Professional Documents

Culture Documents

CE-MI-TEST Integration 01 - Breakdown Maintenance

CE-MI-TEST Integration 01 - Breakdown Maintenance

Uploaded by

Neeraj GuptaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CE-MI-TEST Integration 01 - Breakdown Maintenance

CE-MI-TEST Integration 01 - Breakdown Maintenance

Uploaded by

Neeraj GuptaCopyright:

Available Formats

Testing Script

UNISUP

Integration 01 - Breakdown Maintenance

370825708.doc 1/9 Last updated: 15/07/2004 04:35:00 PM

Integration 01 - Breakdown Maintenance

1. Contents

1. Contents............................................................................................................................................................... 2

2. Overview............................................................................................................................................................... 3

3. Procedure............................................................................................................................................................. 0

1.1 SAP Object Required..................................................................................................................................... 0

1.2 Preparation of Master Data : Material & Equipment......................................................................................0

1.3 Breakdown Processing.................................................................................................................................. 5

370825708.doc 2/9 Last updated: 15/07/2004 04:35:00 PM

Integration 01 - Breakdown Maintenance

2. Overview

Scenario

o A breakdown occurred in Offshore. A Breakdown Notification and Work Order are issued to cover the

works. Specific spare part is resourced to replace broken Equipment. The broken one then send to

Workshop for repair.

Scope

o This Integration test will scope the following subject of Template V3

o V3PM001 Work Order Approval Process

Approval of Work Order shall be limited to user-id that authorized to release Work

Order in certain amount of Estimated Cost in specific WBS

Estimated cost specified for each cost type (plan cost x ratio plan cost to

estimated cost). Ration of plan cost to estimated cost shall be 0, and defined by

Affiliate for each cost type (labor, material & service)

After release, additional resources can be added in the Work Order as long as

not exceeding estimated cost of each cost type.

o V3PM002 Serialized Materials

For materials like PSV, a serial number shall be assigned for each. Equipment

then specifically created correspondent to this serialized materials.

Serial number shall be assigned before material is receipt into the stock.

Movement of this material will be proceed with respect to its serial number.

o V3PM003 Equipment Movement Process

Follow up actions are added in Notification to facilitate equipment movement

process :

o Standard Exchange

o Dismantle

o Install

When adding and releasing follow up action tasks for Standard Exchange or

Dismantle, separate Notification will be created with reference to initial

Notification.

o V3PM006 Equipment retrieval

When there is only one Equipment installed in the Functional Location, the

equipment will be automatically retrieved in Notification and Work Order

whenever the Functional Location is called as the reference object.

o V3PM029 Cost Object Modification in WO

After Work Order released, modification of WBS is prevented when remaining

WBS in Account Assignment different to WBS in Settlement Rule

o V3PM033 Make Functional Location mandatory in Notification at creation

o V3PM039 Basic WO Dates is mandatory

370825708.doc 3/9 Last updated: 15/07/2004 04:35:00 PM

Testing Script

3. Procedure

1.1 SAP Object Required

Functional Location FL1 o FL : F15/F15A /COF/CHEM /PSV-91-741

o WBS : FRAA5161BK

o Auth Group : 012

o Equipment installed : 10000322

FL2 o Workshop FL : F15/F15A /HSG/WW /MNT-WW

o WBS : FRAA5161BK

o Auth Group : 019

Equipment EQ o Initially installed in FL1

o Link to serialized material : 1100032

Material MM o Material No : 1100032

o Serial Number : 123456789

WBS WBS o Correspond to User Authorization : FRAA5161BK

User-ID US1 o US1 : prima

o WBS : FRAA5161BK

o Max Limit authorized to EUR1 : 100 000 EUR

US2 o US2 : irmansyah

o WBS : FRAA5161BK

o Max Limit authorized to EUR2 : 1 000 EUR

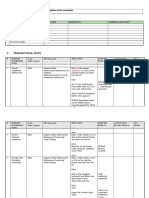

1.2 Preparation of Master Data : Material & Equipment

No. Function T-Code Input Actual Result

Material No : 1100032

1. Change Profile for Serialized Material MM02 Plant : FR20

Serial No. Profile : Y001

2. Create 2 Equipment from Material with Serial IQ01 Material No : 1100032 o Equipment No : 10000322 & 10000323

370825708.doc 4/9 Last updated: 15/07/2004 04:35:00 PM

Integration 01 - Breakdown Maintenance

No. Function T-Code Input Actual Result

Number

Serial No : 123456789 & 987654321

Note: Material has to be serialized before Good o Status : ESTO

Maint Plant : FR20

Receipt to stock

Equipment : 10000322

3. Installed Equipment to Functional Location IE02 o Status : INST

FL : F15/F15A /COF/CHEM /PSV-91-741

1.3 Breakdown Processing

No. Function T-Code Input Expected Result Actual Result

o Notification

created :

