Professional Documents

Culture Documents

Key Concept in Egineering PDF

Key Concept in Egineering PDF

Uploaded by

Abraham AbyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Key Concept in Egineering PDF

Key Concept in Egineering PDF

Uploaded by

Abraham AbyCopyright:

Available Formats

Key Concepts in Welding Engineering

by R. Scott Funderburk

A Look at Input

What is Heat Input?

In arc welding, energy is transferred

from the welding electrode to the base

metal by an electric arc. When the

welder starts the arc, both the base

metal and the filler metal are melted to

create the weld. This melting is possi-

ble because a sufficient amount of

power (energy transferred per unit

time) and energy density is supplied to

the electrode.

Heat input is a relative measure of the

energy transferred per unit length of

weld. It is an important characteristic

because, like preheat and interpass

temperature, it influences the cooling

rate, which may affect the mechanical

properties and metallurgical structure

of the weld and the HAZ (see Figure Figure 1. Heat input influences cooling rate.

1). Heat input is typically calculated

as the ratio of the power (i.e., voltage

x current) to the velocity of the heat

source (i.e., the arc) as follows: How is Heat Input welding cables (see Figure 2). The

Measured? machine voltage, therefore, can be

60 EI used only for approximate calculations

H= Heat input can not be measured

1000 S directly. It can, however, be calculated Heat input is a

where, from the measured values of arc volt- relative measure of

H = heat input (kJ/in or kJ/mm) age, current and travel speed.

E = arc voltage (volts) the energy transferred

I = current (amps) Arc Voltage during welding

S = travel speed (in/min or mm/min) In determining the arc voltage (E), the

voltage should be measured as close and, in the case of significant voltage

This equation is useful for comparing to the arc as possible, as opposed to drops, may lead to heat input calcula-

different welding procedures for a the value displayed on the welding tion errors.

given welding process. However, heat machine voltmeter. Measuring the

input is not necessarily applicable for voltage across the arc provides the Current

comparing different processes (e.g., actual voltage drop across the welding The welding current (I) is measured

SMAW and GMAW), unless additional arc. The welding machine voltmeter with either an inductance meter (tong

data are available such as the heat reading is always higher than the arc meter) or a shunt with appropriate

transfer efficiency (Linnert, 1994). voltage due to the resistance of the metering equipment. The current is

Welding Innovation Vol. XVI, No. 1, 1999

never fixed with respect to time, espe- Transient Values mentation of cooling rate and heat

cially on a microsecond level. With For processes in which the voltage input a more accurate analysis proce-

SMAW, the current is also a function and current vary significantly with time, dure may be required, including

of the arc length, which is dependent such as short-circuiting GMAW, the instantaneously monitoring the volt-

on the welder's skill. Therefore, the average values of these variables are age, current and travel speed to calcu-

current used in the heat input calcula- used in calculating the heat input. For late the actual heat input.

tions should be the average value. example, with GMAW-pulsed arc, the

current is pulsed at a specified fre-

Travel Speed quency from a minimum value (back- Weld Size is Related

The travel speed (S) is the forward ground current) to the maximum value to Heat Input

velocity of the arc measured in either (peak current). The average value The cross-sectional area of a weld is

inches per minute or millimeters per between the maximum and minimum generally proportional to the amount of

minute. Only the forward progress con- current and voltage will provide an heat input. This intuitively makes

tributes to the travel speed. If a weaving approximate heat input value for these sense, because as more energy is

technique is used, only the forward welding processes. supplied to the arc, more filler metal

speed counts, not the oscillation rate. and base metal will be melted per unit

For vertical welding, the upward or With SMAW, the resistance of the length, resulting in a larger weld bead.

downward speed of the arc is used. The electrode changes as it is melted, If a welder makes one weld with a fast

travel speed must be in terms of minutes which results in a voltage change. travel speed and another with a slow

and not seconds for the dimensions to The temperature of the electrode also travel speed, keeping current and volt-

balance in the heat input equation. age the same for both, then the weld

The current made at the slower travel speed will

When the travel speed is measured,

the arc should be established for an

is never fixed be larger than the faster one. The fol-

lowing equation is an approximation

amount of time that will produce an with respect to time for the fillet weld leg size based on

accurate average speed. A continu- heat input (Miller, 1998):

ous welding time of 30 seconds is increases while its length is reduced

suggested. If this is not possible for during welding, both of which influence H

the production joint (e.g., short welds), the overall resistance. Average values

=

500

a test weld should be run on a mock- are used in this case as well.

