Professional Documents

Culture Documents

Install Instr BTS PF Package Rev11-00

Uploaded by

HugoSalido0 ratings0% found this document useful (0 votes)

3 views4 pages08083293 Install Instr BTS PF Package Rev11-00

Original Title

08083293 Install Instr BTS PF Package Rev11-00

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Document08083293 Install Instr BTS PF Package Rev11-00

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

3 views4 pagesInstall Instr BTS PF Package Rev11-00

Uploaded by

HugoSalido08083293 Install Instr BTS PF Package Rev11-00

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 4

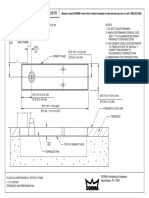

INSTALLATION INSTRUCTIONS

BTS 75V/P, 80/P X 75520 POCKET PIVOT,

BTS 75V/PF, 80/PF xX 75523 POCKET Pivot Ae

SURFACE APPLIED TRACK DORMA

Slide washer over tapered square ‘SPINDLE

‘end of spindle unt fully seated SCREW

in-groove. Fasten spindle. wi

spindle screw provided. Tighten

securely with Smm HEX K SPINDLE

“_/ WASHER

SS

NOTE: RIGHT HAND DOOR SHOWN.

(LH Door) : LEFT HAND IS A MIRROR IMAGE.

ww)

~ 3 _ OFFSET —__ ee

'SPINOLES Te)

Orient arm so ongle of slot oppears os shown

Attach ide block to arm with shoulder screw

provided

Ee SHOULDER SCREW

ae SUDE BLOCK

a ne

{|

(RH DOOR) |} (LH D00R) ;

Talal closer i Toor @ 5€

CRITICAL ‘a ar

Top of cement case must be flush with FINISHED

floor, Cement cose must be LEVEL. ond installed Side orm ossembly into track ond Install track

PERPENDICULAR to frame. Spindle center line must to door with screws possing through end blocks.

be accurately located. Grout cement case in place.

END BLOCK

es END BLOCK

commen! pou ssSeue.s

1 (08083293 11/00

Close both closing speed valves. Align spindle

[ET ceee.uety, closing speed step fac >

controls latch speed trom opprox. 20'—0.

Lr — Controls sweep speed from approx. 90°~20"

ar vaio "Borla clocks, Door

(RH DOOR) (LH D00R) Allow for opprox..#" fall oway when. consid~

tring hold open’ positon. To release door

matualy pull dose cloned 'o few inches,

controls position of latch range. Clockwise

tums increase latch range tove maximum

of 45-0". Counterclockwise tums” decrease

latch range toc minimum of 0"

A

Pisce orm over apindle, Seat arm properly on

Spindle by lapping mits’ hemmer, intel cover

BTS _80F

VALVE “A"= controls closing speed from approx. 90'-C"

Clockwise turns decrease closing speed

Counterciockwise turns increase closing speed.

VALVE "B"— increases closing speed from approx. 7*-0"

Gounterclockwise turns increase closing speed

Clockwise turns return speed to that Set! by

Glosng epeed CG.

controls closing speed from 90-70"

controls closing speed from approx. 70°-0".

CRITICAL

Adjust spring tension, if required,

‘according to the chart.

+

DOOR WIDTH FULL_TURNS

EXTERIOR, INTERIOR OF “SPRING

INCHES] (MM)_[INCHES| (WM)_| ADJUSTING NUT]

rs75v [NCH oe mp

2=8r | ye s=0" | are &

por Data 136" | 1067 2

NOTE: “MAX. 12 TURNS FROM MINIMUM SETTING’.

CONTINUED..

Sealing compound (Optional)

Seoling compound is recommended for exterior

doors or areas with excessive moisture. Make all

final adjustments before adding compound. Refer

to instructions packed with compound for full

detoiis,

BTS 80 3-1/8 (78)

BIS 75V 3-174 (82)

SEE NOTE #7

Trim cover plate os required ond fasten

with four screws provided. Press tab into

place behind closer.

1-3/4" THICK ONLY

1/4

(286)

D0 NOT SCALE DRAWING.

INCHES

OMENSIONS ARE IN MET

RIGHT HAND DOOR SHOWN.

MAXIMUM OPENING $0"

SPINDLE No, 80003 SHOWN. FOR APPLICATIONS:

WITH THRESHOLDS USE SPINDLE No. 80012 AND,

AOD 1/2" TO VERTICLE DIMENSIONS’ NOTED.

FOR DOORS HUNG ON DORA 75520/75523, DOROMATIC

91105/91105F OR RIXSON 519 POCKET PIVOTS,

MINIMUM POCKET DEPTH 4~1/2"

SEX NUTS ARE RECOMMENDED FOR ATTACHMENT

OF COMPONENTS ON UNREINFORCED, COMPOSITE,

OR LABELED FIRE DOORS.

