Professional Documents

Culture Documents

2.1 General Characteristics of Lead-Acid Batteries

Uploaded by

rezki amaliah0 ratings0% found this document useful (0 votes)

11 views2 pagesOriginal Title

Kholia.docx

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views2 pages2.1 General Characteristics of Lead-Acid Batteries

Uploaded by

rezki amaliahCopyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

2.

1 General Characteristics of Lead-Acid Batteries

The lead-acid battery has been a successful article of commerce for over a

century. Its production and use continue to grow because of new applications for

battery power in energy storage, emergency power, and electric and hybrid

vehicles (including off-road vehicles) and because of the increased number of

vehicles for which it provides the energy for engine starting, vehicle lighting, and

engine ignition (SLI). This battery system is also used extensively in telephone

systems, power tools, communication devices, emergency lighting systems, and as

the power source for mining and material-handling equipment. The wide use of

the lead-acid battery in many designs, sizes, and system voltages is accounted for

by the low price and the ease of man-ufacture on a local geographic basis of this

battery system.

There have been many improvements in lead-acid battery design and

charger system logic to make high-voltage batteries more uniform in performance.

The lead-acid battery has a high electrical turnaround efficiency, 75 to 80%,

which makes the system attractive for electric-vehicle and energy-storage use.

Traditional vertical-plate batteries are capable of energy densities greater than 40

Wh/kg. Modified lead-acid batteries are being investigated for both electric and

hybrid-drive vehicles. The worlds largest energy-storage battery system was

finished in late 1988. This 40 MWh battery, located in Chino, Calif, uses

individual industrial-size lead-acid cells in series and parallel connection to make

a 10-MW system delivering energy into the utility grid at 2000 V and 8000 A for

4 hours. This battery operated for more than a decade as a demonstration project.

At the other extreme, small individual lead-acid cells and batteries are now

available with quick connects for use in small electric appliances and electronics

applications. Many of these newer applications require low-maintenance or

maintenance-free designs. Thin film capacitor-like lead-acid batteries have

become commercially available in the past few years, for consumer and electronic

applications. These are discussed in detail Some larger industrial cells are often

virtually maintenance-free using the oxygen-recombination principle and a

resealable Bunsen vent. An approach to high-energy-density, high-power-density,

high-cycle-life lead-acid battery design is the bipolar design, a design which is

still being pursued. The problems which prevent this design from larger scale

commercial use relate to the availability of a bipolar material which is

electronically conductive, nonporous to ions, low cost, and stable against both

positive and negative active materials. Conductive plastics, which are used in

some battery systems, have not been suc-cessful in lead batteries. Experiments

have been carried out with a bipole made from tin oxide coated glass encapsulated

in a plastic matrix, and with multilayers of different lead alloys to slow the

penetration of the bipole by corrosion.

You might also like

- Strategic Innovaton Simulaton: Back Bay Batery Foreground ReadingDocument7 pagesStrategic Innovaton Simulaton: Back Bay Batery Foreground ReadingShaileshNo ratings yet

- Electric Vehicle BatteryDocument15 pagesElectric Vehicle BatteryTotal Acess100% (1)

- BBBV3 ForegroundReading Auto Warehouse UPS PDFDocument8 pagesBBBV3 ForegroundReading Auto Warehouse UPS PDFlanting wuNo ratings yet

- Liquid Electricity: BY Afsal A S5 Eee Roll No: 4Document12 pagesLiquid Electricity: BY Afsal A S5 Eee Roll No: 4afsalNo ratings yet

- Tendências 1Document6 pagesTendências 1carlosalberto.camargoNo ratings yet

- LFC With Battery Energy Storage SystemDocument9 pagesLFC With Battery Energy Storage SystemzahidNo ratings yet

- BBBV3 ForegroundReading Solar UPS MarineDocument7 pagesBBBV3 ForegroundReading Solar UPS MarineSaibal BhattacharyyaNo ratings yet

- Challenges and Opportunities For Batteries of Electric VehiclesDocument5 pagesChallenges and Opportunities For Batteries of Electric VehiclesjubenrajNo ratings yet

