Professional Documents

Culture Documents

Column Jacketing

Column Jacketing

Uploaded by

Kevin Ongjunco0 ratings0% found this document useful (0 votes)

14 views3 pagesColumn Jacketing

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentColumn Jacketing

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views3 pagesColumn Jacketing

Column Jacketing

Uploaded by

Kevin OngjuncoColumn Jacketing

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

Strengthening of reinforced concrete columns is needed when:

1. The load carried by the column is increased due to either increasing the number of floors or due to

mistakes in the design.

2. The compressive strength of the concrete or the percent and type of reinforcement are not according to

the codes requirements.

3. The inclination of the column is more than the allowable.

4. The settlement in the foundation is more than the allowable.

There are two major techniques for strengthening reinforced concrete columns:

1 REINFORCED CONCRETE JACKET

The size of the jacket and the number and diameter of the steel bars used in the jacketing process depend

on the structural analysis that was made to the column.

In some cases, before this technique is carried out, we need to reduce or even eliminate temporarily the

loads applied to the column; this is done by the following steps:

Putting mechanical jacks between floors.

Putting additional props between floors.

Moreover, in some cases, where corrosion in the reinforcement steel bars was found, the following steps

should be carried out:

Remove the concrete cover.

Clean the steel bars using a wire brush or sand compressor.

Coat the steel bars with an epoxy material that would prevent corrosion.

If there was no need for the previous steps, the jacketing process could start by the following steps:

1. Adding steel connectors into the existing column in order to fasten the new stirrups of the jacket in

both the vertical and horizontal directions at spaces not more than 50cm.Those connectors are added into

the column by making holes 3-4mm larger than the diameter of the used steel connectors and 10-15cm

depth.

2. Filling the holes with an appropriate epoxy material then inserting the connectors into the holes.

3. Adding vertical steel connectors to fasten the vertical steel bars of the jacket following the same

procedure in step 1 and 2.

4. Installing the new vertical steel bars and stirrups of the jacket according to the designed

dimensions and diameters.

5. Coating the existing column with an appropriate epoxy material that would guarantee the bond

between the old and new concrete.

6. Pouring the concrete of the jacket before the epoxy material dries. The concrete used should be of

low shrinkage and consists of small aggregates, sand, cement and additional materials to prevent

shrinkage.

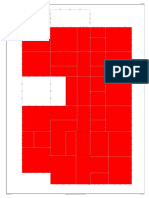

The previous steps are illustrated in Fig 1.

Fig:1. Increasing the cross-sectional area of column by RC jacketing.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1093)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Draft Structural Layout and Details Leading To Technical Drafting NC II PDFDocument46 pagesDraft Structural Layout and Details Leading To Technical Drafting NC II PDFEdgar G. Dela Rosa100% (1)

- Remote Radiator Systems For Generator SetsDocument2 pagesRemote Radiator Systems For Generator SetsJohn P KNo ratings yet

- Workshop Notes Supervision Bored Piles PDFDocument75 pagesWorkshop Notes Supervision Bored Piles PDFkevinyulive.com.sgNo ratings yet

- Technical Specification For 35-5T EOT Crane Nalco 27012021-2021-02-09-03-53-40Document208 pagesTechnical Specification For 35-5T EOT Crane Nalco 27012021-2021-02-09-03-53-40Avinash GuptaNo ratings yet

- Asian CatalogueDocument18 pagesAsian CatalogueAvinash GuptaNo ratings yet

- Electrical: Mep Project Progress ReportDocument11 pagesElectrical: Mep Project Progress ReportAvinash GuptaNo ratings yet

- Stadium Construction Progress Report Number 16, 02.24.11 PDFDocument16 pagesStadium Construction Progress Report Number 16, 02.24.11 PDFAvinash GuptaNo ratings yet

- Hindalco Everlast B2B BrochureDocument6 pagesHindalco Everlast B2B BrochureAvinash GuptaNo ratings yet

- DR Fixit Pidiseal PS 41G and 42P 112 1Document4 pagesDR Fixit Pidiseal PS 41G and 42P 112 1Avinash GuptaNo ratings yet

- Bar Bending ScheduleDocument8 pagesBar Bending ScheduleAvinash GuptaNo ratings yet

- Sawdust ConcreteDocument23 pagesSawdust ConcreteAvinash Gupta100% (1)

