Professional Documents

Culture Documents

Grating Install Clearance

Uploaded by

nalzackCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Grating Install Clearance

Uploaded by

nalzackCopyright:

Available Formats

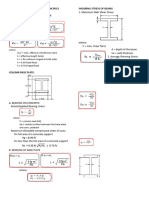

STANDARD INSTALLATION CLEARANCES

Panel length Panel length

Bearing Bearing

bars bars

Panel width

1/4"

1/4"

1/4" clearance between

ends of cross bars on

Panel width

Bearing Bearing

rectangular grating or

bars bars

rivet heads on riveted

grating (3/8" for heavy

duty grating).

* *

3/8"

Bearing Bearing

bars bars

min. clearance

equal to support

angle fillet radius 1/2"

Banding may have less depth than bearing bars

for trench grating to allow drainage. Full depth

banding will be provided unless otherwise specified. Bearing Bearing

bars bars

Clearances shown are recommended, but may vary in

accordance with dimensional tolerances.

*This dimension may vary due to bearing bar

spacing but will not exceed bearing bar spacing.

Heavy duty grating should be designed to have structural

support under each bearing bar at cutouts.

Cutouts for circular obstructions are recommended to

As shown in the drawing below, all rectangular cutouts be at least 2" larger in diameter than the obstruction. It

are made to the next bearing bar beyond the penetration is further recommended that cutouts for all piping 4"

with a clearance not to exceed bearing bar spacing. or less be made in the field.

General Recommendations

for Grating Installation

Gratings must be installed with cross bars on top side.

Notching of bearing bars at supports to maintain proper

specified elevation is generally not recommended. If notching is required

cutout 4" x 6"

for installation, manufacturer should be consulted.

actual

cutout 5-3/4" x 6" Metal should always be used for all grating supports.

A minimum of 1" bearing shall be provided for Aluminum and

Light Duty Steel Grating. For Heavy Duty Steel Grating, 1"

minimum bearing shall be provided for bearing bar depths up

(bearing bar spacing 1-3/16" ) to 2-1/4", and 2" minimum bearing shall be provided for depths

of 2-1/2" and over. This bearing surface does not include the

support angle fillet radius noted above.

TOLL FREE: 1-800-321-9800 107

You might also like

- An Introduction to Metal-Working (Illustrated)From EverandAn Introduction to Metal-Working (Illustrated)Rating: 2.5 out of 5 stars2.5/5 (2)

- Method Statement Partition WorksDocument3 pagesMethod Statement Partition WorksDipin NediyaparambathNo ratings yet

- Sequential Lifting of Tank Shell Used To Repair FloorsDocument4 pagesSequential Lifting of Tank Shell Used To Repair FloorsBIPIN BALANNo ratings yet

- Fireproof Area and Weight CalculationDocument12 pagesFireproof Area and Weight Calculationdraj18759770% (1)

- Handrail StandardsDocument4 pagesHandrail StandardsSachin SithikNo ratings yet

- Concrete SpallingDocument2 pagesConcrete SpallingnlalamNo ratings yet

- HangerDocument8 pagesHangerbnreddy1992No ratings yet

- Bunding and Spill Management - NSW EPADocument8 pagesBunding and Spill Management - NSW EPAPhilip LonerganNo ratings yet

- Numbering Changes of Existing StandardsDocument92 pagesNumbering Changes of Existing Standardszizitro100% (1)

- Monokote Mk6 - Hy TdsDocument2 pagesMonokote Mk6 - Hy TdsEngTamerNo ratings yet

- Acid Resistant Tiles BricksDocument6 pagesAcid Resistant Tiles BricksDeboline MitraNo ratings yet

- Bar ScheduleDocument2 pagesBar SchedulearctusharNo ratings yet

- Introduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Document12 pagesIntroduction To Fr-Acp (Fire Retardant Aluminum Composite Panels)Syed RaziuddinNo ratings yet

- Epoxy Floor Coating: Description FeaturesDocument2 pagesEpoxy Floor Coating: Description FeaturesRayon 9No ratings yet