up joint that will provide a sufficient where,

length to determine the travel speed. The transient nature of these factors is = fillet weld leg size (in)

The travel speed accuracy with manu- usually not considered when calculat- H = heat input (kJ/in)

al or semi-automatic welding is depen- ing heat input, and the averages are

dent on the welder. However, with adequate for procedure qualification or Although the precise relationship

automatic welding, the speed is set on simple comparison of welding proce- between heat input and fillet weld size

the motor controlled travel carriage. dures. However, for scientific experi- also depends on other variables,

including the process and polarity, this

equation is a helpful tool, especially in

creating and reviewing welding proce-

dures. For example, if a minimum fillet

weld size is specified, then the corre-

sponding minimum heat input can be

determined and controlled.

Cooling Rate is a

Function of Heat Input

The effect of heat input on cooling rate

is similar to that of the preheat temper-

ature. As either the heat input or the

preheat temperature increases, the rate

of cooling decreases for a given base

metal thickness. These two variables

interact with others such as material

thickness, specific heat, density, and

Figure 2. The arc voltage is always lower than the machine voltage due to the

resistance of the welding cables.

Welding Innovation Vol. XVI, No. 1, 1999

Table 1. How Material Properties are Affected by Increasing Heat Input for SMAW

thermal conductivity to influence the

cooling rate. The following proportion-

Property* Change

ality function shows this relationship

between preheat temperature, heat

Yield Strength 30%

input and cooling rate:

Tensile Strength 10%

1

R Percent Elongation 10%

To H

Notch Toughness (CVN) 10%, for 15 < H < 50 kJ/in

where,

50%, for 50 < H < 110 kJ/in

R = cooling rate (F/sec or C/sec)

Hardness 10%

To = preheat temperature (F or C)

H = heat input (kJ/in or kJ/mm)

* SMAW with a heat input range of 15 to 110 kJ/in.

The cooling rate is a primary factor

that determines the final metallurgical

structure of the weld and heat affected

zone (HAZ), and is especially impor- tied to the heat input, but is also signif- Welding Codes

tant with heat-treated steels. When icantly influenced by the weld bead

welding quenched and tempered size. As the bead size increases, As discussed previously, heat input

steels, for example, slow cooling rates which corresponds to a higher heat can affect the mechanical properties

(resulting from high heat inputs) can input, the notch toughness tends to and metallurgical structure in the weld

soften the material adjacent to the decrease. In multiple-pass welds, a and HAZ of weldments. The AWS

weld, reducing the load-carrying portion of the previous weld pass is Welding Codes have specific provi-

capacity of the connection. refined, and the toughness improved, sions related to heat input for this very

as the heat from each pass tempers reason. Below are the requirements

the weld metal below it. If the beads for heat input from AWS D1.1 and

How Does Heat Input are smaller, more grain refinement D1.5.

Affect Mechanical occurs, resulting in better notch tough-

Properties? ness, all other factors being even. AWS D1.1 Structural Welding

Code Steel

Varying the heat input typically will Tests have been conducted with The AWS D1.1 Structural Welding

affect the material properties in the SMAW electrodes and procedures that Code Steel controls heat input in

weld. The following table shows how provided heat inputs varying from 15 three areas: (1) qualified Welding

the listed properties change with kJ/in (0.6 kJ/mm) to 110 kJ/in (4.3 Procedure Specifications, (2) minimum

increasing heat input. An arrow point- kJ/mm) (Evans, 1997). This repre- fillet weld sizes and (3) quenched and

ed up, , designates that the property sents a very large heat input range, tempered steels.

