Professional Documents

Culture Documents

Operation V N P T I 132

Uploaded by

Dhiraj SatyamOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation V N P T I 132

Uploaded by

Dhiraj SatyamCopyright:

Available Formats

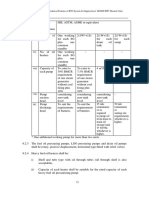

5.

6 EMERGENCY OPERATION

5.6.1 Stator water flow low Check expansion tank level is normal and drains

are closed.

Check position of recirculation value.

Check whether running pump has tripped. Re-

serve pump should start on Auto, if not start

manually.

Check differential pressure across the filter is

normal.

5.6.2 Stator water conductivity high Check D.M. water conductivity from the D.M. Plant.

If normal, then purge same water from system. If

D.M. tank Water conductivity is high then close

D.M. make up valve.

Check stator water cooler for leakage.

Regenerate-polishing unit resin beds & take it into

service.

5.6.3 Hydrogen pressure low Charge fresh hydrogen. If consumption is high

then investigate leaking points. If the pressure

persist to drop then reduce load on generator. If the

pressure can't be maintained then trip the set.

5.6.4 Hydrogen purity low Purge some hydrogen from casing and charge fresh

hydrogen.

Check seal performance is normal.

5.6.5 Seal oil differential high/low Check DPR is functioning normally. If not change

to the bypass line and get DPR attended.

Adjust the pressure at injector/ pump discharge.

5.6.6. Liquid in generator Open the low point drain of generator and check

nature and amount of leakage.

Check proper functioning of DPR.

Check thrust oil pressure.

Check stator water pressure.

5.6.7 Generator stator cooling water Check gas trap and analyse the gas from it. In case

leakage stator water leakage is suspected then shut down

the unit and attend the leak.

5.6.8 Damper tank level low Check DPR operation. If required open the bypass

valve and make up the level. If the level approaches

16w unit will trip.

145

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 2017CH01 Complex Engineering ProblemDocument9 pages2017CH01 Complex Engineering ProblemZohaib Ali100% (1)

- Environmental Planning Laws and AnalysisDocument4 pagesEnvironmental Planning Laws and AnalysisEdmond BakingNo ratings yet

- MEK - Methods 2520of 2520productionDocument4 pagesMEK - Methods 2520of 2520productionJob MateusNo ratings yet

- Super Critical Power - Part91Document1 pageSuper Critical Power - Part91Dhiraj SatyamNo ratings yet

- Super Critical Power - Part88Document1 pageSuper Critical Power - Part88Dhiraj SatyamNo ratings yet

- Super Critical Power - Part85Document1 pageSuper Critical Power - Part85Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part86Document1 pageSuper Critical Power - Part86Dhiraj SatyamNo ratings yet

- Chapter-10 Electrostatic Precipitator: 10.1 Design DataDocument1 pageChapter-10 Electrostatic Precipitator: 10.1 Design DataDhiraj SatyamNo ratings yet

- Super Critical Power - Part92Document1 pageSuper Critical Power - Part92Dhiraj SatyamNo ratings yet

- Super Critical Power - Part83Document1 pageSuper Critical Power - Part83Dhiraj SatyamNo ratings yet

- Super Critical Power - Part79Document1 pageSuper Critical Power - Part79Dhiraj SatyamNo ratings yet

- Super Critical Power - Part77Document1 pageSuper Critical Power - Part77Dhiraj SatyamNo ratings yet

- Super Critical Power - Part81Document1 pageSuper Critical Power - Part81Dhiraj SatyamNo ratings yet

- Super Critical Power - Part78Document1 pageSuper Critical Power - Part78Dhiraj SatyamNo ratings yet

- Super Critical Power - Part80Document1 pageSuper Critical Power - Part80Dhiraj SatyamNo ratings yet

- Suitable For Remote Manual OperationDocument1 pageSuitable For Remote Manual OperationDhiraj SatyamNo ratings yet

- Super Critical Power - Part58Document1 pageSuper Critical Power - Part58Dhiraj SatyamNo ratings yet

- Super Critical Power - Part76Document1 pageSuper Critical Power - Part76Dhiraj SatyamNo ratings yet

- Super Critical Power - Part62Document1 pageSuper Critical Power - Part62Dhiraj SatyamNo ratings yet

- Super Critical Power - Part61Document1 pageSuper Critical Power - Part61Dhiraj SatyamNo ratings yet

- Super Critical Power - Part54Document1 pageSuper Critical Power - Part54Dhiraj SatyamNo ratings yet

- Super Critical Power - Part71Document1 pageSuper Critical Power - Part71Dhiraj SatyamNo ratings yet

- Super Critical Power - Part60Document1 pageSuper Critical Power - Part60Dhiraj SatyamNo ratings yet

- Super Critical Power - Part57Document1 pageSuper Critical Power - Part57Dhiraj SatyamNo ratings yet

- Super Critical Power - Part59Document1 pageSuper Critical Power - Part59Dhiraj SatyamNo ratings yet

- Super Critical Power - Part56Document1 pageSuper Critical Power - Part56Dhiraj SatyamNo ratings yet

