Professional Documents

Culture Documents

Cargo Oil Heating Requirements For An FSO Vessel Conversion PDF

Cargo Oil Heating Requirements For An FSO Vessel Conversion PDF

Uploaded by

nckpourlasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cargo Oil Heating Requirements For An FSO Vessel Conversion PDF

Cargo Oil Heating Requirements For An FSO Vessel Conversion PDF

Uploaded by

nckpourlasCopyright:

Available Formats

Marine Technology, Vol. 33, No. 1, Jan. 1996, pp.

58-68

Cargo Oil Heating Requirements for an FSO Vessel Conversion

Bill C. M. C h e n 1

Highly viscous crude oil stored in a floating-storage-and-offloading (FSO) vessel can provoke

cargo pumping and remain-on-board (ROB) problems. Cargo oil heating in the vessel to reduce the

viscosity and minimize the problems is studied in this paper as well as heating requirements. An

operating scenario is introduced for a vessel of 300 kdwt with assumed data. Heat dissipation from

warm cargo to ambient, heat addition to incoming cold cargo, and heat depletion during cargo

offloading are analyzed for the vessel. A simplified but robust heat loss analysis for the vessel is

presented. Using the readily available product crude as the boiler fuel to heat cargo is a logical

decision. Fuel consumption is estimated for the vessel. Boiler loads for heating steam generation

and heating devices are discussed. The cargo offloading configurations between the vessel and

shuttle tanker are investigated for heated and unheated cargo to determine its deliverability. The

configuration dictates the length of offloading hoses from the vessel to the tanker. High pressure

losses within long hoses may prevent unheated cargo from being delivered at the design rate to the

tanker. Alternatives to cargo heating are postulated. Addition of heating coils to an ultra-large crude

carrier (ULCC) built in the 1970's or 1980's is considered during the vessel conversion. The cost

estimates of addition and conversion for cargo heating are assessed. The transportational consid-

erations are discussed. Conclusions and recommendations are presented.

Introduction Boiler conversion for burning product crude is the prerequi-

site for this replacement.

BOSCAN crude from Venezuela and Duria crude from Indo- The history and applications of FSO vessels are detailed in

nesia are typified by high viscosity and high specific gravity various papers [2]. In the present study, the FSO vessel is a

[1]. 2 Adverse problems such as cargo pumping and remain- converted ultra-large crude carrier (ULCC). The planned

on-board (ROB) can occur during exporting crude oil from a ULCC is 300-plus thousand deadweight tons (kdwtl, built in

floating-storage-and-offioading (FSO) vessel. A trading oil the 1970's or 1980's. During this era, ULCCs were usually

tanker shuttling from the vessel to m a r k e t can encounter the steamships [3]. ULCCs of t h a t size typically do not have any

same problems during transportation of viscous crude. Heat- cargo oil heating facility on board. Therefore, addition of

ing cargo oil stored on a vessel to reduce its viscosity and to heating coils in the vessel is required if cargo heating is

minimize these problems is examined in this study. deemed necessary. Smaller very-large crude carriers

The cargo pumping problem relating to unheated viscous (VLCCs) may have heating coils installed on board.

crude is caused by the high rate of shear due to the rotating Crude oil is produced and processed from inland or subsea

speed of the impeller within a centrifugal pump. The high wellheads. The product crude oil is loaded onto the FSO ves-

shear rate results in the high pressure (or friction) loss and in sel via a subsea pipeline, pipeline-end-manifold (PLEM) as-

the lower pump discharge pressure, discharge rate, and effi- sembly, and hose-string. Cargo from the vessel is pumped

ciency. Premature pitting and wear of the impeller ring and through an oifioading hose-string to a shuttle t a n k e r berthed

pump casing can also be caused by pumping viscous crude oil alongside, in tandem, or at a remote buoy.

with centrifugal pumps. The hose length, which is dictated by the finalized offload-

The ROB problem stems from viscous crude with a high ing configuration, can also affect the cargo pumping problem

pour point and is aggravated by the wax content. The prob- due to high pressure loss of viscous crude flowing through

lem with wax is its buildup in cargo tanks or in offioading hoses. The offioading configuration considered for the FSO

hoses as the crude oil temperature drops below its pour point vessel in this study is one of the following:

and cloud point. Unheated viscous crude and accumulated

wax can choke off pump suctions or block off crude flow within Alongside offioading, Fig. 1: The shuttle t a n k e r is

hoses. For an FSO vessel moored in warm water, such as at berthed side-by-side to the FSO vessel. Cargo oil is of-

Venezuela or the Indonesian coast, the ROB problem may be fioaded to the tanker through a short hose string con-

not an issue. The problem may be a serious issue for the nected between the midship-to-midship manifolds. The

shuttle t a n k e r when it reaches Northern Europe or J a p a n vessel can be moored to a buoy by a single-point-mooring

where the ambient ocean temperatures may drop below the (SPM) system. The buoy is connected to the vessel's bow

crude's pour point especially during winter. (or stern) through an articulated yoke which provides

Crude oil is readily available on board the vessel; there- multi-degrees of freedom. The buoy is moored by chains

fore, it is the logical choice to replace the regular boiler fuel in a catenary-anchor-leg mooring (CALM) arrangement.

for the vessel's steam power plant and for heating its cargo. Tandem offloading, Fig. 2: The shuttle t a n k e r is berthed

in-tandem to the FSO vessel. Cargo oil is oifioaded to the

tanker through a long hose string connected between the

aft, port manifold to midship manifold. The vessel can be

1 Senior principal engineer, Gulf Interstate Engineering Com- moored by the chains of an SPM system. The vessel's

pany, Houston, Texas. bow- (or stern-) turret, which is a structural extension of

2 Numbers in brackets designate References at end of paper. the vessel, is moored in a CALM arrangement.

Manuscript received at SNAME headquarters April 25, 1995. Remote-offtake buoy off[oading, Fig. 3: The shuttle

58 JANUARY 1996 0025-3316/96/3301-0058500.47/0 MARINE TECHNOLOGY

FSOVESSEL ~ ~ ~

MOORING-~_ /;Y "~'~:~ ~~~...-~-~ --

YOKE ~ / ~ ~;y'~-s~-~--T"-~ j

~ ~ PLEM

~..--:'>........ .,":-ff ~ "~.S SPM

"- ,-"'" "~-- "",, /MOORING

~ ,,'"" "~ . . . . . . . . J CHAIN (TYP.)

- ~ ~--'=-- ..~_

Fig. 1 Alongside offloading configuration

SHU'I-I'LE / ~

HAWSERS\

l~ ---~ ~ - ~ ~ OFFLOADING

.-.-~-~ -=S~ -J f ~ ~ HOSES

TURRET~ ~ ....

~_................ ,/'- :: :~? SPM

~-- -"'" ~ ""-, ~MOORING

~ /'"" "',~- ""-.. / CHAIN (TYP,)

Fig. 2 Tandem offloading configuration

tanker is berthed at a buoy distanced from the FSO ves- --analyze and calculate heat losses from heated cargo in

sel. Cargo oil is offioaded to the tanker through a subsea the vessel,

pipeline and hose strings. The offloading hose string is --estimate the fuel consumption for heating cargo in the

connected between the buoy and the midship manifold. vessel,

This configuration is affiliated with the vessel anchored --devise steam heating requirements,

by a spread mooring system. The buoy is secured by a --define offioading system requirements for heated or un-

CALM system. heated cargo, and

--evaluate alternatives, estimate costs and consider trans-

This study defines the initial planning philosophy and cost portation issues.

basis, and supports the later engineering or operational ef-

forts. It is not the intention of this study to work out detailed A s c e n a r i o o f F S O vessel o p e r a t i o n s

design and engineering, to define detailed procedures for op-

eration and maintenance, or to determine the specific equip- Every existing FSO vessel in the world operates differ-

ment needed. The objectives of this study are to: ently. Operations are determined by production and offioad-

JANUARY 1996 MARINE TECHNOLOGY 59

~WSERS

c ~ BUOY ," ", .osEs-~!.)

j OFFLOADING ~' ~

FSO VESSEL ~~~-":=::::: :'-~',~""::::: -""'d.......

.//~ /~JJ:-~ CHAIN

~ -- FLHE_X!IBEEL

,:' (TYP.)

/

Fig. 3 Remote-offtake buoy configuration

ing rates, vessel and shuttle t a n k e r sizes, sea states, etc. To (assumed field production rate), q2 = 45 000 bbl/hr from

avoid being puzzled by these u n k n o w n factors, a simple rule t a n k e r d a t a [3] (total pump discharge r a t e from t h e vessel of

can be e s t a b l i s h e d for the vessel operations. The rule is t h a t 300 kdwt), and n 2 q 2 = 90 to 250 k d w t s h u t t l e t a n k e r s (ap-

w h a t e v e r is incoming to the vessel should be offloaded to a p r o x i m a t e l y 0.66 to 1.90 10 ~ bbl from t a n k e r d a t a [3]).

shuttle tanker(s) in order to have o p t i m u m operations and to Only the p a r t i c u l a r solution is sought in t h i s study, i.e., AQ

m a i n t a i n continuous production. G e n e r a l l y speaking, t h e r e = 0. This p a r t i c u l a r solution is t r u e for the scenario when

are two operation modes in a n operation period (n) for the t h e r e is a fleet of dedicated s h u t t l e t a n k e r s being long-term

vessel. The s t a n d b y mode (nl) r e p r e s e n t s days in which no chartered for the FSO vessel. Therefore, the offloading mode

t a n k e r is b e r t h e d to the vessel. The offloading mode (n2) rep- (n,~) r a n g e s from 0.61 to 1.76 days. The s t a n d b y mode (n 1)

resents days in which a t a n k e r receives cargo from the vessel. spans from 2.69 to 7.74 days. The operation period (n) covers

Times for the t a n k e r ' s waiting, b e r t h i n g and castoff are not from 3,30 to 9.50 days. In conclusion, the offioading modes are

included in the offloading mode. The commercial t e r m s such less t h a n 20% of all operation periods. This percentage will

as laytime, l a y d a y s , and others are i r r e l e v a n t to the opera- be used to justify t h e a v e r a g e fuel consumption from t h e

tion period in this study. Detailed t a n k e r operations are de- m a x i m u m fuel rate.

scribed in other sources [4].

