0.3230 - Average polytropic efficiency 0.77

Tr1= 1.53 - Rpm 2500

From Chart 1, Z1= 0.975 - Head per stage (ft.) 10000

v1= 1.57

Q1= 4757 icfm

STEP 4 Calculate average compressibility STEP 5 Calculate Polytropic Head (Hp):

Pressure ratio r = 3 (n-1)/n = 0.3075

k= 1.310 Hp = 62450 ft.

p= 0.77

From Chart 2 X= 0.3 ad= 0.77 STEP 6 Find number of satges required:

T2 (approx.) = 733.7 R Knowing kMixture, Inlet temperature we can read Hp:

Tr2= 2.125 From Chart 4 Hp= 10000 ft. (Max.Head per Stage)

Pr2= 0.947 Ratio required: 6 (per compressor)

From Chart 1, Z2= 0.97 No. of stages calculated: 2

Zavg.= 0.9725 r= 3.65 4 ratio/stage

STEP 7 Find speed required: STEP 8 Find shaft Horsepower required:

Speed = 2500 rpm Gas HP = 7460 HP

From Chart 5, LOSSES (HP) = 54 hp

Shaft HP = 7406 HP 5443 kW

STEP 9 Find actual discharge temperature: STEP 10 Calculate discharge flow (Q2):

t2 = 141 F 60 C Q2 = 1836 cfm

3122.19 Nm3/h

Refferences:

ELLIOTT COMPANY - MULTISTAGE CENTRIFUGAL COMPRESSORS - JEANNETTE, PENNSYLVANIA, USA

You might also like

- Cost Estimating Manual For Water Treatment FacilitiesDocument197 pagesCost Estimating Manual For Water Treatment FacilitiesSiddhu 2092100% (3)

- Aircooled Heat Exchanger Process Data SheetDocument2 pagesAircooled Heat Exchanger Process Data SheetamitkrayNo ratings yet

- Selection of Centrifugal Compressor For O&G Aplications - GPA - Paper - 2002Document11 pagesSelection of Centrifugal Compressor For O&G Aplications - GPA - Paper - 2002bvalinhasNo ratings yet

- Relief Valve Calculations - According With API 520Document4 pagesRelief Valve Calculations - According With API 520ionutlaur86100% (2)

- Onshore Terminal For KG DWN 98/2 Development Project: B.Sunil PrasadDocument7 pagesOnshore Terminal For KG DWN 98/2 Development Project: B.Sunil Prasadsumit kumar100% (1)

- PSV Calculation Sheet APIDocument10 pagesPSV Calculation Sheet APIionutlaur86100% (2)

- Compressor pressure calculation spreadsheetDocument4 pagesCompressor pressure calculation spreadsheetRahul SarafNo ratings yet

- Centrifugal Compresor CalculationDocument2 pagesCentrifugal Compresor CalculationgrabettyNo ratings yet

- Pipe Thickness Calculation For Straight Pipe Under Internal PressureDocument8 pagesPipe Thickness Calculation For Straight Pipe Under Internal Pressureionutlaur86No ratings yet

- Compressor Sizing CalDocument2 pagesCompressor Sizing CalSimranjeet SinghNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)Document17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet Si Units: Operating Conditions (Each Machine)tutuionutNo ratings yet

- Spreadsheet Heat Loss from a PipeDocument1 pageSpreadsheet Heat Loss from a PipeJogender DhayalNo ratings yet

- 9 - Horizontal Flare Knock Out Drum Sizing1Document2 pages9 - Horizontal Flare Knock Out Drum Sizing1Anonymous APc7I7100% (1)

- Tun PSV SizingDocument70 pagesTun PSV SizingTun Naing WinNo ratings yet

- Air Receiver Sizing CalculationDocument1 pageAir Receiver Sizing CalculationAziz HaqueNo ratings yet

- Emission CalculatorDocument60 pagesEmission Calculatorionutlaur86No ratings yet

- Gas Pipeline Blowdown Time CalculatorDocument7 pagesGas Pipeline Blowdown Time CalculatorKarun DasNo ratings yet

- Pressure Drop CalculationsDocument28 pagesPressure Drop Calculationshicham100% (2)