FL : F15/F15A /COF/CHEM /PSV-91-741

V3PM006 Equipment is 17001004

1. Create Notification for Breakdown IW24 Priority : Urgent

retrieved from FL o Equipment

Dept Responsible : Maintenance

retrieved :

10000322

o When Equipment

Remove Functional Location from Notification for V3PM033 FL is is exist, FL is

2. IW22

Breakdown mandatory retrieve back on

saving

Order Type : WDF

o WO created :

3. Create Work Order for Breakdown IW22 PM Act Type : BK

7001780

Operation 010, 100 HR, 2 Person

o Plan cost material

4. Resource Material in Work Order IW32 Material : 1100032, 1 PC

is calculated

Est Labor Cost : 1 000 EUR

5. Estimate Work Order Cost IW32 Est Material Cost : 100 EUR

Put WO Status : WREL

6. Release Work Order IW32 V3PM001 o Approval limit was not

Enhancement WO exactly referring to

Approval : user limited to amount in

approve WO according to YIUSERAMOUNT

certain limit value on o No check to ratio plan

certain Cost Object cost est cost

o On error, WBS in Add.

Data is removed

o A blnk error message

370825708.doc 5/9 Last updated: 15/07/2004 04:35:00 PM

Integration 01 - Breakdown Maintenance

No. Function T-Code Input Expected Result Actual Result

often appears

V3PM029 - Cost Object

Modification in WO :

Modify WBS in Settlement Rule for Breakdown system prevents WO prevented to be

7. IW32 WBS change to : FRZA516101

Work Order discrepancy between saved

Settlement Rule &

Account Assign

V3PM029 - Cost Object

Modification in WO :

Modify WBS in Account Assignment for system prevents WO prevented to be

8. IW32 WBS change to : FRZA516101

Breakdown Work Order discrepancy between saved

Settlement Rule &

Account Assign

MM Process related to Serialized

9. Convert Transport Requisition O3O_SC01

Material (Serial No. 987654321)

10. Create Delivery for Material VL10B

11. Create and Confirm Pick List VL06O

12. Create Shipment Process VT01N

13. Assign Container to Loading Area O3O_PACK01

14. Pack Delivery into Container O3O_PACK03

15. Move Container to Shipment O3O_PACK05

16. Print Shipment Documentation O3O_SR14

17. Close Shipment Onshore VT02N

18. Post Good Issue Delivery VL06O

19. Material received in Offshore O3O_SR01

20. Close Shipment Offshore VT02N

V3PM002 - Serialized

21. Create Good Issue with Reference to Work Order MIGO_GI Materials : equipment

status becomes AVLB

o New Notification

Notification : 17001004

V3PM003 - Equipment for Dismantle &

Follow up Actions : EQUIPMVT >

Movement Process : Repair is created :

02 - Dismantle

New Notification is 17001005

22. Dismantle and Repair Equipment IW22 Release Task

created o Equipment

Save > Dismantle to Inactive

Equipment is moved dismantled from

Position F15/F15A /HSG/WW /MNT-

to inactive FL FL1 and installed

WW

in FL2

23. Install new material to replace broken Equipment IW22 Notification : 17001004 V3PM003 - Equipment o Equipment

370825708.doc 6/9 Last updated: 15/07/2004 04:35:00 PM

Integration 01 - Breakdown Maintenance

No. Function T-Code Input Expected Result Actual Result

10000323 installed

Follow up Actions : EQUIPMVT > in FL1

03 - Install Movement Process, new o Status : INST

Release Task Equipment installed in o New Equipment is

Save > Installation of Equipment FL1 not retrieved in

10000323 Notification & Work

Order

o Seems checking to

cost ratio is

working

V3PM001 Enhancement o When add new

WO Approval : system materials item,

24. Put Additional Materials for Breakdown IW32 Material No : 1100032 10 PC prevents for additional plan cost is

cost exceed overall increased. But, it

Estimated Cost will not back to

initial when the

material is

removed.

Profile : 103

25. Entry Time Sheet for Breakdown CAT2 Employee number : 31300375 o Time entered

Work Order : 7001781

Employee number : 31300375

26. Approve Time Sheet for Breakdown CAPP o Time approved

Work Order : 7001781

Employee number : 31300375

27. Transfer Cost for Breakdown CAT9 o Cost transferred

Work Order : 7001781

V3PM039 - Basic WO o Start date must

Dates are mandatory, exist before saving

28. Remove Dates from Work Order for Breakdown IW32 Remove start date or both dates system prevents saving if o End date will be