increases as heat input increases. An which encompasses most applications

arrow pointed down, , designates that of SMAW. Qualified Welding Procedure

the property decreases as heat input Specifications (WPSs)

increases. Next to the arrow is the If the changes in heat input are rela- When heat input control is a contract

approximate amount that property tively small, as opposed to those of requirement, and if the procedure

changed from the minimum to maxi- the previous table, then the mechani- used in production has a correspond-

mum value of heat input tested. cal properties may not be significantly ing heat input that is 10% or greater

changed. In another study, no signifi- than that recorded in the Procedure

Other than notch toughness, all of the cant correlation between heat input Qualification Record (PQR), then the

mechanical properties show a monoto- and mechanical properties was estab- qualified WPS must be requalified

nic relationship to heat input, that is, lished for submerged arc welding (AWS D1.1-98, Table 4.5, item 18).

the mechanical property only increas- (SAW) with typical highway bridge This is primarily due to concerns

es or decreases with increasing heat fabrication heat input levels of 50 to 90 regarding the potential alteration of

input. Notch toughness, however, kJ/in (Medlock, 1998). In this case, the weld metal and HAZ mechanical

increases slightly and then drops sig- the tests results did show varying properties.

nificantly as heat input increases. The properties; however, no discernable

change in notch toughness is not just trends were established.

Welding Innovation Vol. XVI, No. 1, 1999

Minimum Fillet Weld Sizes AWS D1.5 Bridge Welding Code Summary

The code also controls the heat input The AWS D1.5-96 Bridge Welding Heat input is a relative measure of the

by limiting the minimum size of fillet Code has provisions for heat input in energy transferred during welding. It

welds (AWS D1.1-98, Table 5.8). two areas: procedure qualification andis a useful tool in evaluating welding

According to the Commentary, For fracture critical nonredundant members.

procedures within a given process.

non-low-hydrogen processes, the The cooling rate, weld size and materi-

minimum size specified is intended to Procedure Qualification al properties may all be influenced by

ensure sufficient heat input to reduce There are three different methods for the heat input. Some welding codes

the possibility of cracking in either the qualifying procedures in D1.5: the place specific controls on the heat

heat-affected zone or weld metal Maximum Heat Input Method, the input. To ensure high quality in welded

(AWS D1.1-98, para. C5.14). For mul- Maximum-Minimum Heat Input construction, it is important to under-

tiple-pass fillet welds, the Commentary Method, and the Production Procedure stand and apply these principles when

includes the following: Method. For the Maximum Heat Input notch toughness and HAZ properties

Method, the heat input must be are to be controlled and when welding

Should fillet weld sizes greater than between 60% and 100% of the value high alloy steels.

the minimum sizes be required for from the Procedure Qualification

these thicknesses, then each indi- Record (PQR) used to qualify the References

vidual pass of multiple-pass welds WPS (AWS D1.5-96, para. 5.12.1). ANSI/AASHTO/AWS D1.5-96 Bridge Welding

must represent the same heat input With the Maximum-Minimum Heat Code. American Welding Society, 1996.

per inch of weld length as provided ANSI/AWS D1.1-98 Structural Welding Code -

D1.1-98 controls heat

by the minimum fillet size required Steel. American Welding Society, 1998.

Evans, G. M. and Bailey, N. Metallurgy of Basic

by Table 5.8. (AWS D1.1-98, para.

C5.14). input in three areas Weld Metal. Abington Publishing, 1997.

Graville, B.A. The Principles of Cold Cracking

Control in Welds. Dominion Bridge Company,

Quenched and Tempered Steels Input Method, the heat input must fall 1975.

Linnert, G.E. Welding Metallurgy, Vol.1.

When quenched and tempered steels between that of the two required quali- American Welding Society, pp.667-693, 1994.

(e.g., A514 and A517) are to be weld- fication tests. If the Production Miller, D.K. and Funderburk, R.S. Reviewing

ed, the heat input, as well as mini- Procedure Method is used, the heat and Approving Welding Procedure

mum preheat and maximum interpass input can only deviate from the PQR Specifications. The National Steel

Construction Conference Proceedings. New

temperatures, must conform to the by the following: an increase of up to Orleans, AISC, 1998.

steel producer's specific written rec- 10% or a decrease not greater than Medlock, Ronald D. Qualification of Welding

ommendations (AWS D1.1-98, para. 30% (AWS D1.5, Table 5.3, item 17). Procedures for Bridges: An Evaluation of the

5.7). If high heat input welding is Heat Input Method. Thesis, University of

Texas, May 1998.

used, the HAZ can be significantly Fracture Critical Nonredundant Stout, R.D. and Doty, W.D. Weldability of Steels.

weakened due to high temperatures Members 2nd Edition. Welding Research Council, pp.

and slower cooling rates. However, Chapter 12 of D1.5 applies to fracture 39-43, 103-107, 217-218, 229-237, 1971.

the requirement does not universally critical nonredundant members Welding Handbook, Vol. 1, 8th Edition.