- Battery Energy Storage System-1Document13 pagesBattery Energy Storage System-1Saleha NadeemNo ratings yet

- BatteriesDocument16 pagesBatteriesLina M. Abd ElSalamNo ratings yet

- Electric Vehicle BatteryDocument24 pagesElectric Vehicle BatteryMonica Canaf100% (1)

- Charging and Discharging Control of Li Ion Battery For Electric Vehicle ApplicationsDocument7 pagesCharging and Discharging Control of Li Ion Battery For Electric Vehicle ApplicationsEditor IJTSRDNo ratings yet

- Assignment # 1 (Rizwan Ali)Document4 pagesAssignment # 1 (Rizwan Ali)Rizwan KhanNo ratings yet

- B-Lab: Changing The Game For Lead Acid: Stephen R. Clarke, CEO Applied Intellectual Capital Alameda, CA 94501Document7 pagesB-Lab: Changing The Game For Lead Acid: Stephen R. Clarke, CEO Applied Intellectual Capital Alameda, CA 94501Naresh RaisinghaniNo ratings yet

- Energy 2007 Report ElectricityStorageReportDocument23 pagesEnergy 2007 Report ElectricityStorageReportgubiliNo ratings yet

- Practical Design Considerations of Power Electronics Hybrid and Fuel Cell VehiclesDocument3 pagesPractical Design Considerations of Power Electronics Hybrid and Fuel Cell VehiclesDanah NarsolisNo ratings yet

- Assignment No 3 - RETDocument4 pagesAssignment No 3 - RETMiguel eNo ratings yet

- Doughty 2010 Electrochem. Soc. Interface 19 49Document6 pagesDoughty 2010 Electrochem. Soc. Interface 19 49andrel0No ratings yet

- anode silicon từ nghiên cứu đến các ứng dụng thực tếDocument33 pagesanode silicon từ nghiên cứu đến các ứng dụng thực tếNgoc Han Huynh ThiNo ratings yet

- Assignment 1 - Energy Storage and Conversion - Adhit RoyDocument15 pagesAssignment 1 - Energy Storage and Conversion - Adhit RoysangsangicnuNo ratings yet

- An Analysis of Current Battery Technology and Electric VehiclesDocument6 pagesAn Analysis of Current Battery Technology and Electric VehiclessamNo ratings yet

- Chemistry ReportDocument13 pagesChemistry ReportVarsha PNo ratings yet

- Supercapacitors 130206061102 Phpapp02Document22 pagesSupercapacitors 130206061102 Phpapp02Brrijesh YadavNo ratings yet

- Liquid Electricity: Name: Piyush Dalal Course: Btech (Eee) 7 Sem. ENROLLMENT: 06215004913Document14 pagesLiquid Electricity: Name: Piyush Dalal Course: Btech (Eee) 7 Sem. ENROLLMENT: 06215004913Piyush Dalal84% (19)

- Electrochemical Capacitors Challenges and Opportunities For Real World Applications.Document5 pagesElectrochemical Capacitors Challenges and Opportunities For Real World Applications.khan445585No ratings yet

- 1 s2.0 S0306261913003231 Main PDFDocument9 pages1 s2.0 S0306261913003231 Main PDFAbderrezak BadjiNo ratings yet

- The Impact of Next Generation Storage On The Electric GridDocument28 pagesThe Impact of Next Generation Storage On The Electric GridEnergy Policy Institute at Chicago100% (1)

- Trends in Electric PropulsionDocument3 pagesTrends in Electric PropulsionggpalomiNo ratings yet

- Liquid ElectricityDocument8 pagesLiquid ElectricityParveen Kumar40% (5)

- Chpter 1-6 BaruqqDocument65 pagesChpter 1-6 BaruqqAshraf Alang AhmadNo ratings yet

- Review On Battery Technology and Its ChallengesDocument9 pagesReview On Battery Technology and Its Challengesjoao pedro caleffiNo ratings yet