- Air CompressorsDocument13 pagesAir CompressorsCalin SeraphimNo ratings yet

- Selection of Gas CompressorsDocument5 pagesSelection of Gas CompressorsstreamtNo ratings yet

- Prediction of Centrifugal Compressor May 201234Document8 pagesPrediction of Centrifugal Compressor May 201234moxlindeNo ratings yet

- Section 10 - CompressorsDocument69 pagesSection 10 - CompressorsChakerZagroubaNo ratings yet

- API 650 Tank Design CalculationDocument8 pagesAPI 650 Tank Design Calculationmail_younes659283% (29)

- STORAGE TANK DESIGN CALCULATIONDocument92 pagesSTORAGE TANK DESIGN CALCULATIONAbelardo ContrerasNo ratings yet

- Selection of Gas Compressor-2Document5 pagesSelection of Gas Compressor-2dhanu_aquaNo ratings yet

- EjectorDocument45 pagesEjectorDeep Das100% (3)

- UMUECHEM BOOSTER COMPRESSOR SELECTIONDocument2 pagesUMUECHEM BOOSTER COMPRESSOR SELECTIONNicolas CardonaNo ratings yet

- Compressor Sizing CalDocument2 pagesCompressor Sizing Calcanada_198020008918No ratings yet

- Compressor Performance CalculatorDocument28 pagesCompressor Performance CalculatorEslamShebl100% (2)

- DAT - Centrifugal CompressorDocument4 pagesDAT - Centrifugal CompressorEDUARDONo ratings yet

- PIPE - ScheduleDocument11 pagesPIPE - Scheduleionutlaur86No ratings yet

- PSVs CalculationDocument24 pagesPSVs Calculationionutlaur86100% (3)

- Heat Loss Insulated PipeDocument3 pagesHeat Loss Insulated PipeKatie BensonNo ratings yet

- Rotary Screw CompressorsDocument22 pagesRotary Screw Compressorsganeshdhage100% (2)

- Centrifugal Refrigeration (R134)Document48 pagesCentrifugal Refrigeration (R134)ionutlaur86100% (1)

- Rupture Disk SizingDocument2 pagesRupture Disk Sizingabhishek shindeNo ratings yet

- PSV Reaction Force - ADocument2 pagesPSV Reaction Force - AAbraham PoolNo ratings yet

- Reciprocating Compressor ImprovementsDocument13 pagesReciprocating Compressor ImprovementsSANJANA SINGHNo ratings yet

- Reciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitsDocument17 pagesReciprocating Compressor (Api 618-4Th) Data Sheet U.S. Customary UnitstutuionutNo ratings yet

- Recip Compressor Calculations For GCP-3Document4 pagesRecip Compressor Calculations For GCP-3Greg GolushkoNo ratings yet

- Tank DesignDocument89 pagesTank DesignDietrich von BismarckNo ratings yet

- Compressor CalculationsDocument7 pagesCompressor CalculationsSantosh100% (1)

- Vertical Separator SizingDocument4 pagesVertical Separator SizingnemprrNo ratings yet

- Natural Gas AnalysisDocument9 pagesNatural Gas AnalysisCharles AshmanNo ratings yet

- Bypass Method For Recip Compressor Capacity ControlDocument4 pagesBypass Method For Recip Compressor Capacity Controlel mouatez billah messiniNo ratings yet

- Sizing Calculation Spreadsheet PSVDocument1 pageSizing Calculation Spreadsheet PSVkenoly123No ratings yet

- Thermal Calculations - WHRSDocument10 pagesThermal Calculations - WHRSshani5573No ratings yet

- PSV Blocked Fire Relief Valve CasesDocument21 pagesPSV Blocked Fire Relief Valve CasesTun Naing WinNo ratings yet

- Process Design of TurboexpanderDocument55 pagesProcess Design of TurboexpanderSaidFerdjallahNo ratings yet

- Air Receiver SizingDocument3 pagesAir Receiver Sizinglutfi awnNo ratings yet

- Rotary Screw Compressor Discussion and Calculations: NotesDocument9 pagesRotary Screw Compressor Discussion and Calculations: Notesfarshad100% (2)

- EjectorDocument6 pagesEjectorbadelitamarius100% (1)