- Cad Weld MSDSDocument5 pagesCad Weld MSDSKatari Murthy NaiduNo ratings yet

- 02 - WORLDBRIDGE - Aluminum Dome RoofDocument50 pages02 - WORLDBRIDGE - Aluminum Dome RoofALONSO GOMEZNo ratings yet

- Flexible Sprinkler HoseDocument7 pagesFlexible Sprinkler HoseSopi LabuNo ratings yet

- 9103 PDFDocument3 pages9103 PDFEong Huat Corporation Sdn BhdNo ratings yet

- High Hydraulic Gradient Per Contract Drawings: System Extension Permit JANUARY 2007Document2 pagesHigh Hydraulic Gradient Per Contract Drawings: System Extension Permit JANUARY 2007manojNo ratings yet

- Specification: Galvanized Iron Scaffold Tubes: Scaffold Tubes Used As Standard, Ledgers, Transoms, TieDocument2 pagesSpecification: Galvanized Iron Scaffold Tubes: Scaffold Tubes Used As Standard, Ledgers, Transoms, TiesalmanNo ratings yet

- What Is Bearing Pressure - Independent Design House LTDDocument6 pagesWhat Is Bearing Pressure - Independent Design House LTDCE Passaj100% (1)

- Inert Gas Fire SuppressionDocument3 pagesInert Gas Fire SuppressionTransgulfNo ratings yet

- Government Gazette - 18th October PADocument52 pagesGovernment Gazette - 18th October PAistructe100% (1)

- Fire Door SpecificationsDocument20 pagesFire Door SpecificationsGopalNo ratings yet

- Lecture On Fire Prevention PlanningDocument73 pagesLecture On Fire Prevention PlanningAsad MehboobNo ratings yet

- 100 cmx75 Cmx2cm-Angle + PinDocument9 pages100 cmx75 Cmx2cm-Angle + PinvtalexNo ratings yet

- Nfpa 20 PDFDocument7 pagesNfpa 20 PDFYashodhan Karkare100% (1)

- Ae-Landing ValveDocument2 pagesAe-Landing ValveAlvi Sarowar100% (1)

- Catalogo Equipos de Riego VyrDocument194 pagesCatalogo Equipos de Riego VyrRaul Yancce Riego Tecnificado100% (2)

- Minimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Document10 pagesMinimum Orifice Plate Thickness To Avoid Plastic Deformation (Buckling)Hadi VeyseNo ratings yet

- The Specialists in Industrial Flooring and Handrailing: Tubular StandardsDocument3 pagesThe Specialists in Industrial Flooring and Handrailing: Tubular StandardsHazim AffendiNo ratings yet

- Fire ProtectionDocument25 pagesFire ProtectionNIBEDITA DEY100% (2)

- Butt WeldingDocument4 pagesButt WeldingHürol KoçoğluNo ratings yet

- Scaffolding TubeDocument1 pageScaffolding TubeChíld Çhïññæ ÇøôlNo ratings yet

- Case StudyDocument12 pagesCase StudyvsrslmNo ratings yet

- Steel Design Formulas and Principles - CompressDocument6 pagesSteel Design Formulas and Principles - CompressClint SusarnoNo ratings yet

- 3.6 Active Fire ControlDocument33 pages3.6 Active Fire Controlmuchelia0% (1)

- Generator Set RoomsDocument7 pagesGenerator Set RoomsAnonymous TvOpvXNo ratings yet

- Norguard Eagle - Horizontal and Vertical Lifeline SystemsDocument4 pagesNorguard Eagle - Horizontal and Vertical Lifeline SystemsnorguardNo ratings yet

- AFSS-Commissioning & Testing..Document4 pagesAFSS-Commissioning & Testing..sanchezdreiNo ratings yet

- Technical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175Document85 pagesTechnical Data Sheet For HIT-HY-200 Injectable Mortar For Anchor and Rebar Technical Information ASSET DOC 2331175ing urbanNo ratings yet

- Isle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingDocument18 pagesIsle of Wight Fire & Rescue Service: Record of Fire Safety Equipment Testing Fire Drills & TrainingcaptalaaNo ratings yet