American Welding Society, pp. 32-34, 1987.

apply to all quenched and tempered (FCMs). The minimum preheat tem- Welding Handbook, Vol. 4, 8th Edition.

steels. For example, with ASTM perature for a FCM is selected based American Welding Society, pp. 43-45, 1998.

A913 Grades 60 or 65, which are on the heat input, material grade and

quenched and self-tempered, the thickness, and filler metal diffusible

heat input limitations of AWS D1.1 hydrogen content (AWS D1.5, Tables

paragraph 5.7 do not apply (AWS 12.3, 12.4 and12.5). Although the

D1.1-98, Table 3.1 and 3.2, footnote 9 focus in chapter 12 of D1.5 is the mini-

and 4, respectively). mum preheat temperature, the heat

input value is an equally controlling

variable.

Welding Innovation Vol. XVI, No. 1, 1999

You might also like

- Shankara Bhashya Taittiriya Upanishad With Bhasyas of Suresvara Sayana PDFDocument815 pagesShankara Bhashya Taittiriya Upanishad With Bhasyas of Suresvara Sayana PDFDanillo Costa Lima100% (11)

- ISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdDocument12 pagesISO 898-6-1994, OCR Mechanical Properties of Fasteners-2nd EdRenatoGolinNo ratings yet

- Handbook of Polymer FoamsDocument304 pagesHandbook of Polymer FoamsMarcos Gilardi100% (2)

- Draw The Lewis Structure and Name The Shape of Each CompoundDocument9 pagesDraw The Lewis Structure and Name The Shape of Each CompoundJuan Frivaldo100% (1)

- Full Lab Report Coulombs Law Phy 150Document8 pagesFull Lab Report Coulombs Law Phy 150fatin nadia0% (1)

- The Einstein-Myth and The Crisis in Modern PhysicsDocument17 pagesThe Einstein-Myth and The Crisis in Modern PhysicsLuis Gerardo Escandon AlcazarNo ratings yet

- Technical Paper - Slope Stability Analysis PDFDocument7 pagesTechnical Paper - Slope Stability Analysis PDFsyah123No ratings yet

- Welding Defects Poster 600x900 Lores enDocument1 pageWelding Defects Poster 600x900 Lores enMostafa ZedNo ratings yet

- Three Dimensional Analysis of - High Frequency Induction - Welding of Steel Pipes With - ImpederDocument7 pagesThree Dimensional Analysis of - High Frequency Induction - Welding of Steel Pipes With - Impederprasanna venkateshNo ratings yet

- Hardox 450Document3 pagesHardox 450Marko RisticNo ratings yet

- M 2 SAW D1.1 2015 Form PDFDocument1 pageM 2 SAW D1.1 2015 Form PDFyounessNo ratings yet

- Gas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Document8 pagesGas Tungsten Arc Welding Practice:: Jobs 19-J1-J19 (Plate)Willy UioNo ratings yet

- 653 231rev0Document16 pages653 231rev0Badiuzzama786No ratings yet

- And Solutions: Welding Problems and Defects - CausesDocument1 pageAnd Solutions: Welding Problems and Defects - CausesAli Osman YaşarNo ratings yet

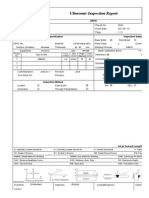

- Ultrasonic Inspection Report: Item Specification Inspection SubjectDocument6 pagesUltrasonic Inspection Report: Item Specification Inspection Subjectehsan.mNo ratings yet

- En 13920-2015Document8 pagesEn 13920-2015mihaiNo ratings yet

- Quality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaDocument5 pagesQuality Oriented and ISO Approved Stainless Steel 904L Buttweld Pipe Fittings Manufacturer in IndiaPetromat Oil and Gas Equipment Pvt. Ltd.No ratings yet