The vessel c o n s t a n t l y receives incoming product crude

from the subsea pipeline. Downtimes due to w e a t h e r or me- Vessel heat loss analysis

chanical problems or both are excluded from this scenario. The cargo oil offloading r a t e from the FSO vessel is a l w a y s

W i t h i n an operation period, n = nl + n2, the volume vari- much g r e a t e r t h a n t h a t of incoming crude oil to the vessel.

ation of crude oil in the vessel can be expressed as The volume of crude oil stored in the vessel changes con-

(nl + n2) ql - n~q2 = AQ s t a n t l y due to the continuous incoming and i n t e r m i t t e n t

offloading. The h e a t loss in this n o n s t e a d y s t a t e of the crude

where oil incoming/offloading requires detailed a n a l y s i s which is

ql, q2 = m e a n r a t e s (bbl/day) of crude oil incoming to outside the scope of this study. However, t h e a n a l y s i s can be

vessel and offioading to shuttle tanker, solved with a few a s s u m p t i o n s and t r a n s f o r m e d into a

respectively steady-state approximation.

n~, n2 = n u m b e r of days when vessel is in standby and Depending on the size of the s h u t t l e t a n k e r , the vessel can

offloading, respectively v a r y from n e a r e m p t y to press-full over a period of several

AQ = Q2 - Q1 = volume (bbl) difference of crude oil days. The near-full condition of 95% provides a conservative

stored in vessel at end of n2 and b e g i n n i n g of and steady-state analysis for the m a x i m u m h e a t loss sce-

n~ nario as shown in Fig. 4. W i t h this assumption, the h e a t loss

is n e a r the m a x i m u m and y e t t h e r e is still room for incoming

The t e r m n2q2 is the oifioading parcel size and also the dwt cargo to be w a r m e d up w i t h i n the vessel. A vessel 98% full is

of a shuttle t a n k e r . AQ can be > 0, = 0, or < 0. A typical FSO recognized as completely full in the m a r i n e industry.

vessel operation is shown in Fig. 4. A scenario of vessel op- H e a t dissipates from the w a r m e r cargo t h r o u g h the vessel

erations in this study is a s s u m e d to be: ql = 200 000 bbl/day hull to the cooler s u r r o u n d i n g atmospheric a i r and seawater.

60 JANUARY 1996 MARINE TECHNOLOGY

~J3

~3

MAXIMUM HEAT LOSS

C)

V)

z

_J AVERAGE HEAT LOSS

O

uJ

0c

o

kQ, %

NOTE DAYS

OPERATION EQUATION

q~(n + r~2)- q2r~ = 0 2- Q~

LEGEND

n~ VESSEL IN STANDBY MODE

;q2 VESSEL IN OFFLOADING MODE

PRODUCTION RATE ( q, )

- - PRODUCTION RATE - OFFLOADING RATE ( q , - q~)

QI CRUDE 0IL AT BEGINNING OF r~

Q2 CRUDE OIL AT END OF n z

Fig. 4 Typical FSO vessel operation

Additional heat is required to warm the continuous incoming for the actual nonsteady operating conditions. The fuel con-

cooler crude, while heat is removed along with intermittent sumption for cargo oil heating is detailed in Appendix 1. The

offioaded cargo. Heat required for cargo heating in the vessel conclusions are summarized as follows:

at standby and offioading modes can be expressed as:

a. FSO vessel in standby mode for about 2.69 to 7.74 days The average crude oil consumption for cargo heating

(from previous section): is estimated to be 51.3 short tons/day or 114 920 bbl/

year. This estimate is based on the FSO vessel being

Heat required = Qair 4- Qwater + Qin partially full on average and heating steam being

turned on about half of all operation periods. The

b. FSO vessel in offloading mode for about 0.61 to 1.76

average heating cost of burning crude for cargo

days (from previous section):

heating is estimated to be 2.30 million $U.S. per

Heat required = Qair + Qwater + Qin - Qoe year at an assumed crude price of $20/bbl. This cost

excludes any other operational expenses such needs

where as cargo offioading, electricity generation, hotel

Qair = heat loss to air through vessel's main deck and equipment, or accommodations.

fore-and-aft bulkheads In order to arrive at the above fuel consumption rate for

Q w a t e r = heat loss to seawater through vessel's cargo heating, the cargo tanks in the FSO vessel are simpli-

sideshells and bottom plate fied into a single large tank as shown by the dotted lines in

Qin = heat transfer to incoming oil Fig. 5 (which is shown with another SPM system). The sim-

Qo~ = heat depletion to offioaded oil plified tank floats on seawater and is subjected to a set of

prescribed environmental conditions. The desirable cargo

Heat required for the FSO vessel in the oifloading mode heating temperature is assumed to be 120F. In this study,

does not provide the near-peak heat loss since the vessel is the bulk of cargo in the tank is maintained at this tempera-

partially empty while oil is oifioaded. Therefore, the heat loss ture, which implies that heating coils are installed in all

calculation during this operating mode will not be performed. tank bottoms evenly. Other coil installations, such as install-

The final crude oil consumption based on 95% full at all times ing in selected large tanks or at sides or both, are not be-

will be adjusted to represent the vessel under all operating lieved applicable to this methodology. Other assumptions for

periods. The heat loss calculations for the vessel of 300 kdwt crude oil consumption calculations are included in Appen-

is detailed in Appendix 1. Basic heat transfer techniques are dix 1.

applied to the calculations.

Steam heating requirements

Fuel c o n s u m p t i o n

No attempts have been made to assess whether the vessel's

The fuel consumption of crude oil burning in the vessel existing boilers can generate sufficient steam to heat and

boilers for cargo heating is proportional to the heat required maintain cargo at the temperature of 120F. A heat balance

to maintain cargo at a constant temperature. The heat loss design [5] sheds light on boiler loads for steam generation

and fuel rate from the steady-state assumption are averaged and utilization. The existing two boilers may have sufficient

JANUARY 1996 MARINE TECHNOLOGY 61

FSO VESSEL ~ ~

ARTICULATED ' ~ %

RISER~ "~"~MpO.R.ING

~ " JACKET

Fig. 5 Simplifiedcargo tank on FSO vessel of 300 kdwt

capacity to generate superheated high pressure (HP) steam loading requirements with and without cargo heating are

to be converted to low pressure (LP) steam to heat cargo at a addressed for three different configurations in the following

temperature while the vessel is in the standby mode. During sections.

this mode, one boiler is sufficient for supporting vessel oper-

ations. This boiler is under 25% of the rated load in the heat Alongside offloading (Fig. 1)

balance design. However, boilers may not have enough ca-

pacity to heat cargo while the vessel is in the offioading mode. The offioading hose is estimated to be 60 ft long for this

During this mode, turbines of cargo transfer pumps consume configuration as demonstrated in Appendix 2. This hose

up to 62% of each boiler load as shown in the design. Addition length shall be long enough to span the midship-to-midship

of an auxiliary boiler on the vessel's main deck for cargo manifolds and the 10-ft-diameter fenders between the FSO

heating is a conceivable solution in this circumstance. vessel and shuttle tanker. The elevation difference due to

An alternative to conserve fuel is to heat cargo just prior to draft changes between the vessel and t a n k e r is included in

the arrival of the shuttle tanker. This is applicable if the the hose length calculation.

vessel's heating coils have enough capacity and the standby The hose size is calculated to be two, 16-in.-diameter flex-

mode is long enough to let the cargo be heated to the desired ible hoses for the unheated cargo from the preliminary anal-

temperature. ysis as shown in Part II of Appendix 3. Other combinations of

The cargo heating system includes steam coils in all cargo, hose sizes may be applicable for this configuration.

slop and forward fuel tanks; an LP steam generator; and a Crude oil does not require heating due to the short hose

drain tank. Selection of the heating coil material will depend span for delivery, but at a severely restricted rate. In other

on the crude oil properties and service factors. Stainless steel words, cargo from the vessel can reach the shuttle t a n k e r at

or nickel brass is the recommended coil material. An LP the much lower oifloading rate with existing transfer pumps

steam generator converts superheated HP steam into LP and without cargo heating under this configuration. In order

heating steam for use in coils. A separate steam condensate to achieve the maximum and average offloading rates, cargo

return system is required and includes an inspection tank, oil must be heated.

monitors, scrubbers, etc. to detect and treat oil contaminants.

The cargo steam heating system is usually separate from the Tandem offioading (Fig. 2)

main steam system to avoid contamination.