- Manufacturing Torkari Bar HB Wires NailsDocument3 pagesManufacturing Torkari Bar HB Wires NailsAvinash Gupta100% (1)

- Sap2000 18.1Document1 pageSap2000 18.1Avinash GuptaNo ratings yet

- Steel Structures: Engr. Dr. Muhammad AslamDocument29 pagesSteel Structures: Engr. Dr. Muhammad AslamArslan RaoNo ratings yet

- WS3-Chapter 10 Room Relationships and SizesDocument2 pagesWS3-Chapter 10 Room Relationships and SizesJCNo ratings yet

- Saginomiya CatalogS - Automatic ControlsDocument128 pagesSaginomiya CatalogS - Automatic Controlskepe81No ratings yet

- WELL Certification Guidebook PDFDocument20 pagesWELL Certification Guidebook PDFtao0% (1)

- Design of Lifting Hook: Earth Fill Load (Dl2)Document21 pagesDesign of Lifting Hook: Earth Fill Load (Dl2)Asaru DeenNo ratings yet

- MD-1 MCQsDocument9 pagesMD-1 MCQsyuvraj PrajapatiNo ratings yet

- Manual MSB Sanitary Container 190408Document57 pagesManual MSB Sanitary Container 190408Егор ГоряевNo ratings yet

- Sabp A 057 PDFDocument11 pagesSabp A 057 PDFWalid MegahedNo ratings yet

- Seven Inch Borewell Submersible Pump Sets: Instruction & Operating ManualDocument38 pagesSeven Inch Borewell Submersible Pump Sets: Instruction & Operating ManualUNITY LEARN100% (1)

- Mechanical Properties of Philippine Wood: Working Stresses of Philippine Woods at 80% Stress GradeDocument8 pagesMechanical Properties of Philippine Wood: Working Stresses of Philippine Woods at 80% Stress GradeJOEZEL ENTIENZANo ratings yet

- Swimming Pool IsolationDocument10 pagesSwimming Pool Isolationchaval01No ratings yet

- Kitchen DimensionsDocument11 pagesKitchen DimensionsMalvin Roix Orense100% (1)

- Navya Lingala Castles: Upcoming ProjectsDocument4 pagesNavya Lingala Castles: Upcoming ProjectsCIVIL DESIGNNo ratings yet

- Pressure Equipment Design Verification: Either To Satisfy The National Generic CompetencyDocument6 pagesPressure Equipment Design Verification: Either To Satisfy The National Generic CompetencykrishimaNo ratings yet

- Sample Plumbing WorksDocument6 pagesSample Plumbing WorksadsasdNo ratings yet

- Senior Piping DesignerDocument2 pagesSenior Piping Designerapi-77709853No ratings yet

- Constant Mesh Manual Transmission Gear BoxDocument33 pagesConstant Mesh Manual Transmission Gear BoxBirhanu AsfawNo ratings yet

- Cen 14578Document12 pagesCen 14578mohamad330No ratings yet

- Parts List - Service Manual 969430401 - MAT 500 - R534 - enDocument2 pagesParts List - Service Manual 969430401 - MAT 500 - R534 - enharrykgs7No ratings yet

- O & M Manual Ut-13000 - Dalmia DSP Unit-1Document62 pagesO & M Manual Ut-13000 - Dalmia DSP Unit-1ranjan shiveshNo ratings yet

- Installation Onwers Manual Mini Chiller Inverter Intensity 0Document16 pagesInstallation Onwers Manual Mini Chiller Inverter Intensity 0vic lucNo ratings yet

- Eaton Fuller RTLO 16918B As Transmission Parts ManualDocument34 pagesEaton Fuller RTLO 16918B As Transmission Parts ManualRoy Hernandez100% (1)

- 07 Ceiling & LiningDocument30 pages07 Ceiling & LiningAjithkumarNo ratings yet

- Seismic Performance and Design Requirements For High1Document27 pagesSeismic Performance and Design Requirements For High1Vijay AravindNo ratings yet

- 1020 Plataforma de Grãos (PT-BR)Document164 pages1020 Plataforma de Grãos (PT-BR)Magno .costaNo ratings yet

- Sample ProcedureManualDocument284 pagesSample ProcedureManualJoy KathleenNo ratings yet

- Previous Standard Previous Steel Grade Current Steel Grade Current StandardDocument1 pagePrevious Standard Previous Steel Grade Current Steel Grade Current StandardakmlogaNo ratings yet