Professional Documents

Culture Documents

Galvanized Steel Vs Paint PDF

Galvanized Steel Vs Paint PDF

Uploaded by

karanderohan0 ratings0% found this document useful (0 votes)

17 views2 pagesOriginal Title

Galvanized_Steel_vs_Paint.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

17 views2 pagesGalvanized Steel Vs Paint PDF

Galvanized Steel Vs Paint PDF

Uploaded by

karanderohanCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

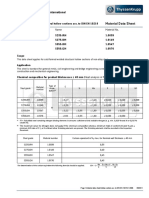

Hot-Dip Galvanized Steel vs.

Paint

Vs. Paint HDG Steel

Special Handling Paper interleve, cloth

No slings, wood separators

No Field Touch-Up Required

Factory Application Field or Factory

No Weather Dependent Yes

-75F to 392F Temperature Range < 200F

Cathodic & Barrier Corrosion Protection Barrier

> 3.9 Mils (1/4 thick steel) Coating Thickness Variable

3600 psi Bond Strength 300-600 psi

Hardness/Abrasion

179 to 250 DPN Resistance

Varies by Type

Service Life -

75 Years Atmospheric 12-15 Years

Metrolina Greenhouses Galvanized in 1971 Painted Parking Garage Stairs after (8 years of service)

Initial and Life-Cycle Cost Analysis1

Coating System Per ft2 Initial Cost Total Per ft2 Life-Cycle Cost2(30 years) Total

Galvanized Steel $1.76 $110,000 $1.76 $110,000

IOZ / HB Epoxy $2.85 $178,375 $6.67 $416,875

Epoxy Zinc/Polyurethane $3.16 $197,750 $7.45 $465,625

IOZ/Epoxy/Polyurethane $4.17 $260,625 $9.56 $597,500

Epoxy/Epoxy $2.61 $163,250 $10.69 $668,125

1

This table represents a practical maintenance cycle of expected service life in an industrial environment. It also represents a 250-ton project of typical size/shape, and a 30-year service life. The paint costs are based on a conventional spray, SP6 surface preparation in eastern U.S. exposure.

Source: NACE Paper C2014-4088 Expected Service Life and Cost Considerations for Maintenance and New Construction Protective Coatings Work (2014)

2

Life-Cycle Cost Based on 4% Interest Rate and 3% Inflation

American Galvanizers Association Phone: 720-554-0900 Fax: 720-554-0909 www.galvanizeit.org aga@galvanizeit.org

Performance Notes

Special Handling Corrosion Protection

The zinc-iron alloy layers of the hot-dip galvanizing (HDG) steel coating are harder than steel Hot-dip galvanizing provides both cathodic and barrier protection to steel, delivering a rust-

and are unaffected by rough handling typical during shipment and erection. Bending of HDG and-maintenance-free system in most environments for 75 years or more.

steel pieces in contact with each other is common and acceptable. Paint is a barrier protector only, and when scratches and cracks occur, corrosion of the

There are significant material and labor costs associated with packaging painted structural steel underlying steel is immediate.

or steel assemblies for shipping, including wood dunnage and soft material (paper, cardboard) Coating Thickness

interleave to prevent contact between individual pieces. The metallurgical reaction between 840F molten zinc and iron in steel ensure a uniform and

guaranteed coating thickness, documented in ASTM specifications

Paint coating thickness on all surfaces is a variable and uniform as the applicator, with

corners and edges highly susceptible to corrosion because of thin films.

Bond Strength

The alloying of zinc and iron in the HDG coating means the zinc and steel metallurgically

become one, yielding a coating bond ten times greater than the strictly mechanical bond of

paint to steel.

Hardness/Abrasion Resistance

With a coating hardness greater than the steel alone, galvanized steel provides a durable,

scratch-resistant coating that maintains the integrity of overall corrosion protection system.

Paints are generally not resistant to scratching, cracking, or impact, resulting in a compromised

coating where corrosion begins and maintenance painting is required.