The offloading hose is estimated to be 1000 ft long for this

configuration as demonstrated in Appendix 2. This hose

Ottloading system requirements length shall be long enough to cover the distance between

two manifold receiving flanges on the FSO vessel and shuttle

Offloading a highly viscous cargo poses problems for exist- tanker, The vessel's manifold is assumed to be located at the

ing FSO vessel transfer pumps of the centrifugal type. Pump- aft and port side. The freeboards of the vessel and t a n k e r are

ing viscous fluid through offloading hoses generates unusu- included in the hose length calculation.

ally high pressure losses which are adverse for any pumping The hose size is calculated to be two 20-in.-diameter float-

operations. In an extreme case, it may not be possible to ing hoses for heated or unheated cargo from the preliminary

deliver cargo at a specific rate to the shuttle tanker, analysis as shown in Part III of Appendix 3. Other combina-

It is assumed that the existing transfer pumps in the tions of hose sizes may be applicable for this configuration.

ULCC will be retained in the FSO vessel conversion. The Calculations show that crude oil can be delivered to the

pumps are usually centrifugal type and their discharge pres- shuttle tanker at varying rates with or without heating. In

sures are predetermined. For a typical ULCC of 300 kdwt, other words, crude oil does not require heating for delivery at

the maximum offioading rate is assumed to be 60 000 bbl/hr at a much lower offioading rate even though the hoses are

120 psig at the offloading manifold, and 45 000 bbl/hr at 150 rather long. In order to achieve the maximum and average

psig is assumed to be the average offloading rate for heated rates, cargo heating is required. The pressure drops for

cargo [6]. The transfer pump discharge rate is assumed to be heated and unheated cargo are calculated for comparison.

30 000 bbl/hr at 75 psig at the offioading manifold for un- For the heated cargo calculation, the assumption is made

heated viscous cargo, which is interpreted from pump char- that cargo is kept at 120F within hoses without any temper-

acteristic curves [7]. Other assumptions are included in Part ature drop. In reality, the majority of long hoses will float on

I, Appendix 3. The type of vessel mooring system will have the sea with surface currents and breezes which tend to cool

minimal effect on hose length determination. The vessel off- off heated cargo along the way. A heat transfer analysis is

62 JANUARY 1996 MARINE TECHNOLOGY

needed to determine heat dissipation from floating hoses. An- Cost estimates

other consideration is the consequence of the crude oil re-

maining in hoses between offioading modes, which can range Addition of heating coils to the FSO vessel is estimated to

from about 3 to 8 days. Crude may deposit wax, making it cost about 2.0 million $U.S., of which installation and mate-

necessary to flush hoses or circulate cargo. rial cost is $1.0 million. The total cost includes engineering,

materials, installation and general shipyard service. The

Remote-offtake buoy otfloading (Fig. 3) coils are installed near tank bottoms of all cargo holds. Other

alternatives such as coil installation in selected large tanks

The otfloading hose is estimated to be 840 ft long from a will cost less and change the analysis scenario of cargo heat-

remote offtake buoy as shown in Appendix 2. The buoy is ing of this study.

loaded through a subsea pipeline 2.4 miles long (assumed) The boiler conversion for the crude oil burning is estimated

from the FSO vessel for this configuration. This hose length to cost about $2.5 million. The cost excludes the boiler over-

shall be long enough to cover the distance between two man- haul for repair and life extension which are performed during

ifold receiving flanges on the buoy and shuttle tanker. The the vessel conversion. About half of the total cost is for en-

shuttle tanker freeboard is included in the hose length cal- gineering and procuring boiler equipment and the other half

culation. for the installation in a shipyard. The boiler equipment in-

The hose size is calculated to be two 20-in.-diameter float- cludes new burners, valves, instrumentation, extraction and

ing hoses for heated cargo from the preliminary analysis as ventilation fans, burner management and control system,

shown in Part IV of Appendix 3. The subsea pipeline is rec- and gas detection system.

ommended to be 36-in. diameter. Considering these sizes of

hoses and the pipeline, the maximum oliloading rate is not Transportational considerations

achievable, but the average ottloading rate can be sustained

with heated cargo. A crude temperature higher than 120F is From the transportation viewpoint of a shuttle tanker, vis-

required for the maximum rate. cous cargo is required to be heated during the tanker voyage

Crude oil is heated and maintained at a constant temper- whether or not it is heated in the FSO vessel [1]. From a

ature of 120F throughout hoses and the subsea pipeline. preliminary analysis, heated cargo will lose all its thermal

Crude oil does require heating for delivery due to the long energy to the environment from an noninsulated shuttle

hose span and the subsea pipeline. In other words, under this tanker during the first few days of the voyage. Cargo heating

configuration cargo in the FSO vessel cannot reach the shut- during the voyage will put an extra burden on the shuttle

tle tanker with the existing transfer pumps and without tankers during transportation.

cargo heating. Positive displacement booster pumps may be The shuttle tankers in the class of ULCC or large VLCC

installed for this configuration if cargo heating is undesir- typically do not have any heating facility, whereas smaller

able. tankers may be fitted with heating coils. Thus, the average

For this study, it is assumed that the cargo oil temperature offioading parcel size from the vessel will probably be re-

is maintained at 120F within hoses and the subsea pipeline duced. Under this condition, the vessel's offloading mode (n2)

without any temperature drop. In reality, the majority of the will decrease.

long hoses will float on the sea with surface currents and

breezes which tend to cool off heated cargo along the way. An

insulated subsea pipeline may be required. The subsea pipe- Conclusions and recommendations

line will lie on the seabed, which will also dissipate heat and

cool down heated cargo. A heat transfer analysis is required For offloading configurations of alongside and in tandem,

to determine the heat dissipation from floating hoses and the cargo heating is required to achieve the maximum and av-

subsea pipeline. erage offloading rates. If cargo heating is not activated, cal-

culations show that the otfioading rate is reduced by an order

of 50% of the maximum rate. The FSO vessel's offioading

Alternatives to cargo heating mode may be doubled if cargo is unheated under these con-

figurations. The production may have to be shut down due to

Besides cargo heating in the FSO vessel, methods for over- the reduced offioading rate--possibly even less than the pro-

coming the pressure loss in hoses are (i) arranging a short duction rate!

hose offloading configuration, (ii) increasing piping and hose For the remote-offtake buoy configuration, cargo heating is

diameters, (iii) adding booster pumps, and (iv) injecting a required to maintain the average offioading rate. The maxi-

drag-reducing agent. mum offloading rate cannot be achieved without cargo heat-

The lengths of oifloading hoses are dictated by the vessel ing to a higher temperature than proposed in this study. The

offioading configuration as well as the size of the shuttle unheated cargo cannot be delivered to the shuttle tanker due

tanker. The configuration is selected for the vessel's optimum to the excessive pressure drop in hoses for this configuration.

offloading and maneuvering operations rather than for the The vessel offioading mode may need to be increased if cargo

cargo pump discharge pressure. The hose diameter should be is not heated to the proper temperature under the configu-

limited to 24 in., which is the maximum commercially avail- ration. Otherwise, production may be shut down due to the

able hose size. lower offloading rate.

Addition of booster pumps is one of the remedies for over- Transferring viscous cargo without heating can increase

coming the high pressure drop in the offloading hoses if heat- the maintenance requirements of cargo pumps. The pumps

ing is undesirable. Gear or screw pumps are ideal for the can be subjected to excessive wear and the maintenance cost

booster pump for pumping the viscous fluid. However, the increases accordingly.

pump discharge pressure shall not exceed the hose design Based on this study, it is recommended that cargo heating

pressure of 225 psig. The discussion of booster pump addition coils be installed in order to maintain operational flexibility.

is outside the scope of this study. Installation of coils during the vessel conversion is more cost

Using a drag-reducing agent extensively and indefinitely effective than installing them later. As operational experi-

in crude oil to reduce its viscosity artificially is expensive, ence is gathered during initial years of operations, it will be

according to estimates. determined to what extent cargo heating is necessary. Hav-

JANUARY 1996 MARINE TECHNOLOGY 63

ing cargo heating available provides a reserve capacity to Qwater2 = 45.395 x 106 B t u / h r loss t h r o u g h v e s s e l ' s b o t t o m

increase ollloading rates if the need arises during high pro- p l a t e to s e a w a t e r

duction periods. Qa~rl = 4.273 106 B t u / h r loss t h r o u g h v e s s e l ' s m a i n deck to

Examining the cost of fuel oil for cargo heating, it may be air

e c o n o m i c a l to a d d i n s u l a t i o n to c a r g o t a n k s i n t h e F S O v e s - Q~,rz - 1.595 10 e~B t u / h r loss t h r o u g h v e s s e l ' s fore a n d aft

b u l k h e a d s to air

sel. T o m i n i m i z e t h e i n s u l a t i o n c o s t , o n l y t h e e x t r e m e o u t e r

Qin = 61.111 x 106 B t u / h r a d d i t i o n to i n c o m i n g crude oil

boundaries of all cargo tanks (shown as dotted lines in Fig. 5) Total h e a t loads - 139.318 x 106 B t u / h r for n e a r - p e a k s c e n a r i o

require insulation.

