0% found this document useful (0 votes)

95 views21 pages1 Laundry Audit1

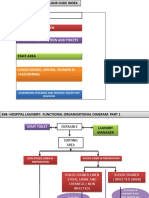

The document describes a laundry audit for an infection control service. It outlines standards and procedures for handling, transporting, washing, and storing linen to prevent the spread of infection. Checklists are provided to audit compliance with best practices for cleanliness, protective equipment, and waste disposal in receiving, sorting, washing, and storage areas.

Uploaded by

Sea GateCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

95 views21 pages1 Laundry Audit1

The document describes a laundry audit for an infection control service. It outlines standards and procedures for handling, transporting, washing, and storing linen to prevent the spread of infection. Checklists are provided to audit compliance with best practices for cleanliness, protective equipment, and waste disposal in receiving, sorting, washing, and storage areas.

Uploaded by

Sea GateCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as DOC, PDF, TXT or read online on Scribd