- Structural Details-Daudi MsikitiniDocument1 pageStructural Details-Daudi MsikitiniGideon ShakurNo ratings yet

- Code of Guidance For Storage of LPG CylindersDocument18 pagesCode of Guidance For Storage of LPG Cylinderskuraimund100% (1)

- Assembly Guide - HD AgrDocument26 pagesAssembly Guide - HD AgrAlNo ratings yet

- Raft 2Document17 pagesRaft 2Kushan Dhanushka NanayakkaraNo ratings yet

- Manhole Channel DesignDocument6 pagesManhole Channel DesignYoke ShuNo ratings yet

- Presentation MSCDocument10 pagesPresentation MSCMd. Mominul IslamNo ratings yet

- Risk Assessment and Safety Management Plan 1. Risk AssessmentDocument6 pagesRisk Assessment and Safety Management Plan 1. Risk AssessmentSaid Massinissa Elhadj AliNo ratings yet

- Ceiling Diaphragm PDFDocument4 pagesCeiling Diaphragm PDFreydudes9156No ratings yet

- Fire Protection For Structural SteelDocument8 pagesFire Protection For Structural SteelcheckshinlNo ratings yet

- Scaffolding Inside The Pre-Heater &: Cyclones CalcinerDocument23 pagesScaffolding Inside The Pre-Heater &: Cyclones CalcinerSuad BushiNo ratings yet

- List of BS CodesDocument33 pagesList of BS CodesRaj ChavanNo ratings yet

- HDPE Pipe InstallationDocument7 pagesHDPE Pipe InstallationJeferson Binay-an100% (1)

- CouplerDocument5 pagesCouplerabdul khader100% (1)

- Material Safety Data Sheet: MSDS: Lafarge Portland CementDocument6 pagesMaterial Safety Data Sheet: MSDS: Lafarge Portland Cementazer100% (1)

- Scaffolding Rental - One Oasis Cdo BLDG 2Document3 pagesScaffolding Rental - One Oasis Cdo BLDG 2Ronell SolijonNo ratings yet

- Standard Installation Clearances: Panel Length Panel Length Bearing BarsDocument1 pageStandard Installation Clearances: Panel Length Panel Length Bearing BarsFWICIPNo ratings yet

- DIN 3015 ClampsDocument17 pagesDIN 3015 ClampsKathirrasuNo ratings yet

- Beam Detailing: Section 8 SP: (S & T) - 1987Document23 pagesBeam Detailing: Section 8 SP: (S & T) - 1987Niraj ShindeNo ratings yet

- Calculation of Blast Loads Structural Components - JRC EU PDFDocument58 pagesCalculation of Blast Loads Structural Components - JRC EU PDFjntbrobalo100% (2)

- Comparison Between Welding in Chinese and American CodeDocument37 pagesComparison Between Welding in Chinese and American CodenalzackNo ratings yet

- TechnicalSplices PDFDocument3 pagesTechnicalSplices PDFengineer_atulNo ratings yet

- 2011 FZJZ 57Document6 pages2011 FZJZ 57rustamriyadiNo ratings yet

- Bolts CatalogueDocument88 pagesBolts CatalogueAnandh PsNo ratings yet

- Bolt Astm A36Document2 pagesBolt Astm A36nalzackNo ratings yet

- Easy Ergonomics For Desktop Computer UsersDocument40 pagesEasy Ergonomics For Desktop Computer UsersAlexandra AntipaNo ratings yet

- Producing Your Own EnzymesDocument37 pagesProducing Your Own EnzymessatiNo ratings yet

- Spinal Cord DetailDocument2 pagesSpinal Cord DetailnalzackNo ratings yet

- Product Design SpecificationDocument2 pagesProduct Design SpecificationCharlie100% (1)

- Arinc 600 Series: Rack & Panel Rectangular ConnectorsDocument48 pagesArinc 600 Series: Rack & Panel Rectangular Connectorstousif111No ratings yet

- L-05 Critical Activities Anp-2Document11 pagesL-05 Critical Activities Anp-2SamNo ratings yet