DAILY CRUDE OIL CONSUMPTION:

C r u d e oil h e a t i n g value, low = 5.9 x 106 Btu/bbl [8] for A P I 20

Acknowledgments deg ( a s s u m e d )

Boiler t h e r m a l efficiency - 90% from h e a t b a l a n c e d e s i g n

The author wishes to thank the management of Gulf In- [5]

terstate Engineering Company for permission to publish this C r u d e oil c o n s u m p t i o n - 26.24 bbl/hr or 629.77 bbl/day

paper. Appreciation also is extended to Mr. William M. Olson (102.6 s h o r t tons/day)

for his guidance and to Drs. Donald Chang and Jim Caldwell Cost of b u r n i n g crude oil = $12 594/day (a $20/bbl

for their technical suggestions and assistance. Thanks also (assumed)

should be offered to Mrs. Judy F. Chen for her proofreading of

the draft. ANNUAL CRUDE OIL CONSUMPTION:

T h e m a x i m u m c r u d e oil c o n s u m p t i o n for t h e cargo oil h e a t i n g

is e s t i m a t e d to be 229 840 bbl/year. T h i s e s t i m a t e is b a s e d on

References t h e a s s u m p t i o n t h a t t h e FSO vessel is 95% full at all t i m e s in

all o p e r a t i n g periods. T h e cargo is m a i n t a i n e d at a c o n s t a n t

1 Price, R.I. in Ship Design and Construction, Chapter II, Second t e m p e r a t u r e of 120F. T h e m a x i m u m h e a t i n g cost of b u r n i n g

Printing, SNAME, 1986. crude oil is e s t i m a t e d to be 4.60 m i l l i o n $U.S. per y e a r at t h e

2 "FPSO Technology," SNAME, Texas Section, Feb., 1993. a s s u m e d crude price of $20/bbl.

3 The Tanker Register, Clarkson Research Studies, Ltd., 1992.

4 Marton, G. S., Tanker Operations, Cornell Maritime Press, Inc. Average crude oil consumption for cargo heating--The vessel is

5 Chen, B. C. M., "Heat Balance Design and System Modifications for

an FSO Vessel Conversion," u n d e r consideration for publication. m o r e realistic at 50% full for all t i m e s on a v e r a g e u n d e r all o p e r a t i n g

6 Petroleum Tankship Operations, Tanker Advisory Center, Inc., Feb. modes. Cargo does n o t need to be h e a t e d d u r i n g t h e s t a n d b y m o d e for

1992. fuel c o n s e r v a t i o n . In t h e cited scenario, cargo n e e d s to be h e a t e d

7 Soete, G. W. in Marine Engineering, Chapter 12, Third Printing, d u r i n g t h e offloading mode, w h i c h is less t h a n 2 0 ~ of all o p e r a t i o n

SNAME, 1980. periods. C a r g o c a n be w a r m e d up to t h e d e s i g n t e m p e r a t u r e d u r i n g

8 Gooding, R. M., Standard Handbook for Mechanical Engineers, Sec- t h e s t a n d b y mode j u s t prior to t h e a r r i v a l of a s h u t t l e t a n k e r , w h i c h

tion 7, 7th ed., McGraw-Hill, New York, pp. 7-23. a m o u n t s to s a y a n o t h e r 25% of a n operation period S u m m a r i z e d from

9 Chapman, A. J., Heat Transfer, 2nd ed. above, it is safe to a s s u m e t h a t t h e fuel c o n s u m p t i o n is a b o u t 50% of

10 Bridgestone, Marine Hose, H4338E-7, p. 137. t h e m a x i m u m rate.

C r u d e oil c o n s u m p t i o n = 114 920 bbl/yr (314.9 bbl/dayl or

Metric Conversion Factors 51.3 s h o r t t o n s / d a y

Cost of b u r n i n g crude oil = $6298/day (~ $20/bbl ( a s s u m e d ) or

1 ft -- 0.3048 m

$2.30 m i l l i o n / y r

1 Btu = 1055 J o u l e s

1 knot = 0.447 m/sec

Analysis data

1 Btu/bbl = 6627 J / m 3, h e a t i n g v a l u e

1 Btu/hr-ft-F = 17.3 W / m - K , t h e r m a l c o n d u c t i v i t y FSO vessel's particulars--The v e s s e l is conceived to be a con-

1 Btu/lb-F = 4184 J / k g - K , specific h e a t v e r t e d U L C C of 300 k d w t w h i c h h a s a capacity of 2.3 x 106 bbls [3].

1 ft2/sec = 929 c e n t i s t o k e s (cSt) (cm2/sec), k i n e m a t i c Typical d i m e n s i o n s of t h e U L C C a r e a p p r o x i m a t e l y 1066 ft in l e n g t h

viscosity b e t w e e n p e r p e n d i c u l a r s (LBPI, 184 ft in b r e a d t h , a n d 94.5 ft in

1 lb = 0.454 k g depth. For t h e simplicity of t h i s s t u d y , t h e cargo h o l d s are c o n s e r v a -

1 psi = 0.07 k g / c m 2 tively a n d globally a s s u m e d to be a big t a n k of 760 x 180 x 94.5 ft

F = C x 1.8 + 32 or 2.30 x 106 bbl, Fig. 5. A f u r t h e r a s s u m p t i o n is m a d e t h a t t h e cargo

I dwt = 1.016 t o n n e s t a n k is 95c full at all t i m e s a n d t h e final idealized cargo t a n k in t h e

vessel is 760 x 180 90 ft or 2.19 x 10 ~ bbl, T h e vessel d r a f t is

a s s u m e d to be 90 ft for s i m p l i f y i n g h e a t t r a n s f e r r~lculations.

Assumed environmental conditions--

Appendix 1

S e a w a t e r t e m p e r a t u r e - 78F Current = 2 knots

A i r t e m p e r a t u r e - 78F W i n d = 10 m p h

Calculations of crude oil consumption for cargo

Assumed crude oil (API 20 degJ rates and properttes [8]--

oil heating

H e a t e d crude oil t e m p e r a t u r e = 120F

Summary Production rate = 250 000 bbl/day (~t 80F

SG, specific g r a v i t y = 0.93, or 58.032 lb/ft a

Maximum crude oil consumption for cargo heating--The v a l u e s %, specific h e a t = 0.45 Btu/lb-F

cited are t h e m a x i m u m possible crude oil c o n s u m p t i o n , w h i c h is K, t h e r m a l c o n d u c t i v i t y - 0.08 Btu/hr-ft-F

obviously o v e r e s t i m a t e d d u e to a s s u m p t i o n s m a d e for t h i s study. ~, t h e r m a l e x p a n s i o n coefficient = 0.000 343/F

These values can be viewed as t h e u p p e r b o u n d of t h e possible con- ~, absolute viscosity = 178 centipoise (cP) (u 120F

s u m p t i o n . T h e a v e r a g e c o n s u m p t i o n clearly will be less t h a n t h e v, k i n e m a t i c viscosity = ~/SG - 191.4 cSt

m a x i m u m . A m u l t i p l i e r c a n be applied to t h e m a x i m u m r a t e to de- ~, absolute viscosity = 191.4 x 1.076 x 10 s x

t e r m i n e t h e a v e r a g e rate. 58.032 x 3600 - 430.25

lbm/ft-hr

F S O VESSEL HEAT LOAD OF:

Qwaterl = 26.944 X 106 B t u / h r loss t h r o u g h v e s s e l ' s 2 s i d e s h e l l s Conversion factors for crude oil (API 20 deg) (a 0.93 SG and (w

to seawater 80F--

64 JANUARY 1996 MARINE TECHNOLOGY

lft 3 = 7.48052gal lbbl = 42gal NG~ = 6.378 1011

lgal = 7.7581b lbbl = 325.831b Np~Nc~ = 1.543 1015

1 metric ton = 6.766 bbl 1 short ton = 6.138 bbl NNu = 0.14 (NprNGr)1/3 f r o m e q u a t i o n (9.6) = 16160.9

1 centistoke = 1.076 10 5 ft2/sec hoi1 = 7.183 Btu/hr-ft2-F, c r u d e oil h e a t t r a n s f e r coefficient

Seawaterproperties (assumed same as fresh water except for den- T h e t h e r m a l r e s i s t a n c e of steel a n d s e a w a t e r is negligible com-

sity) @ 78F p a r e d w i t h t h a t of crude oil.

K, thermal conductivity = 0.355 B t u / h r - f t F TOTAL HEAT LOSS:

v, k i n e m a t i c viscosity = 0.0334 ft2/hr

ix, a b s o l u t e viscosity = 2.08 lbm/ft-hr Qwate~2 = At (area)/(1/hoi 1) = 41.268 106 B t u / h r

p, d e n s i t y = 64 lbm/ft 3 A d d 1 0 ~ to t h e final h e a t loss d u e to t h e cooling fins effect of

stiffeners, girders, braces, a n d f r a m e s on t h e b o t t o m plate. Qwater2

= 45.395 106 B t u / h r .

