Professional Documents

Culture Documents

CNC

Uploaded by

jox0 ratings0% found this document useful (0 votes)

6 views1 page______

Original Title

Cnc

Copyright

© © All Rights Reserved

Available Formats

TXT, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document______

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

6 views1 pageCNC

Uploaded by

jox______

Copyright:

© All Rights Reserved

Available Formats

Download as TXT, PDF, TXT or read online from Scribd

You are on page 1of 1

CNC ==> bekerja dengan data yang telah dikodekan "alphanumerical"

type of CNC : lathe, milling machine, laser, plasma, coordinate measuring machine

etc.

The benefits of CNC are

(1) high accuracy in manufacturing ==> akurasi yang tinggi

(2) short production time ==> produksi yang singkat

(3) greater manufacturing flexibility ==> fleksibilitas yang lebih tinggi

( produk mudah diganti )

(4) simpler fixturing ==> alat - alat yang lebih simple

(5) contour machining (2 to 5 -axis machining) ==> garis bisa dari 2 - 5 sumbu

(6) reduced human error

The drawbacks include high cost, maintenance, and the requirement of skilled part

programmer.

kekurangan :

biaya tinggi

pemeliharaan

dibutuhkan bagian coder yang handal

ELEMENTS OF A CNC

A CNC system consists of three basic components : ==> di CNC plotter ( project )

1 . Part program ==> arduino & processing ==> APT (Automated Programming

Tool) ???

2 . Machine Control Unit (MCU) ==> micro servo & stepper motor

3 . Machine tool (lathe, drill press, milling machine etc) ==> plotter ( spidol )

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (120)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Cyber-Security of SCADA and Other Industrial Control SystemsDocument368 pagesCyber-Security of SCADA and Other Industrial Control Systemsjox100% (7)

- HTML Cheat SheetDocument2 pagesHTML Cheat SheetVel Kumar BalasubramanianNo ratings yet

- HTML Cheat SheetDocument2 pagesHTML Cheat SheetVel Kumar BalasubramanianNo ratings yet

- DevOps For DummiesDocument76 pagesDevOps For Dummieshithamg6152No ratings yet

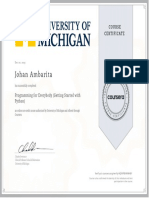

- Coursera LPHW68TQPL35Document1 pageCoursera LPHW68TQPL35joxNo ratings yet

- Programming For Everybody (Getting Started With Python) - University of Michigan (Coursera)Document1 pageProgramming For Everybody (Getting Started With Python) - University of Michigan (Coursera)joxNo ratings yet

- Backend Coding TestDocument1 pageBackend Coding TestjoxNo ratings yet

- Python Data Structures - University of Michigan (Coursera)Document1 pagePython Data Structures - University of Michigan (Coursera)joxNo ratings yet

- Introduction To The Internet of Things and Embedded Systems - University of California Irvine - CourseraDocument1 pageIntroduction To The Internet of Things and Embedded Systems - University of California Irvine - CourserajoxNo ratings yet

- Infopgraphic CanvasCheatSheet Final2Document1 pageInfopgraphic CanvasCheatSheet Final2Hermogenes Alcos JrNo ratings yet

- Apache Kafka Fundamentals - ConfluentDocument1 pageApache Kafka Fundamentals - ConfluentjoxNo ratings yet

- html5 Tag Cheat Sheet 2019Document1 pagehtml5 Tag Cheat Sheet 2019Purushotham reddyNo ratings yet

- html5 Tag Cheat Sheet 2019Document1 pagehtml5 Tag Cheat Sheet 2019Purushotham reddyNo ratings yet

- Infopgraphic CanvasCheatSheet Final2Document1 pageInfopgraphic CanvasCheatSheet Final2Hermogenes Alcos JrNo ratings yet

- Lembar Aktivitas PraktikumDocument9 pagesLembar Aktivitas PraktikumsmahsgxNo ratings yet

- DFR0034SCH V2.0 - Schematic PDFDocument1 pageDFR0034SCH V2.0 - Schematic PDFjoxNo ratings yet

- 8085 CPLD Test1Document2 pages8085 CPLD Test1rohanscar_421321698No ratings yet

- R1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0Document1 pageR1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0joxNo ratings yet

- SmartDocument10 pagesSmartjoxNo ratings yet

- R1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0Document1 pageR1 200K R2 1K C1 0.1uf C2 P1 P2: Audioanalyzer V2.0joxNo ratings yet

- Engineers in Organization: Professional EthicsDocument28 pagesEngineers in Organization: Professional EthicsjoxNo ratings yet

- Engineering Ethics: Three Case Studies: Subtitle: Everything Should Be As Simple As Possible, But Not Simpler)Document28 pagesEngineering Ethics: Three Case Studies: Subtitle: Everything Should Be As Simple As Possible, But Not Simpler)joxNo ratings yet

- Huffman FANODocument3 pagesHuffman FANOjoxNo ratings yet

- Analisis DataDocument7 pagesAnalisis DatajoxNo ratings yet

- 8085 CPLD Test1Document2 pages8085 CPLD Test1rohanscar_421321698No ratings yet

- The Schrodinger Wave EquationDocument7 pagesThe Schrodinger Wave EquationjoxNo ratings yet

- Tugas TE2 Chapter 8Document10 pagesTugas TE2 Chapter 8joxNo ratings yet

- New 2Document1 pageNew 2joxNo ratings yet

- Skyrim FAQsDocument257 pagesSkyrim FAQsIboy Gafar PutraNo ratings yet