start date is not specified calculated by the

system

Work Order : 7001780

29. Completion for Breakdown Entry Findings IW42

Entry Findings

Work Order : 7001780

30. Technical Completion for Breakdown IW32 Puts status : WECO

TECO Work Order

31. Create Work Order for Repair IW22 Notification : 17001005 o New Work Order

Order Type : WDF for repair is

370825708.doc 7/9 Last updated: 15/07/2004 04:35:00 PM

Integration 01 - Breakdown Maintenance

No. Function T-Code Input Expected Result Actual Result

PM Act Type : BK

created : 7001781

Operation 010, 10 HR, 2 Person

V3PM001

Enhancement WO

Est Labor : 2 500 EUR

Approval, user limited to o See note in step

32. Release Work Order for Repair IW32 If not ok,

approve WO according to no. 6

change Est Labor to : 1 000 EUR certain limit value on

certain Cost Object

Profile : 103

33. Entry Time Sheet for Repair CAT2 Employee number : 31300375 o Time entered

Work Order : 7001781

Employee number : 31300375

34. Approve Time Sheet for Repair CAPP o Time approved

Work Order : 7001781

Employee number : 31300375

35. Transfer Cost for Repair CAT9 o Cost transferred

Work Order : 7001781

Work Order : 7001781

36. Completion for Repair Entry Findings IW42

Entry Findings

Work Order : 7001781

37. Technical Completion for Repair IW32 Puts status : WECO o Work Order TECO

TECO Work Order

38. Settlement (for all Work Orders) KO88 FI o Work Order CLSD

370825708.doc 8/9 Last updated: 15/07/2004 04:35:00 PM

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5813)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1092)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (844)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (540)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (348)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (822)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- NBME Step 2 Form 3Document45 pagesNBME Step 2 Form 3bostickdrew16100% (1)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- AdmitCard PDFDocument2 pagesAdmitCard PDFSonu Kumar KumarNo ratings yet

- Redacted Patel IndictmentDocument96 pagesRedacted Patel IndictmentDan McDermottNo ratings yet

- Focused MaxA AE VADocument72 pagesFocused MaxA AE VANeeraj GuptaNo ratings yet

- 5 Day-Wise Plan MRP PlanningDocument1 page5 Day-Wise Plan MRP PlanningNeeraj GuptaNo ratings yet

- Physics ProjectDocument16 pagesPhysics ProjectNeeraj GuptaNo ratings yet

- Pre-Test Questions (Advanced SAP PM Training Program)Document4 pagesPre-Test Questions (Advanced SAP PM Training Program)Neeraj GuptaNo ratings yet

- Assessment (IS-Utilities) : Questions: 50 Time Limit: 60 MinsDocument9 pagesAssessment (IS-Utilities) : Questions: 50 Time Limit: 60 MinsNeeraj GuptaNo ratings yet

- 10-Day-Wise Plan ADM940 and ADM950Document4 pages10-Day-Wise Plan ADM940 and ADM950Neeraj GuptaNo ratings yet

- Post-Test Questions (Advanced SAP PM Training Program)Document3 pagesPost-Test Questions (Advanced SAP PM Training Program)Neeraj GuptaNo ratings yet

- 10-Day-Wise Plan ADM940 and ADM950Document6 pages10-Day-Wise Plan ADM940 and ADM950Neeraj GuptaNo ratings yet

- Pre-Test Questions (Advanced SAP PM Training Program)Document3 pagesPre-Test Questions (Advanced SAP PM Training Program)Neeraj GuptaNo ratings yet

- PM-01 05 Maintain Measuring PointsDocument4 pagesPM-01 05 Maintain Measuring PointsNeeraj GuptaNo ratings yet

- Day-Wise Plan (Training Program - SAP ABAP)Document4 pagesDay-Wise Plan (Training Program - SAP ABAP)Neeraj GuptaNo ratings yet

- CE-MI-TEST V3PM012-Change Code of Functional LocationDocument8 pagesCE-MI-TEST V3PM012-Change Code of Functional LocationNeeraj GuptaNo ratings yet

- PM-02 - 05 - Print Maintenance Works OrderDocument1 pagePM-02 - 05 - Print Maintenance Works OrderNeeraj GuptaNo ratings yet

- Day-Wise Plan (Training Program - SAP ABAP)Document4 pagesDay-Wise Plan (Training Program - SAP ABAP)Neeraj GuptaNo ratings yet

- Setup Data Requirements: Test Script Id TS06 PM-01 - 06 - Manage Documentation PR8/020Document3 pagesSetup Data Requirements: Test Script Id TS06 PM-01 - 06 - Manage Documentation PR8/020Neeraj GuptaNo ratings yet

- PM-02 06 Time ConfirmationDocument4 pagesPM-02 06 Time ConfirmationNeeraj GuptaNo ratings yet

- Sams Teach Yourself ABAP00Document2 pagesSams Teach Yourself ABAP00Neeraj GuptaNo ratings yet