Maximum heat loss calculations

Qwaterl = Heat loss to seawater through 2 vertical sideshells o f Qa~rl = Heat loss to air through horizontal main deck o f F S O ves-

F S O vessel--Heat t r a n s f e r s from h e a t e d c r u d e oil t h r o u g h s i d e s h e l l s s e l - H e a t t r a n s f e r s f r o m h e a t e d c r u d e oil t h r o u g h t h e m a i n deck of

of t h e steel plate to s e a w a t e r h a v i n g a 2 k n o t (3.3 ft/sec) c u r r e n t t h e steel plate to t h e a t m o s p h e r i c air h a v i n g 10 m p h w i n d p a s s i n g

flowing p a r a l l e l to t h e v e s s e l ' s l o n g i t u d i n a l axis. C r u d e oil a n d sea- parallel to t h e vessel's l o n g i t u d i n a l axis. C r u d e oil a n d air e a c h f o r m

w a t e r e a c h form a t h i n l a y e r w h i c h a d h e r e s to e a c h side of t h e steel a t h i n b o u n d a r y l a y e r a r o u n d t h e m a i n deck. T h e l a y e r s c o n s t i t u t e

plate. T h e l a y e r s c o n s t i t u t e t h e r m a l r e s i s t a n c e to t h e h e a t t r a n s f e r . t h e t h e r m a l r e s i s t a n c e s to t h e h e a t t r a n s f e r . T h e h e a t t r a n s f e r for

T h e h e a t t r a n s f e r for c r u d e oil is u n d e r free convection w h e r e a s t h e crude oil is u n d e r free convection w h e r e a s air is u n d e r forced con-

s e a w a t e r is u n d e r forced convection. All f o r m u l a s a n d e q u a t i o n s vection. T h e air g a p of 95% full, w h i c h is above t h e c r u d e oil a n d

s h a l l be referred to C h a p t e r s 8 a n d 9 of reference [9]. below t h e m a i n deck, also provides t h e r m a l r e s i s t a n c e d u e to free

convection a n d radiation. T h e air h e a t c o n d u c t i o n w i t h i n t h i s g a p is

CRUDE OIL HEAT TRANSFER BY FREE CONVECTION: negligible. All f o r m u l a s a n d e q u a t i o n s s h a l l be r e f e r r e d to C h a p t e r s

8, 9 a n d 13 of reference [9].

Npr = IXCp/K,P r a n d t l n u m b e r = 430.25 0.45/0.08 =

2420 AIR HEAT TRANSFER BY FORCED CONVECTION ABOVE MAIN DECK:

NG r = .y~3 [3At/v2, G r a s h o f n u m b e r

= 32.2 (90) 3 0.000343 (120 - 78) hair1 = 5.5 Btu/hr-ft2-F, air h e a t t r a n s f e r coefficient as

(3600)2/(430.25/58.032) 2 r e c o m m e n d e d by A m e r i c a n Society of H e a t i n g a n d

= 7.973 10 l Ventilating Engineers

NprNGr = 1.9295 1014, log (NprNcr) = 14.28

A I R HEAT TRANSFER BY FREE CONVECTION BELOW MAIN DECK AND

log (NNu) = 3.70 from Fig. 9.3, NNu = hl/K or N u s s e l t n u m b e r

ABOVE HEATED CRUDE OIL:

= 5011.9

ho~1 = 5011.9 0.08/90 - 4.455 Btu/hr-ft2-F, crude oil hair2 - 0.12 IAt/1) 14 from Table 9.1 - 0.0834 Btu/hr-ft2-F, a i r

h e a t t r a n s f e r coefficient h e a t t r a n s f e r coefficient

STEEL HEAT TRANSFER BY CONDUCTION: A I R HEAT TRANSFER BY RADIATION BETWEEN THE AIR GAP BELOW

MAIN DECK AND ABOVE HEATED CRUDE OIL:

K = 20 Btu/hr-ft-F, or

hstee1 = 240 Btu/hr-ft2-F ( a s s u m e 1 in. wall t h i c k n e s s ) , steel ha,r3 = (r(to, 1 + tstee l) X (~,l + t~t~d)/[(1/Eo,l) + (1/E.~teel) -- 1]

plate h e a t t r a n s f e r coefficient from e q u a t i o n (13.8) -~ 0.780 Btu/hr-ftU-~F, a i r g a p

r a d i a t i o n coefficient

SEAWATER HEAT TRANSFER BY FORCED CONVECTION OF 3.3 FT/SEC

CRUDE OIL HEAT TRANSFER BY FREE CONVECTION:

CURRENT:

ho, l = 7.183 Btu/hr-ft2-F from Qwater2, crude oil h e a t t r a n s f e r

Npr = 5.85

coefficient

NR~ = vl/v, R e y n o l d s n u m b e r

= 3.3 760 3600/0.0334 = 270.323 10 ~, TOTAL HEAT LOSS:

t u r b u l e n t flow

NNu = 0.036 (NRe) 's (NRr) lj3 from e q u a t i o n (8.6) = Qa,rl = At x (area)/[1/ha,rl + 1/(hair2 + haw3) z_ 1/holl ] = 3.885

361017.06 10 ~ B t u / h r

h . . . . . t~ = 168.6 Btu/hr-ft2-F, s e a w a t e r h e a t t r a n s f e r

coefficient A d d 10% to t h e final loss due to t h e cooling fins effect of stiffeners,

girders, braces, a n d f r a m e s below m a i n deck plate. Qairl = 4.273

TOTAL HEAT LOSS: 106 B t u / h r .

Qw,~rl = At (area)/(1/hoi 1 + 1/hstee1 + 1/h . . . . . ter ) Qa~r2 - Heat loss to air through vertical fore a n d aft bulkheads in

(120 - 78) (760 90 2)/(1/4.455 + 1/240 +

F S O vessel--All f o r m u l a s a n d e q u a t i o n s s h a l l be r e f e r r e d to C h a p -

1/168.6) = 24.495 106 B t u / h r

t e r s 8 a n d 9 of reference [9].

AIR IN VENTILATED ROOM SUCH AS PUMP ROOM:

T h e t h e r m a l r e s i s t a n c e of steel or s e a w a t e r is negligible c o m p a r e d

w i t h t h a t of c r u d e oil. A d d 10% to t h e final h e a t loss d u e to t h e h ~ r = 1.4 Btu/hr-ft2-F, air h e a t t r a n s f e r coefficient as

cooling fins effect of stiffeners, girders, braces, a n d f r a m e s w i t h i n t h e r e c o m m e n d e d by A m e r i c a n Society of H e a t i n g a n d

cargo t a n k s : Qwaterl = 26.944 106 B t u / h r . Ventilating Engineers

Q w a t e r 2 = Heat loss to seawater through horizontal bottomplate of CRUDE OIL HEAT TRANSFER BY FREE CONVECTION BEHIND

F S O vessel--All f o r m u l a s a n d e q u a t i o n s s h a l l be referred to C h a p - BULKHEADS:

t e r s 8 a n d 9 of r e f e r e n c e [9].

hoi~ = 4.455 Btu/hr-ft2-F from Q w a t e r l , crude oil h e a t t r a n s f e r

coefficient

CRUDE OIL HEAT TRANSFER BY FREE CONVECTION:

Np~ = 2420 f r o m Qwaterl TOTAL HEAT LOSS:

JANUARY 1996 MARINE TECHNOLOGY 65

Line distance from buoy- - 824 ft including t a n k e r

Q~i~2 = A t (area)/(1/h~r + 1/ho~) = 1.450 106 B t u / h r freeboard only

. O f f l o a d i n g hose l e n g t h - - = 840 ft

Add 10% to the final h e a t loss due to cooling fins effect of stiffeners,

girders, braces, and f r a m e s on bulkheads. Qa,r2 - 1595 106 Appendix 3

Btu/hr.

Q i , = H e a t t r a n s f e r to i n c o m i n g c r u d e oil onto F S O vessel-- Calculations of pressure losses in hose strings

A s s u m e d production rate = 10 420 bbl/hr, or 3.395 106 lb/hr Part I. Assumed crude oil properties and transfer

(a, 80F pump characteristics

Q ~ = (mass) cp A t = 61.111 106

Btu/hr Absolute viscosity of crude, ~ = 178 cP (a'120F [heated), or

848 cP (~ 80 F (unheated)

Kinematic viscosity of crude, v = W/P, 191.4 cSt or 191.4

Appendix 2 10 Gm 2 sec for h e a t e d

crude cargo t 120F, or

912 or 912 x 10 6 m 2 s e c

Calculations of ofltoading hose length for u n h e a t e d crude cargo

(~i 80F

Vessel and tanker particulars Specific g r a v i t y of crude, p = 0.93

Specific w e i g h t of crude, ~ 929.73 kg m 3 at all t e m p e r a t u r e

The FSO vessel is a s s u m e d to be a converted ULCC of 300 kdwt. (assumed)

Typical d i m e n s i o n s of the ULCC are a p p r o x i m a t e l y 1115 ft in length Cargo t r a n s f e r p u m p s discharge r a t e and p r e s s u r e at the vessel's

overall ( L O A ) , 184 ft in b r e a d t h , and 94.5 ft in depth [3]. The design offioading manifold:

draft is 74 ft. The largest s h u t t l e t a n k e r is a s s u m e d to be a 250 kdwt. Case 1. m a x i m u m rate and h e a t e d cargo (a 120F =

The typical d i m e n s i o n s of the t a n k e r are a p p r o x i m a t e l y 1141 ft in 60 000 bbl h r (a 120 psig

L.O.A., 170 ft in b r e a d t h , and 84 ft in depth. The design draft is 66 Case 2. a v e r a g e r a t e and heated cargo (6 120F =

ft and the light ship draft is a s s u m e d to be 20 ft. 45 000 bbl h r (a 150 psig

Case 3. average rate and u n h e a t e d crude cargo (w80F -

Alongside offioading configuration with 30 000 bbl h r (a 75 psig

midship-to-midship manifolds

Part II. Alongside olttoading configuration

V e r t i c a l d i s t a n c e , a s s u m e b o t h m a n i f o l d s are s a m e h e i g h t f r o m

main decks-- One hose size is a s s u m e d for the whole hose string. P r e s s u r e re-

a. FSO vessel freeboard - 20 ft quired to overcome the elevation difference of crude oil b e t w e e n the

b. s h u t t l e t a n k e r freeborad - 64 ft FSO vessel and s h u t t l e t a n k e r is included. All f o r m u l a s shall be

c. net freeboard difference - 4 4 f t referred to reference [10].

