0% found this document useful (0 votes)

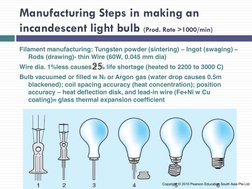

1K views54 pagesGeneral Introduction: Manufacturing Engineering Technology in SI Units, 6 Edition

Chapter 00

Uploaded by

李尚倫Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd

0% found this document useful (0 votes)

1K views54 pagesGeneral Introduction: Manufacturing Engineering Technology in SI Units, 6 Edition

Chapter 00

Uploaded by

李尚倫Copyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as PDF, TXT or read online on Scribd