Professional Documents

Culture Documents

TTB CTR 20 DS 001 A4 Rev.0 DS For Premium Storage Tank

Uploaded by

Iman Rahmatullah0 ratings0% found this document useful (0 votes)

38 views3 pagesDoc

Original Title

TTB CTR 20 DS 001 A4 Rev.0 DS for Premium Storage Tank

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentDoc

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

38 views3 pagesTTB CTR 20 DS 001 A4 Rev.0 DS For Premium Storage Tank

Uploaded by

Iman RahmatullahDoc

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

DOCUMENT NO.

:

DATA SHEET FOR PREMIUM

STORAGE TANK TTB-CTR-20-DS-001-A4

PAGE : 3 of 4

PROJECT NAME : JOB NO.

PEMBANGUNAN TBBM TEGAL BARU

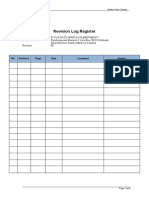

0 18-Apr-17 MLY ISSUED FOR APPROVAL DATE REVISION

REV. DATE BY DESCRIPTION 18-Apr-17 0

TAG NO. : T-TGL-100 A/B CONTRACTOR COMPANY

SERVICE : PREMIUM STORAGE TANK ORIGINATOR: CHECKED: APPROVED: APPROVED:

MLY GK SH

1 Applicable to : Proposal Purchase As Built

2 Quantity : 2 set

3 Manufacturer : Barata Indonesia

4 DESIGN DATA MATERIAL

5 Service Premium Storage Tank Part Material Spec (Note 8.)

6 Liquid Flash Point o

C 43 Shell ASTM A-573 Gr. 70

7 Code API 650 12th Ed.2013 Bottom ASTM A-283 Gr. C

8 Temperature Design C 60 Roof ASTM A-283 Gr. C

9 Operating C 35 Reinforcing pads ASTM A-573 Gr. 70

10 Pressure Flange ASTM A-105

11 Design kg/cm2 Full of Liquid Nozzle pipes ASTM A-106 Gr. B

12 Operating kg/cm2 Atmosphere Earthing lugs ASTM A-36

13 Hydrotest Pressure kg/cm2 Full of Water Platform, ladder, pipe clip ASTM A-36

14 MAWP kg/cm2 As per code Structure - tower ASTM A-36

15 Capacity Support beam ASTM A-36

16 Nominal m3 3000 Platform grating Note 6.

17 Working m3 2670 Handrail Galvanized Pipe

18 Tank Type Cylindrical Saddle N/A

19 Tank Dimension Inlet Baffle N/A

20 Diameter mm 21000 Internal Pipe ASTM A-106 Gr. B

21 Height / Length mm 9000 Internal Ladder ASTM A-36

22 Corrosion Allowance mm 3 Stiffening Ring ASTM A-36

23 Wall Thickness Base Ring / Plate ASTM A-36

24 Shell minimum mm 6 External Attachment

25 Bottom minimum mm 10 Support beam ASTM A-36

26 Roof minimum mm 8 Grating Note 6.

27 Weld Joint Efficiency Ladder ASTM A-36

28 Shell 0.85 Nameplate 304 SS

29 Bottom 0.85 Bracket ASTM A-573 Gr. 70

30 Roof 0.85 External

31 Non Destructive Test SHELL BOTTOM ROOF Bolts SA 193 Gr. B7 Flouro Carbon

32 Radiography Note 3. Note 3. Note 3. Nuts SA 194 Gr. 2H Flouro Carbon

33 Ultrasonic Note 3. Note 3. Note 3. Gasket Spiral Wound 316 SS Graphite Filler

34 Magnetic Particle Note 3. Note 3. Note 3. Internal

35 Dye Penetrant Note 3. Note 3. Note 3. Bolts N/A

36 PWHT N/A Nuts N/A

37 Insulation mm N/A Material impact test required No

38 Fire Proofing mm N/A Certified low temp. test req. No

39 Painting Note 9. CONSTRUCTION

40 External Yes Type of Bottom Fall at center, Slope 1:120

41 Internal No Type of Roof Fixed Cone Roof

42 Seismic Design as per SNI 1726 - 2012 Internal Floating Roof No

43 Seismic Zone G 0.25 Type of Support N/A

44 Wind Code ASCE Latest Ed. Platform, ladder, pipe clip Circular Ladder

45 Wind Speed km/hr 130 Insulation ring clip No

46 ESTIMATED WEIGHT Manhole Yes

47 Empty (incl. attached piping) ton 72.23 Earthing lugs Yes

48 Shipping Approx. ton - Lifting Lugs - eyes No

49 Operating Approx. ton 2443.12 Nameplate Yes

50 Shop Test Approx. ton 3189.47 Foundation Concrete

51 Roof handrail Yes

52 Setting bolts SA193 Gr.B7 Hot Dipped Galvanized

53 Code stamp No

54

55

56

DOCUMENT NO.:

DATA SHEET FOR PREMIUM

STORAGE TANK TTB-CTR-20-DS-001-A4

PAGE : 4 of 4

PROJECT NAME : JOB NO.