Horizontal distance--

Conditions-- hose size = 0.380 m inside d i a m e t e r for

a. fender size, d i a m e t e r = lOft

16-in. *hose

b. manifold to deck edge = 20 ft for both ships

hose length = 18.3 m from A p p e n d i x 2

c. total distance - 30ft

Straight-line distance- - 53.3 ft C a l c u l a t i o n s for a v e r a g e o f f l o a d i n g r a t e - - C a s e 3:

. O f f l o a d i n g hose l e n g t h - - = 60 ft w i t h two 30-ft hose s t r i n g s Offloading r a t e for u n h e a t e d cargo (a 80F, Q = 30 000 0.15899

= 4769.7 m3/hr

Tandem otttoading configuration with an aft, port Flow velocity in each of 2-hose string: V - 4 (Q/2)/[3600 ~ (h) 2]

manifold to a midship manifold IV16 in. = 4 (4769.7/2)/[3600 ~ I0.380) 2] = 5.84 m/sec

Reynolds n u m b e r , NRe -- D V / v , N R d 6 ,n. = 0.380 5.84/(912

V e r t i c a l d i s t a n c e - - S a m e as i m m e d i a t e l y preceding for alongside 10 6) = 2434

offioading configuration. Friction factor, h - 0.0096 + 5.7 (K/D) 1'2 + 1.7 (1/NRe) ~/2

Horizontal distance-- h~G in. = 0.0096 + 5.7 (0.3 10 ~/0.380W '~ + 1.7 (1/2434) 1/2

a. h a w s e r = 150 ft = 0.049122

b. h a l f of t a n k e r l e n g t h = 570 ft for midship manifold P r e s s u r e loss, A p = ~ L V 2 "y 10 4/(2gD)

c. t a n k e r manifold to deck edge - 15 ft including manifold Adding 10c~ to original hose l e n g t h to account for i r r e g u l a r s of

height elbows, fittings etc.:

d. vessel manifold to s t e r n = 100 ff ~ r aff, p o r t m a n i ~ l d

e. allowances = 60 5PlGi, = 0.049122 20.1 (5.84) 2 929.73 10- 4/

f. total distance -895 (2 9.81 0.380)

= 0.42 kg/cm 2 - 5.97 psi > 4.04 psi

Line distance-- 979 ff including FSO vessel Aph -- 44 ft, elevation difference of manifolds from

freeboard Appendix 2 = 17.73 psi

O f f l o a d i n g hose l e n g t h - - -1000 Total Apl Gi n = APlG in. + APh = 23.70 psi < 75 psig for

u n h e a t e d cargo ffi 80F

Remote-offtake buoy configuration with

Conclusions: Case 1. Cargo oil can be delivered to s h u t t l e

bow-to-midship manifolds

tanker.

Vertical distance, a s s u m e both manifolds the s a m e h e i g h t from Case 2. Cargo oil can be delivered to s h u t t l e

tanker.

m a i n d e c k s - - S a m e as preceding for alongside offloading configura-

tion Case 3. Cargo oil can be delivered to s h u t t l e

Horizontal distance from buoy-- tanker.

a. h a w s e r = 150 ft

Part III. Tandem offioading configurations

b. h a l f of t a n k e r l e n g t h - 570 ft for midship manifold

c. t a n k e r manifold to deck edge = 15 ft including manifold The h e a t loss along hoses is neglected in the study. One hose size

height is a s s u m e d for a whole hose string. P r e s s u r e r e q u i r e d to overcome

d. allowances = 25 ft including vessel bow the elevation difference of crude oil b e t w e e n the FSO vessel and

to SPM s h u t t l e t a n k e r is included. All f o r m u l a s shall be referred to reference

e. total distance - 760 ft [10].

66 JANUARY 1996 MARINE TECHNOLOGY

Conditions-- hose size = 0.486 m inside d i a m e t e r for string. P r e s s u r e r e q u i r e d to overcome the elevation difference of

20 in. *hose crude oil in the FSO vessel and s h u t t l e t a n k e r is included. Two

hose l e n g t h = 305 m from Appendix 2 swivels are a s s u m e d in the configuration. All f o r m u l a s shall be re-

ferred to reference [10].

Calculations for maximum o f ] l o a d i n g r a t e - - C a s e 1:

Offloading r a t e for heated cargo O 120F, Q = 60 000 x 0.15899 Conditions

= 9539.4 mS/hr

Flow velocity in each of 2-hose string: V2o in. = 4 x (9539.4/2)/

[3600 ~ (0.486) 2] Offtake s u b s e a pipe size, l e n g t h = 36 in. a' (0.9144 m inside

= 7.14 m/sec diameter) x 0.625-in.

Reynolds n u m b e r , NR~20,n = 0.486 X 7.14/(191.4 X 10 6) = wall thickness, 1.5 k m

18 130 Offioading hose size, l e n g t h = 0.486 m inside d i a m e t e r for

Friction factor, ~2o m. = 0.0096 + 5.7 x (0.3 x 10 a/0.486) ~/2 + 20 in. hose, 256 m from

1.7 x (1/18 130) 1~2 Appendix 2

= 0.026704

Calculations for maximum r a t e - - C a s e 1:

P r e s s u r e loss

Oittoading rate for h e a t e d cargo @ 120F, Q = 60 000 x 0.15899

Adding 10% to the original hose l e n g t h to account for i r r e g u l a r s

= 9539.4 m3/hr

of elbows, fittings etc.:

Flow velocity V36 = 4 x (9539.4)/[3600 ~ (0.9144) 2]

hp2o in. = 0.026704 335.5 17.14) 2 x 929.73 x 1 0 - 4 / = 4.04 m/sec (13.25 fps) for 36 in. steel

(2 x 9.81 x 0.486) pipeline

= 4.45 kg/cm 2 = 63.33 psi V2o ,n = 4 X (9539.4/2)/[3600 ~r (0.486) 2]

APh = 44 ft, elevation difference of manifolds from -- 7.14 m/sec for each 20 in. hose

Appendix 2 = 17.73 psi

Total 5p2 o i~. = hP2o ,n + h P h = 81.1 psi < 120 psig for heated

cargo (a 120F Reynolds n u m b e r NR~36 ~n = 0.9144 X 4.04/(191.4 X 10 G)

= 19 301 for 36-in. ~ steel pipeline

NRe2O in. = 0.486 X 7.14/(191.4 X 10 ~)

C a l c u l a t i o n s f o r a v e r a g e o f f l o a d i n g r a t e - - C a s e 2: = 18 130 for each 20-in. hose

Otttoading r a t e for h e a t e d cargo (d, 120F, Q = 7154.6 m3/hr

Flow velocity in each of 2-hose string, V2o ,n = 5.36 m/sec

Friction factor

Reynolds n u m b e r , Np~2o ,. = 13 610

)t361n. = 0.0096 + 5.7 x (0.5 x 10 6/0.9144)1:2 + 1.7 x

Friction factor, k2o ,n. = 0.028650

(1/19 301) 1~2

P r e s s u r e loss

= 0.026052 for 36-in. ~ steel s u b s e a pipeline

Adding 10% to the original hose l e n g t h to account for i r r e g u l a r s

k2oin. = 0.0096 + 5.7 x (0.3 x 10 6/0.486) 1/2 + 1.7 x

of elbows, fittings etc.:

(1/18 130) 1/2

= 0.026704 for each 20-in. ~ hose

Ap2o in. : 38.29 psi

Aph = 44 ft, elevation difference of manifolds from

Appendix 2 = 17.73 psi

Total hp2o ,,. = Ap2o j,. + Aph = 56.0 psi < 150 psig for h e a t e d P r e s s u r e loss

cargo @ 120F Adding 10% to the original hose l e n g t h to account for i r r e g u l a r s

of elbows, valves etc:

C a l c u l a t i o n s f o r u n h e a t e d o # l o a d i n g r a t e - - C a s e 3:

Offloading r a t e for u n h e a t e d cargo (co 80F, Q = 4769.7 m3/hr Apae in. = 0.026052 x 1650 x (4.04) 2 x 929.73 x 10-4/(2 x

Flow velocity in each of 2-hose string, Veo i~ = 3.57 m/sec 9.81 0.9144)

Reynolds n u m b e r , NR~2O ~n = 1903 = 3.64 kg/cm 2 = 51.70 psi for 36-in. steel s u b s e a