OVEL HOS YOOT NI SITOH (Z) OML

TIRG 8/2 3SN SLAN X3S x

Tila ,2¢/s_3sN_G3GIAONE SMa¥OS GOOM wi

Tiida ZON 3SN SMBYOS SNIHOWN OZ-+/1 YOS

SNM 40014 G3HSINIS aWvad 40 3903

/i-ti = Age Sie

91/L-€1 — 08 SiB

NOUISOd 035079

NI NMOHS 3000,

(os) z - ase sus

(09) 8/e-z — 08 sie

f

4OOTd O3HSIN

ONIN3GO_ YOO)

40 NOWORBIC

FNGNdS ¢o008'

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 16 Measurement and ControlsDocument4 pages16 Measurement and ControlsHugoSalidoNo ratings yet

- 17 Engineering EconomicsDocument7 pages17 Engineering EconomicsM Hadianto WaruwuNo ratings yet

- Environmental engineering guideDocument23 pagesEnvironmental engineering guideFaiqoh NahareyNo ratings yet

- 15 Computer SpreadsheetsDocument1 page15 Computer SpreadsheetsHugoSalidoNo ratings yet

- Ethics: Model Rules, Section 240.15, Rules of Professional ConductDocument2 pagesEthics: Model Rules, Section 240.15, Rules of Professional ConductHugoSalidoNo ratings yet

- Biology Cell Structure and Catabolic PathwaysDocument9 pagesBiology Cell Structure and Catabolic PathwaysHugoSalidoNo ratings yet

- Statics: Force Centroids of Masses, Areas, Lengths, and VolumesDocument5 pagesStatics: Force Centroids of Masses, Areas, Lengths, and VolumesHugoSalidoNo ratings yet

- Heat Transfer FundamentalsDocument6 pagesHeat Transfer FundamentalsMuhammad FahadNo ratings yet

- Chemistry: Acids, Bases, and PHDocument4 pagesChemistry: Acids, Bases, and PHHugoSalidoNo ratings yet

- BTS Accessories 4-14rp3-15 Lo PDFDocument16 pagesBTS Accessories 4-14rp3-15 Lo PDFHugoSalidoNo ratings yet

- Fluid MechanicsDocument11 pagesFluid Mechanicsjhc1123No ratings yet

- 11 Transport PhenomenaDocument1 page11 Transport PhenomenaTarek MonierNo ratings yet

- BTS-26 Install Instr 3-4 Offset ThresholdDocument2 pagesBTS-26 Install Instr 3-4 Offset ThresholdHugoSalidoNo ratings yet

- MECHANICS OF MATERIALS stress-strainDocument7 pagesMECHANICS OF MATERIALS stress-strainHugoSalidoNo ratings yet

- Bts TMP A B G H PackagesDocument3 pagesBts TMP A B G H PackagesHugoSalidoNo ratings yet

- bts-86 Install Instr BTS Center Hung Terrazzo Pan PDFDocument2 pagesbts-86 Install Instr BTS Center Hung Terrazzo Pan PDFHugoSalidoNo ratings yet

- 3 MathematicsDocument12 pages3 MathematicsHugoSalidoNo ratings yet

- BTS-27 Install Instr 1 1-2 ThresholdDocument2 pagesBTS-27 Install Instr 1 1-2 ThresholdHugoSalidoNo ratings yet

- BTS-28 Install Instr Center Hung ThresholdDocument2 pagesBTS-28 Install Instr Center Hung ThresholdHugoSalidoNo ratings yet

- BTS-28 Install Instr Center Hung Threshold PDFDocument2 pagesBTS-28 Install Instr Center Hung Threshold PDFHugoSalidoNo ratings yet

- Floor-Concealed Door Closers for Thin Concrete InstallationsDocument8 pagesFloor-Concealed Door Closers for Thin Concrete InstallationsHugoSalidoNo ratings yet

- Bts-78 Install Instr BTS 3-4 Offset Cement CaseDocument1 pageBts-78 Install Instr BTS 3-4 Offset Cement CaseHugoSalidoNo ratings yet

- BTS-88 Install Instr I Package ThresholdDocument2 pagesBTS-88 Install Instr I Package ThresholdHugoSalidoNo ratings yet

- Bts-77 Install Instr BTS Center Hung Cement CaseDocument1 pageBts-77 Install Instr BTS Center Hung Cement CaseHugoSalidoNo ratings yet

- Bts-86 Install Instr BTS Center Hung Terrazzo PanDocument2 pagesBts-86 Install Instr BTS Center Hung Terrazzo PanHugoSalidoNo ratings yet

- TMP Bts Terrazzo Rev0809Document2 pagesTMP Bts Terrazzo Rev0809HugoSalidoNo ratings yet

- BTS-79 Install Instr BTS 1 1-2 Offset Cement CaseDocument4 pagesBTS-79 Install Instr BTS 1 1-2 Offset Cement CaseHugoSalidoNo ratings yet