PEMBANGUNAN TBBM TEGAL BARU

0 18-Apr-17 MLY ISSUED FOR APPROVAL DATE REVISION

REV. DATE BY DESCRIPTION 18-Apr-17 0

TAG NO. : T-TGL-100 A/B CONTRACTOR COMPANY

SERVICE : PREMIUM STORAGE TANK ORIGINATOR: CHECKED: APPROVED: APPROVED:

MLY GK SH

1 CONSTRUCTION DETAILS (CONTINUED)

2

3 SCHEDULE OF APPURTENANCES

4

5 SIZE ANSI FLANGE REMARKS

MARK DESCRIPTION QTY.

6 (in) CLASS TYPE

7 N1 Inlet Nozzle 1 6 #150 RFWN From Premium unloading pump

8 N2 Outlet Nozzle 1 16 #150 RFWN To Premium loading pump

9 N3 Pressure Indicator Transmitter 1 2 #150 RFWN

10 N4A Level Switch Low Level 1 1 2 #150 RFWN

11 N4B Level Switch Low Level 2 1 2 #150 RFWN

12 N5A Level Switch High High 1 1 2 #150 RFWN

13 N5B Level Switch High High 1 1 2 #150 RFWN

14 N6A Drain 1 4 #150 RFWN To Premium closed drain

15 N6B Drain 1 4 #150 RFWN To Premium open drain

15 N7 Spare 1 4 #150 RFWN c/w Blind Flange

16 N8 Level Indicator Transmitter 1 6 #150 RFWN c/w Stilling Well

17 N9 Temperature Indicator 1 2 #150 RFWN c/w Thermowell

18 N10 Slot Dipping Device 1 3 #150 RFWN c/w Gauge hatch

19 MH1A/B Manhole 1 24 #150 RFWN c/w Davit

20 MH2A/B Roof Manhole 1 24 #150 RFWN c/w Davit, MH2B c/w emergency vent

21 V1 PVV 1 8 #150 RFWN Breather valve

22

V1

23

24 N9 N10

25 N8 M2

26

27

28

29

30 N5A

31

32

33

34 N3 N4A N5B

35

N7

36

37

38 N4B N2

N1

39 M1 N6B

40

N6A

41

42

1

43 120

44

45 Notes : 1. Specification for this tank should be refer to TTB-CTR-20-SP-001-A4, General Specification for Storage Tank

46 2. All materials used in construction, fabrication and assembly shall conform to all applicable ANSI and ASTM listed publications.

47 3. All weld joints must conform to the applicable listed AWS publications & API 650 12 th ed. 2013

48 4. All tank connections shall conform to ANSI B16.5

49 5. Refer to API 650 12 th ed. 2013

50 6. Grating should be hot dip galvanized

51 7. Tank fabricator / manufacturer should determined details engineering stage before construction phase

52 8. Refer to ASTM materials standard

53 9. Project Specification TTB-CTR-40-SP-003-A4 General Specification for Painting and Protective Coating

54

55

56

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Keepa ApiDocument55 pagesKeepa ApiQazi Sohail AhmadNo ratings yet

- Roundtracer Flash En-Us Final 2021-06-09Document106 pagesRoundtracer Flash En-Us Final 2021-06-09Kawee BoonsuwanNo ratings yet

- Tabel Baja-Besi-HollowDocument11 pagesTabel Baja-Besi-HollowIman Rahmatullah100% (3)

- Concrete Box Culvert Design Based On AASHTO 17th & ACI 318-14Document6 pagesConcrete Box Culvert Design Based On AASHTO 17th & ACI 318-14Iman RahmatullahNo ratings yet

- LG001 Csa Cal 026Document89 pagesLG001 Csa Cal 026Iman RahmatullahNo ratings yet

- Calculation Sheet Gantry Tower Gi 150kv Ambalut Extension - Rev1.0Document191 pagesCalculation Sheet Gantry Tower Gi 150kv Ambalut Extension - Rev1.0Iman RahmatullahNo ratings yet

- Pipa 4 Inch: ID Diameter Dalam 101.6 MM Ds Diameter Luar Tcorr Tebal Corrosion Coating TCC Tebal Concrete CoatingDocument1 pagePipa 4 Inch: ID Diameter Dalam 101.6 MM Ds Diameter Luar Tcorr Tebal Corrosion Coating TCC Tebal Concrete CoatingIman RahmatullahNo ratings yet

- AfesDocument52 pagesAfesIman RahmatullahNo ratings yet

- Afes Calc. of Found. Diesel Oil TankDocument52 pagesAfes Calc. of Found. Diesel Oil TankIman RahmatullahNo ratings yet