Friction factor, ~2o in = 0.053048 pipeline

P r e s s u r e loss Ap2o in = 0.026704 X 281.6 X (7.14) 2 X 929.73 X 10 4/(2 X

Adding 10% to the original hose length to account for i r r e g u l a r s 9.81 X 0.486)

of t u r n s , fittings etc: 3.74 kg/cm 2 = 53.15 psi for each 20-in. ~ hose

h p h = 44 ft, elevation difference of manifolds from

Appendix 2 = 17.73 psi

Ap2o m. = 31.45 psi Total Ap = AP36 in. + Apeo in. + Aph + APswivel X 2

Aph = 44 ft, elevation difference of manifolds from Ap- 51.70 + 53.15 + 17.73 + 10 X 2

pendix B = 17.73 psi 142.58 psi > 120 psig for h e a t e d cargo @ 120F

Total Ape om. = Ap2o ,.. + APh = 49.2 psi < 75 psig for u n h e a t e d

cargo @ 80 F

Conclusions: Case 1. Cargo oil can be delivered to s h u t t l e C a l c u l a t i o n s f o r a v e r a g e r a t e - - C a s e 2:

tanker. Oittoading rate for h e a t e d cargo @ 120F, Q = 7154.6 m~/hr

Case 2. Cargo oil can be delivered to s h u t t l e

tanker. Flow velocity V36 in. = 3.03 m/sec for 36-in. ~ steel s u b s e a

Case 3. Cargo oil can be delivered to s h u t t l e pipline

tanker. V2o in. = 5.36 m/sec for each 20-in. hose

Reynolds n u m b e r Nae3~ in. = 14 476 for 36-in. ~ steel s u b s e a

pipeline

NRe2O i n 13 610 for each 20-in. ~ hose

Part IV. Remote-offtake buoy configuration

Friction factor )t3~ in. = 0.027944 for 36-in.steel s u b s e a

pipeline

H e a t losses along the s u b s e a pipline of 2.4 miles long and hoses are k2o in. = 0.028650 for each 20-in. ~ hose

ignored in this study. One hose size is a s s u m e d for the whole hose

JANUARY 1996 MARINE TECHNOLOGY 67

P r e s s u r e loss P r e s s u r e loss

Adding 10% to the original hose l e n g t h to account for i r r e g u l a r s Adding 10% to the original hose length to account for i r r e g u l a r s

of elbows, valves etc: of elbows, valves etc:

AP36 in = 2.19 kg/cm 2 = 31.19 psi for 36-in. ~ steel s u b s e a

pipeline P36m . 1.80 kg/cm 2 = 25.60 psi for 36-in. ~ steel s u b s e a

Ap2o ~. = 2.26 kg/cm 2 = 32.14 psi for each 20-in.* hose pipline

hph = 44 ft, elevation difference of manifolds from AP2o in -

1.86 kg/cm 2 = 26.40 psi for each 20-in. ~' hose

Appendix 2 = 17.73 psi Aph- 44 ft, elevation difference of manifolds from A p p e n d i x

Total Ap = Ap36 i~. + Ap2o m. + hph + Ap . . . . . 1 + 2 2 = 17.73 psi

= 101.07 psi < 150 psig for h e a t e d cargo (a 120F

Calculations for average rate--Case 3: Total Ap - ~P36 in. ~P2o m. + ~Ph -F ~p . . . . . l X 2

Offioading r a t e for u n h e a t e d cargo (~ 80F, Q - 4769.7 m~/hr 89.33 psi > 75 psig for u n h e a t e d cargo (w 80F < 225

psig for hose design

Flow velocity V36 ~. = 2.02 m/sec for 36-in. 'b steel s u b s e a

pipline

Veo m. = 3.57 m/sec for each 20-in. * hose

Reynolds n u m b e r Nrea6 ~. = 2025 for 36-in. 6 steel s u b s e a

pipeline Conclusions: Case 1. Cargo oil cannot be delivered to

NR~2O m. 1902 for each 20-in. '~ hose shuttle tanker.

Case 2. Cargo oil can be delivered to s h u t t l e

Friction factor k3~ in = 0.051593 for 36-in. * steel s u b s e a tanker.

pipeline Case 3. Cargo oil cannot be delivered to

~'20 m. : 0.053059 for each 20-in. '~ hose shuttle tanker.

68 JANUARY 1996 MARINE TECHNOLOGY

You might also like

- Tandem Mooring & OffloadingDocument12 pagesTandem Mooring & OffloadingJim StrakerNo ratings yet

- Commissioning of Offshore InstallationsDocument55 pagesCommissioning of Offshore Installationsrenjithv_488% (8)

- Development and Construction of LPG-FPSODocument6 pagesDevelopment and Construction of LPG-FPSOkanakarao1No ratings yet

- 140 Recommended Guidelines For Offshore Loading Shuttle Tankers PDFDocument69 pages140 Recommended Guidelines For Offshore Loading Shuttle Tankers PDFChowdhury FatemaNo ratings yet

- Offshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsFrom EverandOffshore Mechanics: Structural and Fluid Dynamics for Recent ApplicationsNo ratings yet

- A Comparison Between Conventional Buoy Mooring CBMDocument10 pagesA Comparison Between Conventional Buoy Mooring CBMdaniellaNo ratings yet

- Design of Crude Oil TankerDocument3 pagesDesign of Crude Oil TankerT VigneshwarNo ratings yet

- Brief Instruction of FSRUDocument21 pagesBrief Instruction of FSRUwutigarNo ratings yet

- Document Instruction Offtake OC 039 (MT - Samos-Subs)Document2 pagesDocument Instruction Offtake OC 039 (MT - Samos-Subs)Ihwan AsrulNo ratings yet

- White Paper: Computer Simulation of Buoy Mooring SystemsDocument12 pagesWhite Paper: Computer Simulation of Buoy Mooring Systemssmithwork100% (1)

- DSME VLCC CrosstielessDocument1 pageDSME VLCC Crosstielesssilidiri100% (1)

- Platform Supply Vessel - Analisis de La DemandaDocument9 pagesPlatform Supply Vessel - Analisis de La DemandaSullivan F'gNo ratings yet

- OCIMF PublicationsDocument8 pagesOCIMF PublicationsSahil BiswasNo ratings yet

- Amends To SDs 2011Document214 pagesAmends To SDs 2011duaankushNo ratings yet

- Design Aspects of A DP System For FPSO Applications in The GOMDocument17 pagesDesign Aspects of A DP System For FPSO Applications in The GOMmanz1301100% (6)

- Ocimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014Document2 pagesOcimf 2014年第5版 船靠船作业指南 介绍 20-Tech-feb-2014xingangNo ratings yet

- OTC13999 Development For A Deep Sea FPSO Suitable For The GoMDocument8 pagesOTC13999 Development For A Deep Sea FPSO Suitable For The GoMAnil ChananaNo ratings yet

- Tanker Terminal and Liquid Cargo CourseDocument4 pagesTanker Terminal and Liquid Cargo CourseAnonymous yJ7VjL28iNo ratings yet

- OCIMF High Risk' Observations ListDocument7 pagesOCIMF High Risk' Observations ListFerdinand ArsolonNo ratings yet

- OCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atDocument4 pagesOCIMF Books: Books Can Be Obtained From The Publishers Witherby Seamanship International atRobson PaixãoNo ratings yet

- Ectc Guide e AbsDocument7 pagesEctc Guide e AbsCanumalla RamkumarNo ratings yet

- Mooring Rules Operations SPM BerthsDocument10 pagesMooring Rules Operations SPM BerthsHRC100% (1)

- Project D2 - Bilge, Ballast Systems, Brem PavloDocument7 pagesProject D2 - Bilge, Ballast Systems, Brem PavloПавел БремNo ratings yet

- Methanol Bunkering Barge Supplier Conssolidated Checklist PackDocument20 pagesMethanol Bunkering Barge Supplier Conssolidated Checklist PackMehtab Alam ShaikhNo ratings yet

- 2596.1.03 - OfFSHORE - 02 - Selection of Trading Tankers For FPSO Conversion ProjectsDocument15 pages2596.1.03 - OfFSHORE - 02 - Selection of Trading Tankers For FPSO Conversion Projectsbooraj007100% (1)

- Ship Type and CharacteristicsDocument15 pagesShip Type and Characteristicsmukesh_mlbNo ratings yet

- 337TO 003 World's Largest FLNG PreludeDocument9 pages337TO 003 World's Largest FLNG PreludeRamNo ratings yet

- Marine Engineering System CODAG and SystemDocument9 pagesMarine Engineering System CODAG and SystemIkhwan Azizie100% (2)

- SHIPOWNERS Sampling Procedures For TankersDocument5 pagesSHIPOWNERS Sampling Procedures For TankersErsin SaltNo ratings yet

- Port State Control in The USA ChecklistDocument3 pagesPort State Control in The USA Checklistrabi4457No ratings yet

- Otc 18681Document10 pagesOtc 18681Cadu PradoNo ratings yet

- CB Mooring SystemsDocument5 pagesCB Mooring SystemsCojocaru LaviniaNo ratings yet

- Cargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureDocument8 pagesCargo Tank Inerting Prior To Gassing Up - LPG Tanker ProcedureLukasz ZablockiNo ratings yet

- Tanker LCC Operating ProceduresDocument37 pagesTanker LCC Operating ProceduresCiocio CiohodaruNo ratings yet

- Guidelines For A Structure of An Integrated System of Contingency Planning For Shipboard EmergenciesDocument24 pagesGuidelines For A Structure of An Integrated System of Contingency Planning For Shipboard Emergenciesapi-3719613No ratings yet

- As 2809.5-2001 Road Tank Vehicles For Dangerous Goods Tankers For Bitumen-Based ProductsDocument7 pagesAs 2809.5-2001 Road Tank Vehicles For Dangerous Goods Tankers For Bitumen-Based ProductsSAI Global - APACNo ratings yet