Time to First Maintenance

Field Touch-Up Hot-Dip Galvanized steel commonly provides maintenance-free corrosion protection for

Rarely needed for HDG steel unless for cosmetic reasons to hide a chain mark or to provide 75 years or more in atmospheric use, especially as our environment and air have become

corrosion protection to a field-modified area. cleaner as a result of regulation.

There is usually a time-consuming inspection and field touch-up necessary to repair damaged Sun, heat, wind and weathering are constants that result in paint typically requiring touch-up and

areas of painted bare steel. replacement in 12-15 years, costing far more than galvanizing over the intended life of the project.

Application

Galvanizing is always factory-controlled, with a precise, scientific methodology that ensures

complete coverage and corrosion protection.

Whether the application of paint is done in the factory or field, the internal tubular sections

and hard-to-reach areas of bare steel remain unprotected; these areas are where corrosion

usually begins.

Weather Dependent

Hot-dip galvanizing can be done 24/7/365, the process is totally independent of weather

conditions.

Painted systems often experience project delays because of unpredictable weather. When

the parameters of safe and quality painting (temperature, humidity, wind) are stretched or

compromised, coating failure is almost assured.

2013 American Galvanizers Association. The material provided herein has been developed to provide accurate and authoritative information about after-fabrication hot-dip galvanized steel. This material provides general information only and is not intended

as a substitute for competent professional examination and verification as to suitability and applicability. The information provided herein is not intended as a representation or warranty on the part of the AGA. Anyone making use of this information assumes

all liability arising from such use.

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5819)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (845)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- MISUMI - Mold Plastic Injection Standard ComponentDocument1 pageMISUMI - Mold Plastic Injection Standard Componentgemilang metalindoNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- MS - 50002 - F (00000002)Document33 pagesMS - 50002 - F (00000002)charssx100% (6)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Table of Bolt-Torque PDFDocument1 pageTable of Bolt-Torque PDFe.vicente.caballero100% (2)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 004-PA-16 Technosheet ICP2 LRDocument2 pages004-PA-16 Technosheet ICP2 LRHossam Mostafa100% (1)

- SCHOTT Solar Saudi-German CSP-WS Riad 20112013Document23 pagesSCHOTT Solar Saudi-German CSP-WS Riad 20112013e.vicente.caballeroNo ratings yet

- A New Method To Evaluate The Sealing RelDocument5 pagesA New Method To Evaluate The Sealing Rele.vicente.caballeroNo ratings yet

- Modeling The Uniformity of Manifold With Various ConfigurationsDocument17 pagesModeling The Uniformity of Manifold With Various Configurationse.vicente.caballeroNo ratings yet

- Sabic Chile Ptfe Hoja TecnicaDocument1 pageSabic Chile Ptfe Hoja Tecnicae.vicente.caballeroNo ratings yet

- Concrete Anchor BoltsDocument5 pagesConcrete Anchor Boltse.vicente.caballeroNo ratings yet

- Submersible Pressure Transmitter MPC Data SheetDocument8 pagesSubmersible Pressure Transmitter MPC Data Sheete.vicente.caballeroNo ratings yet

- Syn ManualDocument119 pagesSyn Manuale.vicente.caballero100% (1)

- Volume (11) Issue (3) 362-382Document21 pagesVolume (11) Issue (3) 362-382e.vicente.caballeroNo ratings yet

- Threaded Boss: Length of Thread Screwed Into FittingDocument1 pageThreaded Boss: Length of Thread Screwed Into Fittinge.vicente.caballeroNo ratings yet

- Preservation Program Works For Outages From One Month To Several YearsDocument4 pagesPreservation Program Works For Outages From One Month To Several Yearse.vicente.caballeroNo ratings yet

- Synchrotact 5100Document40 pagesSynchrotact 5100e.vicente.caballeroNo ratings yet

- Wet Storage Stain On Galvanized SteelDocument5 pagesWet Storage Stain On Galvanized Steele.vicente.caballeroNo ratings yet

- Thesis 1993 D427a PDFDocument149 pagesThesis 1993 D427a PDFe.vicente.caballeroNo ratings yet

- Sicam TM Io Te6420Document4 pagesSicam TM Io Te6420e.vicente.caballeroNo ratings yet