- Super Critical Power - Part50Document1 pageSuper Critical Power - Part50Dhiraj SatyamNo ratings yet

- Super Critical Power - Part48Document1 pageSuper Critical Power - Part48Dhiraj SatyamNo ratings yet

- Super Critical Power - Part52Document1 pageSuper Critical Power - Part52Dhiraj SatyamNo ratings yet

- Super Critical Power - Part53Document1 pageSuper Critical Power - Part53Dhiraj SatyamNo ratings yet

- Super Critical Power - Part49Document1 pageSuper Critical Power - Part49Dhiraj SatyamNo ratings yet

- Super Critical Power - Part47Document1 pageSuper Critical Power - Part47Dhiraj SatyamNo ratings yet

- Environment & Ecosystem Notes PDFDocument26 pagesEnvironment & Ecosystem Notes PDFK 309 Divya ChaudharyNo ratings yet

- Environmental Risk Aug enDocument26 pagesEnvironmental Risk Aug enRuxandra TudorașcuNo ratings yet

- Andrew Pravin - Field OperatorDocument6 pagesAndrew Pravin - Field OperatorVenkatesh VaradarajanNo ratings yet

- ATU / SBR Systems: RuralDocument2 pagesATU / SBR Systems: RuralMarcel MrcNo ratings yet

- Jamia Millia Islamia: Development of Dams in IndiaDocument13 pagesJamia Millia Islamia: Development of Dams in IndiaAnugya JhaNo ratings yet

- Introductory Thermal Physics Worksheets and SolutionsDocument30 pagesIntroductory Thermal Physics Worksheets and SolutionsLetmiDwiridalNo ratings yet

- CBSE 8, Science, CBSE-Materials-metals and Non-Metals, NCERT SolutionsDocument3 pagesCBSE 8, Science, CBSE-Materials-metals and Non-Metals, NCERT SolutionsSoumitraBagNo ratings yet

- Notice: Environmental Statements Availability, Etc.: Cape Cod Water Resources Restoration Project, MADocument2 pagesNotice: Environmental Statements Availability, Etc.: Cape Cod Water Resources Restoration Project, MAJustia.comNo ratings yet

- Catalogo KomibrightDocument5 pagesCatalogo KomibrightJonathan BedoyaNo ratings yet

- Chapter Three - Sources of WaterDocument75 pagesChapter Three - Sources of WaterBEZU A.GERESUNo ratings yet

- Isol Job Reference 2008-2017 PDFDocument9 pagesIsol Job Reference 2008-2017 PDFAbu Zafeera Saqib SipahiNo ratings yet

- Western Australian Water in Mining Guideline: Water Licensing Delivery Series Report No. 12 May 2013Document75 pagesWestern Australian Water in Mining Guideline: Water Licensing Delivery Series Report No. 12 May 2013Rob LauchlanNo ratings yet

- Line Sizing GuidelinesDocument6 pagesLine Sizing GuidelinesvishnuprasadNo ratings yet

- Concoctions and FertilizersDocument43 pagesConcoctions and FertilizersalexontingNo ratings yet

- Impact of Population On EnviornmentDocument47 pagesImpact of Population On EnviornmentMansi SinghNo ratings yet

- Gokilaht (2012)Document5 pagesGokilaht (2012)rei estacioNo ratings yet

- NSTP NotesDocument14 pagesNSTP NotesA 3No ratings yet

- 8 4 Carlo MangiaDocument21 pages8 4 Carlo MangiayuniNo ratings yet

- Solution Manual For Fundamentals of Law Office Management 5th EditionDocument38 pagesSolution Manual For Fundamentals of Law Office Management 5th Editionwarepneumomxkhf100% (15)

- Tutor Marked Assignment Course Code: BEVAE-181 Assignment Code: BEVAE-181/TMA/2020-21Document26 pagesTutor Marked Assignment Course Code: BEVAE-181 Assignment Code: BEVAE-181/TMA/2020-21IGNOU ASSIGNMENT100% (1)

- MSDS Ammonium Hydroxide PDFDocument1 pageMSDS Ammonium Hydroxide PDFciscaNo ratings yet

- Sea Transport of Liquid Chemicals in Bulk PDFDocument131 pagesSea Transport of Liquid Chemicals in Bulk PDFDiana MoralesNo ratings yet

- Msds Unioleo ChemicalDocument8 pagesMsds Unioleo ChemicalB4nt3nNo ratings yet

- Green Water On Ship-Type Offshore Structures: Bas BuchnerDocument284 pagesGreen Water On Ship-Type Offshore Structures: Bas BuchnerNANTHAKUMAR GANESANNo ratings yet

- Blackwater EstuaryDocument7 pagesBlackwater EstuaryLauraNo ratings yet

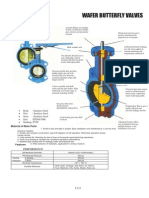

- Wafer Butterfly ValvesDocument2 pagesWafer Butterfly ValvesSandi AslanNo ratings yet

- Ecological Riverfront DesignDocument146 pagesEcological Riverfront Designsakthivisalakshi100% (2)