- Gas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetDocument5 pagesGas Properties, Flowrate and Conditions: Reciprocating Compressor Calculation SheetNaqqash Sajid0% (2)

- Tank Vessel HandbookDocument76 pagesTank Vessel HandbooklsgmzNo ratings yet

- Actual compressor capacity calculation based on site conditionsDocument1 pageActual compressor capacity calculation based on site conditionsrinabiswasNo ratings yet

- Flare Calc Sheet API - RP 521Document13 pagesFlare Calc Sheet API - RP 521ionutlaur86100% (1)

- KodDocument2 pagesKodionutlaur86No ratings yet

- Combustion Table Industrial Energy ProcessDocument4 pagesCombustion Table Industrial Energy Processsara_ghaemNo ratings yet

- CALCULATION SHEET - CompressorDocument18 pagesCALCULATION SHEET - CompressorHusni RadiyanNo ratings yet

- Calculate Saturated-Gas Loads For Vacuum SystemsDocument3 pagesCalculate Saturated-Gas Loads For Vacuum SystemsFred FaberNo ratings yet

- Calculating Gas Properties with Mixing Rule SpreadsheetDocument2 pagesCalculating Gas Properties with Mixing Rule Spreadsheetvictor javier nuñezNo ratings yet

- Introduction To LNGDocument27 pagesIntroduction To LNGdensandsNo ratings yet

- BoilerCalcSteamPropDocument4 pagesBoilerCalcSteamPropMarc EdwardsNo ratings yet

- Pump Sizing CalculationDocument12 pagesPump Sizing Calculationionutlaur86No ratings yet

- CompressorDocument27 pagesCompressorsoxal100% (1)

- Design Construction EjectorDocument136 pagesDesign Construction Ejectorssmith2007100% (1)

- Ogpe OGPE Oil Fields: Calculation SheetDocument4 pagesOgpe OGPE Oil Fields: Calculation SheetFaber TrujilloNo ratings yet

- Desuperheater Boiler Feed Water RequirementDocument2 pagesDesuperheater Boiler Feed Water Requirementmehul10941No ratings yet

- Can Length 6.875 6 Top: Input Data in Orange Area OnlyDocument13 pagesCan Length 6.875 6 Top: Input Data in Orange Area Onlyionutlaur86No ratings yet

- Wet Air Properties Calculation Sheet: at Low PressureDocument2 pagesWet Air Properties Calculation Sheet: at Low Pressurezsmith0% (1)

- Air Cooler Design (Ujian)Document36 pagesAir Cooler Design (Ujian)Wahyu JatiNo ratings yet

- Centrifugal Compressor Power-US Field UnitsDocument4 pagesCentrifugal Compressor Power-US Field UnitssurawutwijarnNo ratings yet

- Stepless Variable Capacity ControlDocument7 pagesStepless Variable Capacity Controlswapneel_kulkarniNo ratings yet

- 8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)Document22 pages8474L-000-JSS-1031-001-0 (Specification For Rotary Compressor)LongTuanNo ratings yet

- Ejector BasicsDocument2 pagesEjector Basicsa234f56No ratings yet

- Natural Gas Homework2Document42 pagesNatural Gas Homework2Khanz KhanNo ratings yet

- Hall Yarborough ZDocument4 pagesHall Yarborough ZDanny MoralesNo ratings yet

- Closed DrainDocument1 pageClosed Drainionutlaur86No ratings yet

- 02 Sisteme de Masurare A Gazelor Naturale - Gaz CromatografDocument78 pages02 Sisteme de Masurare A Gazelor Naturale - Gaz Cromatografionutlaur86No ratings yet

- Heat Capacity Ratio of Real GasesDocument2 pagesHeat Capacity Ratio of Real GasesilyesinNo ratings yet

- L-G Separator CalculationDocument1 pageL-G Separator Calculationionutlaur86No ratings yet

- How To Select A Pump-By Majid HamedyniaDocument72 pagesHow To Select A Pump-By Majid Hamedyniamajid100% (2)

- Foraj Marin - Lazar Avram PDFDocument106 pagesForaj Marin - Lazar Avram PDFionutlaur860% (1)

- Water Treatment Plant Design PDFDocument67 pagesWater Treatment Plant Design PDFAriston100% (1)