- Joint Restraint - Improper Bead Shape - Hydrogen Pickup - Rapid Cooling Rate - High Carbon/Alloy Content - Low Melting Point ContaminantsDocument1 pageJoint Restraint - Improper Bead Shape - Hydrogen Pickup - Rapid Cooling Rate - High Carbon/Alloy Content - Low Melting Point ContaminantsLucian HoudiniNo ratings yet

- Wopq Asme Section IxDocument2 pagesWopq Asme Section IxkanchanabalajiNo ratings yet

- Effect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316Document11 pagesEffect of Laser Welding Process Parameters On Mechanical P Roperties of Stainless Steel-316kamal touilebNo ratings yet

- ASME WPS-PQR-WQT CombinedDocument6 pagesASME WPS-PQR-WQT CombinedStan HonNo ratings yet

- Hybrid Welding AssignmentDocument7 pagesHybrid Welding Assignmentsalem atefNo ratings yet

- Optimization of Parameters For Effective Laser Welding of Aerospace ComponentsDocument16 pagesOptimization of Parameters For Effective Laser Welding of Aerospace ComponentsVigneswaranNo ratings yet

- Murex Tig Poster 2008 PDFDocument1 pageMurex Tig Poster 2008 PDFPCNo ratings yet

- Small Diameter Boiler Tube Butt Weld Acceptance Criteria - Arnold - 20 May 2015 PDFDocument8 pagesSmall Diameter Boiler Tube Butt Weld Acceptance Criteria - Arnold - 20 May 2015 PDFAnaximenes 12No ratings yet

- En 10029 Dimensional TolerancesDocument1 pageEn 10029 Dimensional ToleranceswhngomjNo ratings yet

- HRSG HydrotestDocument7 pagesHRSG Hydrotestshubham raj bhawsarNo ratings yet

- ASTM A453 Grade 660 Stud - Bolt.nut - WasherDocument1 pageASTM A453 Grade 660 Stud - Bolt.nut - WasherTdk DallasNo ratings yet

- E545-99 Neutron Image QualityDocument4 pagesE545-99 Neutron Image QualityaboutdestinyNo ratings yet

- Inspections and Audits For Boilers and Pressure VesselsDocument2 pagesInspections and Audits For Boilers and Pressure VesselsNDTInstructorNo ratings yet

- Evaluation of 8090 and Weldalite-049 Aluminum-Lithium AlloysDocument39 pagesEvaluation of 8090 and Weldalite-049 Aluminum-Lithium Alloysskylancer-3441No ratings yet

- Study On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationDocument7 pagesStudy On Welding Temperature Distribution in Thin Welded Plates Through Experimental Measurements and Finite Element SimulationManuel CarreñoNo ratings yet

- Getting StartedDocument89 pagesGetting StartedYraidis Pertuz RobleNo ratings yet

- ARTICLE - Destructive Testing Basics (2012)Document4 pagesARTICLE - Destructive Testing Basics (2012)Sangameswaran RamarajNo ratings yet

- Evaluation of Welds - Macro-Examination - Hardness PDFDocument37 pagesEvaluation of Welds - Macro-Examination - Hardness PDFdavideNo ratings yet

- Wel 13 HDocument8 pagesWel 13 HWilly Uio100% (1)

- WpsDocument2 pagesWpsjsmargate100% (1)

- Ut 4 PDFDocument42 pagesUt 4 PDFtusharNo ratings yet

- WPS Ernicu 7 R1 3 6 PDFDocument4 pagesWPS Ernicu 7 R1 3 6 PDFandresNo ratings yet

- Tektronix - 577-177-D1 577-177-D2 - Curve - Tracer - WW PDFDocument57 pagesTektronix - 577-177-D1 577-177-D2 - Curve - Tracer - WW PDF240GL guy100% (2)

- WPS 05Document4 pagesWPS 05Naqqash SajidNo ratings yet

- Helling Katalog NDTDocument43 pagesHelling Katalog NDTjeyaselvanmNo ratings yet

- Incertech Catalogue.Document24 pagesIncertech Catalogue.NS QCNo ratings yet

- Er 100 S 1Document1 pageEr 100 S 1Oliver Quezada Inostroza100% (1)

- Thermanit MTS 3 - GTAWDocument1 pageThermanit MTS 3 - GTAWdnageshm4n244No ratings yet