- Electric Vehicle BatteryDocument30 pagesElectric Vehicle BatteryUpendraJavaNo ratings yet

- Supercapacitors 101: A home Inventors HandbookFrom EverandSupercapacitors 101: A home Inventors HandbookRating: 5 out of 5 stars5/5 (1)

- Rechargeable Lithium Ion Battery StorageDocument43 pagesRechargeable Lithium Ion Battery StoragePRANAV SHARMANo ratings yet

- Storage Battery System For Solar Home Lightings and Mini-Grid System - Purely Off-Grid Installations - Zakir HossainDocument14 pagesStorage Battery System For Solar Home Lightings and Mini-Grid System - Purely Off-Grid Installations - Zakir HossainEnergy for AllNo ratings yet

- Pedl Exp 4Document8 pagesPedl Exp 4Tejas MayekarNo ratings yet

- Advances and Trends of Energy Storage Technology in Microgrid 2013 PDFDocument13 pagesAdvances and Trends of Energy Storage Technology in Microgrid 2013 PDFbdsrlNo ratings yet

- ChaptersDocument17 pagesChaptersJairus OlimaNo ratings yet

- CHAPTER OneDocument3 pagesCHAPTER OneAung MyatNo ratings yet

- Reading Comprehension - 1Document4 pagesReading Comprehension - 1chethanmadival8888No ratings yet

- Telecom - Appnote Fuel CellDocument2 pagesTelecom - Appnote Fuel Cellapolinario mabiniNo ratings yet

- CCC Battery Cost - Element Energy Report - March2012 - Public PDFDocument100 pagesCCC Battery Cost - Element Energy Report - March2012 - Public PDFjuanpazagoNo ratings yet

- Advancement in Energy Storage DevicesDocument9 pagesAdvancement in Energy Storage Devicesash200459No ratings yet

- Energy Recovery Technology - 2011Document5 pagesEnergy Recovery Technology - 2011Saibal RoyNo ratings yet

- Vanadium Redox Battery - Data SheetDocument2 pagesVanadium Redox Battery - Data SheetSanrasniNo ratings yet

- Modern Technology Used in Laptop BatteryDocument6 pagesModern Technology Used in Laptop BatteryThakur ErnNo ratings yet

- Energy Storage Systems For Transportand Grid ApplicationsDocument15 pagesEnergy Storage Systems For Transportand Grid Applicationsmateuszek3tiNo ratings yet

- Ashutosh PaperDocument9 pagesAshutosh PaperDhananjay KumarNo ratings yet

- Seminar Report On Integration of Fuel Cells With Micro Grid: National Institute of Technology, KurukshetraDocument14 pagesSeminar Report On Integration of Fuel Cells With Micro Grid: National Institute of Technology, Kurukshetra4152SANYAM NAHTAEE-B-08No ratings yet

- ESS in EVsDocument6 pagesESS in EVsRoy RoyNo ratings yet

- Berg2015Document8 pagesBerg2015Mohammad Muhtasim Mashfy, 170011054No ratings yet

- Next-Generation Batteries: Problems and Solutions: Sam JaffeDocument4 pagesNext-Generation Batteries: Problems and Solutions: Sam JaffeNIBIN MARTINNo ratings yet

- Solar Power SystemDocument33 pagesSolar Power Systemrksingh00722100% (1)

- Electricvehiclebatteries 150130163418 Conversion Gate02Document20 pagesElectricvehiclebatteries 150130163418 Conversion Gate02AryanNo ratings yet

- Ee8015-Unit-5-Domestic Utilization of Electrical EnergyDocument38 pagesEe8015-Unit-5-Domestic Utilization of Electrical EnergyS Jey RhajenNo ratings yet

- All-Solid-State Lithium-Ion and Lithium Metal Batteries-2018schnellDocument16 pagesAll-Solid-State Lithium-Ion and Lithium Metal Batteries-2018schnellRodrigo VieiraNo ratings yet

- Backward Forward PropogationDocument19 pagesBackward Forward PropogationConrad WaluddeNo ratings yet