- Hub AppletonDocument2 pagesHub AppletonDavid JuyarNo ratings yet

- Triple Star Fire Catalogue Price List v2.5Document16 pagesTriple Star Fire Catalogue Price List v2.5pastorgeeNo ratings yet

- Exercises On Fracture MechanicsDocument33 pagesExercises On Fracture Mechanicsyaswanth199260% (5)

- Rotary Force Exciter Cell VZDocument4 pagesRotary Force Exciter Cell VZEduardo MendozaNo ratings yet

- 3046 Heavy Equipment Maintenance RepairDocument12 pages3046 Heavy Equipment Maintenance Repairام احمدNo ratings yet

- Dikin VRVDocument52 pagesDikin VRVahmedomar_953724702No ratings yet

- 5R110W Assembly PDFDocument16 pages5R110W Assembly PDFLuis VelazquezNo ratings yet

- Ibrahiiiiim Rep. Conradson Carbon ResidueDocument7 pagesIbrahiiiiim Rep. Conradson Carbon ResidueIbrahim Dewali100% (2)

- Group 5 - Sec D - MA - Shun ElectronicsDocument7 pagesGroup 5 - Sec D - MA - Shun ElectronicsYATIN BAJAJNo ratings yet

- 2016 Oshima AlGaO-GaO - Unintentional Doping DOPEDDocument4 pages2016 Oshima AlGaO-GaO - Unintentional Doping DOPEDakashNo ratings yet

- Helix Installation Manual Rev 002Document112 pagesHelix Installation Manual Rev 002Edgar Mendoza100% (2)

- Ferite CheckDocument16 pagesFerite CheckAli VarmazyarNo ratings yet

- Breathing-Air-Purifiers Atlas CapcoDocument6 pagesBreathing-Air-Purifiers Atlas CapcoVara PrasadNo ratings yet

- Sikagard - 701W: Alkylalkoxy Siloxane Micro-Emulsion Water Repellent ImpregnationDocument2 pagesSikagard - 701W: Alkylalkoxy Siloxane Micro-Emulsion Water Repellent Impregnationthe pilotNo ratings yet

- AMIE Sample Paper 2Document3 pagesAMIE Sample Paper 2skannan1980No ratings yet

- Ebarra Pump SpecsDocument13 pagesEbarra Pump SpecsLiz BargolaNo ratings yet

- Chapter 8 - Part A - Fully Developed Laminar Flow PDFDocument12 pagesChapter 8 - Part A - Fully Developed Laminar Flow PDFShubham ChoudharyNo ratings yet

- Science 5 Q1 WK7Document12 pagesScience 5 Q1 WK7ivy loraine enriquezNo ratings yet

- Hantemp Controls SSFL Bulletin WebDocument4 pagesHantemp Controls SSFL Bulletin WebVishalNo ratings yet

- Materials in Orthodontics / Orthodontic Courses by Indian Dental AcademyDocument124 pagesMaterials in Orthodontics / Orthodontic Courses by Indian Dental Academyindian dental academy100% (2)

- Transportation Research Part E: Ya-Jun Cai, Tsan-Ming Choi TDocument21 pagesTransportation Research Part E: Ya-Jun Cai, Tsan-Ming Choi TLucero CastañedaNo ratings yet

- Dehydration SugarDocument2 pagesDehydration SugarAyu Dara KharismaNo ratings yet

- Oscillating Magnetos Jack Beater 1940Document3 pagesOscillating Magnetos Jack Beater 1940Steven Howell0% (1)

- Basics in Turbomachinery&Gas TurbineDocument85 pagesBasics in Turbomachinery&Gas TurbineAhmed Adel IbrahimNo ratings yet

- Innoplus 1100J PDFDocument1 pageInnoplus 1100J PDFindahNo ratings yet

- Strainoptic Stress ManualDocument9 pagesStrainoptic Stress Manualjsrplc7952No ratings yet

- Steel Structure AssessmentDocument23 pagesSteel Structure AssessmentYudi Agung NugrohoNo ratings yet