- Echograph 1095 PDFDocument6 pagesEchograph 1095 PDFBlack NevadaNo ratings yet

- Transformer-WPS OfficeDocument19 pagesTransformer-WPS OfficeVinaya kumar BGNo ratings yet

- Welder Certificate Akilesh YadavDocument1 pageWelder Certificate Akilesh Yadavtripatipankaj023No ratings yet

- BS en 50504 Validation of Arc Welding Equipment Specifies Validation Methods For Arc Welding Equipment Constructed and Used To The Accuracy Specified inDocument1 pageBS en 50504 Validation of Arc Welding Equipment Specifies Validation Methods For Arc Welding Equipment Constructed and Used To The Accuracy Specified inBézier DominatoricNo ratings yet

- WeldDocs WPSDocument2 pagesWeldDocs WPSMDSIKKU_2005No ratings yet

- Surface Tension Transfer (STT) Pipe WeldingDocument3 pagesSurface Tension Transfer (STT) Pipe WeldingahmedNo ratings yet

- Laser Welder - Presentation 060117ADocument20 pagesLaser Welder - Presentation 060117Aaman_singh0705No ratings yet

- CARGAS B31.4 Sostenidas Ocasionales Constructivas Transitorias Valores de Esfuerzos PermisiblesDocument6 pagesCARGAS B31.4 Sostenidas Ocasionales Constructivas Transitorias Valores de Esfuerzos PermisiblesFREDYTOAPANTANo ratings yet

- SS 409M WeldingDocument12 pagesSS 409M WeldingwentropremNo ratings yet

- Steel Data ChartDocument2 pagesSteel Data Chartsmartcad60No ratings yet

- 008a.rtfi - AbbrevationsDocument2 pages008a.rtfi - AbbrevationsVivekanandan JNo ratings yet

- Bright Annealing Process of Stainless S Teel TubeDocument2 pagesBright Annealing Process of Stainless S Teel TubeViraj ShiroleNo ratings yet

- Zetec - Topaz 16Document6 pagesZetec - Topaz 16pokeboy19No ratings yet

- Key Concepts in Welding EngineeringDocument4 pagesKey Concepts in Welding EngineeringXNo ratings yet

- A Look at Input: Key Concepts in Welding EngineeringDocument4 pagesA Look at Input: Key Concepts in Welding EngineeringpvdrameshNo ratings yet

- Ob Knowledge 139: FAQ On The Difference Between Heat Input and Arc EnergyDocument1 pageOb Knowledge 139: FAQ On The Difference Between Heat Input and Arc EnergyJacques SauNo ratings yet

- New Findings On The Efficiency of Gas Shielded Arc WeldingDocument7 pagesNew Findings On The Efficiency of Gas Shielded Arc WeldingIshan ShuklaNo ratings yet

- Artigo 2015 Computational Analysis of The Effect of Welding Parameters On Energy Consumption in GTA Welding ProcessDocument9 pagesArtigo 2015 Computational Analysis of The Effect of Welding Parameters On Energy Consumption in GTA Welding ProcessJoão Paulo NascimentoNo ratings yet

- Resistance Spot WeldingDocument6 pagesResistance Spot WeldingashkansoheylNo ratings yet

- Thremal Analysis of Friction Stir Welding Process Uner Different Control and Energy ParametersDocument9 pagesThremal Analysis of Friction Stir Welding Process Uner Different Control and Energy Parameterscuentas ricardoNo ratings yet

- SRM 3006 Reference Book Prof DR WuschekDocument13 pagesSRM 3006 Reference Book Prof DR WuschekBama RamachandranNo ratings yet

- LTE Base Station and EMF Eumc .2015.7345905 Matthias WuschekDocument4 pagesLTE Base Station and EMF Eumc .2015.7345905 Matthias WuschekBama RamachandranNo ratings yet

- Wi Max Base Station and Cell Radiation Matthias Wuschek EMCZUR.2009.4783458Document4 pagesWi Max Base Station and Cell Radiation Matthias Wuschek EMCZUR.2009.4783458Bama RamachandranNo ratings yet

- Gases Methane and UsesDocument15 pagesGases Methane and UsesBama RamachandranNo ratings yet