- Clean Oil GuideDocument48 pagesClean Oil GuideDarío CostasNo ratings yet

- Standards Specs and Procedures PDFDocument33 pagesStandards Specs and Procedures PDFe.vicente.caballeroNo ratings yet

- Are View of Cryogenic Treatment On Cutting ToolsDocument20 pagesAre View of Cryogenic Treatment On Cutting ToolsPrashant JondhaleNo ratings yet

- Fastener Torque Table SAE Grade - Engineers Edge PDFDocument1 pageFastener Torque Table SAE Grade - Engineers Edge PDFnate anantathatNo ratings yet

- Iadc Dull Grading: Cutting StructureDocument2 pagesIadc Dull Grading: Cutting StructuredayanaNo ratings yet

- FRPDocument165 pagesFRPAditya VardhanNo ratings yet

- Submerged Arc TechnologyDocument11 pagesSubmerged Arc TechnologymerlonicolaNo ratings yet

- Stainless Steel - Grade 410Document4 pagesStainless Steel - Grade 410Lindsey PatrickNo ratings yet

- Product Specification Ovax 800: General InformationDocument4 pagesProduct Specification Ovax 800: General InformationAntonioNo ratings yet

- ScrubberDocument3 pagesScrubberriz2010No ratings yet

- BCT Wooden PanellingDocument14 pagesBCT Wooden PanellingDevershi BisaniNo ratings yet

- PP 2021Document2 pagesPP 2021GuriNo ratings yet

- Valve Test & Repair Equipment: Catalogue 2018Document68 pagesValve Test & Repair Equipment: Catalogue 2018Kauffman LOKONo ratings yet

- Hollow Section Acc. To 10219Document3 pagesHollow Section Acc. To 10219Abdul HadhiNo ratings yet

- Guidelines For Specification, Welding and Inspection of Stainless Alloy PipingDocument19 pagesGuidelines For Specification, Welding and Inspection of Stainless Alloy Pipingafr5364No ratings yet

- Sikasil PoolDocument4 pagesSikasil PoolRockweed InternationalNo ratings yet

- Manufacturing LectureDocument124 pagesManufacturing Lecturemohtram1037No ratings yet

- L - 9 Ah - SSBLF I (6.5)Document7 pagesL - 9 Ah - SSBLF I (6.5)Arjun SharmaNo ratings yet

- MT Lab Manual (Final) PDFDocument79 pagesMT Lab Manual (Final) PDFDushyanthkumar DasariNo ratings yet

- Introduction To Machine Tool, Machine Tool ClassificationsDocument33 pagesIntroduction To Machine Tool, Machine Tool ClassificationsDeepan Raj100% (1)

- International Coatings System ISO 12944Document7 pagesInternational Coatings System ISO 12944jr_satishNo ratings yet

- WJM Awjm AjmDocument106 pagesWJM Awjm AjmDipen KNo ratings yet

- Jotun Facade 2286, 2287, 2288: Technical Data SheetDocument4 pagesJotun Facade 2286, 2287, 2288: Technical Data SheetWan Mohd ThariqNo ratings yet

- Iso 15607-2003 PDFDocument18 pagesIso 15607-2003 PDFIonut Florica100% (1)

- Chapter - 13 - Chemical - Kinetics (Compatibility Mode) PDFDocument40 pagesChapter - 13 - Chemical - Kinetics (Compatibility Mode) PDFLel Lailiy100% (1)

- Concresive ZR: Single Component Polyurethane Based Zinc Rich Primer For SteelDocument2 pagesConcresive ZR: Single Component Polyurethane Based Zinc Rich Primer For Steelmohamed ayadNo ratings yet

- 6-Aircraft Painting and Finishing - TextDocument3 pages6-Aircraft Painting and Finishing - TextGian DumasNo ratings yet

- EC100 V2.0 ReleasedDocument3 pagesEC100 V2.0 Releasedzoranbt80_324037655No ratings yet

- SK Acrylic EnamelDocument1 pageSK Acrylic EnamelChristinaNo ratings yet