- B - 9.11.7. Bunker ManagementDocument2 pagesB - 9.11.7. Bunker ManagementCesar Augusto Arias CastroNo ratings yet

- Gow Strategy Review March 2011Document15 pagesGow Strategy Review March 2011Shraddha GhagNo ratings yet

- L01 - Introduction To SPS PDFDocument39 pagesL01 - Introduction To SPS PDFariful islamNo ratings yet

- Liquid Chemicals Cargo On Ships - Complete Details Including DiaDocument35 pagesLiquid Chemicals Cargo On Ships - Complete Details Including DiaShoaib100% (1)

- IACS Technical BackgroudDocument552 pagesIACS Technical BackgroudSeong Ju KangNo ratings yet

- UK P I Bunkers and BunkeringDocument48 pagesUK P I Bunkers and BunkeringGeorgios PapakostasNo ratings yet

- Hwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSODocument8 pagesHwang, J.K., Et Al. - 2009 - Detailed Design and Construction of The Hull of An FPSOVeeraiah AnbuNo ratings yet

- UTImeterDocument9 pagesUTImeterWisnu KusumaNo ratings yet

- FPSO TrendsDocument15 pagesFPSO TrendsMarios Dias100% (2)

- Vapour Emission Control System Operation ProcedureDocument2 pagesVapour Emission Control System Operation ProcedureRahulChoudharyNo ratings yet

- Vec ManualDocument171 pagesVec ManualEhsan Abbas niaNo ratings yet

- Rules For The Classification and Construction of Sea-Going Ships, Part V SubdivisionDocument47 pagesRules For The Classification and Construction of Sea-Going Ships, Part V SubdivisionKevin ChanNo ratings yet

- Otc 21292 FPSO Motion CriteriaDocument7 pagesOtc 21292 FPSO Motion CriteriaJean David ChanNo ratings yet

- Safety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsDocument19 pagesSafety of Offshore Topside Processing Facilities: The Era of Fpsos and FlngsFoyez AhmadNo ratings yet

- Shuttle Tankers: Windsor KnutsenDocument2 pagesShuttle Tankers: Windsor KnutsenCarlos HuancaNo ratings yet

- Intecsea Lm-FpsoDocument40 pagesIntecsea Lm-FpsomuhamadsaffuanNo ratings yet

- OC034 Tandem Mooring Operation Sequences.Document11 pagesOC034 Tandem Mooring Operation Sequences.Ihwan AsrulNo ratings yet

- Ships Lay Up and Reactivation Normal Procedures For Ships Lay UpDocument23 pagesShips Lay Up and Reactivation Normal Procedures For Ships Lay UpRiteshNo ratings yet

- Survey Planning Questionnaire For Oil Tanker - CASDocument4 pagesSurvey Planning Questionnaire For Oil Tanker - CASrays100% (1)

- Submitted By-Ajendra Singh Mtech Ist YearDocument23 pagesSubmitted By-Ajendra Singh Mtech Ist YearaksasinghNo ratings yet

- Dynamic positioning The Ultimate Step-By-Step GuideFrom EverandDynamic positioning The Ultimate Step-By-Step GuideRating: 5 out of 5 stars5/5 (1)

- TankOptimization SPE APOGCE2019 09082019Document11 pagesTankOptimization SPE APOGCE2019 09082019Gamang GamingNo ratings yet

- LNG Questions (PHASE-1) INDIADocument21 pagesLNG Questions (PHASE-1) INDIARohit KarwasraNo ratings yet

- How To Batch Convert Your IDWDocument6 pagesHow To Batch Convert Your IDWPierluigiBusettoNo ratings yet

- Selecting A Thermal Fluid Heater Ebook PDFDocument6 pagesSelecting A Thermal Fluid Heater Ebook PDFPierluigiBusettoNo ratings yet

- Optimum Design of Pressure Vessel Subjected To Autofrettage ProcessDocument6 pagesOptimum Design of Pressure Vessel Subjected To Autofrettage ProcessPierluigiBusettoNo ratings yet

- Heat Balance Calculation Sheet - Part ADocument1 pageHeat Balance Calculation Sheet - Part APierluigiBusettoNo ratings yet

- A Complete Design of Ship Propellers Using The New Computer SystemDocument6 pagesA Complete Design of Ship Propellers Using The New Computer SystemPierluigiBusettoNo ratings yet

- Overview Heat Transfer Fluid - Gilles Flamant PDFDocument51 pagesOverview Heat Transfer Fluid - Gilles Flamant PDFPierluigiBusettoNo ratings yet

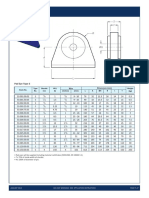

- Pad Eyes PDFDocument1 pagePad Eyes PDFPierluigiBusettoNo ratings yet

- Overview Heat Transfer Fluid - Gilles Flamant PDFDocument51 pagesOverview Heat Transfer Fluid - Gilles Flamant PDFPierluigiBusettoNo ratings yet

- Data Sheet - HFO Heavy Fuel OilDocument9 pagesData Sheet - HFO Heavy Fuel OilPierluigiBusettoNo ratings yet

- Introduction To Polymath For Workshop PDFDocument30 pagesIntroduction To Polymath For Workshop PDFrosendo rojas barraganNo ratings yet

- IBO 2005 Theory Answers - CCLDocument3 pagesIBO 2005 Theory Answers - CCLmartynapetNo ratings yet

- Ge Ifix - Lan Redundancy Ifix 5.8 Sp2Document39 pagesGe Ifix - Lan Redundancy Ifix 5.8 Sp2Omar Alfredo Del Castillo100% (1)

- Manual Videojet PDFDocument356 pagesManual Videojet PDFsicituradastra50% (2)

- Presented By:-: Shivani Chopra Mcom 2 Sem Roll No. 20Document20 pagesPresented By:-: Shivani Chopra Mcom 2 Sem Roll No. 20Yogita BansalNo ratings yet

- Death of Dhirubhai AmbaniDocument10 pagesDeath of Dhirubhai AmbanimnjbashNo ratings yet

- Fire Hydrant SystemDocument12 pagesFire Hydrant Systemabdullah sahib100% (1)

- Philippine Psychometricians Licensure Exam RevieweDocument1 pagePhilippine Psychometricians Licensure Exam RevieweKristelle Mae C. Azucenas0% (1)

- World Bank Procurement Plan-21082015Document7 pagesWorld Bank Procurement Plan-21082015Felisberto Ermindo ManuelNo ratings yet

- BMW ProjectDocument17 pagesBMW ProjectshaimaaelgamalNo ratings yet

- DP XUSB 15025 DriversDocument93 pagesDP XUSB 15025 DriversMohammed Tahver Farooqi QuadriNo ratings yet

- Site Exploration: Vedprakash C. MarlapalleDocument45 pagesSite Exploration: Vedprakash C. Marlapallevedprakash marlapalle100% (1)

- Bunn O Matic Tea Machine Operating ManualDocument79 pagesBunn O Matic Tea Machine Operating ManualwarriorsageNo ratings yet

- Vehicle and Driver Vibration - PPTDocument16 pagesVehicle and Driver Vibration - PPTAnirban MitraNo ratings yet

- Administrative Block For N.I.T. Raipur (New Campus) Towards A Green BuildingDocument28 pagesAdministrative Block For N.I.T. Raipur (New Campus) Towards A Green BuildingPranav Mishra80% (5)

- M4 Spool ReplacementDocument11 pagesM4 Spool ReplacementJeyaseela100% (3)

- Modern Digital Signal Processing - Robert o CristiDocument36 pagesModern Digital Signal Processing - Robert o Cristiaditvas0% (2)

- Radio-Frequency Identification (Rfid) : Internal Test IDocument6 pagesRadio-Frequency Identification (Rfid) : Internal Test IjayanthikrishnanNo ratings yet

- Heat Transfer in Agitated VesselDocument4 pagesHeat Transfer in Agitated Vesselshaz_don100% (2)

- MCQ QuestionsDocument1 pageMCQ Questionsمريم أحمد بهاء الدينNo ratings yet

- British Standard Bs 8110Document10 pagesBritish Standard Bs 8110م.عمرو عبداللهNo ratings yet

- K Single ImpellerDocument12 pagesK Single ImpellerHoằng Phạm ĐứcNo ratings yet

- Digital Thermometer: MKA - Shah PatelDocument2 pagesDigital Thermometer: MKA - Shah Patelshahpatel19No ratings yet

- Tpe Processing GuideDocument12 pagesTpe Processing GuideprashanthNo ratings yet

- 8086 Supports 6 Types of InstructionsDocument49 pages8086 Supports 6 Types of InstructionsAbdel Hamied EbrahemNo ratings yet

- International Certification Application Form: Application Checklist Contact InformationDocument1 pageInternational Certification Application Form: Application Checklist Contact InformationAlmiraNo ratings yet

- "Performance Appraisal System at ITC LTD Haridwar": Project Report ONDocument6 pages"Performance Appraisal System at ITC LTD Haridwar": Project Report ONAnkur UpadhyayNo ratings yet

- MGT619 Final ProjectDocument5 pagesMGT619 Final Projectcs619finalproject.com50% (2)

- Eureka Forbes ProDocument18 pagesEureka Forbes ProRakesh SinghNo ratings yet