- Natya Shastra Translation Volume 2 - Bharat MuniDocument290 pagesNatya Shastra Translation Volume 2 - Bharat MuniBama RamachandranNo ratings yet

- Natya Shastra Translation Volume 1 - Bharat MuniDocument652 pagesNatya Shastra Translation Volume 1 - Bharat MuniBama Ramachandran0% (1)

- CSWIP Document WI-6-92 2009 EditionDocument16 pagesCSWIP Document WI-6-92 2009 EditionKarthik KarunanidhiNo ratings yet

- Science 9 3rd Quarter Curriculum GuideDocument4 pagesScience 9 3rd Quarter Curriculum GuideJerica Joy BundocNo ratings yet

- Engineering Physics: Defects in SolidsDocument5 pagesEngineering Physics: Defects in Solidsrajesh.v.v.kNo ratings yet

- Modified Lo-Chau QKD ProtocolDocument5 pagesModified Lo-Chau QKD ProtocolMLhkuNo ratings yet

- Flyndon Mark Dagalea: Lecturer, College of Science-UEPDocument10 pagesFlyndon Mark Dagalea: Lecturer, College of Science-UEPyoonglespianoNo ratings yet

- FM1 AS-level Formula SheetDocument3 pagesFM1 AS-level Formula SheetewjuhewauwajuawhukawhdwajhdwajwadhjadwhNo ratings yet

- QUESTION BANK Electrical Engineering Material-1Document3 pagesQUESTION BANK Electrical Engineering Material-1pkumarmys100% (1)

- Chap-1 AntennaDocument13 pagesChap-1 AntennaShivam SinghNo ratings yet

- Seismic Assessment of Reinforced Concrete Buildings With Coupled WallsDocument12 pagesSeismic Assessment of Reinforced Concrete Buildings With Coupled WallsSebastian Contreras ContrerasNo ratings yet

- NIA Graduate Program: Fall 2016: Full Course ListDocument12 pagesNIA Graduate Program: Fall 2016: Full Course ListMarsala NistoNo ratings yet

- The Principles of Quantum Mechanics. by P. A. M. Dirac. Second EditionDocument3 pagesThe Principles of Quantum Mechanics. by P. A. M. Dirac. Second EditionBNo ratings yet

- PVT Lab ReportDocument21 pagesPVT Lab ReportaminsubriNo ratings yet

- Definition of Inverse VariationDocument7 pagesDefinition of Inverse VariationGary NugasNo ratings yet

- Electric Field and Electric Forces PDFDocument69 pagesElectric Field and Electric Forces PDFRia Grace P AbdonNo ratings yet

- CHEM1102 Lecture Notes 2Document30 pagesCHEM1102 Lecture Notes 2Callum BiggsNo ratings yet

- 9709 w15 QP 41Document4 pages9709 w15 QP 41yuke kristinaNo ratings yet

- Rotary DryerDocument29 pagesRotary DryerbennypatriaNo ratings yet

- D 6180 - 98 - Rdyxoda - PDFDocument6 pagesD 6180 - 98 - Rdyxoda - PDFjayakumarNo ratings yet

- 1 - Circular Motion-Theory& Example Module-2Document24 pages1 - Circular Motion-Theory& Example Module-2Raju SinghNo ratings yet

- Engineering Mechanics ModuleDocument7 pagesEngineering Mechanics ModuleJoshua OrcalesNo ratings yet

- 02 Finite DifferencesDocument27 pages02 Finite DifferencesCham AmirruddinNo ratings yet

- Powering Disney's "Frozen" With A Carnot RefrigeratorDocument3 pagesPowering Disney's "Frozen" With A Carnot RefrigeratorInquit_No ratings yet

- Albert Einstein - BiographyDocument3 pagesAlbert Einstein - BiographyoscarguardadojrNo ratings yet

- Craig-Bampton Method For A Two Component System: This Is A Work in ProgressDocument15 pagesCraig-Bampton Method For A Two Component System: This Is A Work in ProgressnemaderakeshNo ratings yet

- Electric Charges and FieldsDocument13 pagesElectric Charges and FieldsPriyanshu KumarNo ratings yet

- 5.1.2 - Electrostatic Force - QUESTIONSDocument3 pages5.1.2 - Electrostatic Force - QUESTIONSdsdfusdNo ratings yet