- PM-02 - 08 - Technical Completion of The WorkorderDocument2 pagesPM-02 - 08 - Technical Completion of The WorkorderNeeraj GuptaNo ratings yet

- CE-MI-TEST Integration 01 - Breakdown MaintenanceDocument4 pagesCE-MI-TEST Integration 01 - Breakdown MaintenanceNeeraj GuptaNo ratings yet

- Setup Data Requirements: Description Maintplant Abc Indic Main Work CenterDocument4 pagesSetup Data Requirements: Description Maintplant Abc Indic Main Work CenterNeeraj GuptaNo ratings yet

- OpenSAP Iot3 PrototypeChallenge TemplateDocument4 pagesOpenSAP Iot3 PrototypeChallenge TemplateNeeraj GuptaNo ratings yet

- Chapter 9 Gem The Life and Works of RizalDocument8 pagesChapter 9 Gem The Life and Works of Rizalrmm0415No ratings yet

- Lemon TreeDocument2 pagesLemon TreeMarjorie ConradeNo ratings yet

- Child Centred EducationDocument2 pagesChild Centred EducationHarshita VarshneyNo ratings yet

- MSDS Stored Pressure Fire ExtinguishersDocument5 pagesMSDS Stored Pressure Fire ExtinguishersWaquar AhmadNo ratings yet

- Senate Hearing, 108TH Congress - Embryonic Stem Cell Research: Exploring The ControversyDocument87 pagesSenate Hearing, 108TH Congress - Embryonic Stem Cell Research: Exploring The ControversyScribd Government Docs100% (1)

- Teacher Employment Agreement ContractDocument6 pagesTeacher Employment Agreement ContractIndra GajmerNo ratings yet

- Grammar Test 5ºDocument2 pagesGrammar Test 5ºblogteacher20103678100% (1)

- Beneficiary & Emergency FormDocument2 pagesBeneficiary & Emergency FormreyjornNo ratings yet

- Tissue - Class 9Document9 pagesTissue - Class 9Rohit Jain100% (1)

- Students Innovation Festival Space HackathonDocument6 pagesStudents Innovation Festival Space HackathonAsad ShadNo ratings yet

- A Antimicrobial Susceptibility TestingDocument13 pagesA Antimicrobial Susceptibility TestingkurfaNo ratings yet

- MCQ in Engineering EconomicsDocument60 pagesMCQ in Engineering EconomicsFrosch EsquierdoNo ratings yet

- Aqa Bl2hpGCSEQuestionPapers Jan13Document20 pagesAqa Bl2hpGCSEQuestionPapers Jan13Alice LamNo ratings yet

- Tibet: Freedom in Exile: Tashi Delek!Document10 pagesTibet: Freedom in Exile: Tashi Delek!Isaac SamuelNo ratings yet

- Operational/Administrati VE & Financial Analysis: By: Marcelina L. Ramal MAED-EM DiscussantDocument13 pagesOperational/Administrati VE & Financial Analysis: By: Marcelina L. Ramal MAED-EM DiscussantKenneth Delos SantosNo ratings yet

- Gcse River Study CourseworkDocument7 pagesGcse River Study Courseworkf5dpebax100% (2)

- Horizons, Vol. 60, No. 3, Pp. 395-404.: Singh, Poonam, 6585450Document2 pagesHorizons, Vol. 60, No. 3, Pp. 395-404.: Singh, Poonam, 6585450Poonam SinghNo ratings yet

- AJPDocument35 pagesAJPAnonymous g5Xzu4V8No ratings yet

- Karnataka 12th STD Science 2023 24 Batch Samples 2Document24 pagesKarnataka 12th STD Science 2023 24 Batch Samples 2mayanksharma251307No ratings yet

- New Aspect For Organic Farming Practices: Controlled Crop Nutrition and Soilless AgricultureDocument6 pagesNew Aspect For Organic Farming Practices: Controlled Crop Nutrition and Soilless AgricultureIman AzrbjNo ratings yet

- Tech2 Users GuideDocument301 pagesTech2 Users Guideurazapenje100% (3)

- DipIFR TextbookDocument375 pagesDipIFR TextbookEmin SaftarovNo ratings yet

- AD302 - Tightening of BoltsDocument2 pagesAD302 - Tightening of BoltsdenismcnelisNo ratings yet

- Sociolinguistic Survey of Northern Pakistan Volume 4Document194 pagesSociolinguistic Survey of Northern Pakistan Volume 4bashoooo1No ratings yet

- Pre Joining Orientation Questions Set BDocument4 pagesPre Joining Orientation Questions Set BHtet lynnNo ratings yet

- Qulalys Sample ReportDocument6 pagesQulalys Sample Reporteagleboy007No ratings yet

- Nonrenewable Energy ResourcesDocument54 pagesNonrenewable Energy ResourcesEUNAH LimNo ratings yet