- Reading Proficiency Level of Students: Basis For Reading Intervention ProgramDocument13 pagesReading Proficiency Level of Students: Basis For Reading Intervention ProgramSONY JOY QUINTONo ratings yet

- AT ChapIDocument48 pagesAT ChapIvigneshwaranbeNo ratings yet

- Florida Motor Fuel Tax Relief Act of 2022Document9 pagesFlorida Motor Fuel Tax Relief Act of 2022ABC Action NewsNo ratings yet

- Evolution DBQDocument4 pagesEvolution DBQCharles JordanNo ratings yet

- DAB Submersible PumpsDocument24 pagesDAB Submersible PumpsMohamed MamdouhNo ratings yet

- Swanand 2009Document3 pagesSwanand 2009maverick2929No ratings yet

- Quemador BrahmaDocument4 pagesQuemador BrahmaClaudio VerdeNo ratings yet

- SHAW Superdew 3 Specification SheetDocument3 pagesSHAW Superdew 3 Specification SheetGeetha ManoharNo ratings yet

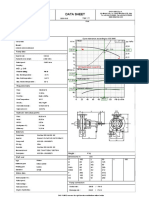

- Data Sheet: Item N°: Curve Tolerance According To ISO 9906Document3 pagesData Sheet: Item N°: Curve Tolerance According To ISO 9906Aan AndianaNo ratings yet

- Assistant Bookkeeper Resume Sample - Best Format - Great Sample ResumeDocument4 pagesAssistant Bookkeeper Resume Sample - Best Format - Great Sample ResumedrustagiNo ratings yet

- 4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsDocument4 pages4.1 Hydrostatic Force On Curved Surfaces - CE 309-CE22S2 - Fluid MechanicsRUSSELNo ratings yet

- Aspen Plus User ModelsDocument339 pagesAspen Plus User Modelskiny81100% (1)

- A Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Document292 pagesA Guide To Sample Size For Animal-Based Studies (VetBooks - Ir)Jonathan MannNo ratings yet

- Num Sheet 1Document1 pageNum Sheet 1Abinash MohantyNo ratings yet

- SL 4001Document2 pagesSL 4001ardiNo ratings yet

- Concrete Lab ManualDocument20 pagesConcrete Lab ManualkelmazodroNo ratings yet

- Feasibility and Optimization of Dissimilar Laser Welding ComponentsDocument366 pagesFeasibility and Optimization of Dissimilar Laser Welding Componentskaliappan45490No ratings yet

- Course Outline Principles of MarketingDocument3 pagesCourse Outline Principles of MarketingKhate Tria De LeonNo ratings yet

- Zilog Z80-SIO Technical Manual TextDocument58 pagesZilog Z80-SIO Technical Manual Textprada.rizzoplcNo ratings yet

- Time Table & Instruction For Candidate - Faculty of Sci & TechDocument3 pagesTime Table & Instruction For Candidate - Faculty of Sci & TechDeepshikha Mehta joshiNo ratings yet

- Jarir IT Flyer Qatar1Document4 pagesJarir IT Flyer Qatar1sebincherianNo ratings yet

- Activity 2Document5 pagesActivity 2DIOSAY, CHELZEYA A.No ratings yet

- DD 3334Document2 pagesDD 3334FAQMD2No ratings yet

- Focal Length of Convex LensDocument5 pagesFocal Length of Convex LensHey AnuragNo ratings yet

- Bohler Dcms T-MCDocument1 pageBohler Dcms T-MCFlaviu-Andrei AstalisNo ratings yet

- Phase DiagramDocument3 pagesPhase DiagramTing TCNo ratings yet

- Classroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsDocument1 pageClassroom Debate Rubric Criteria 5 Points 4 Points 3 Points 2 Points 1 Point Total PointsKael PenalesNo ratings yet

- EVSDocument3 pagesEVSSuyash AgrawalNo ratings yet

- ZH210LC 5BDocument24 pagesZH210LC 5BPHÁT NGUYỄN THẾ0% (1)