- Single Pile Capacity-R1Document401 pagesSingle Pile Capacity-R1Iman RahmatullahNo ratings yet

- Datasheet - Ewon Cosy 131Document3 pagesDatasheet - Ewon Cosy 131Omar AzzainNo ratings yet

- Dual Nature of Radiation and MatterDocument5 pagesDual Nature of Radiation and Mattercopadag753No ratings yet

- Civil Engineering Construction Manager in ST Louis MO Resume Mark JensenDocument3 pagesCivil Engineering Construction Manager in ST Louis MO Resume Mark JensenMark JensenNo ratings yet

- AI LabDocument17 pagesAI LabTripti JainNo ratings yet

- Basic Customer Service SkillsDocument90 pagesBasic Customer Service SkillsGillian Delos ReyesNo ratings yet

- 9.LearnEnglish Writing A2 Instructions For A Colleague PDFDocument5 pages9.LearnEnglish Writing A2 Instructions For A Colleague PDFوديع القباطيNo ratings yet

- 2-Amino-5-Aryl-2-Oxazolines.: (,ee TableDocument7 pages2-Amino-5-Aryl-2-Oxazolines.: (,ee TableChristopher HowellNo ratings yet

- Soil ResistivityDocument6 pagesSoil ResistivityAnonymous EP0GKhfNo ratings yet

- RCU II Open Protocol Communication Manual FV 9 10 31 08 PDFDocument17 pagesRCU II Open Protocol Communication Manual FV 9 10 31 08 PDFAndrés ColmenaresNo ratings yet

- WestIntroToSSB PDFDocument100 pagesWestIntroToSSB PDFnaval_05No ratings yet

- Micron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesDocument92 pagesMicron Serial NOR Flash Memory: 3V, Multiple I/O, 4KB Sector Erase N25Q256A FeaturesAENo ratings yet

- Libra Office Question Answer EnglishDocument11 pagesLibra Office Question Answer EnglishAndrew ParkarNo ratings yet

- Syllabus Financial AccountingDocument3 pagesSyllabus Financial AccountingHusain ADNo ratings yet

- Coca-Cola BeverageDocument17 pagesCoca-Cola BeverageMahmood SadiqNo ratings yet

- Technik: RefraDocument54 pagesTechnik: Reframustaf100% (1)

- Improving Radar Echo Lagrangian Extrapolation Nowcasting by Blending Numerical Model Wind Information: Statistical Performance of 16 Typhoon CasesDocument22 pagesImproving Radar Echo Lagrangian Extrapolation Nowcasting by Blending Numerical Model Wind Information: Statistical Performance of 16 Typhoon CasesLinh DinhNo ratings yet

- ShowimgDocument76 pagesShowimgROSHAN ROBERTNo ratings yet

- Shock Cat 2009Document191 pagesShock Cat 2009gersonplovasNo ratings yet

- Ed508-5e-Lesson-Plan-Severe Weather EventsDocument3 pagesEd508-5e-Lesson-Plan-Severe Weather Eventsapi-526575993No ratings yet

- Sri Anjaneya Cotton Mills LimitedDocument63 pagesSri Anjaneya Cotton Mills LimitedPrashanth PB50% (2)

- Public Economics - All Lecture Note PDFDocument884 pagesPublic Economics - All Lecture Note PDFAllister HodgeNo ratings yet

- Effect of Different Laser Texture Configurations On Improving Surface Wettability and Wear Characteristics of Ti6Al4V Implant MaterialDocument14 pagesEffect of Different Laser Texture Configurations On Improving Surface Wettability and Wear Characteristics of Ti6Al4V Implant Materialnitish kumar100% (1)

- Colony Earth - Part X: The Myriad WorldsDocument7 pagesColony Earth - Part X: The Myriad WorldsV. Susan FergusonNo ratings yet

- Battle Group Builder + Commonwealth Infantry Roster - Wargames DesignDocument12 pagesBattle Group Builder + Commonwealth Infantry Roster - Wargames DesignPete PoliNo ratings yet

- Pre-Colonial Philippine ArtDocument5 pagesPre-Colonial Philippine Artpaulinavera100% (5)

- 2015.15009.fundamental Principles of Physical Chemistry - Text PDFDocument782 pages2015.15009.fundamental Principles of Physical Chemistry - Text PDFAnoif Naputo Aidnam100% (1)

- Barista TestDocument7 pagesBarista Testwinnie chanNo ratings yet

- Sari Sari Store in Tabango Leyte The Business Growth and Its Marketing Practices 124 PDF FreeDocument11 pagesSari Sari Store in Tabango Leyte The Business Growth and Its Marketing Practices 124 PDF FreeJim Ashter Laude SalogaolNo ratings yet